Carbonization characteristics of ethylene tar narrow fractions

-

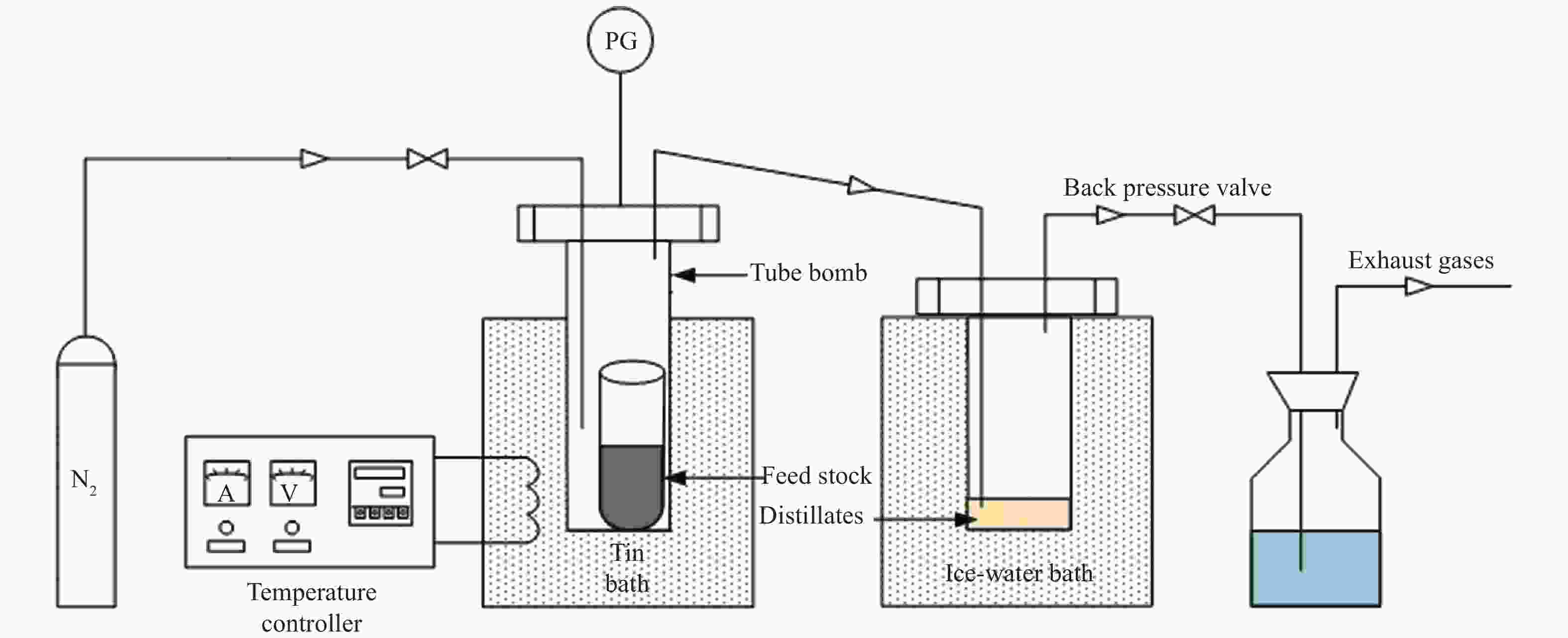

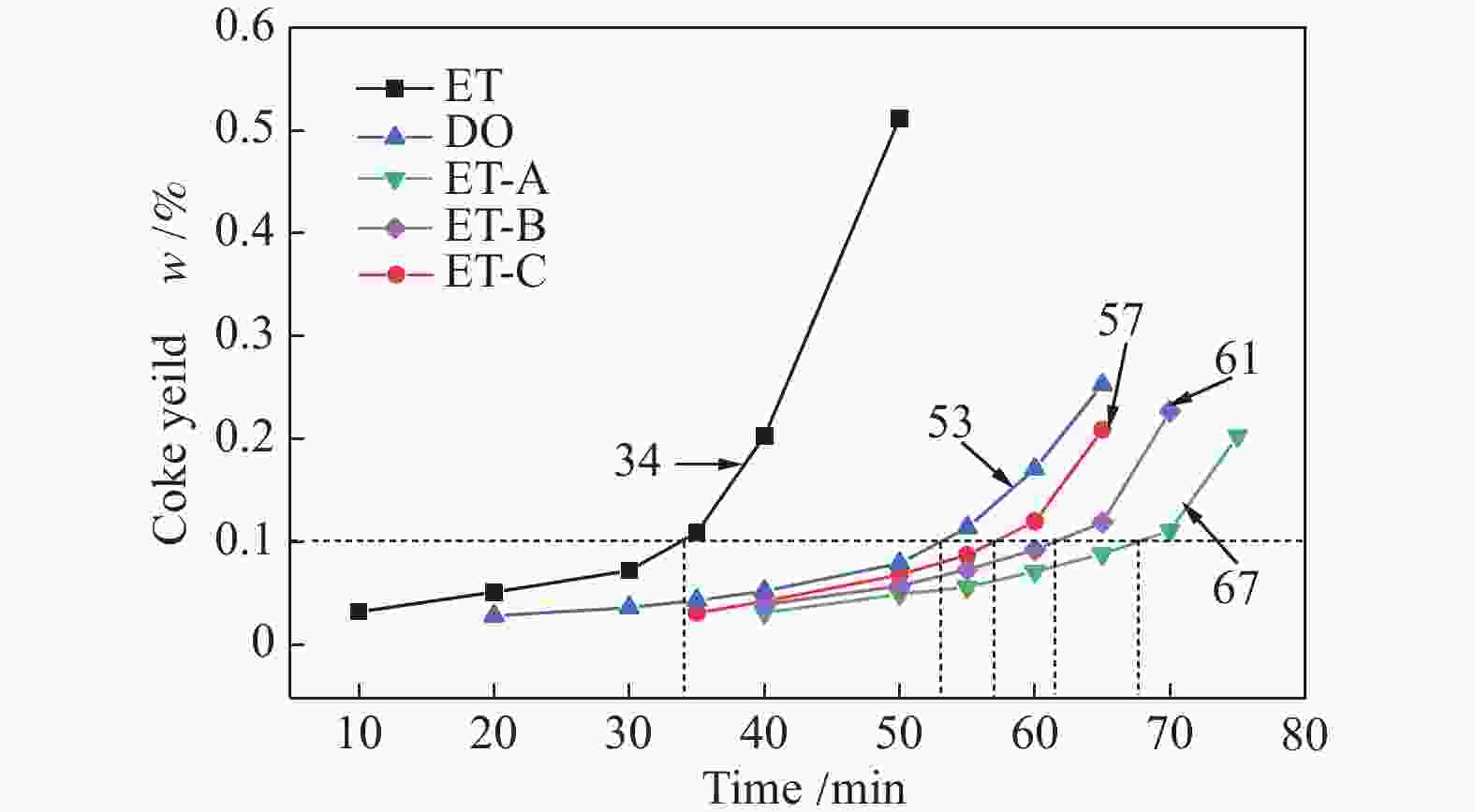

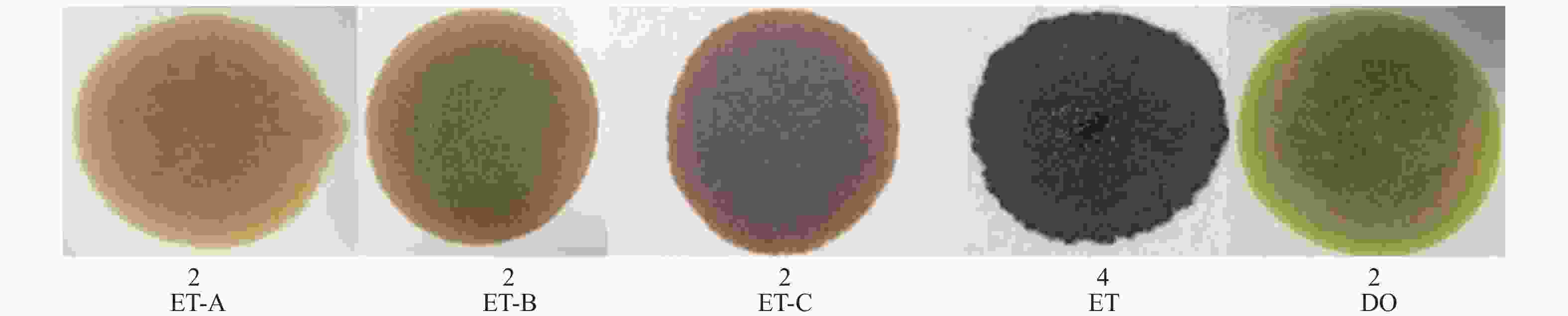

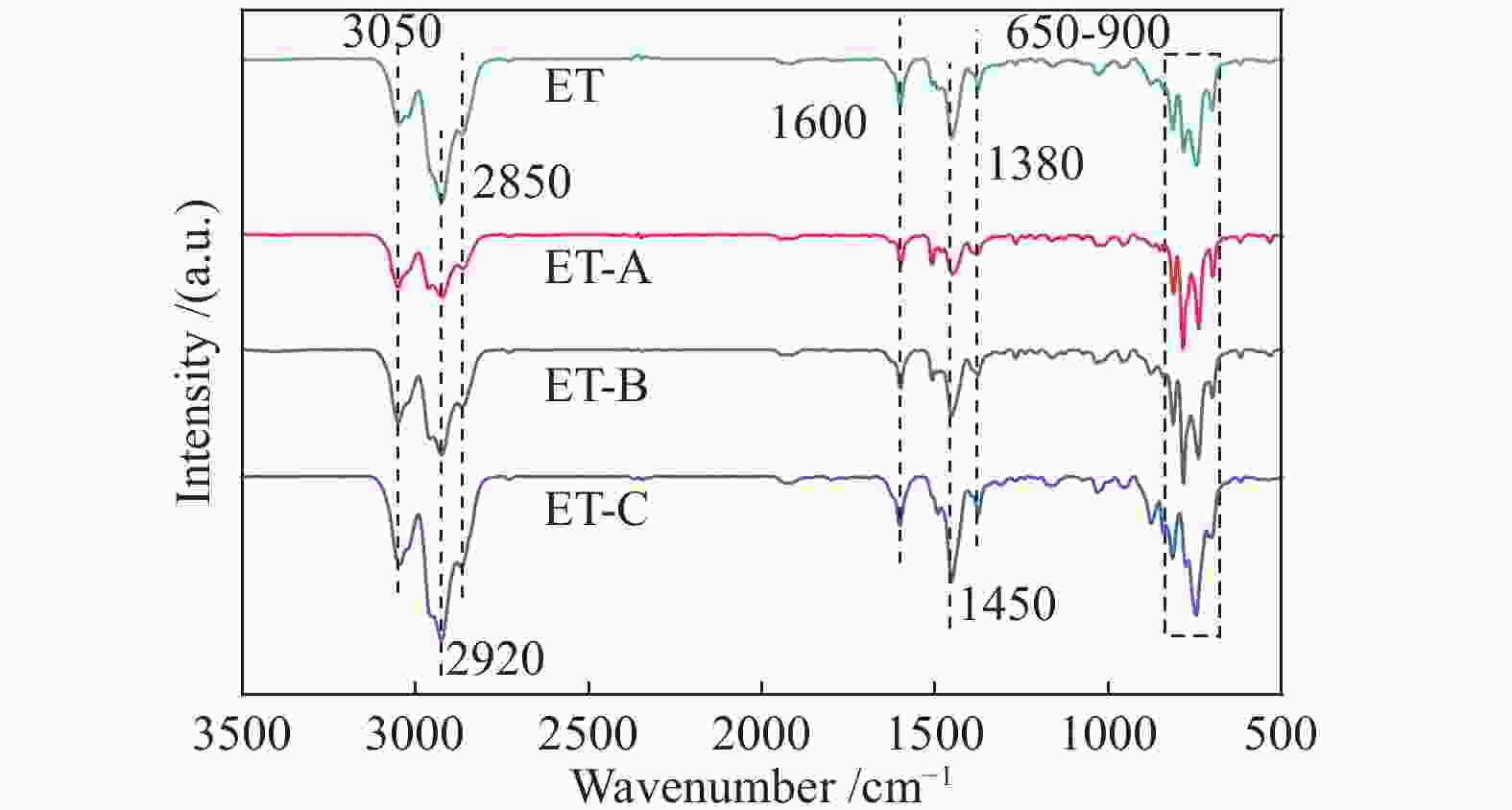

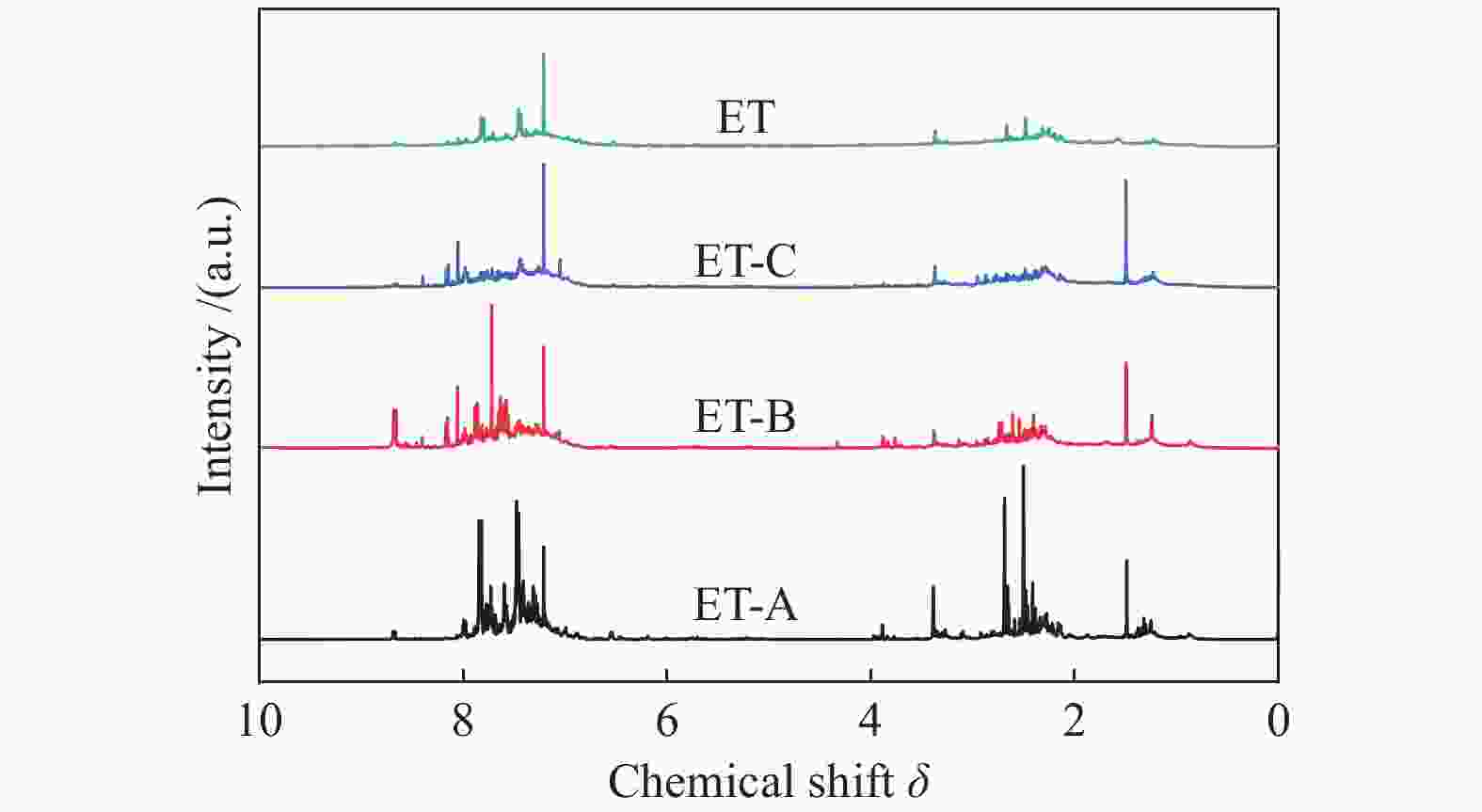

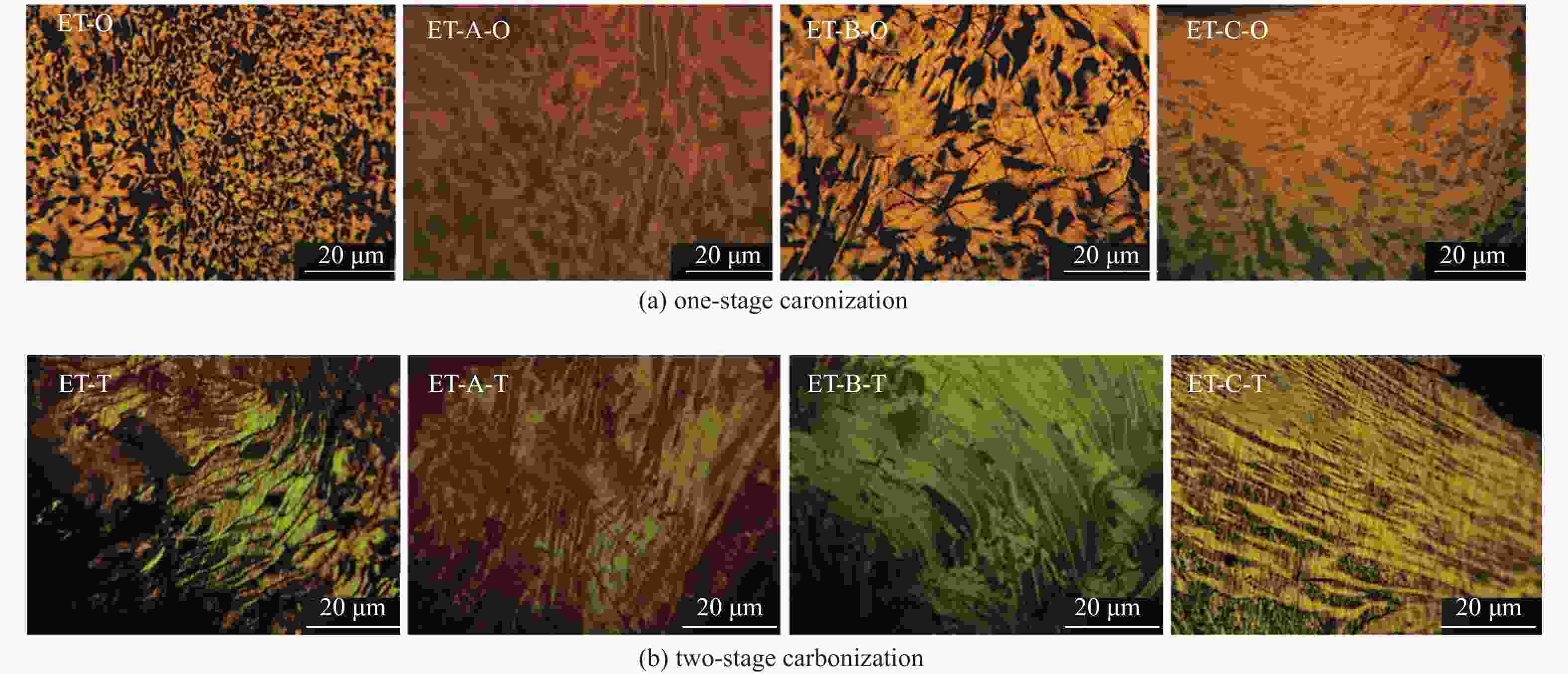

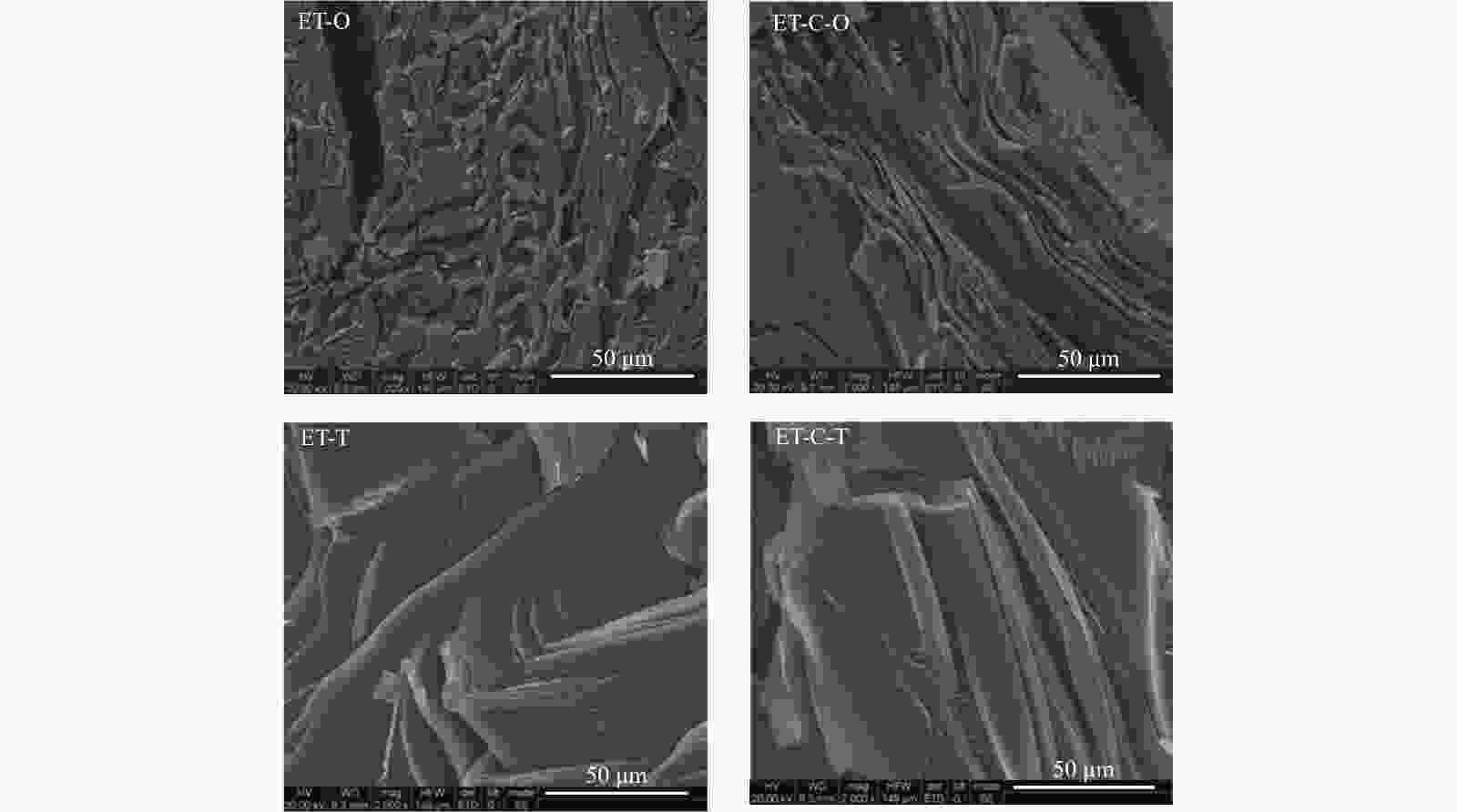

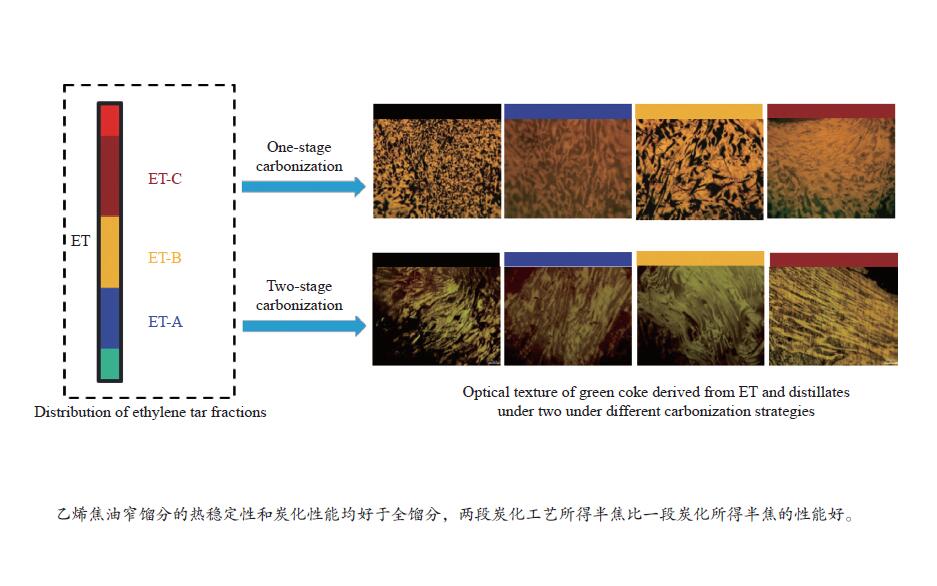

摘要: 为研究乙烯焦油作为生产针状焦原料的可行性,以某炼厂乙烯焦油及对其蒸馏切割所得窄馏分油为研究对象,通过元素分析、红外光谱(FT-IR)、核磁共振氢谱(1H NMR)、生焦诱导期测定及焦化进料热稳定性模拟等方法,对油样的基本性质、结构组成和热稳定性进行研究,并通过偏光显微镜、X射线衍射仪(XRD)、扫描电子显微镜(SEM)等方法对各油样在不同炭化条件下的产物性能进行分析。结果表明,乙烯焦油全馏分沥青质含量高达22.04%,且烯烃等热反应活性组分含量较高,热稳定性较差,生焦诱导期仅为34 min。蒸馏处理所得馏分油不含沥青质,热反应活性组分含量较低,热稳定性变好,生焦诱导期均大于55 min。窄馏分油由于分子分布范围较窄、热反应活性组分含量低,相较于全馏分形成的半焦具有更好的各向异性结构和微晶结构。两段炭化相较于一段炭化更有利于中间相的融并发育及有序排列,形成纤维状的广域流线型结构。两段炭化制得焦炭热膨胀系数(CTE)的值均优于一段炭化,馏分油(ET-C)在两段炭化条件下制得针状焦的CTE值为2.49×10−6 ℃−1,符合针状焦CTE值不大于2.60×10−6 ℃−1的标准。Abstract: In this study, the feasibility of using ethylene tar (ET) as raw material for needle coke production was investigated. The basic properties, structural compositions, and thermal stability of ethylene tar and its narrow fractions were studied by elemental analysis, Fourier transform-infrared spectroscopy (FT-IR), 1H nuclear magnetic resonance (1H NMR), the coke induction period, and simulation of thermal stability of coking feed. The properties of the products were analyzed by a polarized light microscope, X-ray diffraction (XRD), and scanning electron microscopy (SEM). The results showed that the content of asphaltenes was up to 22.04% in ET, and the thermal stability was poor due to the high content of olefin and other thermally sensitive components. Thus, the coke induction period of ET was only 34 min. After distillation, narrow fractions had no asphaltenes and a low quantity of heat-sensitive components, resulting in improved fraction thermal stability with coke induction period of more than 55 min. Due to its narrow molecular distribution and low content of heat-sensitive components of narrow fractions, the semi-cokes formed from narrow fractions possessed better anisotropic and microcrystalline structures than those formed from the ET. Compared with one-stage carbonization, the two-stage carbonization was more conducive to the coalescence, development, and orientation of mesophase, leading to the formation of a fibrous wide-area streamline structure. The needle coke prepared from the fraction of ET-C had a lower thermal expansion coefficient (CTE), as low as 2.49 ×10−6 ℃−1, meeting the CTE requirement of needle coke.

-

Key words:

- ethylene tar /

- thermal stability /

- two-stage carbonization /

- needle coke

-

表 1 ET及窄馏分基本性质

Table 1 Selected properties of ET and its narrow fractions

Item ET ET-A ET-B ET-C H w /% 7.46 7.47 7.37 7.32 C w /% 92.08 92.01 92.29 92.30 S w /% 0.16 0.03 0.04 0.09 N w /% 0.08 0 0 0 C/H (atomic ratio) 1.036 1.034 1.051 1.058 Ash /(μg·g−1) 26 0 0 0 QI w /% 0.06 0 0 0 Carbon residue w /% 15.21 0.82 1.28 1.44 Saturates w /% 9.06 13.9 8.72 4.37 Aromatics w /% 58.67 85.34 88.75 90.87 Resins w /% 10.23 0.76 2.53 6.76 Asphaltenes w /% 22.04 0 0 0 表 2 斑点等级评价标准

Table 2 Evaluation standards of spot number

Spot number Characterizing features 1 the spot is uniform and there is no inner spot 2 there is subtle and indistinct inner spot 3 there is distinct thin inner spot, and is slightly darker than background color 4 there is distinct inner spot, and is darker than background color 5 the inner spot is almost solid state, and is much darker than background color 表 3 ET及窄馏分中类型氢含量及分布

Table 3 Hydrogen distribution of ET and its narrow fractions

Hydrogen type Chemical shift δ[20] Hydrogen content /% ET ET-A ET-B ET-C Har 9.0–6.0 47.72 56.73 52.53 47.06 Ho 6.0–4.5 1.65 1.33 1.31 1.37 Hα 4.0–2.0 36.13 31.13 29.67 33.45 Hn 2.0–1.6 6.22 2.46 4.88 5.55 Hβ 1.6–1.0 7.17 6.72 9.55 10.54 Hγ 1.0–0.5 1.13 1.62 1.96 2.03 Hβ/ Hγ – 6.37 4.14 4.87 5.20 * Har: aromatic hydrogens; Ho: hydrogens in olefin; Hn: naphthenic hydrogen; Hα: aliphatic hydrogens in α-position to the aromatic carbon; Hβ: aliphatic hydrogens in β-position to the aromatic carbon; Hγ: aliphatic hydrogens in γ-position to the aromatic carbon 表 4 各油样在两种炭化条件下产物的微晶结构参数

Table 4 XRD crystal parameters of the green cokes derived from ET and its narrow fractions under two carbonization conditions

Sample 2θ(002)/(°) β002 d002/Å Lc/nm ET-O 25.432 0.0942 3.502 1.4928 ET-A-O 25.457 0.0938 3.499 1.4998 ET-B-O 25.479 0.0931 3.496 1.5109 ET-C-O 25.525 0.0929 3.490 1.5138 ET-T 25.463 0.0937 3.498 1.5007 ET-A-T 25.568 0.0922 3.484 1.5261 ET-B-T 25.635 0.0903 3.475 1.5584 ET-C-T 25.743 0.0885 3.461 1.5903 表 5 各油样在两种炭化条件下所得针状焦的热膨胀系数

Table 5 CTE of the needle cokes derived from ET and its narrow fractions under two carbonization conditions

Sample CTE*/ (1×10−6·℃−1) one-stage carbonization two-stage carbonization ET 3.35 3.08 ET-A 3.17 2.83 ET-B 3.09 2.72 ET-C 2.84 2.49 Commercial needle coke-1 2.47 Commercial needle coke-2 2.39 *Requirement: 2.6×10−6 ℃−1,according to RIPP method[25] -

[1] 刘建锟, 蒋立敬, 杨涛, 方向晨. 乙烯焦油加工利用进展[J]. 化工进展,2012,31(1):402−405.LIU Jian-kun, JIANG Li-jing, YANG Tao, FANG Xiang-chen. Ethylene tar processing and utilization progress[J]. Chem Ind Eng Prog,2012,31(1):402−405. [2] 刘毓敏, 牟永波, 乔海燕, 石薇薇, 曹祖斌. 乙烯焦油综合利用研究进展[J]. 现代化工,2020,40(6):42−46.LIU Yu-min, MOU Yong-bo, QIAO Hai-yan, SHI Wei-wei, CAO Zu-bin. Research progress on comprehensive utilization of ethylene tar[J]. Mod Chem Ind,2020,40(6):42−46. [3] ABRAHAMSON J P, WINCEK R T, ESER S. Scheme for hydrotreatment of fluid catalytic cracking decant oil with reduced hydrogen consumption and high needle coke yield upon carbonization[J]. Energy Fuels,2016,30(10):8150−8155. doi: 10.1021/acs.energyfuels.6b01443 [4] 林雄超, 盛喆, 邵苛苛, 许德平, 王永刚. 煤焦油沥青族组成对针状焦中间相结构的影响[J]. 燃料化学学报,2021,49(2):151−159.LIN Xiong-chao, SHENG Zhe, SHAO Ke-ke, XU De-ping, WANG Yong-gang. Influence of group component distribution of coal tar pitch on mesophase structure development of needle coke[J]. J Fuel Chem Technol,2021,49(2):151−159. [5] JIAO S H, GUO A J, WANG F, YU Y Y, BERNARD W B, LIU H, CHEN K, LIU D, WANG Z X, SUN L Y. Sequential pretreatments of an FCC slurry oil sample for preparation of feedstocks for high-value solid carbon materials[J]. Fuel,2021,285:119169. doi: 10.1016/j.fuel.2020.119169 [6] MOCHIDA I, FEI Y Q, KORAI Y. A study of the carbonization of ethylene tar pitch and needle coke formation[J]. Fuel,1990,69(6):667−671. doi: 10.1016/0016-2361(90)90026-M [7] 杨万强. 掺炼预处理乙烯焦油对延迟焦化装置的影响[J]. 石化技术与应用,2020,38(6):399−402. doi: 10.3969/j.issn.1009-0045.2020.06.010YANG Wan-qiang. Effect of blending pretreatment ethylene tar on delayed coking unit[J]. Petrochem Technol Appl,2020,38(6):399−402. doi: 10.3969/j.issn.1009-0045.2020.06.010 [8] 马文斌. 几种石油系重质原料焦炭化性能的对比分析[J]. 石油炼制与化工,2014,45(9):30−35. doi: 10.3969/j.issn.1005-2399.2014.09.015MA Wen-bin. Comparison of coking properties of heavy petroleum raw materials[J]. Pet Process Petrochem,2014,45(9):30−35. doi: 10.3969/j.issn.1005-2399.2014.09.015 [9] 钱树安, 李春锋, 周国英. 炭化原料的组成结构和中间相组织形态之间的关系[J]. 燃料化学学报,1984,12(4):348−360.QIAN Shu-an, LI Chun-feng, ZHOU Guo-ying. The relationship between the composition and molecular structure of carbonizing feedstocks and mesophase texture formed in pyrolysis[J]. J Fuel Chem Technol,1984,12(4):348−360. [10] 丁宗禹. 扩大针状焦的原料[J]. 石油炼制与化工,1988,19(9):30−35.DING Zong-yu. Extending the feedstock for needle coke production[J]. Pet Process Petrochem,1988,19(9):30−35. [11] YOKONO T, OBARA T, SANADA Y, MARSH H. Carbonization of hydrogenated ethylene tar pitch; study of the pitch molecular compactness factor and coke optical texture[J]. Fuel,1986,65(2):300−301. doi: 10.1016/0016-2361(86)90028-1 [12] 肖志军, 祖德光. 从乙烯焦油生产针状焦的研究[J]. 石油学报(石油加工),1995,11(2):63−71.XIAO Zhi-jun, ZU De-guang. Study on production of needle coke form ethylene tar[J]. Acta Pet Sin (Pet Process Sect),1995,11(2):63−71. [13] 李锐, 丁宗禹, 祖德光. 乙烯装置渣油综合利用技术[J]. 炼油设计,1998,28(4):16−21.LI Rui, DING Zong-yu, ZU De-guang. Comprehensive utilization technology for tar form ethylene unit[J]. Pet Refin Eng,1998,28(4):16−21. [14] ESER S, JENKINS R G, DERBYSHIRE F J, MALLADI M. Carbonization of coker feedstocks and their fractions[J]. Carbon,1986,24(1):77−82. doi: 10.1016/0008-6223(86)90213-7 [15] ESER S, DERBYSHIRE F J, KARSNER G G. Development of coke texture by thermal pretreatment of petroleum residua[J]. Fuel,1989,68(9):1146−1151. doi: 10.1016/0016-2361(89)90186-5 [16] MOCHIDA I, OYAMA T, KORAI Y. Formation scheme of needle coke from FCC decant oil[J]. Carbon,1988,26(1):49−55. doi: 10.1016/0008-6223(88)90008-5 [17] JIAO S H, GUO A J, WANG F, CHEN K, LIU H, UMMUL-KHAIRI I, WANG Z X, SUN L Y. Effects of olefins on mesophase pitch prepared from fluidized catalytic cracking decant oil[J]. Fuel,2020,262:116671. doi: 10.1016/j.fuel.2019.116671 [18] 焦守辉, 林祥钦, 郭爱军, 陈坤, 王宗贤, 佟佳俊, 耿羽轩, 李若萌, 刘晴昊. 劣质渣油性质对受热生焦趋势影响的研究[J]. 燃料化学学报,2017,45(2):165−171. doi: 10.3969/j.issn.0253-2409.2017.02.005JIAO Shou-hui, LIN Xiang-qin, GUO Ai-jun, CHEN Kun, WANG Zong-xian, TONG Jia-jun, GENG Yu-xuan, LI Ruo-meng, LIU Qing-hao. Effect of characteristics of inferior residues on thermal coke induction periods[J]. J Fuel Chem Technol,2017,45(2):165−171. doi: 10.3969/j.issn.0253-2409.2017.02.005 [19] 梁文杰, 阙国和, 刘晨光. 石油化学[M]. 第2版. 东营: 中国石油大学出版社, 2008: 172.LIANG Wen-jie, QUE Guo-he, LIU Chen-guang. Petroleum Chemistry[M]. 2nd ed. Dongying: China University of Petroleum Press, 2008: 172. [20] GUO A J, WANG F, JIAO S H, IBRAHIM U, LIU H, CHEN K, WANGZ X. Mesophase pitch production from FCC slurry oil: Optimizing compositions and properties of the carbonization feedstock by slurry-bed hydrotreating coupled with distillation[J]. Fuel,2020,262:116639. doi: 10.1016/j.fuel.2019.116639 [21] LI M, LIU D, LOU B, HOU X, CHEN P. Relationship between structural modification of aromatic-rich fraction from heavy oil and the development of mesophase microstructure in thermal polymerization process[J]. Energy Fuels,2016,30(10):8177−8184. doi: 10.1021/acs.energyfuels.6b01496 [22] 程相林, 查庆芳, 钟景涛, 侯宝花, 郭燕生. 烷基在针状焦形成中的作用[J]. 燃料化学学报,2009,37(2):166−169. doi: 10.3969/j.issn.0253-2409.2009.02.008CHENG Xiang-lin, ZHA Qing-fang, ZHONG Jing-tao, HOU Bao-hua, GUO Yan-sheng. Influence of alkyl group on the formation of needle coke[J]. J Fuel Chem Technol,2009,37(2):166−169. doi: 10.3969/j.issn.0253-2409.2009.02.008 [23] 程俊霞, 朱亚明, 高丽娟, 赵雪飞. 煤系针状焦煅烧过程中焦炭微晶结构的演变规律[J]. 燃料化学学报,2020,48(9):1071−1078. doi: 10.3969/j.issn.0253-2409.2020.09.006CHENG Jun-xia, ZHU Ya-ming, GAO Li-juan, ZHAO Xue-fei. Evolution of coke microcrystalline structure during calcination process of coal-based needle coke[J]. J Fuel Chem Technol,2020,48(9):1071−1078. doi: 10.3969/j.issn.0253-2409.2020.09.006 [24] 刘杰, 史雪梅, 崔楼伟, 范晓勇, 施俊合, 徐贤, 田佳勇, 田育成, 郑金欣, 李冬. 原料组成对针状焦结构的影响[J]. 燃料化学学报,2021,49(4):546−553. doi: 10.1016/S1872-5813(21)60026-9LIU Jie, SHI Xue-mei, CUI Lou-wei, FAN Xiao-yong, SHI Jun-he, XU Xian, TIAN Jia-yong, TIAN Yu-cheng, ZHENG Jin-xin, LI Dong. Study on the influence of raw material composition on the structure of needle coke[J]. J Fuel Chem Technol,2021,49(4):546−553. doi: 10.1016/S1872-5813(21)60026-9 [25] 杨翠定. 石油化工分析方法: RIPP试验方法[M]. 北京: 科学出版社, 1990: 63.YANG Cui-ding. Analysis Methods for Petrochemical Industry: RIPP Test Methods[M]. Beijing: Science Press, 2009: 63. -

下载:

下载: