Migration characteristics of heavy metals during co-combustion of dehydrated sludge with straw

-

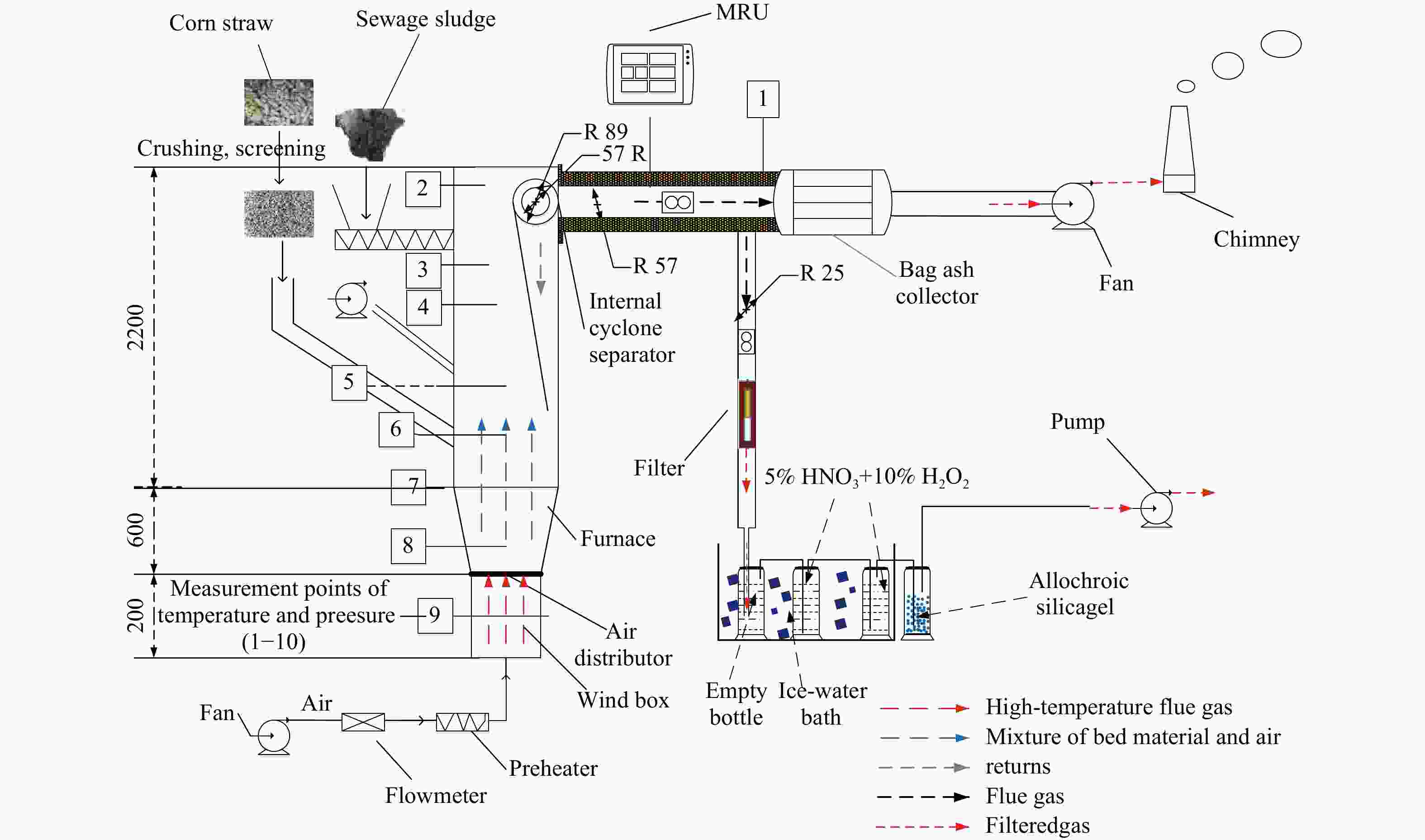

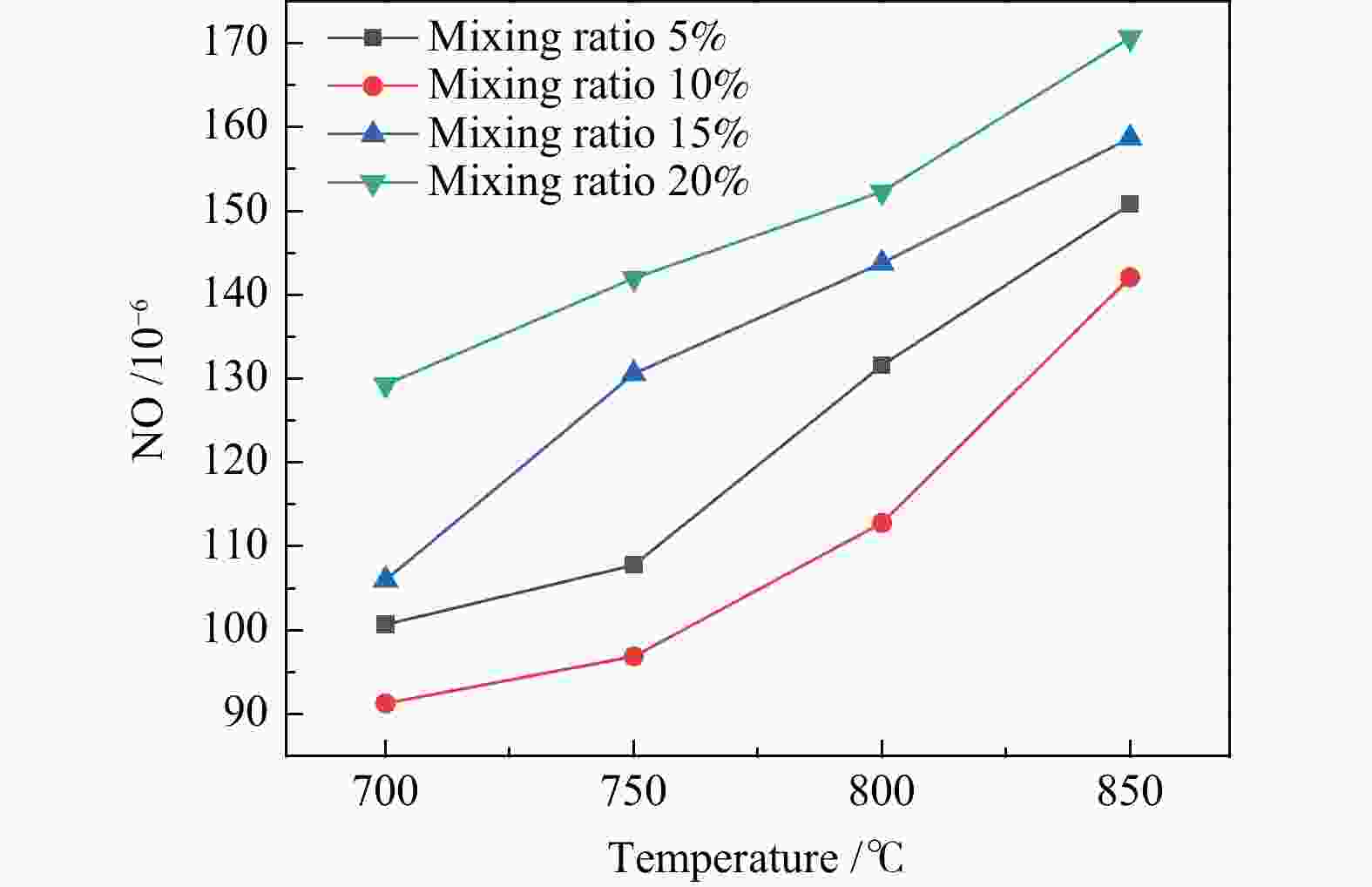

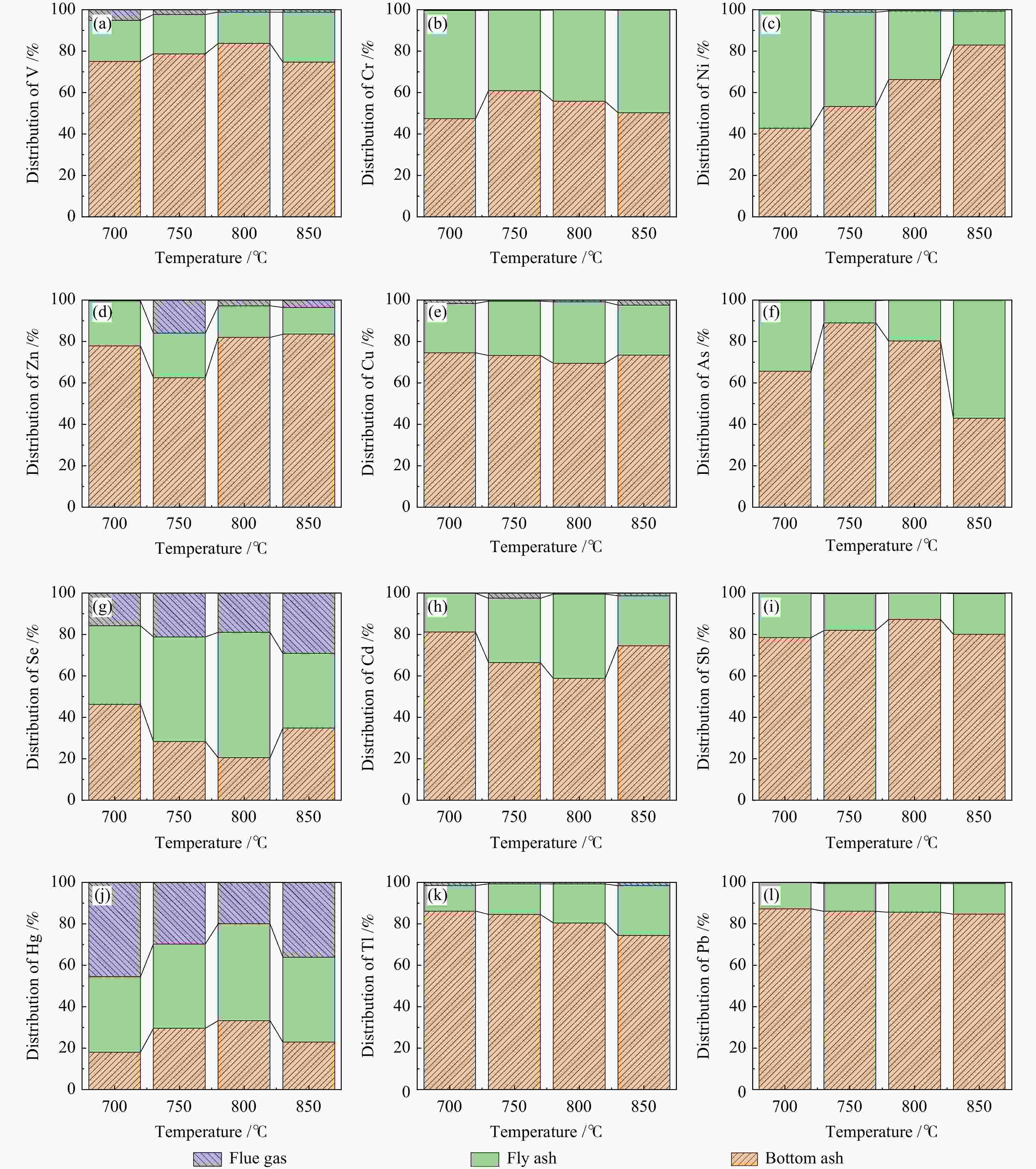

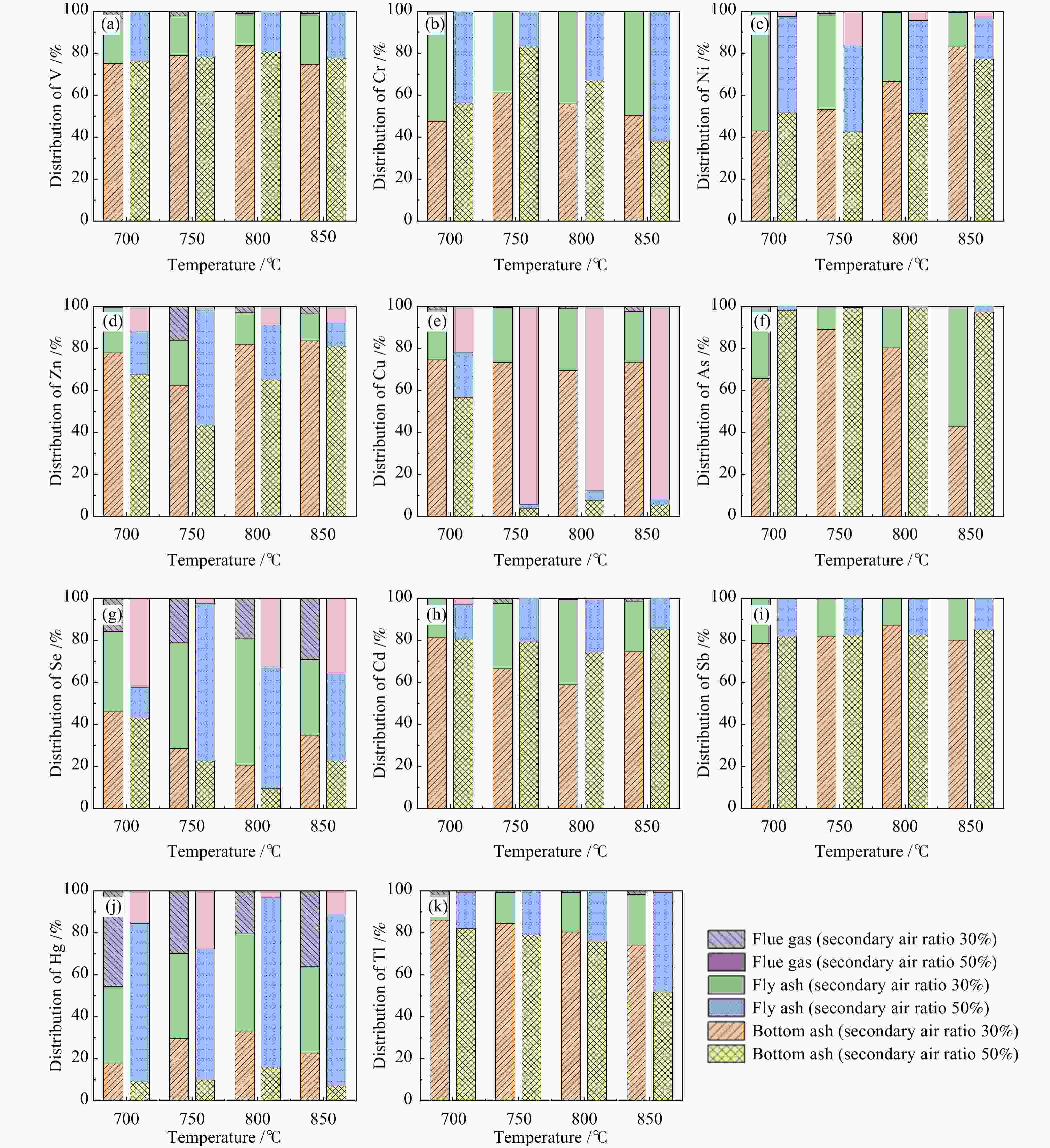

摘要: 在一台实验室规模的内循环流化床中,研究了700−850 ℃下脱水污泥与玉米秸秆的掺烧反应。目的是研究不同温度、污泥掺混比、二次风比率对掺烧后NO排放以及各种重金属在底灰、飞灰、烟气中迁移规律。结果表明,在实验工况下,随着温度升高,NO排放上升,底灰中V、Cr、As、Sb、Hg含量先增大后减小,Zn、Cu、Se、Cd与之相反,且大部分重金属的转折点在800 ℃;随着污泥掺混比的增加,NO排放先减少后增加,底灰中Cu、Hg、Tl含量均先增加后减小,Cr与之相反,且转折点均在污泥掺混比为10%时;随着二次风比率的增加,NO排放降低,底灰中重金属Zn、Cu、Se、Hg含量减少,As、Cd与之相反。Abstract: Sludge incineration technology has significant advantages such as capacity reduction and energy utilization, but it will cause heavy metal pollution. Therefore, the co-combustion of dewatered sludge with corn straw at 700−850 ℃ was studied in a laboratory scale internal circulating fluidized bed. The effects of different temperature, sludge mixing ratio and secondary air ratio on the NO emission and the migration of different heavy metals in bottom ash, fly ash and flue gas after co-combustion were examined. The results show that under the experimental conditions, with the increase in temperature, the NO emission concentration increases, and the concentrations of V, Cr, As, Sb and Hg first increase and then decrease in the bottom ash, while the concentrations of Zn, Cu, Se and Cd vary to the contrary. The turning point of most heavy metals concentration is at 800 ℃. However, with the increase in the sludge mixing ratio, the NO emission concentration first decreases and then increases, and the Cu, Hg and Tl concentrations all increase first and then decrease in the bottom ash, while the Cr concentration change is the opposite, with turning points all at the sludge mixing ratio of 10%. Also, with the increase in the secondary air ratio, the NO emission concentration decreases, and the Zn, Cu, Se and Hg concentrations in bottom ash decrease, on the contrary, the As and Cd concentrations increase.

-

Key words:

- fuel /

- pollution /

- fluidized bed /

- co-combustion /

- heavy metal

-

表 1 样品的元素分析和工业分析

Table 1 Proximate and ultimate analyses of samples

Sample Ultimate analysis wad/% Proximate analysis wad/% C H ${\rm{O} }^*$ N S M V A FC Sewage sludge 18.03 2.85 13.81 2.07 0.60 3.84 32.66 58.80 4.70 Corn straw 48.73 6.65 33.20 0.92 0.28 4.81 76.56 5.41 13.22 *: by difference 表 2 原料的重金属及Cl含量分析

Table 2 Concentration of heavy metals and Cl in raw materials(mg·kg−1)

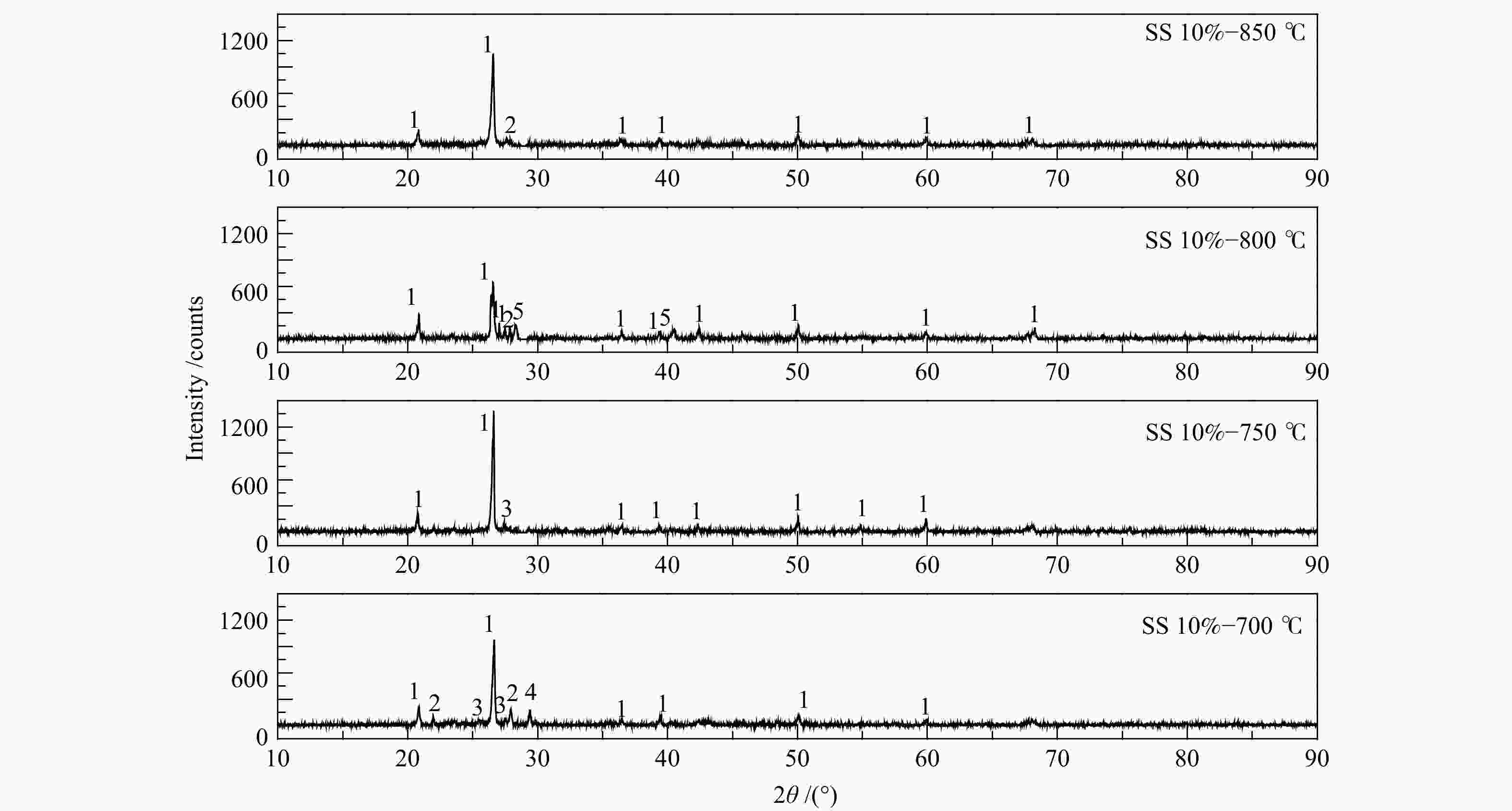

Sample As Cr Hg Ni Cu Zn Sb Pb Cl Sewage sludge 44.60 227.87 35.24 52.21 104.83 1158.88 3.74 41.72 411 Corn straw 221.86 6.36 0.07 3.63 6.14 314.01 1.53 5.75 1520 表 3 10%污泥掺混比在不同温度下掺烧后飞灰中主要物质含量

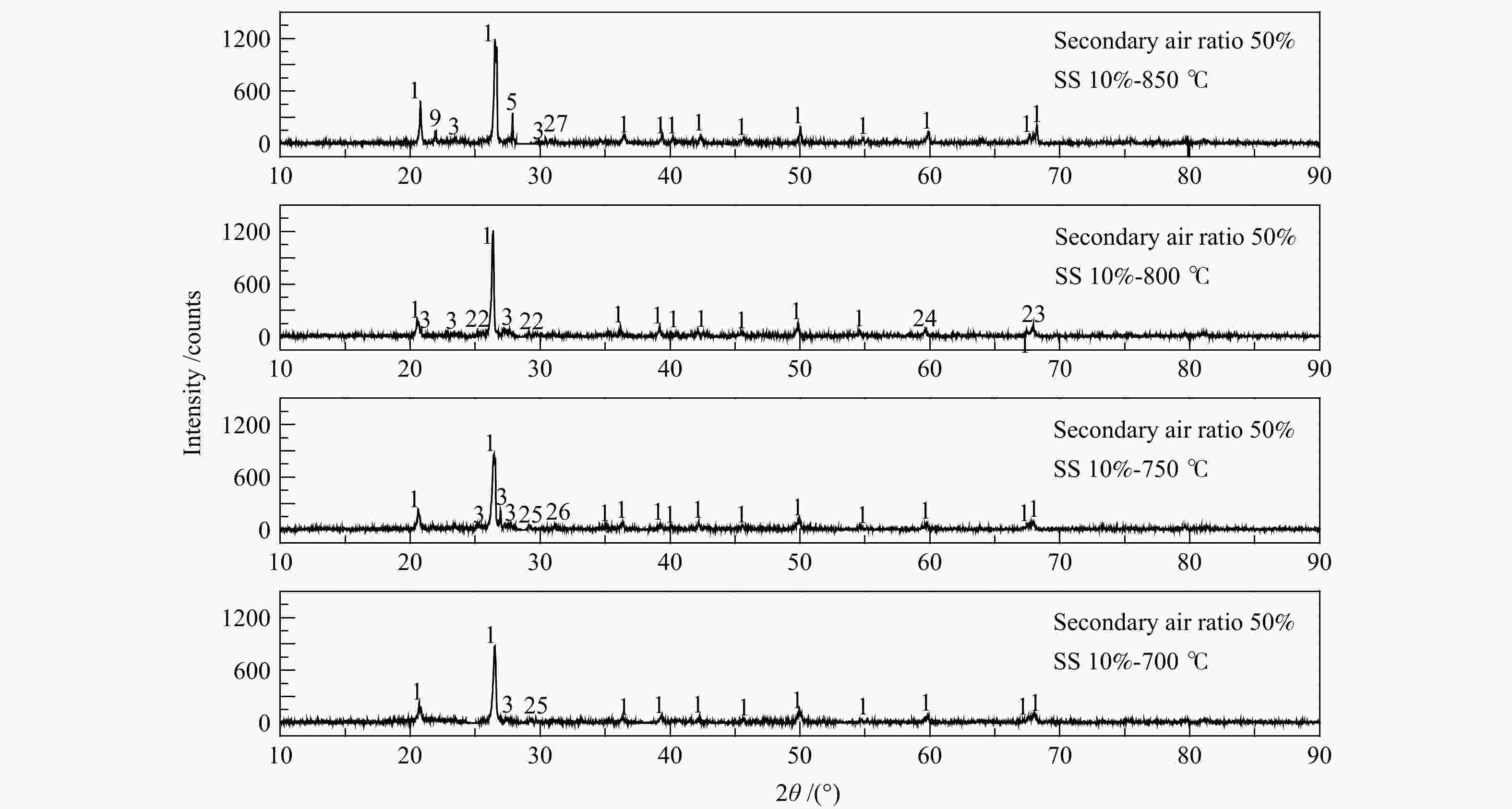

Table 3 Concentration of main substances in fly ash at different temperatures with a 10% sludge mixing ratio

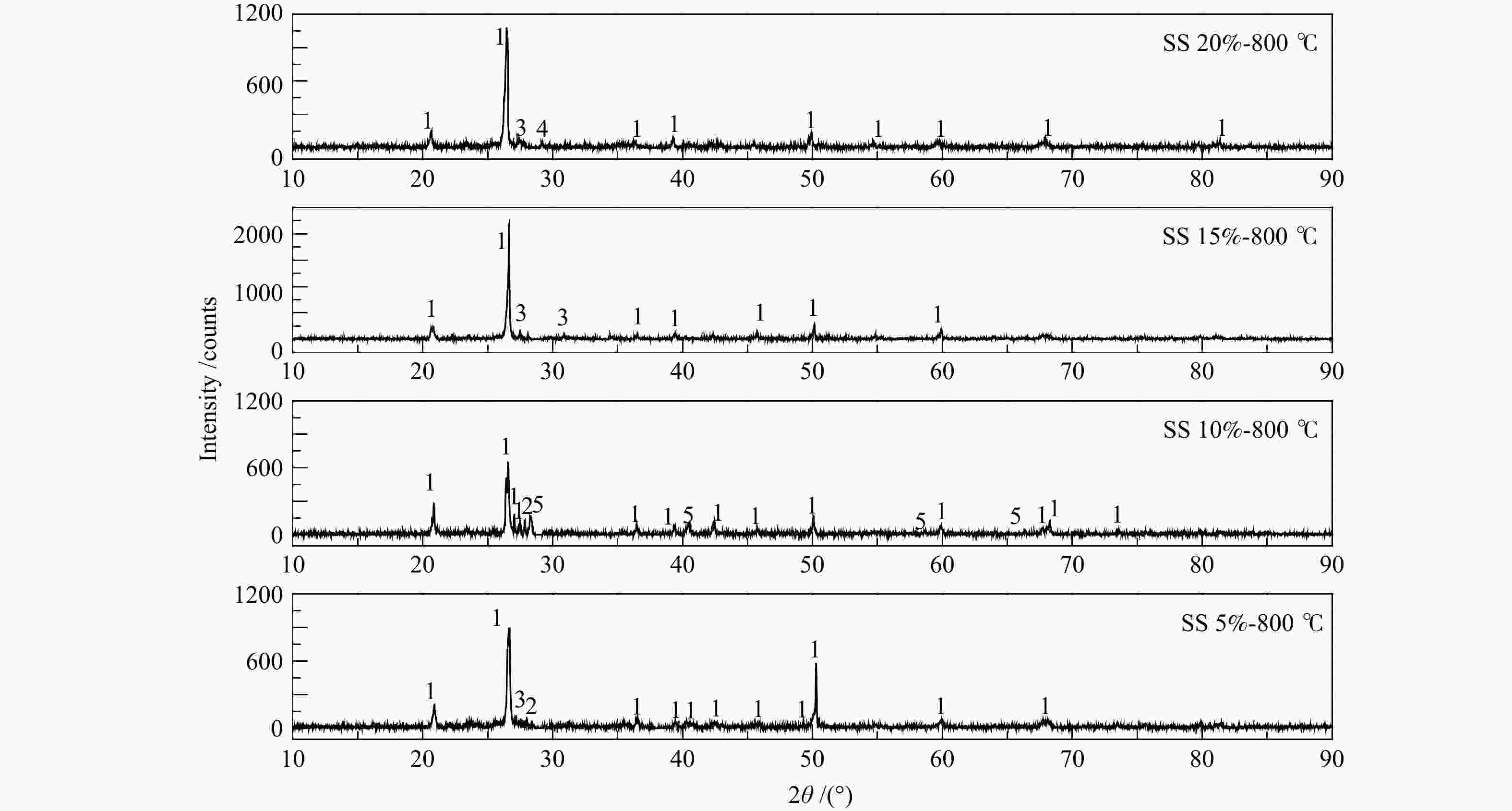

t/℃ w/% SiO2 Na(AlSi3O8) KAlSi3O8 CuFeS2 KCl 700 39.7 52.5 5.5 2.2 − 750 41.3 − 58.7 − − 800 94.4 5.4 − − 0.2 850 24.0 76.0 − − − 表 4 800 ℃时不同污泥掺混比下掺烧飞灰中主要物质浓度

Table 4 Main substances concentration in fly ash with different sludge mixing ratios at 800 ℃

Concentration w/% SiO2 Na(AlSi3O8) KAlSi3O8 CaCl2 KCl Mixing ratio 5% 16.6 68.4 15.0 − − Mixing ratio 10% 94.4 5.4 − − 0.2 Mixing ratio 15% 60.2 − 39.8 − − Mixing ratio 20% 23.2 − 76.5 0.3 − 表 5 不同二次风比率下掺烧飞灰中主要物质浓度

Table 5 Concentration of main substances in fly ash with different secondary air ratios

t/℃ w/% SiO2 Na(AlSi3O8) KAlSi3O8 Ca(Al2Si2O8) Al2O3 K2FeO4 FeSO3 CaCl2 HCl(l) 700 37 − 57.6 − − − − − 5.4 750 41.2 − 6.8 − − − − 52 − 800 64.1 − 18.9 − 1.5 13.4 2.1 − − 850 1.6 91.7 − 6.7 − − − − − -

[1] 曹美英, 潘红霞. 浅析城市污水处理现状及提升改进措施[J]. 智能建筑与工程机械,2019,1(7):99−101.CAO Mei-ying, PAN Hong-xia. Analysis of the status quo of urban sewage treatment and improvement measures[J]. Intell Build Constr Mach,2019,1(7):99−101. [2] 赵玉晨, 王磊. 2020中国环境科学学会科学技术年会论文集(第二卷)[C]. 南京: 中国环境科学学会, 2020. 5.ZHAO Yu-chen, WANG Lei. Chinese Society For Environmental Sciences. 2020 Proceedings of Science and Technology Annual Meeting of Chinese Society for Environmental Sciences (Vol. 2)[C]. Nanjin: Chinese Soc For Environ Sci, 2020. 5. [3] 郭家磊, 肖一帆, 李小燕, 王杰. 污水处理固体废弃物污泥的处置方法研究[J]. 再生资源与循环经济,2021,14(2):39−40. doi: 10.3969/j.issn.1674-0912.2021.02.015GUO Jia-lei, XIAO Yi-fan, LI Xiao-yan, WANG Jie. Study on disposal method of solid waste sludge in sewage treatment[J]. Recyclable Resour Circular Eco,2021,14(2):39−40. doi: 10.3969/j.issn.1674-0912.2021.02.015 [4] WANG Y G, LIU Y, YANG W J, ZHAO Q X, DAI Y J. Evaluation of combustion properties and pollutant emission characteristics of blends of sewage sludge and biomass[J]. Sci Total Environ,2020,720:137−365. [5] 朱栋, 徐颖. 国内外城市污泥处理处置技术研究现状及发展趋势[J]. 科学中国人,2017,(20):279.ZHU Dong, XU Ying. Research status and development trend of municipal sludge treatment technology at home and abroad[J]. Sci Chin,2017,(20):279. [6] FU B, LIU G J, MIAN M M, ZHOU C C, SUN M, WU D, LIU Y. Co-combustion of industrial coal slurry and sewage sludge: Thermochemical and emission behavior of heavy metals[J]. Chemosphere,2019,233:440−451. doi: 10.1016/j.chemosphere.2019.05.256 [7] 陈红霞. 生活污泥处理与处置技术的研究进展[J]. 山西化工,2021,41(1):190−192.CHEN Hong-xia. Research progress of domestic sludge treatment and disposal technology[J]. Shanxi Chem Ind,2021,41(1):190−192. [8] 魏亮, 金星, 马丽萍. 污水厂剩余污泥处理处置技术研究进展[J]. 农业与技术,2021,41(8):8106−8108.WEI Liang, JIN Xing, MA Li-ping. Research progress on treatment and disposal technology of surplus sludge in sewage treatment plant[J]. Agr Technol,2021,41(8):8106−8108. [9] CHEN L M, LIAO Y F, MA X Q, LU S G. Heavy metals chemical speciation and environmental risk of bottom slag during co-combustion of municipal solid waste and sewage sludge[J]. J Cleaner Prod,2020,262:121−318. [10] WANG T, XUE Y J, ZHOU M, LIANG A N, LIU J X, MEI M, LAO X B, HOU H B, LI J P. Effect of addition of rice husk on the fate and speciation of heavy metals in the bottom ash during dyeing sludge incineration[J]. J Cleaner Prod,2020,244:118−851. [11] ZHANG S, WANG F, MEI Z Y, LV L K, CHI Y. Status and development of sludge incineration in China[J]. Waste Biomass Valorizat,2020,12(7):3541−3574. [12] LIN K S, KUO J H, LIN C L, LIU Z S, LIU J Y. Sequential extraction for heavy metal distribution of bottom ash from fluidized bed co-combusted phosphorus-rich sludge under the agglomeration/defluidization process[J]. Waste Manage Res,2020,38(2):122−133. doi: 10.1177/0734242X19886927 [13] ZHA J R, HUANG Y J, PETER T CLOUGH, DONG L, XU L G, LIU L Q, ZHU Z C, YU M Z. Desulfurization using limestone during sludge incineration in a fluidized bed furnace: Increased risk of particulate matter and heavy metal emissions[J]. Fuel,2020,273:117−614. [14] PENIDO E S, MARTINS G C, MENDES T B M, MELO L C A, GUIMARAES I D R, GUILHERME L R G. Combining biochar and sewage sludge for immobilization of heavy metals in mining soils[J]. Ecotoxicol Environ Saf,2019,172:326−333. doi: 10.1016/j.ecoenv.2019.01.110 [15] LIU H P, ZHANG S Q, FENG S Y, JIA C X, GUO S, SUN B Z, WANG Q. Combustion characteristics and typical pollutant emissions of corn stalk blending with municipal sewage sludge[J]. Environ Sci Pollut Res,2021,28(8):9792−9805. doi: 10.1007/s11356-020-11463-y [16] JIN Y Y, LI Y Y, LIU F Q. Combustion effects and emission characteristics of SO2, CO, NOx and heavy metals during co-combustion of coal and dewatered sludge[J]. Frontiers of Environ Sci Eng,2016,10(1):201−210. doi: 10.1007/s11783-014-0739-9 [17] ZHAN M X, SUN C, CHEN T, LI X D. Emission characteristics for co-combustion of leather wastes, sewage sludge, and coal in a laboratory-scale entrained flow tube furnace[J]. Environ Sci Pollut Res,2019,26(10):9707−9716. doi: 10.1007/s11356-019-04347-3 [18] ZHANG S R, JIANG X G, LV G J, WU L, LI W, WANG Y F, FANG C Q, JIN Y Q, YAN J H. Co-combustion of Shenmu coal and pickling sludge in a pilot scale drop-tube furnace: Pollutants emissions in flue gas and fly ash[J]. Fuel Process Technol,2019,184:57−64. doi: 10.1016/j.fuproc.2018.11.009 [19] GUO F H, ZHONG Z P, XUE H. Partition of Zn, Cd, and Pb during co-combustion of sedum plumbizincicola and sewage sludge[J]. Chemosphere,2018,197:50−56. doi: 10.1016/j.chemosphere.2018.01.021 [20] CHEN L M, LIAO Y F, MA X Q. Heavy metals volatilization characteristics and risk evaluation of co-combusted municipal solid wastes and sewage sludge without and with calcium-based sorbents[J]. Ecotoxicol Environ Saf,2019,182:109−370. [21] ZHAO Y, JIA H, REN Q. The Characteristics of zinc and arsenic from Co-firing of municipal sewage sludge with biomass in a fluidized bed[J]. Energy Fuels,2016,31(1):755−762. [22] 董浩. 制革污泥与煤在流化床内的共处置燃烧和铬迁移特性研究[D]. 浙江: 浙江大学, 2018.DONG Hao. Study on co-combustion characteristics of tannery sludge with coal and fate of chromium in fluidized bed incinerator[D]. Zhejiang: Zhejiang University, 2018. [23] 张琳, 周国顺, 郭镇宁, 钟文琪, 徐鹏程. 污泥协同焚烧应用及污染物排放特性[J]. 化学工程与装备,2020,,(12):7−8.ZHANG Lin, ZHOU Guo-shun, GUO Zhen-ning, ZHONG Wen-qi, XU Peng-cheng. Application and pollutant emission characteristics of sludge co-incineration[J]. Chem Eng Equip,2020,,(12):7−8. [24] 刘志强, 刘青, 蒋文斌, 肖峰, 吕俊复. 循环流化床锅炉SO2和NOx排放的影响规律研究[J]. 锅炉技术,2013,44(3):23−27. doi: 10.3969/j.issn.1672-4763.2013.03.006(LIU Zhi-qiang, LIU Qing, JIANG Wen-bin, XIAO Feng, LU Jun-fu. The effect of the emission in circulating fluidized bed boilers[J]. Boiler Technol,2013,44(3):23−27. doi: 10.3969/j.issn.1672-4763.2013.03.006 [25] 张盈文, 金晶, 张号, 刘娓, 赵庆庆, 刘磊. 污泥燃烧过程中NOx排放特性的实验研究[J]. 上海理工大学学报,2015,37(3):233−237.ZHANG Ying-wen, JIN Jing, ZHANG Hao, LIU Wei, ZHAO Qing-qing. LIU Lei. Experimental study on property of NOx emission during combustion of sludge[J]. J Univ Shanghai Sci Technol,2015,37(3):233−237. [26] SÄNGER M, WERTHER J, OGADA T. NOx and N2O emission characteristics from fluidised bed combustion of semi-dried municipal sewage sludge[J]. Fuel (Guildford),2001,80(2):167−177. doi: 10.1016/S0016-2361(00)00093-4 [27] WANG S J, HE P J, SHAO L M, ZHANG H. Multifunctional effect of Al2O3, SiO2 and CaO on the volatilization of PbO and PbCl2 during waste thermal treatment[J]. Chemosphere,2016,161:242−250. doi: 10.1016/j.chemosphere.2016.07.020 [28] ZHOU H, SUN J, MENG A H, LI Q H, ZHANG Y G. Effects of sorbents on the partitioning and speciation of Cu during municipal solid waste incineration[J]. Chin J Chem Eng,2014,22(11/12):1347−1351. doi: 10.1016/j.cjche.2014.09.030 [29] HUANG Q X, CAI X, ALHADJ MALLAH M M, CHI Y, YAN J H. Effect of HCl/SO2/NH3/O2 and mineral sorbents on the partitioning behaviour of heavy metals during the thermal treatment of solid wastes[J]. Environ technol,2015,36(23):3043−3049. doi: 10.1080/09593330.2014.963693 [30] FOLGUERAS M B, DIAZ R M, XIBERTA J, ALONSO M. Effect of inorganic matter on trace element behavior during combustion of coal-sewage sludge blends[J]. Energy Fuels,2007,21(2):744−755. doi: 10.1021/ef060536r [31] HALL B, LINDQVIST O, LJUNGSTROEM E. Mercury chemistry in simulated flue gases related to waste incineration conditions[J]. Environ Sci Technol,1990,24(1):108−111. doi: 10.1021/es00071a013 [32] WU C J, DUAN Y F, ZHAO C S, WANG Y J, WANG Q, YANG L G, JIANG Y M. Mercury emission from Co-combustion of coal and sludge in a circulating fluidized-bed incinerator[J]. Energy Fuels,2010,24(1):220−224. doi: 10.1021/ef900565c -

下载:

下载: