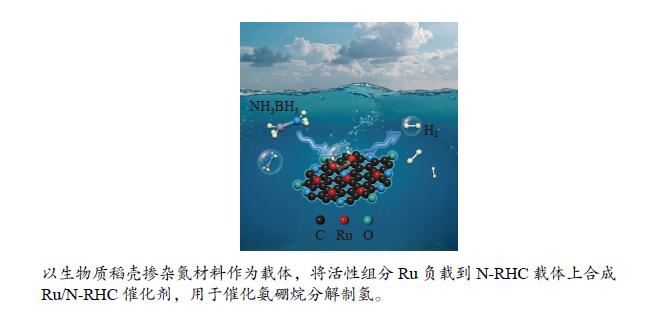

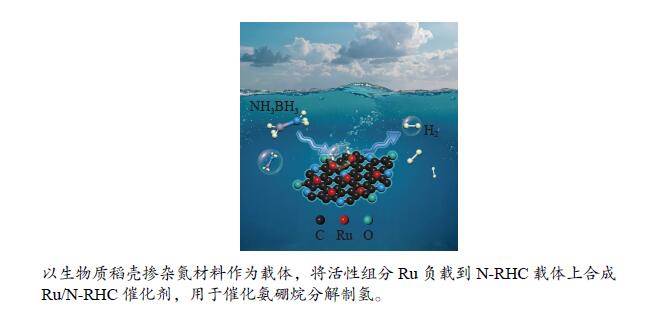

Preparation of rice husk-based carbon supported ruthenium catalyst for the hydrolysis of ammonia borane to produce hydrogen

-

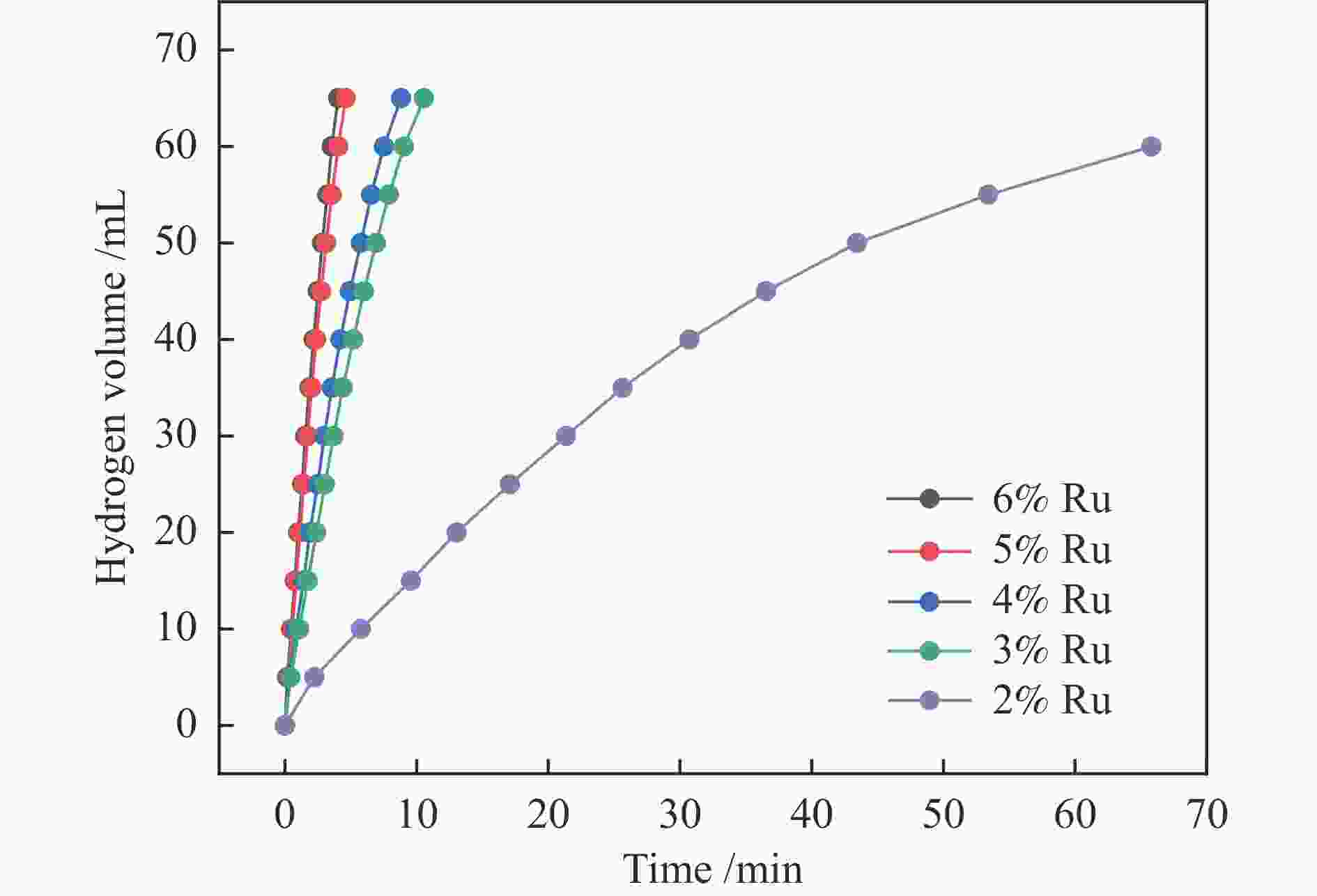

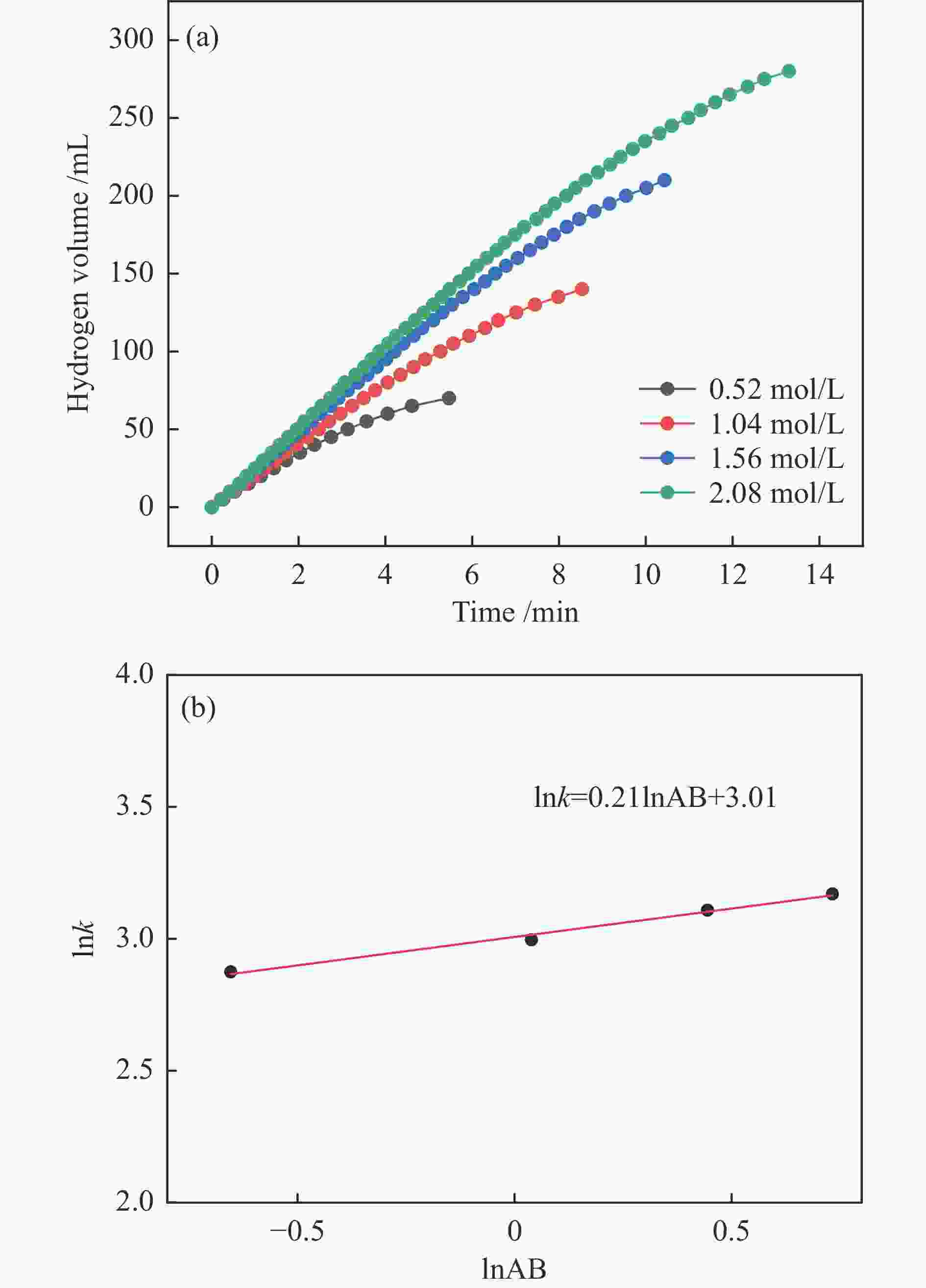

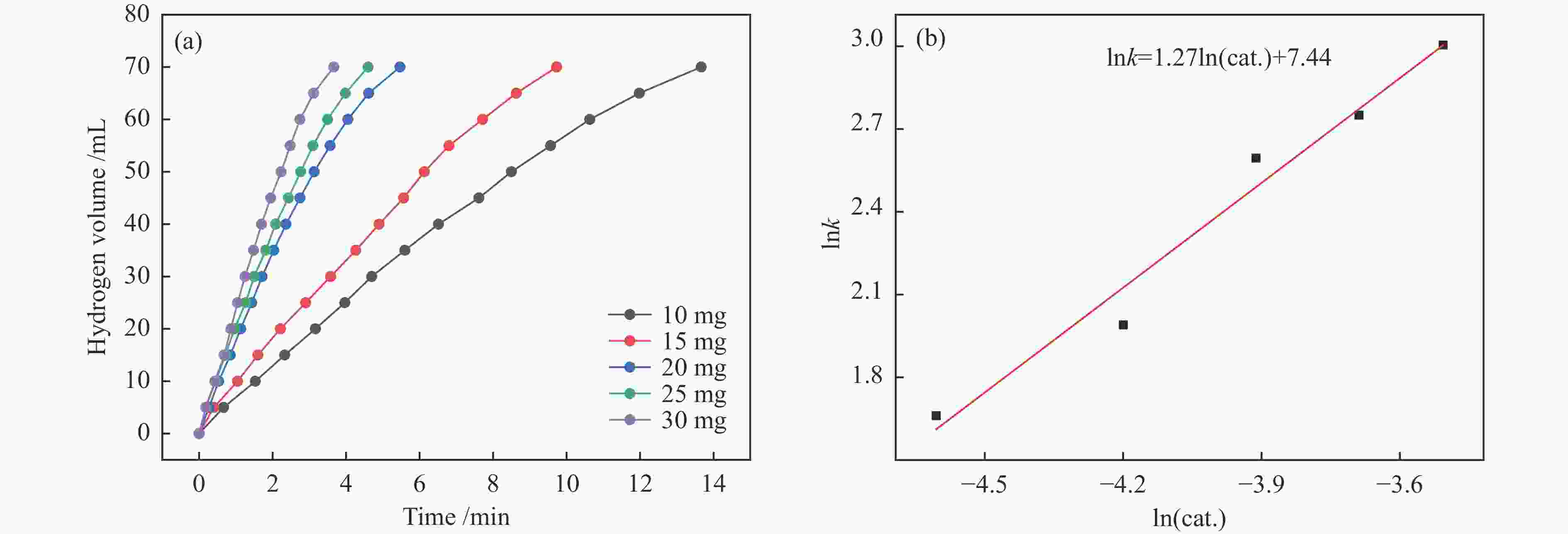

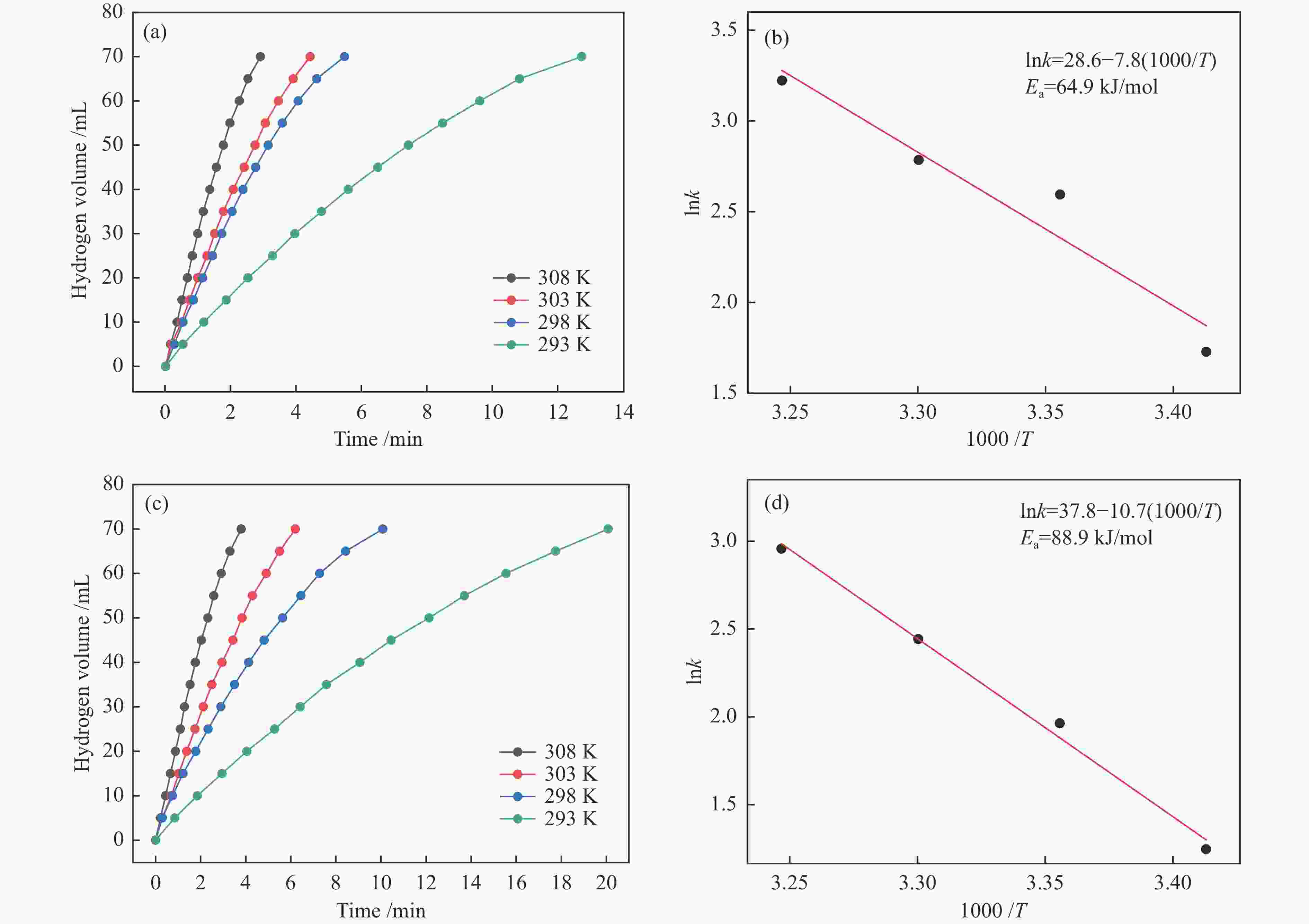

摘要: 本研究采用简单的浸渍还原法,在N2气氛下高温焙烧三聚氰胺和稻壳来制备氮掺杂稻壳活性炭载体(N-RHC),再采用RuCl3溶液通过浸渍法将活性组分Ru负载到N-RHC载体上,得到Ru/N-RHC催化剂,探究了其对氨硼烷制氢的催化性能。结果表明,Ru负载量为5%(质量分数)的Ru/N-RHC催化剂具有较好的氨硼烷制氢催化性能,反应转化频率(TOF)达83.71 min−1,在光的照射下,该催化剂上氨硼烷水解的活化能从88.9 kJ/mol降到64.9 kJ/mol,且制氢速率与氨硼烷浓度以及催化剂浓度呈现正相关。Abstract: An efficient dehydrogenation catalyst is crucial for the application of ammonia borane (NH3BH3, AB) as a solid chemical hydrogen storage material. In this work, a kind of nitrogen-doped rice husk activated carbon (N-RHC) was prepared by roasting melamine and rice husk at high temperature under nitrogen atmosphere. With N-RHC as the support, the rice husk-based carbon supported ruthenium catalyst (Ru/N-RHC) was prepared through impregnation with the RuCl3 solution and its catalytic performance in the hydrolysis of ammonia borane to produce hydrogen was investigated. The results indicate that the Ru/N-RHC catalyst with a Ru loading of 5% performs excellently in the hydrolysis of ammonia borane; the reaction turnover frequency (TOF) reaches 83.71 min−1 and the apparent activation energy decreases from 88.9 to 64.9 kJ/mol under light irradiation. In addition, the hydrogen production rate is positively correlated with the content of ammonia borane and catalyst.

-

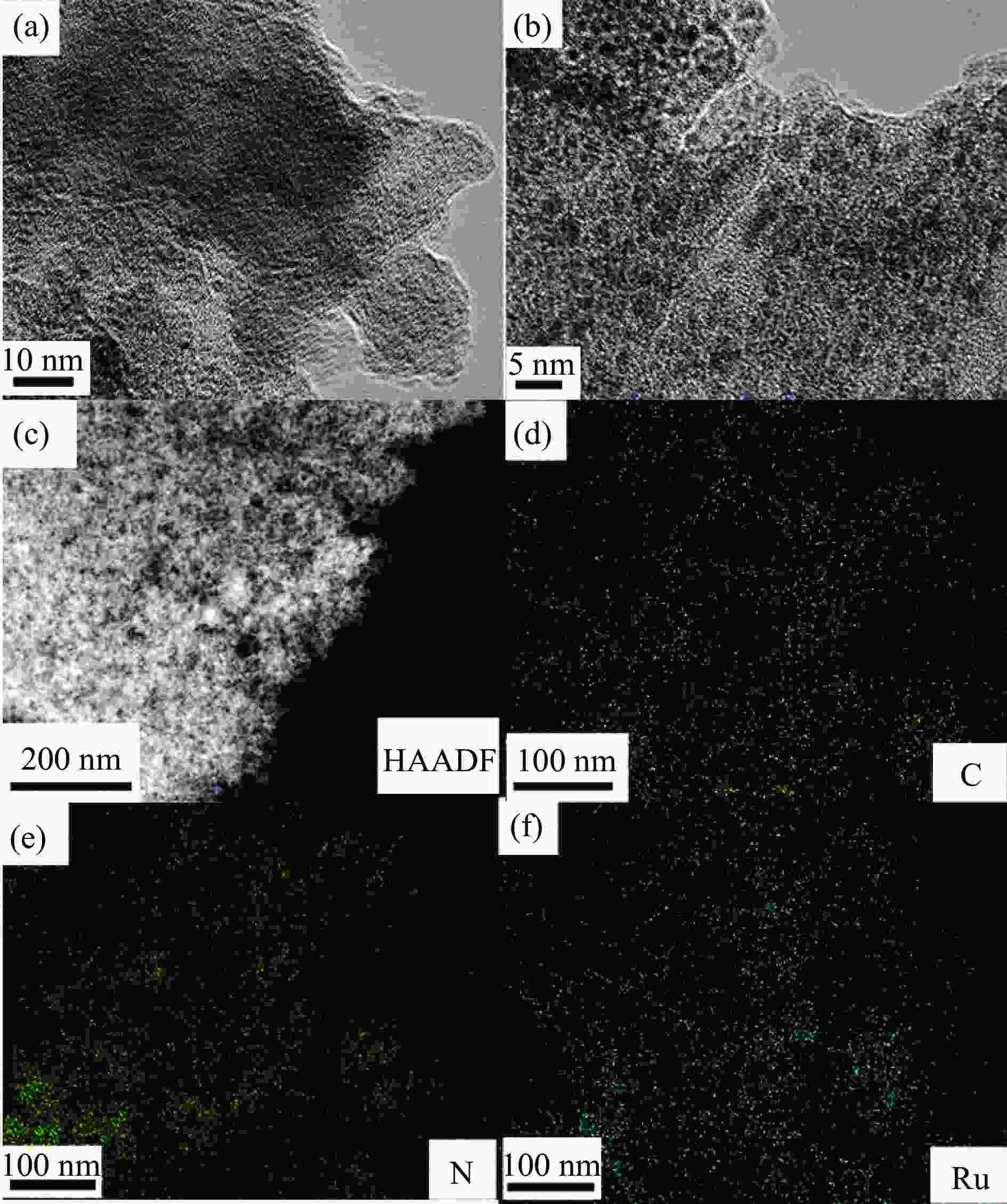

图 1 ((a)、(b)) 5%Ru/N-RHC0.5-873 K 催化剂不同放大倍数下的TEM 照片; (c) 5%Ru/N-RHC0.5-873 K 催化剂的HAADF照片; (d) C, (e) N, (f) Ru 三种元素的分布

Figure 1 ((a), (b)) TEM images of 5%Ru/N-RHC0.5-873 K with different magnification; (c) HADDF images and elemental mapping of C (d), N (e) and Ru (f) elements for the 5%Ru/N-RHC0.5-873 K catalysts

图 8 有光时不同温度下5%Ru/N-RHC0.5-873 K 催化AB脱氢速率(a)和阿伦尼乌斯方程:lnk与1000/T关系(b);无光时不同温度下5%Ru/N-RHC0.5-873 K 催化AB脱氢速率(c)和阿伦尼乌斯方程:lnk与1000/T关系(d)

Figure 8 AB dehydrogenation rate curves over the 5%Ru/N-RHC0.5-873 K catalyst at different temperatures under light irradiation (a) and corresponding Arrhenius plot of lnk versus 1000/T (b);AB dehydrogenation rate curves over the 5%Ru/N-RHC0.5-873 K catalyst at different temperatures without light irradiation (c) and corresponding Arrhenius plot of lnk versus 1000/T (d)

-

[1] LI H, ZHOU Y T, ZHAO M, JIN B, WEN Z, XIE H M, DOU S X, JIANG Q. Suppressed shuttle via inhibiting the formation of long-chain lithium polysulfides and functional separator for greatly improved lithium-organosulfur batteries performance[J]. Adv Energy Mater,2020,10(3):1902695. doi: 10.1002/aenm.201902695 [2] LI H, ZHAO M, JIN B, WEN Z, LIU H K, JIANG Q. Mesoporous nitrogen-doped carbon nanospheres as sulfur matrix and a novel chelate-modified separator for high-performance room-temperature Na-S batteries[J]. Small,2020,16(29):1907464. doi: 10.1002/smll.201907464 [3] JU Q J, MA R G, PEI Y, GUO B B, LI Z C, LIU Q, THOMAS T J, YANG M H, HUTCHINGS G J, WANG J C. Ruthenium triazine composite: A good match for increasing hydrogen evolution activity through contact electrification[J]. Adv Energy Mater,2020,10(21):2000067. doi: 10.1002/aenm.202000067 [4] 邹爱华, 徐晓梅, 周浪, 林路贺, 康志兵. 石墨烯负载Co-CeOx纳米复合物的制备及其对氨硼烷水解产氢的催化性能[J]. 燃料化学学报,2021,49(9):1371−1378. doi: 10.1016/S1872-5813(21)60085-3ZOU Ai-hua, XU Xiao-mei, ZHOU Lang, LIN Lu-he, KANG Zhi-bing. Preparation of graphene-supported Co-CeOx nanocomposites as a catalyst for the hydrolytic dehydrogenation of ammonia borane[J]. J Fuel Chem Technol,2021,49(9):1371−1378. doi: 10.1016/S1872-5813(21)60085-3 [5] WU H, WU M, WANG B Y, YONG X, LIU Y S, LI B J, LIU B Z, LU S Y. Interface electron collaborative migration of Co-Co3O4/carbon dots: Boosting the hydrolytic dehydrogenation of ammonia borane[J]. J Energy Chem,2020,48:43−53. doi: 10.1016/j.jechem.2019.12.023 [6] AKBAYRAK S, ÖZKAR S. Ammonia borane as hydrogen storage materials[J]. Int J Hydrogen Energy,2018,43(40):18592−18606. doi: 10.1016/j.ijhydene.2018.02.190 [7] ZHANG Z J, ZHANG S L, YAO Q L, FENG G, ZHU M H, LU Z H. Metal-organic framework immobilized RhNi alloy nanoparticles for complete H2 evolution from hydrazine borane and hydrous hydrazine[J]. Inorg Chem Front,2018,5(2):370−377. doi: 10.1039/C7QI00555E [8] ALPAYDıN C Y, GÜLBAY S K, COLPAN C O. A review on the catalysts used for hydrogen production from ammonia borane[J]. Int J Hydrogen Energy,2020,45(5):3414−3434. doi: 10.1016/j.ijhydene.2019.02.181 [9] ZHOU L M, MENG J, LI P, TAO Z L, MAI L Q, CHEN J. Ultrasmall cobalt nanoparticles supported on nitrogen-doped porous carbon nanowires for hydrogen evolution from ammonia borane[J]. Mater Horiz,2017,4(2):268−273. doi: 10.1039/C6MH00534A [10] CHEN W Y, LI D L, WANG Z J, QIAN G, SUI Z J, DUAN X Z, ZHOU X G, YEBOAH I, CHEN D. Reaction mechanism and kinetics for hydrolytic dehydrogenation of ammonia borane on a Pt/CNT catalyst[J]. AIChE J,2017,63(1):60−65. doi: 10.1002/aic.15389 [11] TONBUL Y, AKBAYRAK S, ÖZKAR S. Magnetically separable rhodium nanoparticles as catalysts for releasing hydrogen from the hydrolysis of ammonia borane[J]. J Colloid Interface Sci,2019,553:581−587. doi: 10.1016/j.jcis.2019.06.038 [12] 孙海杰, 刘欣改, 陈志浩, 陈凌霞, 李聪聪, 梅洋洋. 二氧化硅负载钌催化剂催化氨硼烷水解产氢研究[J]. 无机盐工业,2020,52(5):81−85. doi: 10.11962/1006-4990.2019-0398SUN Hai-jie, LIU Xin-gai, CHEN Zhi-hao, CHEN Ling-xia, LI Cong-cong, MEI Yang-yang. Research on Ru/SiO2 catalysts for hydrogen generation from catalytic hydrolysis of ammonia borane[J]. Inorg Chem Ind,2020,52(5):81−85. doi: 10.11962/1006-4990.2019-0398 [13] OIU P Y, DESCHAMPS F, CALDARELLA G, CHATENET M, JOB N. Investigation of platinum and palladium as potential anodic catalysts for direct borohydride and ammonia borane fuel cells[J]. J Power Sources,2015,297:492−503. doi: 10.1016/j.jpowsour.2015.08.022 [14] PENG S G, LIU J C, ZHANG J, WANG F Y. An improved preparation of graphene supported ultrafine ruthenium (0) NPs: Very active and durable catalysts for H2 generation from methanolysis of ammonia borane[J]. Int J Hydrogen Energy,2015,40(34):10856−10866. doi: 10.1016/j.ijhydene.2015.06.113 [15] LUO Z C, ZHU Z G, XIAO R. Hydrogenolysis of lignin to aromatics over Ru-based catalysts[J]. Biomass Convers Biorefin, 2022, in press. [16] ZHU X B, LIU J, HU X L, ZHOU Z J, LI X B, WANG W T, WU R B, TU X. Plasma-catalytic synthesis of ammonia over Ru-based catalysts: Insights into the support effect[J]. J Energy Inst,2022,102:240−246. doi: 10.1016/j.joei.2022.02.014 [17] ZHONG F Y, WANG Q, XU C L, YANG Y C, WANG Y, ZHANG Y, GAO D J, BI J, FAN G Y. Ultrafine and highly dispersed Ru nanoparticles supported on nitrogen-doped carbon nanosheets: Efficient catalysts for ammonia borane hydrolysis[J]. Appl Surf Sci,2018,455:326−332. doi: 10.1016/j.apsusc.2018.05.192 [18] 鲍英, 詹亮, 王春晓, 王艳莉, 杨光智, 杨俊和, 乔文明, 凌立成. 用作气相催化反应体系CNF/泡沫炭催化剂载体的合成[J]. 新型炭材料,2011,26(5):341−346. doi: 10.1016/S1872-5805(11)60086-3BAO Ying, ZHAN Liang, WANG Chun-xiao, WANG Yan-li, YANG Guang-zhi, YANG Jun-he, QIAO Wen-ming, LING Li-cheng. Synthesis of carbon nano-fiber/carbon-foam composite for catalyst support in gas-phase catalytic reactions[J]. New Carbon Mater,2011,26(5):341−346. doi: 10.1016/S1872-5805(11)60086-3 [19] LIU Y Z, LI Y F, YUAN S X, CHEN S, WANG C W, LI X M, SU F Y, CHEN C M. Synthesis of 3D N, S dual-doped porous carbons with ultrahigh surface areas for highly efficient oxygen reduction reactions[J]. ChemElectroChem,2018,5(22):3506−3513. doi: 10.1002/celc.201800937 [20] LI Y F, LIU Y Z, LIANG Y, GUO X H, CHEN C M. Preparation of nitrogen-doped graphene/activated carbon composite papers to enhance energy storage in supercapacitors[J]. Appl Phys A,2017,123(9):1−6. [21] 吴明铂, 李玲燕, 刘军, 李杨, 艾培培, 吴文婷, 郑经堂. 稻壳基介孔炭的制备及其在超级电容器中的应用[J]. 新型炭材料,2015,30(5):471−475. doi: 10.1016/S1872-5805(15)60201-3WU Ming-bo, LI Ling-yan, LIU Jun, LI Yang, AI Pei-pei, WU Wen-ting, ZHENG Jing-tang. Template-free preparation of mesoporous carbon from rice husks for use in supercapacitors[J]. New Carbon Mater,2015,30(5):471−475. doi: 10.1016/S1872-5805(15)60201-3 [22] IWANOW M, GäRTNER T, SIEBER V, KÖNIG B. Activated carbon as catalyst support: precursors, preparation, modification and characterization[J]. Beilstein J Org Chem,2020,16(1):1188−1202. [23] ZHOU M H, TIAN L F, NIU L, LI C, XIAO G M, XIAO R. Upgrading of liquid fuel from fast pyrolysis of biomass over modified Ni/CNT catalysts[J]. Fuel Process Technol,2014,126:12−18. doi: 10.1016/j.fuproc.2014.04.015 [24] 陈志浩, 晁威, 丰祎, 金璐, 朱燕超, 杨晓敏, 王子忱. 稻壳基活性炭负载镍催化剂的制备及在香草醛加氢脱氧反应中的催化性能[J]. 新型炭材料,2018,33(5):417−423. doi: 10.1016/S1872-5805(18)30008-8CHEN Zhi-hao, CHAO Wei, FENG Yi, JIN Lu, ZHU Yan-chao, YANG Xiao-min, WANG Zi-chen. Preparation of Ni-rice husk carbon catalysts for the hydrodeoxygenation of vanillin[J]. New Carbon Mater,2018,33(5):417−423. doi: 10.1016/S1872-5805(18)30008-8 [25] LI J, CHEN S G, LI W, WU R, IBRAHEEM S, LI J, DING W, LI L, WEI Z D. A eutectic salt-assisted semi-closed pyrolysis route to fabricate high-density active-site hierarchically porous Fe/N/C catalysts for the oxygen reduction reaction[J]. J Mater Chem A,2018,6(32):15504−15509. doi: 10.1039/C8TA05419C [26] LAI Q X, ZHENG L R, LIANG Y Y, HE J P, ZHAO J X, CHEN J H. Metal-organic-framework-derived Fe-N/C electrocatalyst with five-coordinated Fe-Nx sites for advanced oxygen reduction in acid media[J]. ACS Catal,2017,7(3):1655−1663. doi: 10.1021/acscatal.6b02966 [27] 刁金香, 张超, 张敏华, 牛芳芳, 刘肖杰. Cu纳米颗粒负载N掺杂生物质炭及其在锌空气电池中的应用[J]. 化工新型材料,2022,50(7):273−276.DIAO Jin-xiang, ZHANG Chao, ZHANG Min-hua, NIU Fang-fang, LIU Xiao-jie. Cu nanoparticles in N-doped biomass carbon for Zn-air battery[J]. New Chem Mater,2022,50(7):273−276. [28] DING X Y, GU R, SHI P H, XU Q J, MIN Y L. A three-dimensional hierarchical porous carbon network decorated with MnO2 nanoparticles (HPCM) as an efficient sulfur host for high-performance lithium-sulfur batteries (LSBs)[J]. J Alloys Compd,2020,835:155206. doi: 10.1016/j.jallcom.2020.155206 [29] SONG H Q, WU M, TANG Z Y, TSE J S, YANG B, LU S Y. Single atom ruthenium‐doped CoP/CDs nanosheets via splicing of carbon‐dots for robust hydrogen production[J]. Angew Chem Int Ed,2021,60(13):7234−7244. doi: 10.1002/anie.202017102 [30] LI S H, SONG X R, LI Y T, ZHAO Y Q, ZHENG X C. Efficient hydrolytic dehydrogenation of ammonia borane over ultrafine Ru nanoparticles supported on biomass-derived porous carbon[J]. Int J Hydrogen Energy,2021,46(54):27555−27566. doi: 10.1016/j.ijhydene.2021.06.029 [31] LI W D, ZHAO Y X, LIU Y, SUN M Z, WATERHOUSE G I N, HUANG B L, ZHANG K, ZHANG T R, LU S Y. Exploiting Ru-induced lattice strain in CoRu nanoalloys for robust bifunctional hydrogen production[J]. Angew Chem Int Ed,2021,133(6):3327−3335. doi: 10.1002/ange.202013985 [32] 李贵, 李蓉, 刘勇, 许立信, 叶明富, 万超. Rh/N-SBC纳米催化剂的制备及其催化氨硼烷水解产氢性能研究[J]. 稀有金属, 2022.LI Gui, LI Rong, LIU Yong, XU Li-xin, YE Ming-fu, WAN Chao. Preparation of Rh/N-SBC nanocatalyst and its catalytic performance for the Hydrolytic dehydrogenation of ammonia borane[J]. Chin J Rare Metals, 2022. [33] LI R R, WANG S T, HU Y, CHEN H, CHEN J J, CHU C, ZHENG J L. Pd supported on N-doped-ordered mesoporous carbons’ catalysts for selective hydrodechlorination of 4-chlorophenol[J]. Chem Pap,2018,72(10):2425−2432. doi: 10.1007/s11696-018-0477-8 [34] SONG H Q, YU J K, TANG Z Y, YANG B, LU S Y. Halogen-doped carbon dots on amorphous cobalt phosphide as robust electrocatalysts for overall water splitting[J]. Adv Energy Mater,2022,12(14):2102573. doi: 10.1002/aenm.202102573 [35] 李宇明, 刘梓烨, 张启扬, 王雅君, 崔国庆, 姜桂元, 贺德华. 氮掺杂碳材料的制备及其在催化领域中的应用[J]. 化工学报,2021,72(8):3919−3932. doi: 10.11949/0438-1157.20201932LI Yu-ming, LIU Zi-ye, ZHANG Qi-yang, WANG Ya-jun, CUI Guo-qing, JIANG Gui-yuan, HE De-hua. Preparation of nitrogen-doped carbon materials and their applications in catalysis[J]. CIESC J,2021,72(8):3919−3932. doi: 10.11949/0438-1157.20201932 [36] WAN H R, HU X F. Nitrogen doped biomass-derived porous carbon as anode materials of lithium ion batteries[J]. Solid State Ionics,2019,341:115030. doi: 10.1016/j.ssi.2019.115030 [37] 谭诗宇, 谭习有, 蔡冬琦, 高晓虹, 徐佩艳, 翁杨琳, 游诚航. 椰子壳衍生钕氮掺杂碳制备及其电催化氧还原反应性能研究[J]. 海南师范大学学报(自然科学版),2019,32(3):249−253.TAN Shi-yu, TAN Xi-you, CAI Dong-qi, GAO Xiao-hong, XU Pei-yan, WENG Yang-lin, YOU Cheng-hang. Coconut shell derived neodymium and nitrogen Co-doped carbon and its catalytic performance towards oxygen reduction[J]. J Hainan Norm Univ, Nat Sci,2019,32(3):249−253. [38] NIE R F, JIANG H Z, LU X H, ZHOU D, XIA Q H. Highly active electron-deficient Pd clusters on N-doped active carbon for aromatic ring hydrogenation[J]. Catal Sci Technol,2016,6(6):1913−1920. doi: 10.1039/C5CY01418B [39] SU F B, POH C K, CHEN J S, XU G W, WANG D, LI Q, LIN J Y, LOU X W. Nitrogen-containing microporous carbon nanospheres with improved capacitive properties[J]. Energy Environ Sci,2011,4(3):717−724. doi: 10.1039/C0EE00277A [40] XIAO B, BOUDOU J P, THOMAS K M. Reactions of nitrogen and oxygen surface groups in nanoporous carbons under inert and reducing atmospheres[J]. Langmuir,2005,21(8):3400−3409. doi: 10.1021/la0472495 [41] 李贵, 梁雨, 郑君宁, 许立信, 叶明富, 万超. Rh/N-GMCs纳米催化剂的制备及其催化氨硼烷水解产氢性能研究[J]. 燃料化学学报, 2023, 51(4): 528−537.LI Gui, LIANG Yu, ZHENG Jun-ning, XU Li-xin, YE Ming-fu, WAN Chao. Preparation of Rh/N-GMCs nanocatalyst and its catalytic performance for the Hydrolytic dehydrogenation of ammonia borane[J]. J Fuel Chem Technol, 2023, 51(4): 528−537. [42] RAKAP M, KALU E E, ÖZKAR S. Polymer-immobilized palladium supported on TiO2 (Pd-PVB-TiO2) as highly active and reusable catalyst for hydrogen generation from the hydrolysis of unstirred ammonia-borane solution[J]. Int J Hydrogen Energy,2011,36(2):1448−1455. doi: 10.1016/j.ijhydene.2010.10.097 [43] WEN L, ZHENG Z, LUO W, CAI P, CHENG G Z. Ruthenium deposited on MCM-41 as efficient catalyst for hydrolytic dehydrogenation of ammonia borane and methylamine borane[J]. Chin Chem Lett,2015,26(11):1345−1350. doi: 10.1016/j.cclet.2015.06.019 [44] 郭俊兰, 梁英华, 王欢, 刘利, 崔文权. 光催化制氢的助催化剂[J]. 化学进展,2021,33(7):1100−1114.GUO Jun-lan, LIANG Ying-hua, WANG Huan, LIU Li, CUI Wen-quan. The cocatalyst in photocatalytic hydrogen evolution[J]. Prog Chem,2021,33(7):1100−1114. [45] ZHAI Q G, XIE S J, FAN W Q, ZHANG Q H, WANG Y, DENG W P, WANG Y. Photocatalytic conversion of carbon dioxide with water into methane: platinum and copper (I) oxide Co-catalysts with a core-shell structure[J]. Angew Chem Int Ed,2013,125(22):5888−5891. doi: 10.1002/ange.201301473 [46] XIAO J D, HAN L L, LUO J, YU S H, JIANG H L. Integration of plasmonic effects and schottky junctions into metal-organic framework composites: Steering charge flow for enhanced visible-light photocatalysis[J]. Angew Chem Int Ed,2018,57(4):1118−1118. doi: 10.1002/anie.201713194 -

下载:

下载: