Effect of oxidative torrefaction upgrade on physicochemical properties of rice straw

-

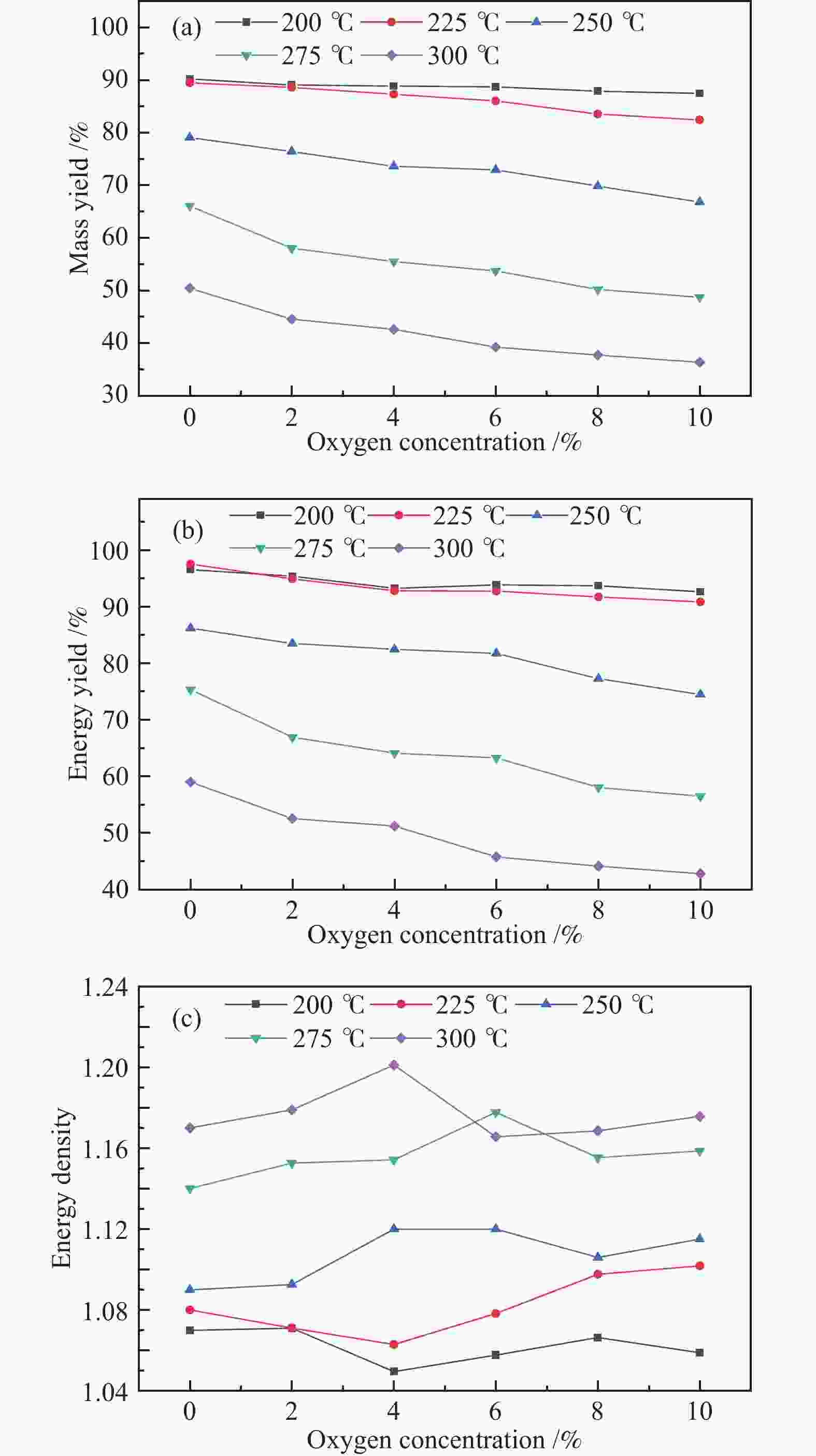

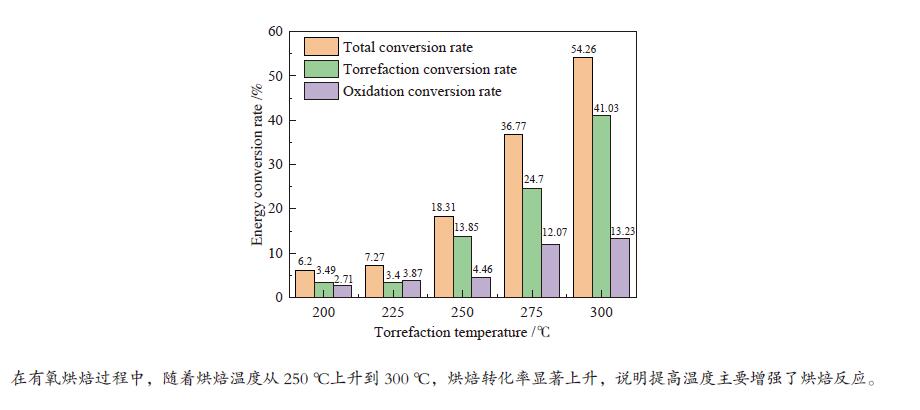

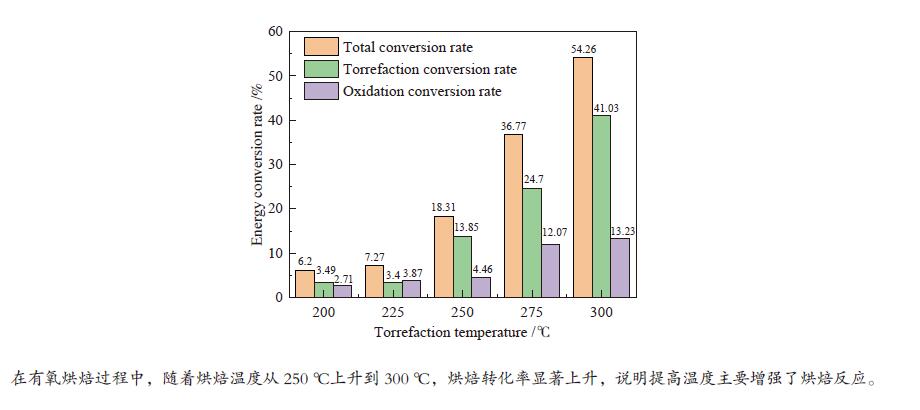

摘要: 本研究通过模拟富氧燃烧烟气气氛探究了有氧烘焙过程中氧气和烘焙温度对稻秆理化特性的影响。结果表明,与氧气相比,温度对有氧烘焙的影响更加显著。在低温段(< 250 ℃),氧气对烘焙稻秆的质量和能量收率影响较小,但在高温段(> 250 ℃)作用明显。随着温度的上升(> 250 ℃),烘焙稻秆的质量和能量收率大幅下降。烘焙温度为250 ℃,氧气体积分数为6%是比较合适的有氧烘焙工况,此时烘焙稻秆的质量和能量收率能分别保持在70%和80%以上。提高温度主要增强了烘焙反应,氧化反应在氧气体积分数超过6%时作用明显。氯、钾的留存率随着温度和氧气的升高均表现出下降的趋势,但温度的影响更加显著。Abstract: Torrefaction atmosphere is one of the key problems in industrial application of torrefaction technology. In this paper, the effects of oxygen concentration and torrefaction temperature on the physicochemical properties of rice straw during oxidative torrefaction were investigated by simulating the atmosphere of oxy-fuel combustion flue gas. The results show that the effect of temperature on oxidative torrefaction is more significant compared with oxygen concentration. At low temperature (< 250 ℃), oxygen concentration has little effect on the mass and energy yield of torrefied rice straw, but it has obvious effect at high temperature (> 250 ℃). With the increase of temperature (> 250 ℃), the mass and energy yields of torrefied rice straw decrease significantly. When the temperature and oxygen concentration are 250 ℃ and 6%, respectively, it is a suitable oxidative torrefaction condition. Under this condition, the mass and energy yields of torrefied rice straw can be maintained above 70% and 80%, respectively. Increasing the temperature mainly enhances the torrefaction reaction, and the oxidation reaction has an obvious effect when the oxygen concentration exceeds 6%. The retention ratio of chlorine and potassium has an downward trend with the increase of temperature and oxygen concentration, and the effect of increasing temperature is more significant.

-

Key words:

- biomass /

- oxidative torrefaction /

- oxygen concentration /

- chlorine /

- potassium

-

表 1 稻秆的工业分析和元素分析(干燥基)

Table 1 Proximate and ultimate analyses of RRSa (dry basis)

Proximate analysis

w/%Ultimate analysis

w/%QHHV/

(kJ·kg−1)A V FCa C H N Ob 16217 9.86 76.27 13.87 40.31 5.44 0.94 43.45 a: raw rice straw, b: calculated by difference 表 2 烘焙稻秆的工业分析和元素分析

Table 2 Proximate and ultimate analyses of TRSa (dry basis)

100%CO2-0%O2-TRS 98%CO2-2%O2-TRS 200 ℃ 225 ℃ 250 ℃ 275 ℃ 300 ℃ 200 ℃ 225 ℃ 250 ℃ 275 ℃ 300 ℃ Proximate analysis w/% A 10.12 10.51 10.79 12.84 16.76 9.82 10.12 10.60 13.39 17.13 V 75.62 74.66 73.87 68.78 56.47 75.79 73.70 73.17 58.04 50.86 FC 14.26 14.83 15.34 18.38 26.77 14.39 16.18 16.23 28.57 32.01 Ultimate analysis w/% C 43.69 44.08 44.46 47.19 48.99 43.59 43.56 44.51 47.69 50.39 H 5.41 5.28 4.97 4.29 3.83 5.55 5.43 5.18 4.42 3.02 N 1.16 1.36 1.26 1.28 1.19 1.12 1.22 1.33 1.25 1.14 Ob 39.62 38.77 38.52 34.40 28.77 39.92 39.67 38.38 33.25 28.32 QHHV/(kJ·kg−1) 17412 17573 17679 18509 18963 17368 17371 17718 18694 19119 96%CO2-4%O2-TRS 94%CO2-6%O2-TRS 200 ℃ 225 ℃ 250 ℃ 275 ℃ 300 ℃ 200 ℃ 225 ℃ 250 ℃ 275 ℃ 300 ℃ Proximate analysis w/% A 9.98 10.78 11.03 14.14 19.13 10.12 10.52 12.17 14.20 19.46 V 77.41 75.32 70.26 55.94 42.11 74.44 72.44 69.23 54.09 41.86 FC 12.61 13.90 18.71 29.92 38.76 15.44 17.05 18.60 31.71 38.68 Ultimate analysis w/% C 42.67 43.23 45.67 47.91 51.36 42.90 43.86 45.46 49.19 49.47 H 5.65 5.45 5.04 4.20 3.16 5.59 5.42 5.27 4.00 3.04 N 1.03 1.09 1.38 1.25 1.35 1.39 1.29 1.53 1.36 1.39 Ob 40.68 39.45 36.88 32.50 24.99 40.02 38.92 35.57 31.24 26.64 QHHV/(kJ·kg−1) 17021 17237 18118 18720 19480 17154 17486 18085 19098 18902 92%CO2-8%O2-TRS 90%CO2-10%O2-TRS 200 ℃ 225 ℃ 250 ℃ 275 ℃ 300 ℃ 200 ℃ 225 ℃ 250 ℃ 275 ℃ 300 ℃ Proximate analysis w/% A 10.21 10.68 11.70 15.71 22.17 10.15 10.86 11.74 16.65 23.84 V 73.83 71.18 69.99 56.42 42.24 74.14 70.95 69.61 56.45 41.36 FC 15.96 18.14 18.30 27.87 35.58 15.71 18.19 18.64 26.89 34.80 Ultimate an alysis w/% C 43.36 44.74 45.09 48.01 50.01 43.01 44.97 45.58 48.15 50.54 H 5.69 5.42 5.29 4.20 2.72 5.66 5.45 5.30 4.11 2.73 N 1.19 1.25 1.39 1.14 1.38 1.24 1.11 1.15 1.36 1.22 Ob 39.56 37.90 36.54 30.94 23.71 39.94 37.61 36.23 29.73 21.67 QHHV/(kJ·kg−1) 17293 17801 17936 18737 18949 17172 17868 18082 18791 19068 a: torrefied rice straw, b: calculated by difference 表 3 烘焙稻秆的氯、钾含量

Table 3 Content of Cl and K in TRS under different conditions

RRS 6%O2-TRS 250°C-TRS 200 ℃ 225 ℃ 250 ℃ 275 ℃ 300 ℃ 0 2% 4% 6% 8% 10% Contents of chlorine and potassium w/% Cl 0.626 0.667 0.684 0.752 0.951 1.259 0.707 0.722 0.747 0.752 0.784 0.811 K 1.133 1.175 1.196 1.332 1.643 2.16 1.256 1.278 1.328 1.332 1.394 1.452 表 4 不同工况下烘焙稻秆的氯、钾留存率

Table 4 Retention ratio of Cl and K of TRS under different conditions

RRS 6%O2-TRS 250 ℃-TRS 200 ℃ 225 ℃ 250 ℃ 275 ℃ 300 ℃ 0 2% 4% 6% 8% 10% Cl/% 100 94.49 93.97 87.62 81.56 78.92 89.27 88.10 87.83 87.62 87.45 86.50 K/% 100 91.97 90.78 85.75 77.86 74.81 87.62 86.17 86.27 85.75 85.92 85.57 Cl/K 0.61 0.641 0.650 0.634 0.666 0.676 0.630 0.635 0.629 0.634 0.629 0.620 -

[1] GAO X P, CHEN Y, SHENG C D, WU H W. Interaction between sodium vapor and reactor wall during biomass combustion and its influence on measurement of particulate matter emission[J]. Fuel,2016,165:260−263. doi: 10.1016/j.fuel.2015.10.065 [2] NIU Y H, HAN F T, CHEN Y S, LYU Y L, WANG L. Experimental study on steam gasification of pine particles for hydrogen-rich gas[J]. J Energy Inst,2017,90(5):715−724. doi: 10.1016/j.joei.2016.07.006 [3] NIU Y Q, LV Y, LEI Y, LIU S Q, LIANG Y, WANG D H, HUI S E. Biomass torrefaction: properties, applications, challenges, and economy[J]. Renewable Sustainable Energy Rev,2019,115:109395. doi: 10.1016/j.rser.2019.109395 [4] HE Q, GUO Q H, DING L, GONG Y. Co-pyrolysis behavior and char structure evolution of raw/torrefied rice straw and coal blends[J]. Energy Fuels,2018,32:12469−12476. doi: 10.1021/acs.energyfuels.8b03469 [5] PIMCHUAI A, DUTTA A, BASU P. Torrefaction of agriculture residue to enhance combustible properties[J]. Energy Fuels,2010,24:4638−4645. doi: 10.1021/ef901168f [6] ROUSSET P, AGUIAR C, LABBÉ N, COMMANDRÉ J M. Enhancing the combustible properties of bamboo by torrefaction[J]. Bioresour Technol,2011,102:8225−8231. doi: 10.1016/j.biortech.2011.05.093 [7] SINGH R N. Equilibrium moisture content of biomass briquettes[J]. Biomass Bioenergy,2004,26:251−253. doi: 10.1016/S0961-9534(03)00082-5 [8] WANNAPEERA J, FUNGTAMMASAN B, WORASUWANNARAK N. Effects of temperature and holding time during torrefaction on the pyrolysis behaviors of woody biomass[J]. J Anal Appl Pyrolysis,2011,92:99−105. doi: 10.1016/j.jaap.2011.04.010 [9] STELT M J C V D, GERHAUSER H, KIEL J H A, PTASINSKI K J. Biomass upgrading by torrefaction for the production of biofuels: A review[J]. Biomass Bioenergy,2011,35:3748−3762. [10] NIU Y Q, TAN H Z, MA L, POURKASHANIAN M. Slagging characteristics on the superheaters of a 12 MW biomass-fired boiler[J]. Energy Fuels,2010,24:5222−5227. doi: 10.1021/ef1008055 [11] ARIAS B, PEVIDA C, FERMOSO J, PLAZA M G, RUBIERA F, PIS J J. Influence of torrefaction on the grindability and reactivity of woody biomass[J]. Fuel Process Technol,2008,89:169−175. doi: 10.1016/j.fuproc.2007.09.002 [12] UEMURA Y, MATSUMOTO R, SAADON S, MATSUMURA Y. A study on torrefaction of Laminaria japonica[J]. Fuel Process Technol,2015,138:133−138. doi: 10.1016/j.fuproc.2015.05.016 [13] MEI Y Y, LIU R J, YANG Q, YANG H P, SHAO J G, C RAPER D, ZHANG S H, CHEN H P. Torrefaction of cedarwood in a pilot scale rotary kiln and the influence of industrial flue gas[J]. Bioresour Technol,2015,177:355−360. doi: 10.1016/j.biortech.2014.10.113 [14] FAIZAL H M, SHAMSUDDIN H S, HEIREE M H M, HANAFFI M F M A, RAHMAN M R A, RAHMAN M M, LATIFF Z A. Torrefaction of densified mesocarp fibre and palm kernel shell[J]. Renewable Energy,2018,122:419−428. doi: 10.1016/j.renene.2018.01.118 [15] 谢腾, 丛宏斌, 赵立欣, 邱凌, 姚宗路, 张天乐, 霍丽丽. 烘焙对生物质理化特性影响综述与秸秆烘焙研究前景分析[J]. 应用化工,2020,49(11):175−180.XIE Teng, CONG Hong-bin, ZHAO Li-xin, QIU Ling, YAO Zong-lu, ZHANG Tian-le, HUO Li-li. A review of the effects of torrefaction on biomass physicochemical properties and analysis of research prospects for straw torrefaction[J]. Chin J Appl Chem,2020,49(11):175−180. [16] CHEN W H, LIN B J, LIN Y Y, CHU Y S, UBANDO A T, SHOW P L, ONG H C, CHANG J S, HO S H, CULABA A B, PÉTRISSANS A, PÉTRISSANS M. Progress in biomass torrefaction: Principles, applications and challenges[J]. Prog Energy Combust,2021,82:100887. doi: 10.1016/j.pecs.2020.100887 [17] XIN S Z, HUANG F, LIU X Y, MI T, XU Q L. Torrefaction of herbal medicine wastes: Characterization of the physicochemical properties and combustion behaviors[J]. Bioresour Technol,2019,287:121408. doi: 10.1016/j.biortech.2019.121408 [18] BRIDGEMAN T G, JONES J M, WILLIAMS A, WALDRON D J. An investigation of the grindability of two torrefied energy crops[J]. Fuel.,2010,89(12):3911−3918. doi: 10.1016/j.fuel.2010.06.043 [19] MCLAREN D. A comparative global assessment of potential negative emissions technologies[J]. Process Saf Environ,2012,90:489−500. doi: 10.1016/j.psep.2012.10.005 [20] KEMPER J. Biomass and carbon dioxide capture and storage: A review[J]. Int J Greenh Gas Control,2015,40:401−430. doi: 10.1016/j.ijggc.2015.06.012 [21] OLUGBADE T O, OJO O T. Biomass torrefaction for the production of high-grade solid biofuels: A review[J]. Bioenergy Res,2020,13:999−1015. doi: 10.1007/s12155-020-10138-3 [22] WANG Q, SUN S, ZHANG X, LIU H, GUO S. Influence of air oxidative and non-oxidative torrefaction on the chemical properties of corn stalk[J]. Bioresour Technol,2021,2:125120. [23] WANG C W, PENG J H, LI H, BI X T, LEGROS R, LIM C J, SOKHANSANJ S. Oxidative torrefaction of biomass residues and densification of torrefied sawdust to pellets[J]. Bioresour Technol,2013,127:318−325. doi: 10.1016/j.biortech.2012.09.092 [24] TRAN K Q, TRINH T N, BACH Q V. Development of a biomass torrefaction process integrated with oxy-fuel combustion[J]. Bioresour Technol,2016,199:408−413. doi: 10.1016/j.biortech.2015.08.106 [25] 刘汝杰, 梅艳阳, 杨晴, 杨海平, 陈应泉, 王贤华, 陈汉平. 氧浓度对生物质烘焙特性的影响[J]. 太阳能学报,2016,37(8):2154−2159. doi: 10.3969/j.issn.0254-0096.2016.08.039LIU Ru-jie, MEI Yan-yang, YANG Qing, YANG Hai-ping, CHEN Ying-quan, WANG Xian-hua, CHEN Han-ping. Influence of oxygen concentration on biomass torrefaction[J]. Acta Energ Sol Sin,2016,37(8):2154−2159. doi: 10.3969/j.issn.0254-0096.2016.08.039 [26] 曲磊, 聂士伟, 胡国荣, 王贤华, 杨海平, 陈汉平. 烘焙方式对生物质燃料特性的影响[J]. 太阳能学报,2020,41(8):364−369.QU Lei, NIE Shi-wei, HU Guo-rong, WANG Xian-hua, YANG Hai-ping, CHEN Han-ping. Effects of torrefaction method on biomass fuel properties[J]. Acta Energ Sol Sin,2020,41(8):364−369. [27] YANG T H, JIE Y F, LI B S, KAI X P, YAN Z, LI R D. Catalytic hydrodeoxygenation of crude bio-oil over an unsupported bimetallic dispersed catalyst in supercritical ethanol[J]. Fuel Process Technol,2016,148:19−27. doi: 10.1016/j.fuproc.2016.01.004 [28] XIN S Z, MI T, LIU X Y, HUANG F. Effect of torrefaction on the pyrolysis characteristics of high moisture herbaceous residues[J]. Energy,2018,152:586−593. doi: 10.1016/j.energy.2018.03.104 [29] ZENG K, HE X, YANG H P, WANG X H, CHEN H P. The effect of combined pretreatments on the pyrolysis of corn stalk[J]. Bioresour Technol,2019,281:309−317. doi: 10.1016/j.biortech.2019.02.107 [30] ZHANG Y, YAO A Y, SONG K Y. Torrefaction of cultivation residue of auricularia auricula-judae to obtain biochar with enhanced fuel properties[J]. Bioresour Technol,2016,206:211−216. doi: 10.1016/j.biortech.2016.01.099 [31] XIN S Z, YANG H P, CHEN Y Q, YANG M F, CHEN L, WANG X H, CHEN H P. Chemical structure evolution of char during the pyrolysis of cellulose[J]. J Anal Appl Pyrolsis,2015,116:263−271. doi: 10.1016/j.jaap.2015.09.002 [32] KAI X P, MENG Y X, YANG T H, LI B S, XING W L. Effect of torrefaction on rice straw physicochemical characteristics and particulate matter emission behavior during combustion[J]. Bioresour Technol,2019,278:1−8. doi: 10.1016/j.biortech.2019.01.032 [33] TCHOFFOR P A, DAVIDSSON K O, THUNMAN H. Transformation and release of potassium, chlorine, and sulfur from wheat straw under conditions relevant to dual fluidized bed gasification[J]. Energy Fuels,2013,27:7510−7520. doi: 10.1021/ef401703a [34] SALEH S B, FLENSBORG J P, SHOULAIFAR T K, SÁROSSY Z, HANSEN B B, EGSGAARD H, DEMARTINI N, JENSEN P A, GLARBORG P, JOHANSEN K D. Release of chlorine and sulfur during biomass torrefaction and pyrolysis[J]. Energy Fuels,2014,28:3738−3746. doi: 10.1021/ef4021262 [35] 吴鹏, 余春江, 柏继松, 李廉明, 黄芳. 生物质热解氯的析出机制研究[J]. 中国电机工程学报,2013,33:75−81.WU Peng, YU Chun-jiang, BAI Ji-song, LI Lian-ming, HUANG Fang. Mechanism study of chlorine release during biomass pyrolysis[J]. Proc CSEE,2013,33:75−81. [36] JOHANSEN J M, JAKOBSEN J G, FRANDSEN F J, GLARBORG P. Release of K, Cl, and S during pyrolysis and combustion of high-chlorine biomass[J]. Energy Fuels,2011,25:4961−4971. doi: 10.1021/ef201098n [37] 邓剑, 罗永浩, 王贵军, 张睿智, 匡江红, 张云亮. 稻秆的烘焙预处理及其固体产物的气化反应性能[J]. 燃料化学学报,2011,39(1):26−32. doi: 10.3969/j.issn.0253-2409.2011.01.005DENG Jian, LUO Yong-hao, WANG Gui-jun, ZHANG Rui-zhi, KUANG Jiang-hong, ZHANG Yun-liang. Torrefaction pretreatment of straw and gasification reactivity of the solid product[J]. J Fuel Chem Technol,2011,39(1):26−32. doi: 10.3969/j.issn.0253-2409.2011.01.005 -

下载:

下载: