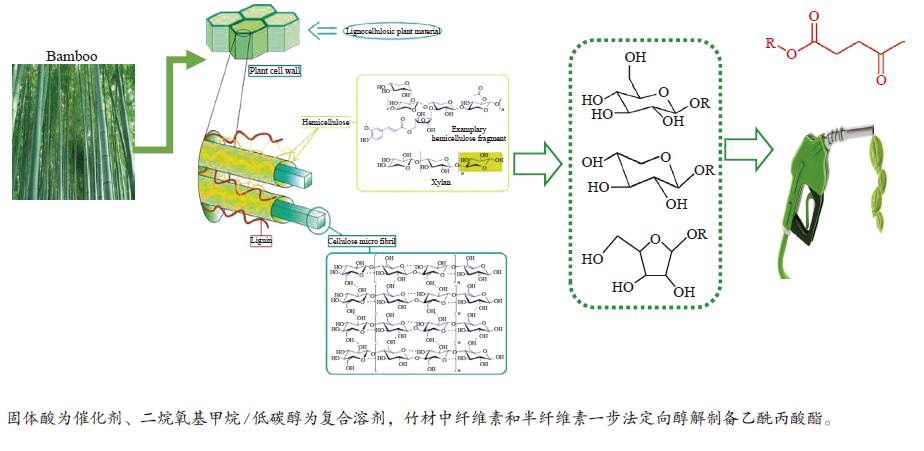

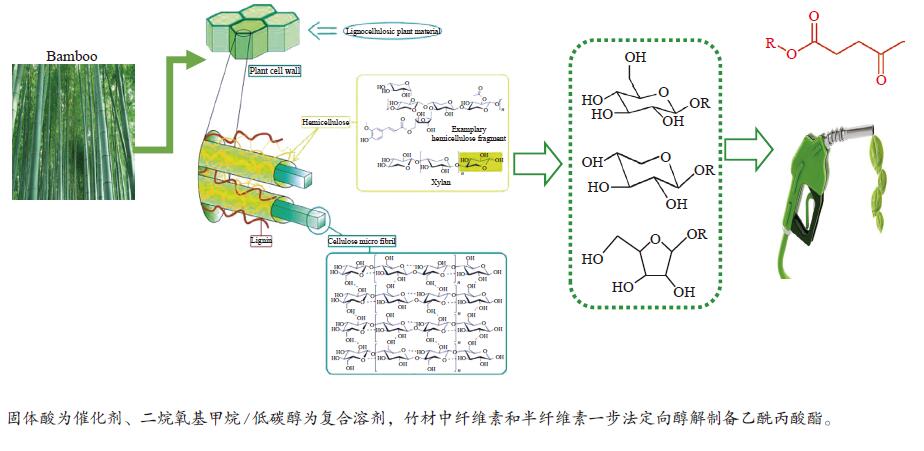

Study on preparation of methyl levulinate by directional alcoholysis of bamboo biomass

-

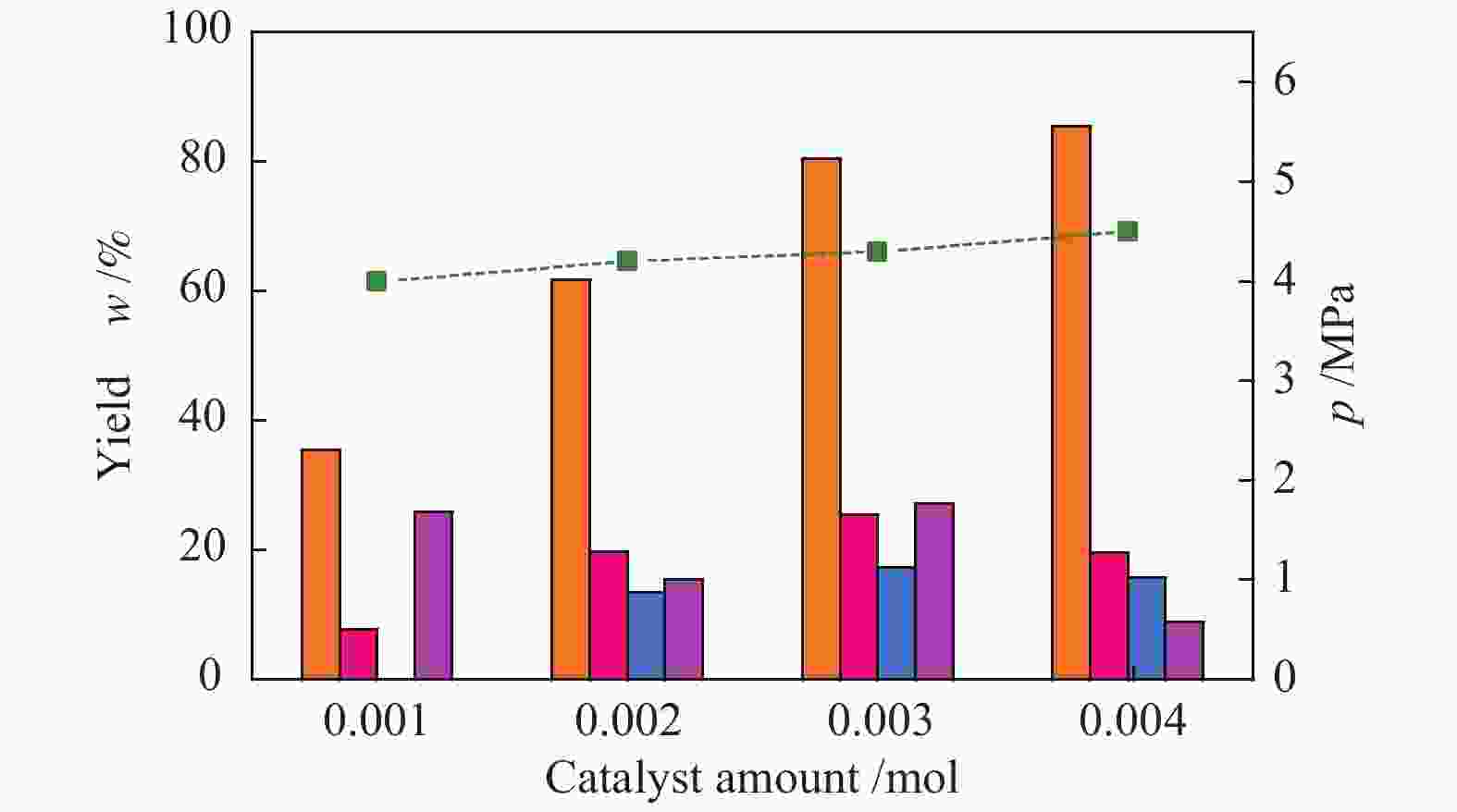

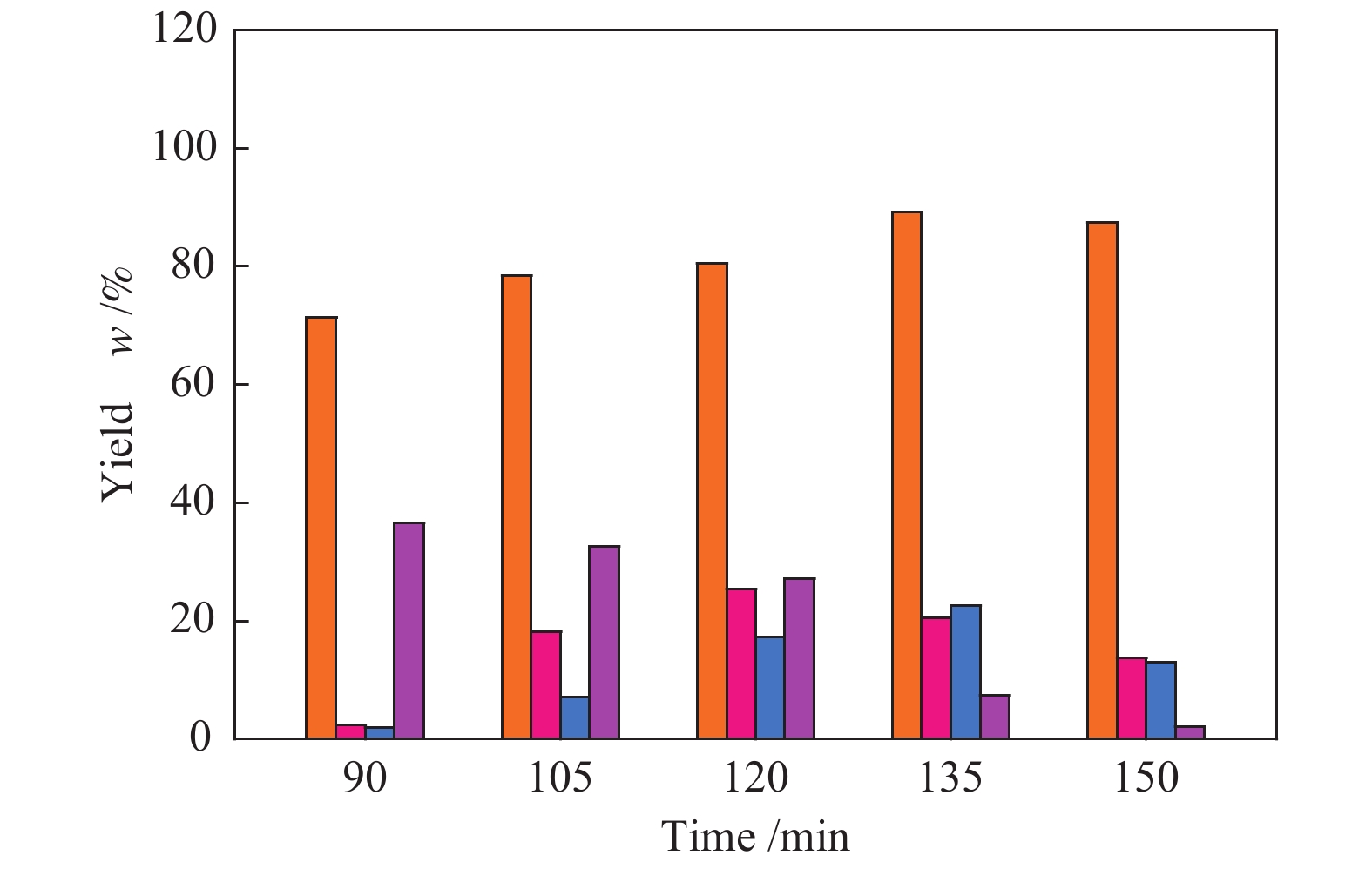

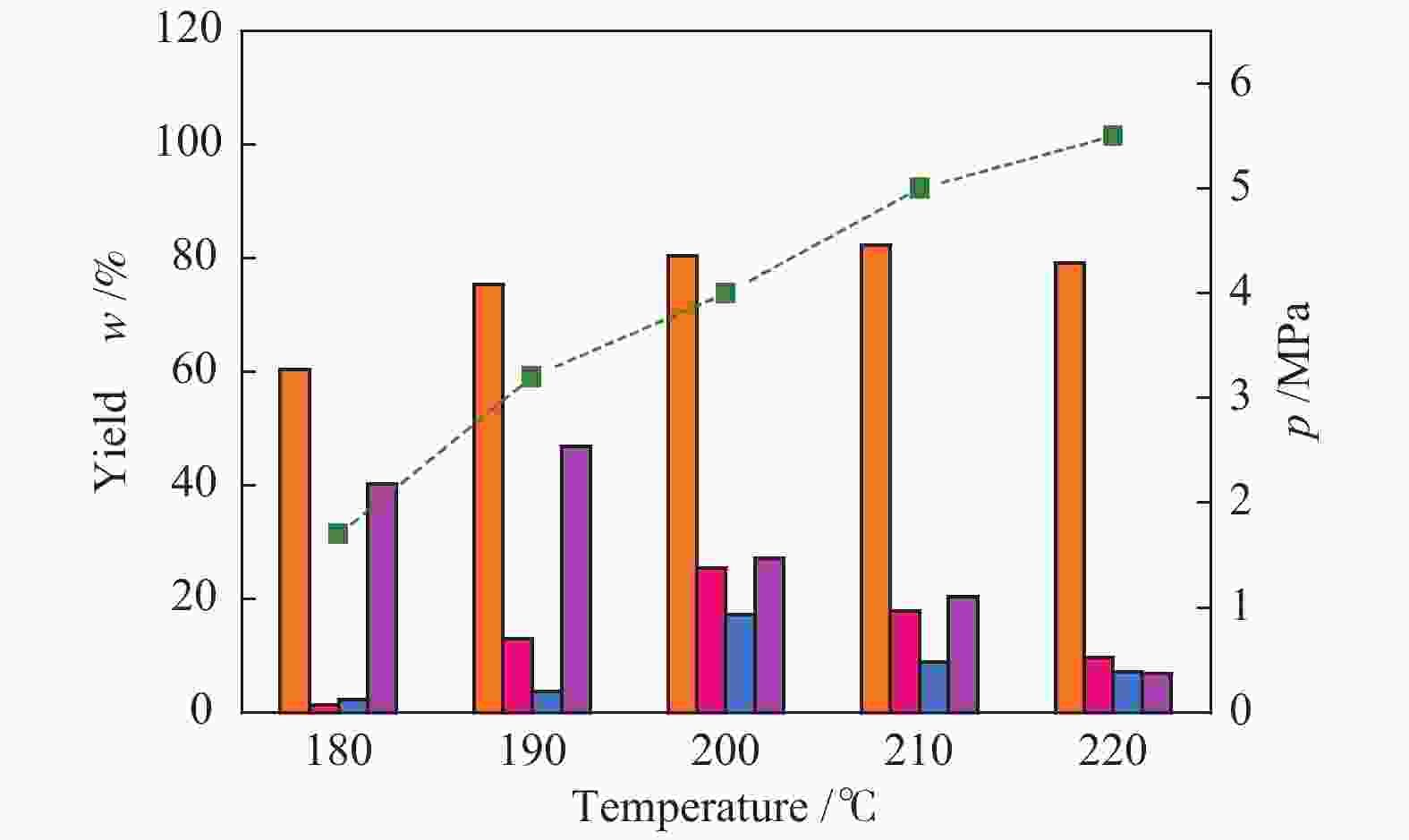

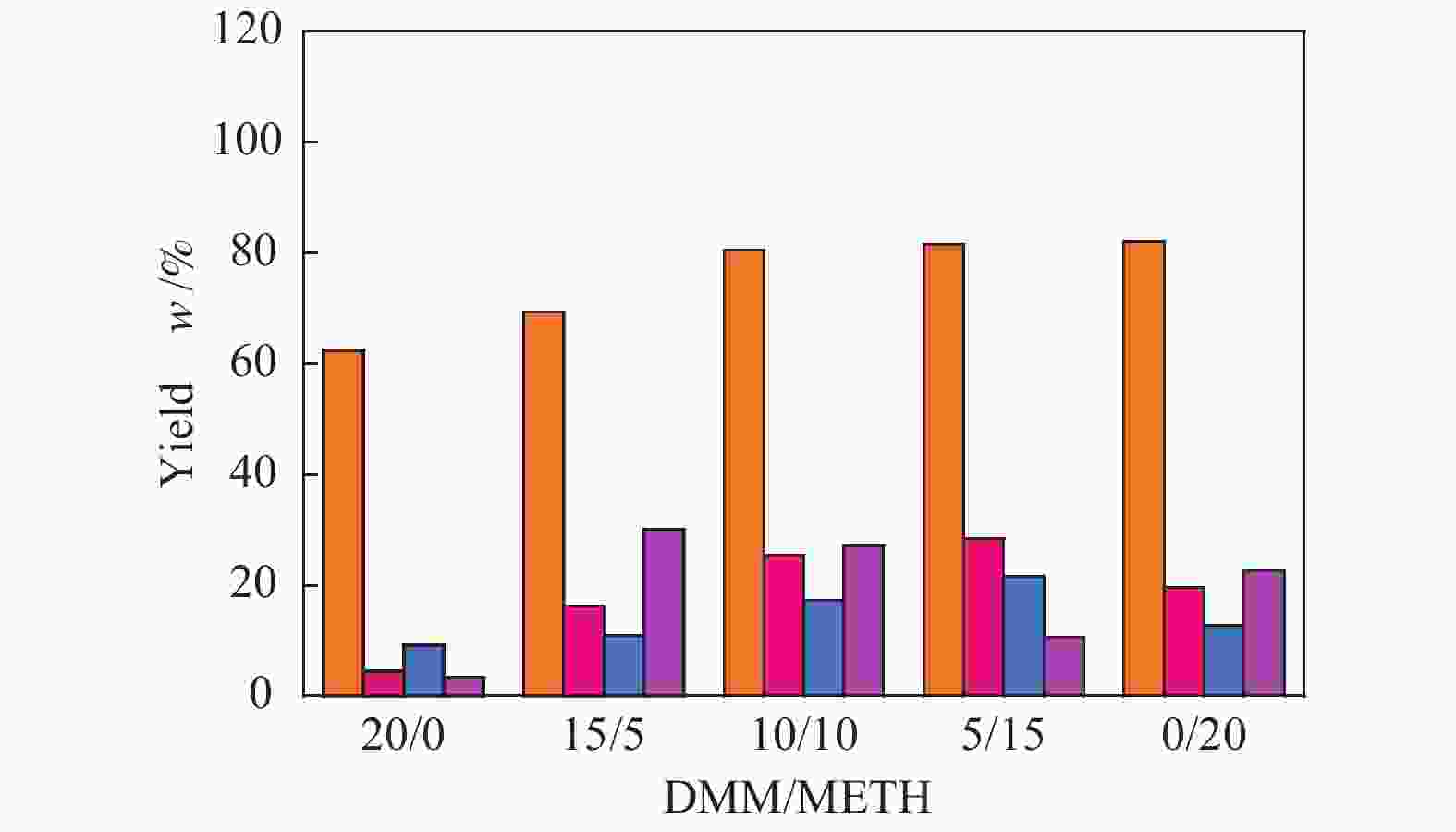

摘要: 以固体酸为催化剂、二烷氧基甲烷/低碳醇为复合溶剂,考察竹材中纤维素和半纤维素定向醇解的过程。通过调控反应条件(复合溶剂的组成和配比、固体酸催化剂的种类和用量、反应温度和时间),获得最佳反应条件(复合溶剂二甲氧基甲烷/甲醇质量比为5 g∶15 g,硅钨酸的用量为0.002 mol,120 min,200 ℃)下,竹材的转化率为81.53%,乙酰丙酸甲酯的得率为28.39%。同时,研究多种生物质模型化合物(葡萄糖、木糖、5-羟甲基糠醛、糠醛、戊聚糖和微晶纤维素)的转化过程,结合反应过程中间产物的检测结果,推断竹材中半纤维素、纤维素“一步法”定向醇解制备乙酰丙酸酯的过程。Abstract: The process of directional alcoholysis of cellulose and hemicellulose in bamboo was investigated using solid acid as catalyst and dialkoxymethane/lower alcohol as co-solvent. By adjusting the reaction conditions (composition and ratio of the co-solvent, the type and amount of solid acid catalyst, reaction temperature and time), the optimal reaction conditions were obtained (dimethoxymethane/methanol with a mass ratio of 5 g/15 g, the solid acid catalyst silicotungstic acid 0.002 mol, reaction time 120 min, and reaction temperature 200 ℃), the conversion of bamboo was 81.53%, and the yield of methyl levulinate was 28.39%. At the same time, the conversion process of a variety of biomass model compounds (xylose, glucose, furfural, 5-hydroxymethyl furfural, pentosan and microcrystalline cellulose) was studied in detail, then the fundamental mechanism of directional alcoholysis conversion of cellulose and hemicellulose to produce methyl levulinate was put forward according to the detection results of intermediate products in the reaction process.

-

Key words:

- biomass /

- directional alcoholysis /

- methyl levulinate /

- co-solvent

-

表 1 生物质原料的元素分析和成分分析

Table 1 Elemental and compositional properties of the waste lignocellulosic biomass

Materials Element analysis w/% Composition analysis w/% C H O N S ash extractives cellulose lignin holocellulose pentosan Bamboo 47.89 4.55 47.21 0.07 0.28 1.08 3.46 43.69 23.68 70.83 26.45 表 2 不同溶剂对竹材生物质原料定向转化过程的影响

Table 2 Effects of different solvents on directional conversion of cellulose and hemicellulose in bamboo

Solvent Conv./% Levulinates yield w/% Furfurals yield w/% Glycosides yield w/% Recovery yield w/% Pressure p/MPa Methanol 60.72 7.49 20.19 13.64 94.31 4.2 Dimethoxymethane 55.30 9.66 35.74 7.92 96.57 4.2 Dioxane 66.83 0.04 0.54 7.13 89.12 3.0 Dichloromethane 80.25 4.40 15.93 2.49 95.78 4.5 Dichloroethane 73.94 0.77 26.52 5.87 90.33 3.7 Diethoxymethane 59.93 5.64 38.81 6.20 91.24 2.8 Reaction conditions: bamboo 2 g, methanol 10 g, reagent 10 g, amberlyst 15 0.002 mol, sodium chloride 0.2 g, reaction temperature 200 ℃, reaction time 120 min 表 3 不同催化剂对竹材生物质原料定向转化过程的影响

Table 3 Effects of different electrophiles on directional conversion of cellulose and hemicellulose in bamboo

Catalyst Conv./% Levulinates yield w/% Furfurals yield w/% Glycosides yield w/% Pressure p/MPa Hydrochloric acid 41.31 6.16 − 15.73 4.0 Amberlyst 15 55.30 9.66 35.74 7.92 4.5 p-Toluenesulfonic acid 69.04 2.30 35.82 8.65 4.3 Silicotungstic acid 60.91 15.58 23.16 10.21 4.2 Aluminum chloride 40.67 2.81 24.93 5.78 4.2 Reaction conditions: bamboo 2 g, methanol 10 g, catalyst 0.002 mol, dimethoxymethane 10 g, sodium chloride 0.2 g, reaction conditions 200 ℃, 120 min 表 4 不同低碳醇对竹材生物质原料定向转化过程的影响

Table 4 Effects of different alcohol on directional conversion of cellulose and hemicellulose in bamboo

Alcohol Conv./% Levulinates yield w/% Furfurals yield w/% Glycosides yield w/% Recovery yield w/% Pressure p/MPa Methanol 60.91 15.58 23.16 10.21 95.30 4.2 Isopropanol 45.63 5.79 32.59 6.83 91.43 2.5 Ethanol 54.35 12.32 31.75 9.64 93.22 3.0 N-butanol 54.28 2.27 28.45 7.75 92.04 2.0 Reaction conditions: bamboo material 2 g, dimethoxymethane 10 g, lower alcohol 10 g, silicotungstic acid 0.002 mol, sodium chloride 0.2 g, 200 ℃, 120 min 表 5 氯化钠对竹材中纤维素和半纤维素定向转化过程的影响

Table 5 NaCl amount on directional conversion of cellulose and hemicellulose in bamboo

Additives Alcohol Conv./% Levulinates yield/% Furfurals yield/% Glycosides yield/% NaCl 0.2 g methanol 50.91 15.58 23.16 8.34 ethanol 54.52 12.32 31.75 6.20 No NaCl methanol 61.76 19.80 13.49 15.36 ethanol 64.05 15.40 11.10 19.88 Reaction conditions: bamboo 2 g, dimethoxymethane 10 g, alcohol 10 g, silicotungstic acid 0.002 mol, 200 ℃, 120 min 表 6 不同生物质碳水化合物的定向转化

Table 6 Directional conversion results of different biomass carbohydrates

Raw material Temp./℃ Conv./% Levulinates yield/% Furfurals yield/% Glycosides yield/% Furfural 160 84.77 13.20 16.29 − 180 92.27 54.47 8.56 − 5-Hydroxymethyl furfural 160 93.61 69.23 0.29 − 180 78.98 58.70 9.25 − Xylose 160 76.64 32.27 38.81 23.35 180 83.52 45.47 14.65 16.48 Glucose 160 96.10 46.85 0.79 3.90 180 88.85 54.54 2.54 11.15 Pentosan 180 71.95 24.92 10.37 29.84 200 84.13 36.81 33.05 10.27 Microcrystalline cellulose 180 71.86 18.63 25.26 19.78 200 87.72 25.54 29.39 25.61 Reaction conditions: raw materials 2 g, methanol 10 g, dimethoxymethane 10 g, catalyst 0.002 mol, reaction time 120 min -

[1] ZHANG T. Taking on all of the biomass for conversion[J]. Science,2020,367:1305−1306. doi: 10.1126/science.abb1463 [2] ZHANG Z, SONG J, HAN B. Catalytic transformation of lignocellulose into chemicals and fuel products in ionic liquids[J]. Chem Rev,2017,117(10):6834−6880. doi: 10.1021/acs.chemrev.6b00457 [3] ENNAERT T, VAN AELST J, DIJKMANS J, DE CLERCQ R, SCHUTYSER W, DUSSELIER M, SELS B. Potential and challenges of zeolite chemistry in the catalytic conversion of biomass[J]. Chem Soc Rev,2016,45(3):584−611. doi: 10.1039/C5CS00859J [4] CHEN Y W, LEE H V. Recent progress in homogeneous Lewis acid catalysts for the transformation of hemicellulose and cellulose into valuable chemicals, fuels, and nanocellulose[J]. Rev Chem Eng,2020,36(2):215−235. doi: 10.1515/revce-2017-0071 [5] HAN Y, YE L, GU X, ZHU P, LU X. Lignin-based solid acid catalyst for the conversion of cellulose to levulinic acid using γ-valerolactone as solvent[J]. Ind Crop Prod,2019,127:88−93. doi: 10.1016/j.indcrop.2018.10.058 [6] 杨佳鑫, 司传领, 刘坤, 刘华玉, 李晓云, 梁敏. 木质纤维生物质制备乙酰丙酸及其应用综述[J]. 林业工程学报,2020,5(5):21−27.YANG Jia-xin, SI Chuan-ling, LIU Kun, LIU Hua-yu, LI Xiao-yun, LIANG Min. Production of levulinic acid from lignocellulosic biomass and application[J]. J Forestry Eng,2020,5(5):21−27. [7] FENG J, ZHANG L, JIANG J, HSE C, SHUPE T, PAN H. Directional synergistic conversion of lignocellulosic biomass with matching-solvents for added-value chemicals[J]. Green Chem,2019,21(18):4951−4957. doi: 10.1039/C9GC02365H [8] ZHU S, GUO J, WANG X, WANG J, FAN W. Alcoholysis: a promising technology for conversion of lignocellulose and platform chemicals[J]. ChemSusChem,2017,10(12):2547−2559. doi: 10.1002/cssc.201700597 [9] MORAIS A, MATUCHAKI M, ANDREAUS J, BOGEL-LUKASIK R. A green and efficient approach to selective conversion of xylose and biomass hemicellulose into furfural in aqueous media using high-pressure CO2 as a sustainable catalyst[J]. Green Chem,2016,18(10):2985−2994. doi: 10.1039/C6GC00043F [10] 孙娇, 王娅莉, 解新安, 黎巍, 李璐, 李雁, 樊荻, 魏星. 纤维素在亚/超临界甲醇中液化条件对主要化合物产物的影响[J]. 燃料化学学报,2017,45:660−668. doi: 10.3969/j.issn.0253-2409.2017.06.003SUN Jiao, WANG Ya-li, XIE Xin-an, LI Wei, LI Lu, LI Yan, FAN Di, WEI Xing. Effect of liquefaction parameters of cornstalk cellulose in sub-supercritical methanol on dominant chemical products[J]. J Fuel Chem Technol,2017,45:660−668. doi: 10.3969/j.issn.0253-2409.2017.06.003 [11] 于杰, 王景芸, 王震, 周明东, 王海彦. 复合分子筛的合成及其在纤维素水解反应中的应用[J]. 燃料化学学报,2018,46(4):419−426. doi: 10.3969/j.issn.0253-2409.2018.04.007YU Jie, WANG Jing-yun, WANG Zhen, ZHOU Ming-dong, WANG Hai-yan. Synthesis of composite zeolites and their performance in hydrolysis of cellulose[J]. J Fuel Chem Technol,2018,46(4):419−426. doi: 10.3969/j.issn.0253-2409.2018.04.007 [12] HEDA J, NPPHADKAR P, BOKADE V. Efficient synergetic combination of H-USY and SnO2 for direct conversion of glucose into ethyl levulinate (biofuel additive)[J]. Energy Fuels,2019,33(3):2319−2327. doi: 10.1021/acs.EnergyFuels.8b04395 [13] HUANGY B, YANG T, LIN Y T, PAN H. Facile and high-yield synthesis of methyl levulinate from cellulose[J]. Green Chem,2018,20(6):1323−1334. doi: 10.1039/C7GC02883K [14] LAPPALAINEN K, DONG Y. Simultaneous production of furfural and levulinic acid from pine sawdust via acid-catalysed mechanical depolymerization and microwave irradiation[J]. Biomass Bioenergy,2019,123:159−165. doi: 10.1016/j.biombioe.2019.02.017 [15] MIKA L, CSEFALVAY E, NEMETH A. Catalytic conversion of carbohydrates to initial platform chemicals: chemistry and sustainability[J]. Chem Rev,2018,118(2):505−613. doi: 10.1021/acs.chemrev.7b00395 [16] LI X, LU X, NIE S, LIANG M, YU Z, DUAN B, SI C Efficient catalytic production of biomass-derived levulinic acid over phosphotungstic acid in deep eutectic solvent[J]. Ind Crop Prod, 2020, 145, 112−154. [17] NEGAHDAR L, DELIDOVICH I, PALKOVITS R. Aqueous-phase hydrolysis of cellulose and hemicelluloses over molecular acidic catalysts: Insights into the kinetics and reaction mechanism[J]. Appl Catal B: Environ,2016,184:285−298. doi: 10.1016/j.apcatb.2015.11.039 [18] FENG S, WEI R, LEITCH M, XU C. Comparative study on lignocellulose liquefaction in water, ethanol, and water/ethanol mixture: Roles of ethanol and water[J]. Energy,2018,155:234−241. doi: 10.1016/j.energy.2018.05.023 [19] DU H, MA X, YAN P, JIANG M, ZHAO Z, ZHANG Z C. Catalytic furfural hydrogenation to furfuryl alcohol over Cu/SiO2 catalysts: A comparative study of the preparation methods[J]. Fuel Process Technol,2019,193:221−231. doi: 10.1016/j.fuproc.2019.05.003 [20] SWEYGERS N, ALEWATERS N, DEWIL R, APPELS L. Microwave effects in the dilute acid hydrolysis of cellulose to 5-hydroxymethylfurfural[J]. Sci Rep-UK,2018,8(1):1−11. [21] FENG J, TONG L, ZHU Y, JIANG J, HSE C, PAN H. Efficient utilization and conversion of whole components in waste biomass with one-pot-oriented liquefaction[J]. ACS Sustainable Chem Eng,2019,7:18142−18152. doi: 10.1021/acssuschemeng.9b05272 -

下载:

下载: