Microalgae co-pyrolysis with waste plastics to prepare low-O/N and hydrocarbon-rich liquid oil

-

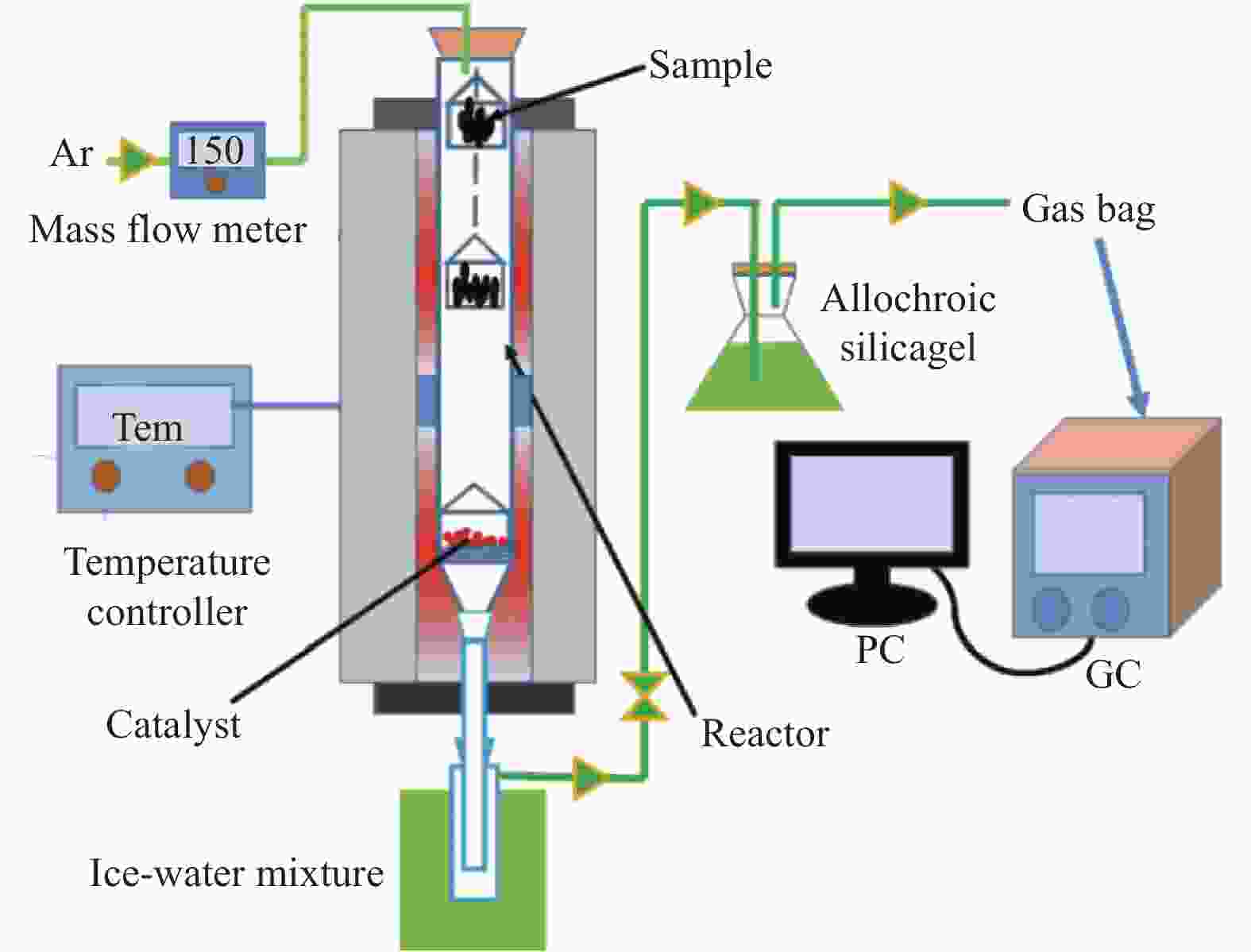

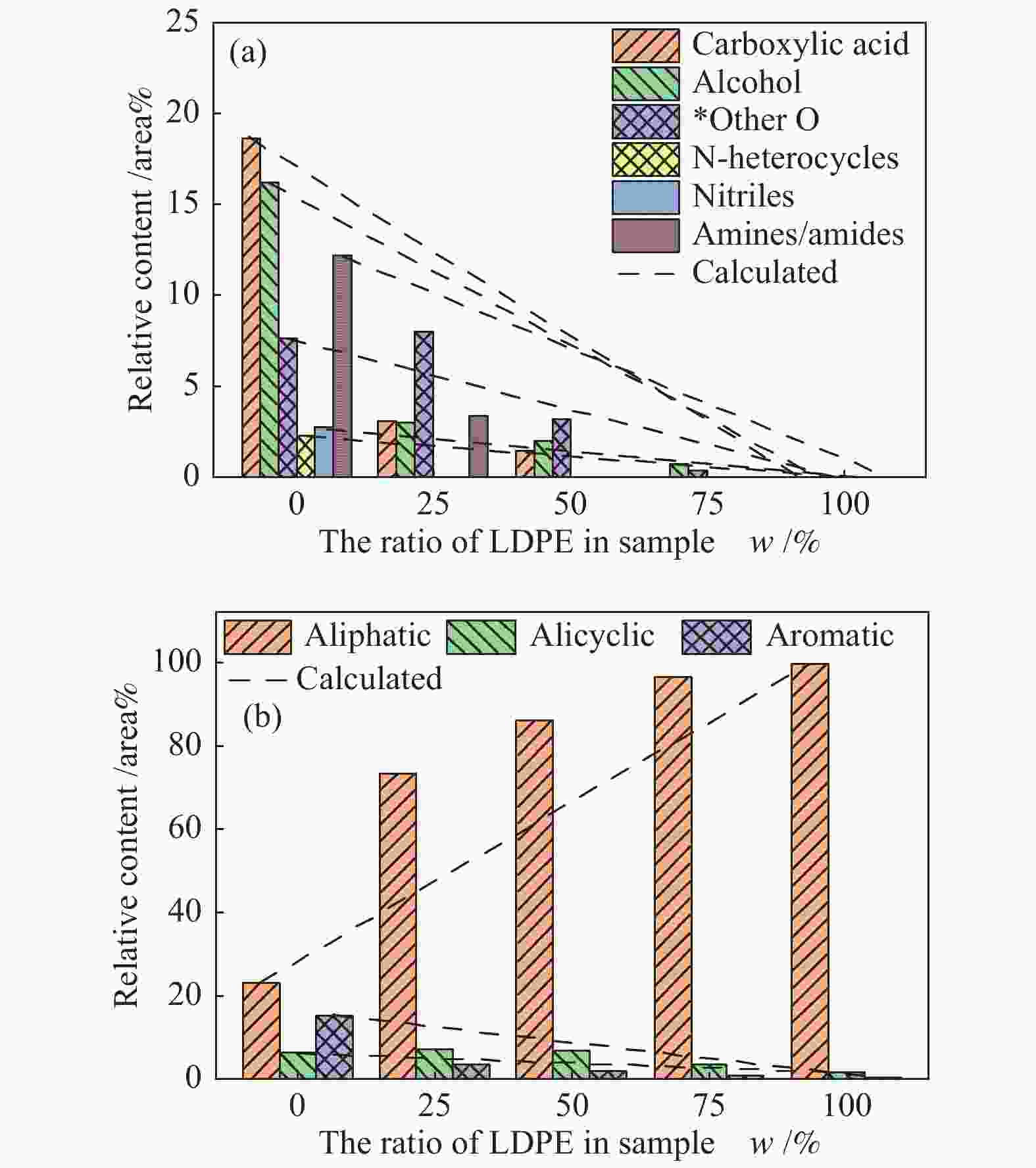

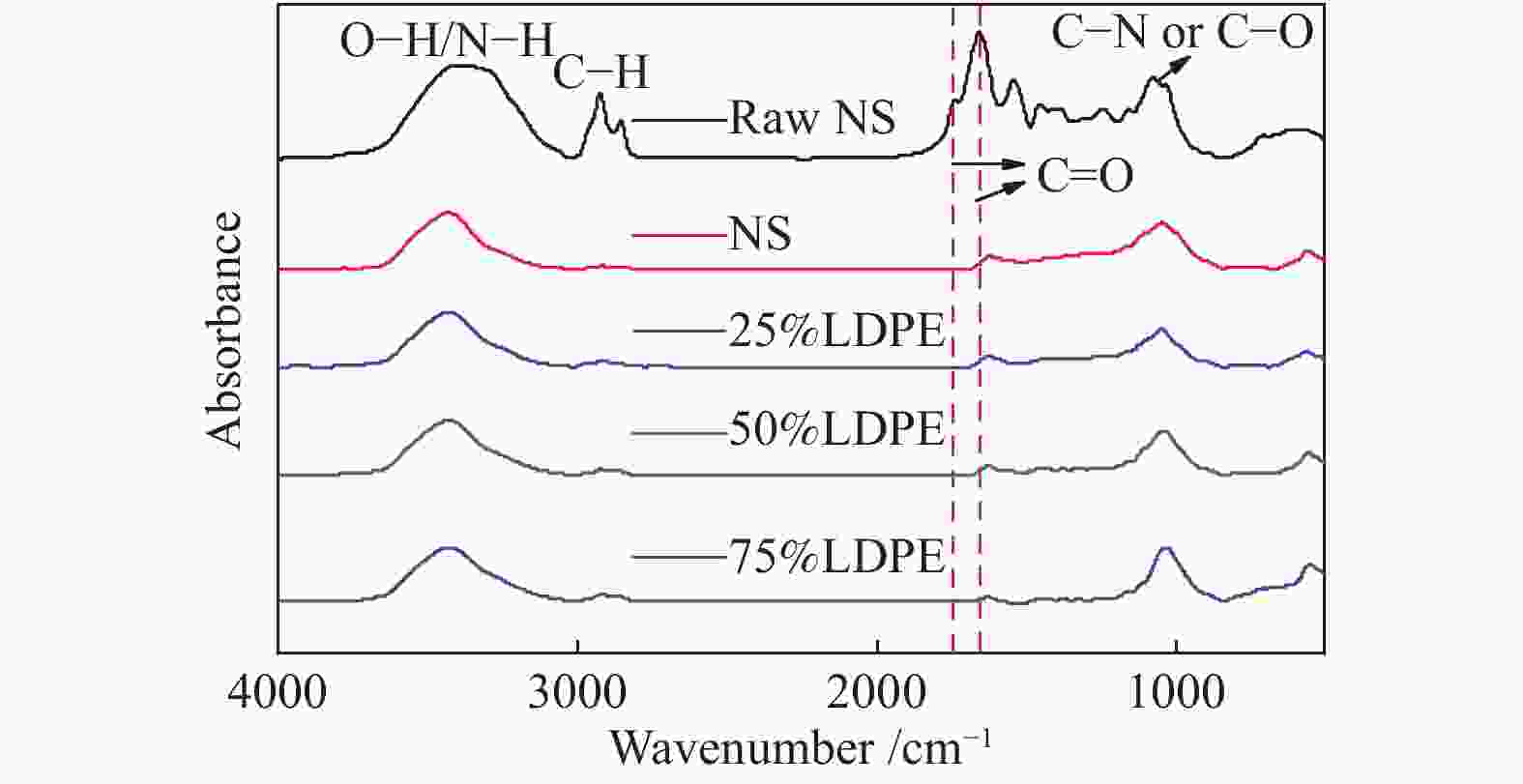

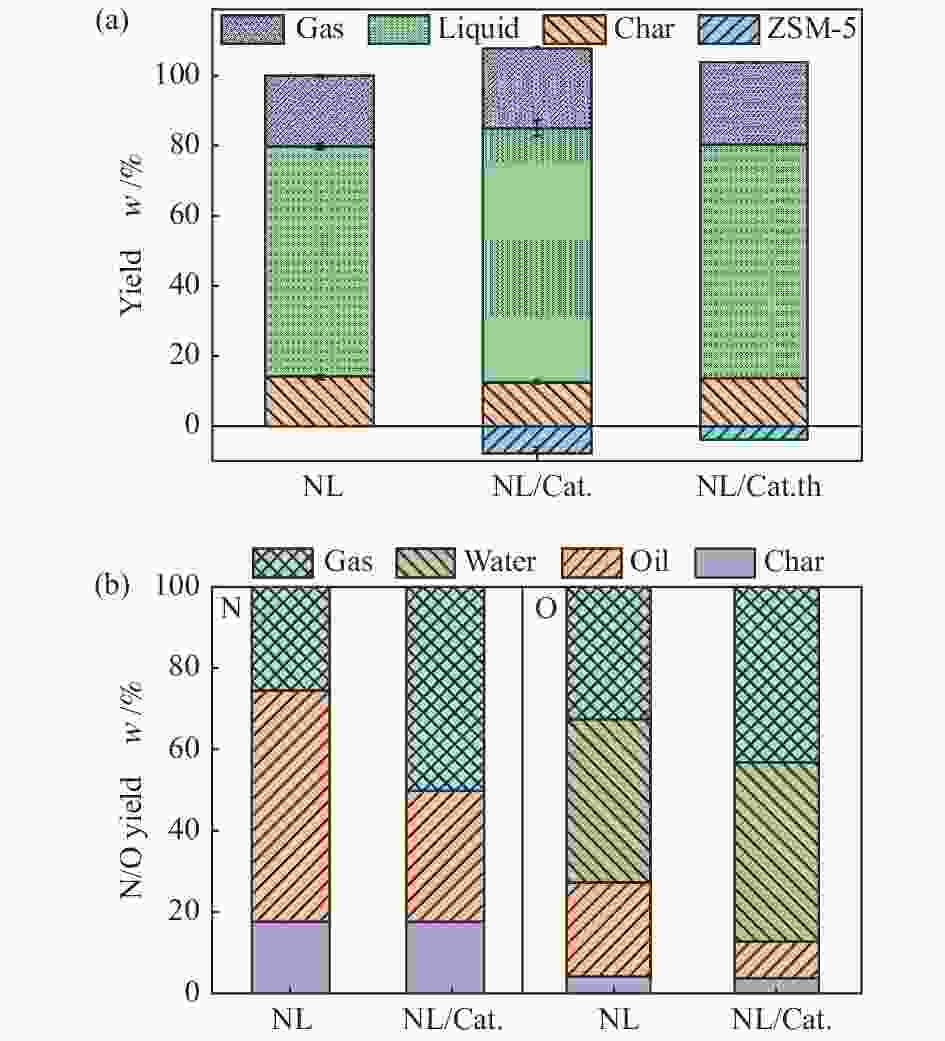

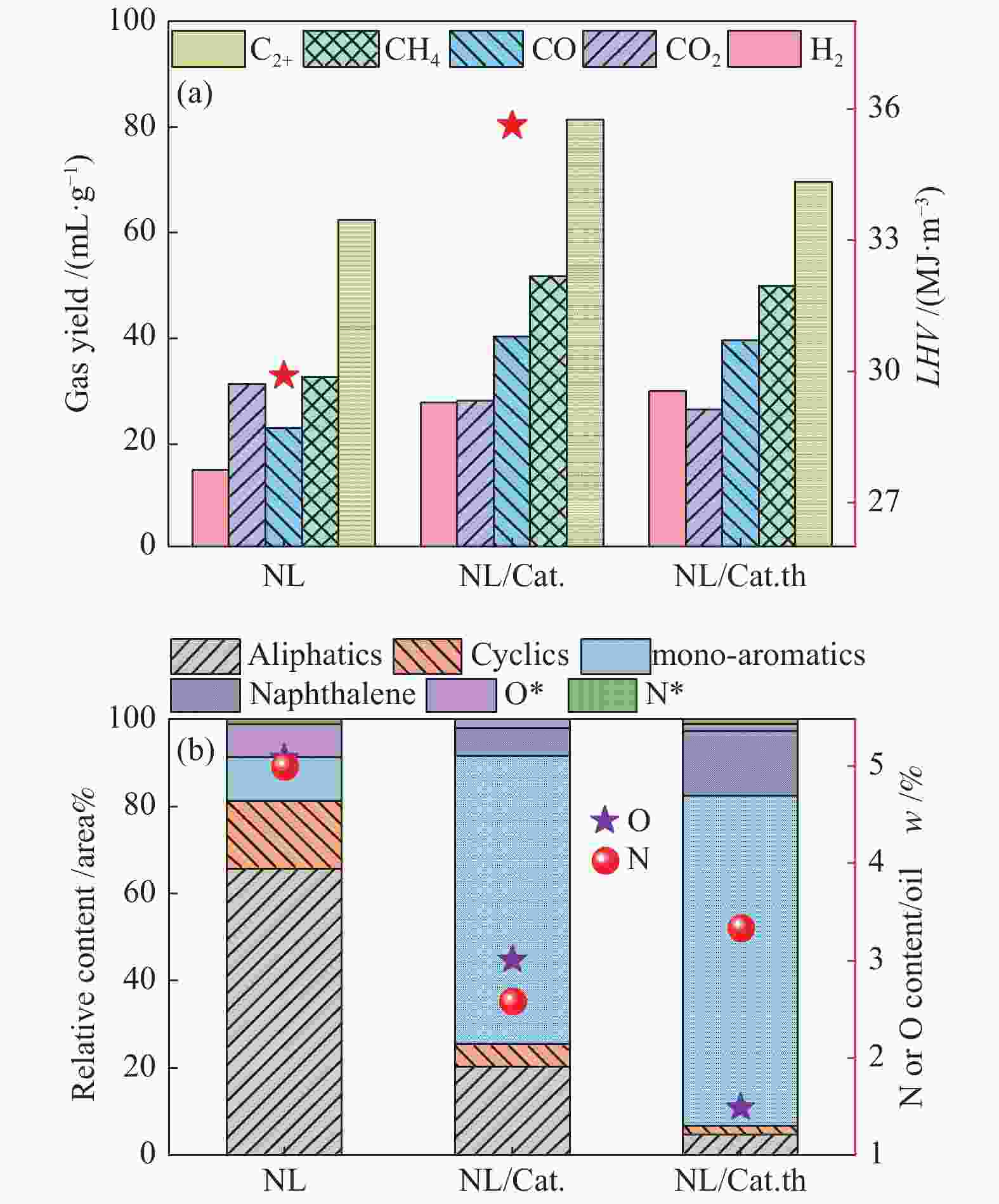

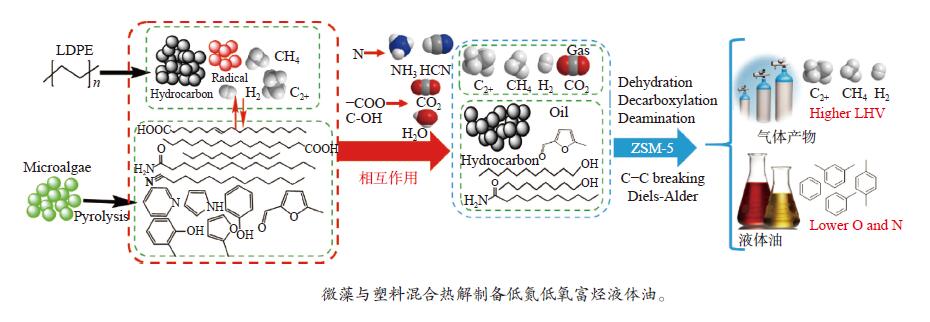

摘要: 为了减少油中氮氧化合物,提高微藻生物油品质,本研究在固定床上开展了微拟球藻(NS)和聚乙烯塑料(LDPE)的混合热解/催化特性,探讨了O和N在热解气、液、固相的分布,并以此探讨了微藻与LDPE之间的交互作用以及催化剂的加入对混合热解的影响。研究发现,混合热解能有效抑制O和N向油中转移,促进微藻中O转变为H2O,N向气体产物转移。此外塑料添加明显减少了油中羧酸、酰胺和含氮杂环等含氧/氮化合物,提高了脂肪烃含量,同时有效促进碳氢气体的形成,并对CO和H2也有一定的协同作用,特别是在25%LDPE时协同效应最强。同时ZSM-5能促进碳氢气体形成,提高气体产物的热值(35.6 MJ/m3),并进一步减少油中含氮化合物,促进N向气体转移,O向气体和H2O中转移,从而使油中O、N含量明显降低;此外混合催化热解能在一定程度上抑制芳烃的形成,提高脂肪烃选择性。Abstract: In order to reduce N-/O-compounds content and improve the quality of microalgae bio-oil, the co-pyrolysis/catalytic of Nannochloropsis sp. (NS) and polyethylene (LDPE) were studied in a fixed bed, and the distribution of N and O was discussed, as well as the interaction between microalgae and LDPE and the influence of the addition of catalyst. It was found that co-pyrolysis could effectively inhibit the transformation of O and N to oil, and promote the O release as H2O and N conversion to gas products. In addition, plastic adding significantly reduced the content of O-/N-compounds in oil, such as carboxylic acid, amide and N-heterocyclic, and increased the aliphatics content. Besides, it effectively promoted the formation of hydrocarbon gas, and showed a certain synergistic effect on CO and H2, and the interaction reached the maximum at 25%LDPE. Furthermore, ZSM-5 could promote the formation of hydrocarbon gas, increase the LHV of gas products (35.6 MJ/Nm3), and further reduce the nitrogen compounds in the oil, while the N in microalgae transferred to gas, and O converted to gas and H2O, which resulted in the further reduction of the O and N contents in the oil. Moreover, catalytic co-pyrolysis could inhibit the formation of aromatic hydrocarbons to a certain extent and improve the selectivity of aliphatic hydrocarbons.

-

Key words:

- co-pyrolysis/catalysis /

- microalgae /

- LDPE /

- interaction /

- deoxygenation and denitrification

-

表 1 样品的工业分析、元素分析和微藻的生化组成

Table 1 Proximate, ultimate analysis of samples and biochemical constituents of microalgae

Sample Ultimate analysis wad/% Proximate analysis wad/% Biochemical constituents wad/% C H N S O* M V FC A lipid protein carbohydrate* NS 50.61 7.31 6.68 0.64 24.8 4.01 79.61 10.38 6 30 40.8 19.2 LDPE 84.32 15.47 − 0.21 − − 100 − − * : by difference; –: not detected -

[1] 唐晓莲. 秸秆转化成生物质燃料的应用技术研究[J]. 能源化工,2021,42(2):14−17. doi: 10.3969/j.issn.1006-7906.2021.02.004TANG Xiao-lian. Study on appliciation of straw conversion to biomass fuel[J]. Energy Chem Ind,2021,42(2):14−17. doi: 10.3969/j.issn.1006-7906.2021.02.004 [2] ROSS, A B, BILLER P, KUBACKI M L, LI H, LEA–LANGTON A, JONES J M. Hydrothermal processing of microalgae using alkali and organic acids[J]. Fuel,2010,89(9):2234−2243. doi: 10.1016/j.fuel.2010.01.025 [3] LI F H, SRIKANTH C S, SANKAR B. A review on catalytic pyrolysis of microalgae to high-quality bio-oil with low oxygeneous and nitrogenous compounds[J]. Renewable Sustainable Energy Rev,2019,108:481−497. doi: 10.1016/j.rser.2019.03.026 [4] BACH Q V, CHEN W H, Pyrolysis characteristics and kinetics of microalgae via thermogravimetric analysis (TGA): A state-of-the-art review[J]. Bioresour Technol, 2017, 246: 88–100. [5] AYSU T M, MAROTO-VALER M M, SANNA A. Ceria promoted deoxygenation and denitrogenation of Thalassiosira weissflogii and its model compounds by catalytic in-situ pyrolysis[J]. Bioresour Technol,2016,208:140−148. doi: 10.1016/j.biortech.2016.02.050 [6] AZIZI K, MOSTAFA K M, HAMED A N. A review on bio-fuel production from microalgal biomass by using pyrolysis method[J]. Renewable Sustainable Energy Rev,2018,82:3046−3059. doi: 10.1016/j.rser.2017.10.033 [7] CAMPANELLA A, MICHAEL P H. Fast pyrolysis of microalgae in a falling solids reactor: Effects of process variables and zeolite catalysts[J]. Biomass Bioenergy,2012,46:218−232. doi: 10.1016/j.biombioe.2012.08.023 [8] SUNG W K, BON S K, DONG H L. A comparative study of bio-oils from pyrolysis of microalgae and oil seed waste in a fluidized bed[J]. Bioresour Technol,2014,162:96−102. doi: 10.1016/j.biortech.2014.03.136 [9] 毛俏婷, 胡俊豪, 赵雨佳, 闫舒航, 杨海平, 陈汉平, 生物质和废塑料混合热解协同特性研究[J]. 燃料化学学报, 2020, 48(3): 286–292.MAO Qiao-ting, HU Jun-hao, ZHAO Yu-jia, YAN Shu-hang, YANG Hai-ping, CHEN Han-ping. Synergistic effect during biomass and waste plastics co-pyrolysis[J]. J Fuel Chem Technol, 2020, 48(3): 286–292. [10] RANJEET K M, KAUSTUBHA M. Co-pyrolysis of waste biomass and waste plastics (polystyrene and waste nitrile gloves) into renewable fuel and value-added chemicals[J]. Carbon Resour Convers,2020,3:145−155. doi: 10.1016/j.crcon.2020.11.001 [11] GHORBANNEZHAD P, SUNKYU P, JUDE A O. Co-pyrolysis of biomass and plastic waste over zeolite- and sodium-based catalysts for enhanced yields of hydrocarbon products[J]. Waste Manage,2020,102:909−918. doi: 10.1016/j.wasman.2019.12.006 [12] EYLEM O, BASAK B U, AYSE E P. Bio-oil production via co-pyrolysis of almond shell as biomass and high density polyethylene[J]. Energy Conv Manag,2014,78:704−710. doi: 10.1016/j.enconman.2013.11.022 [13] WANG Y Z, LI Y J, ZHANG C X, YANG L G, FAN X X, CHU L Z. A study on co-pyrolysis mechanisms of biomass and polyethylene via ReaxFF molecular dynamic simulation and density functional theory[J]. Process Saf Environ Protect,2021,150:22−35. doi: 10.1016/j.psep.2021.04.002 [14] CHEN R J, ZHANG S Y, YANG X X, LI G H, ZHOU H, LI Q H, ZHANG Y G. Thermal behaviour and kinetic study of co-pyrolysis of microalgae with different plastics[J]. Waste Manag,2021,126:331−339. doi: 10.1016/j.wasman.2021.03.001 [15] PAN P, HU C W, YANG W Y, LI Y S, DONG L L, ZHU L F, TONG D M, QING R W, FAN Y. The direct pyrolysis and catalytic pyrolysis of Nannochloropsis sp. residue for renewable bio-oils[J]. Bioresour Technol,2010,101(12):4593−4599. doi: 10.1016/j.biortech.2010.01.070 [16] DU Z Y, HU B, MA X C, CHENG Y L, LIU Y H, LIN X Y, WAN Y Q, LEI H W, CHEN P, ROGER R. Catalytic pyrolysis of microalgae and their three major components: Carbohydrates, proteins, and lipids[J]. Bioresour Technol,2013,130:777−782. doi: 10.1016/j.biortech.2012.12.115 [17] RAHMAN M H, PRAKASHBHAI R B, ARPITA S, VIVEK P, SUSHIL A. Thermo-catalytic co-pyrolysis of biomass and high-density polyethylene for improving the yield and quality of pyrolysis liquid[J]. Energy,2021,225:120231. [18] XU S N, CAO B, UZOEJINWA B B, ODEY E A, WANG S, SHANG H, LI C H, HU Y M, WANG Q, NWAKAIRE J N. Synergistic effects of catalytic co-pyrolysis of macroalgae with waste plastics[J]. Process Saf Environ Protect,2020,137:34−48. doi: 10.1016/j.psep.2020.02.001 [19] QI P Y, CHANG G Z, WANG H C, ZHANG X L, GUO Q J. Production of aromatic hydrocarbons by catalytic co–pyrolysis of microalgae and polypropylene using HZSM-5[J]. J Anal Appl Pyrolysis,2018,136:178−185. doi: 10.1016/j.jaap.2018.10.007 [20] AUGUSTINA E, DOAN P M, DAMIEN L, CARLOS P, PATRICK S, ANGE N. Co–pyrolysis of wood and plastics: Influence of plastic type and content on product yield, gas composition and quality[J]. Fuel,2018,231:110−117. doi: 10.1016/j.fuel.2018.04.140 [21] XU X W, TU R, SUN Y, LI Z Y, JIANG E. Influence of biomass pretreatment on upgrading of bio-oil: Comparison of dry and hydrothermal torrefaction[J]. Bioresour Technol,2018,262:261−270. doi: 10.1016/j.biortech.2018.04.037 [22] TANG Z Y, CHEN W, HU J H, LI S Q, CHEN Y Q, YANG H P, CHEN H P. Co-pyrolysis of microalgae with low-density polyethylene (LDPE) for deoxygenation and denitrification[J]. Bioresour Technol,2020,311:123502. doi: 10.1016/j.biortech.2020.123502 [23] CHEN W, CHEN Y Q, YANG H P, XIA M W, LI K X, CHEN X, CHEN H P. Co-pyrolysis of lignocellulosic biomass and microalgae: Products characteristics and interaction effect[J]. Bioresour Technol,2017,245:860−868. doi: 10.1016/j.biortech.2017.09.022 [24] LI J, LIU Y W, SHI J Y, WANG Z Y, HU L, YANG X, WANG C X. The investigation of thermal decomposition pathways of phenylalanine and tyrosine by TG-FTIR[J]. Thermochimica Acta,2008,467(1):20−29. [25] DEBIAGI P E A, TRINCHERA M, FRASSOLDATI A, FARAVELLI T, RAVIKRISHNAN V, ELISEO R. Algae characterization and multistep pyrolysis mechanism[J]. J Anal Appl Pyrolysis,2017,128:423−436. doi: 10.1016/j.jaap.2017.08.007 [26] WANG J J, MA X Q, YU Z S, PENG X W, LIN Y S. Studies on thermal decomposition behaviors of demineralized low-lipid microalgae by TG-FTIR[J]. Thermochim Acta,2018,660:101−109. doi: 10.1016/j.tca.2018.01.001 [27] CHEN W, CHEN Y Q, YANG H P, LI K X, CHEN X, CHEN H P. Investigation on biomass nitrogen-enriched pyrolysis: Influence of temperature[J]. Bioresour Technol, 2018, 249(Supplement C): 247–253. [28] WANG K G, ROBERT C B. Catalytic pyrolysis of microalgae for production of aromatics and ammonia[J]. Green Chem,2013,15(3):675. doi: 10.1039/c3gc00031a -

下载:

下载: