Study on structure and gasification reactivity of lignite char from different pyrolysis reactor

-

摘要: 本研究以褐煤为样品,流化床和下落床为反应器在900−1100 ℃条件下热解制备了系列煤焦,通过X射线衍射仪(XRD)、Raman光谱仪、静态物理吸附仪及固定床反应器研究了煤焦物化结构及CO2气化反应性。结果表明,流化床和下落床反应器中热解煤焦的气化反应性主要取决于其化学结构。两种反应器中,随热解温度升高,煤焦缩聚反应加深,微晶尺寸(芳香片层堆积高度Lc、平均直径La)增加、大环与小环比

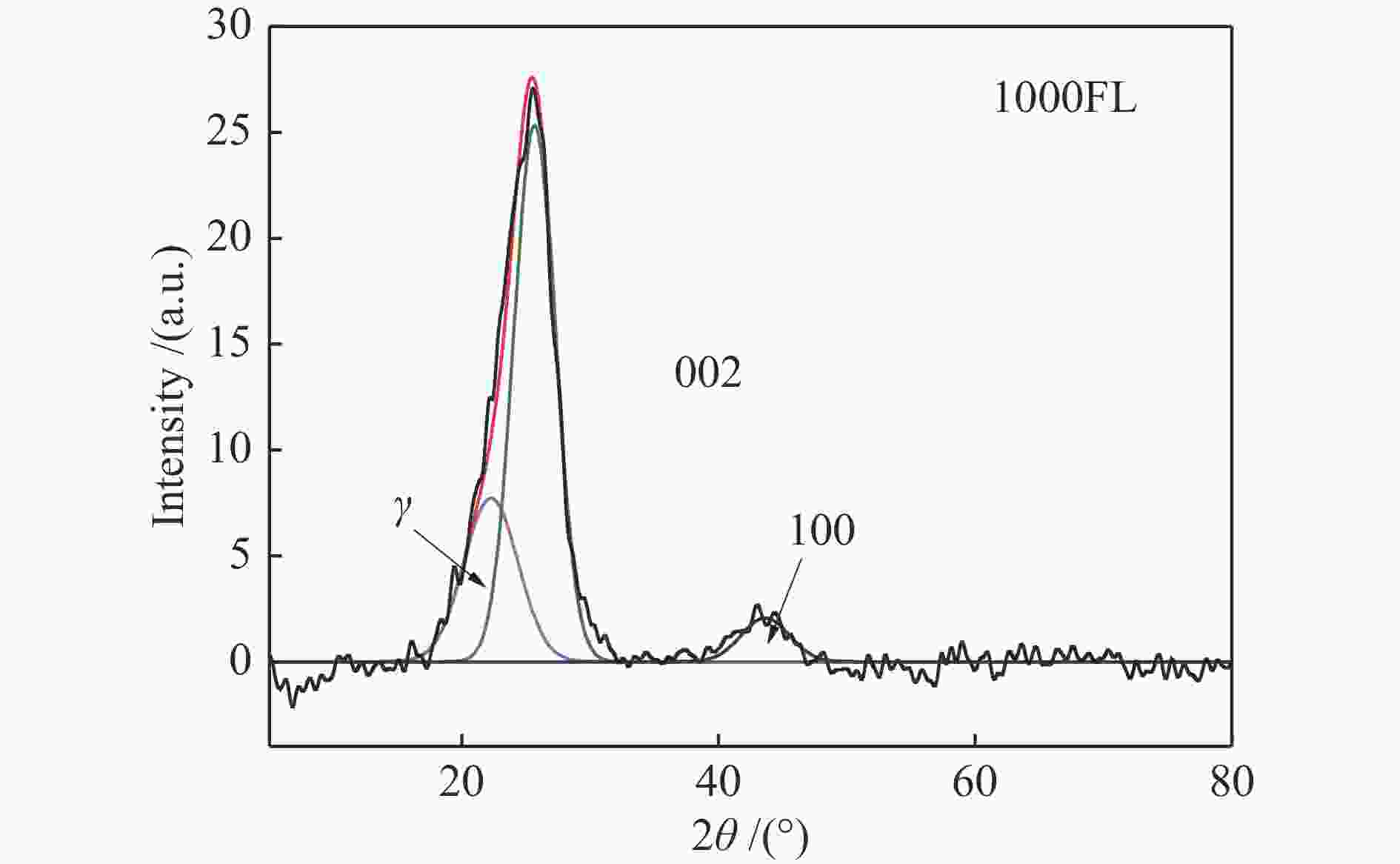

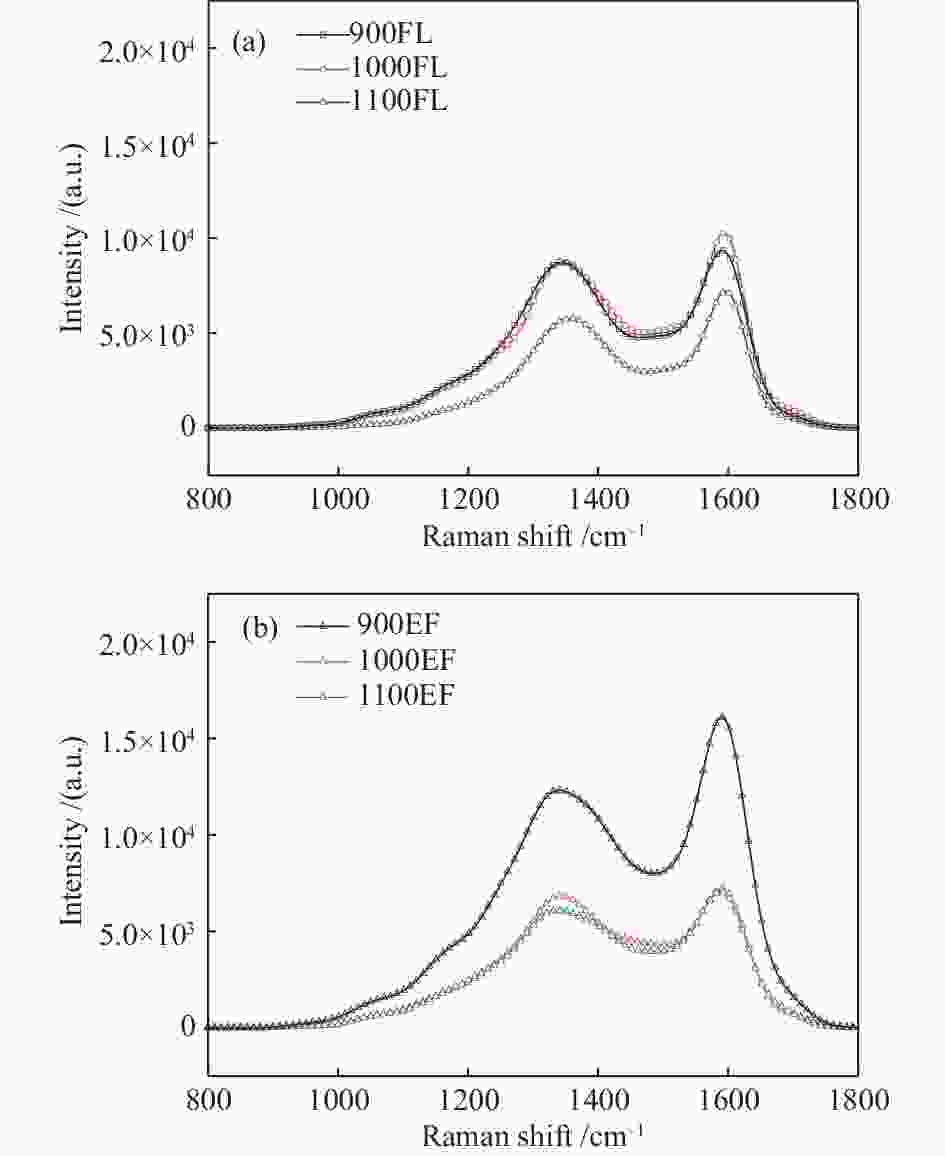

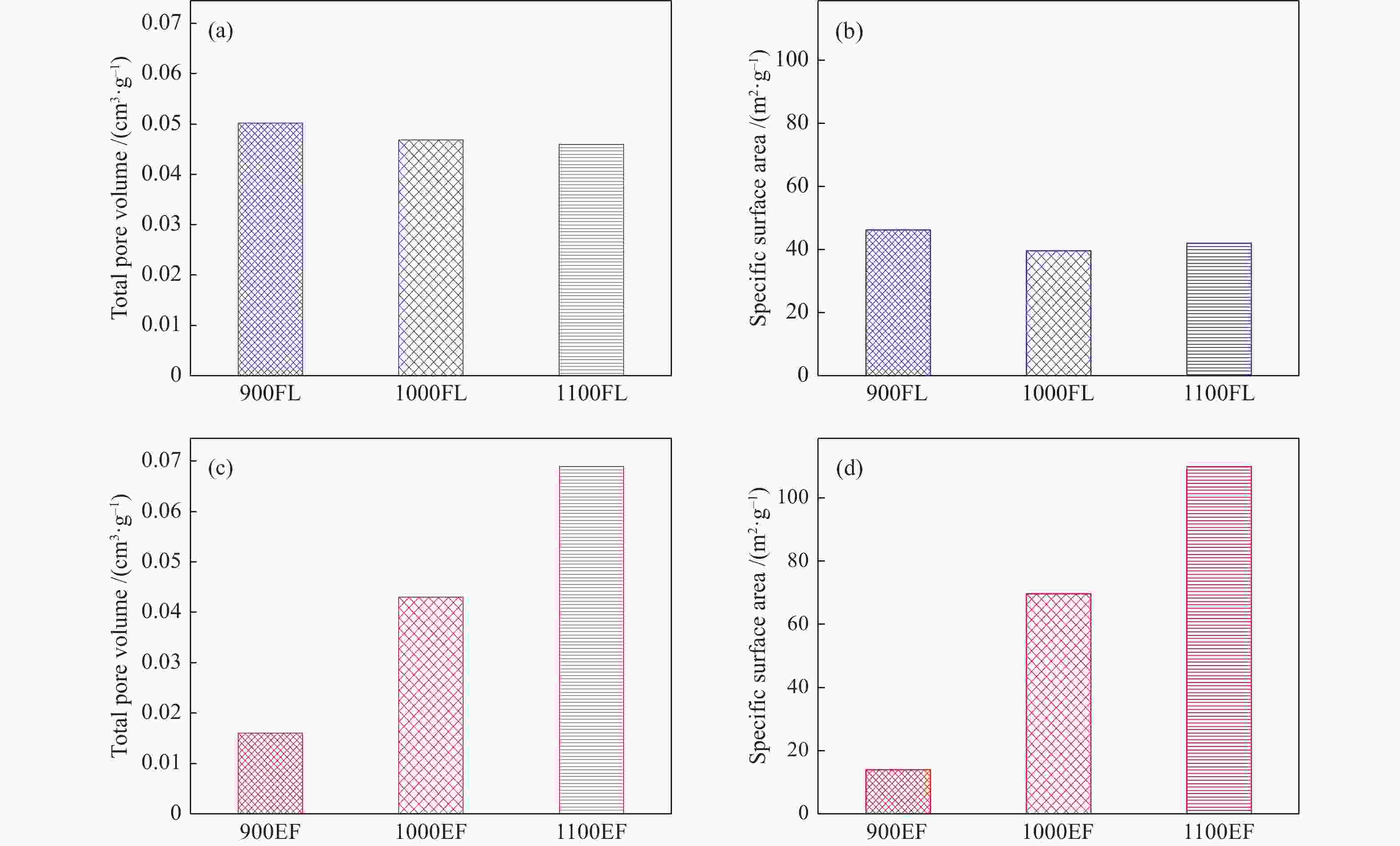

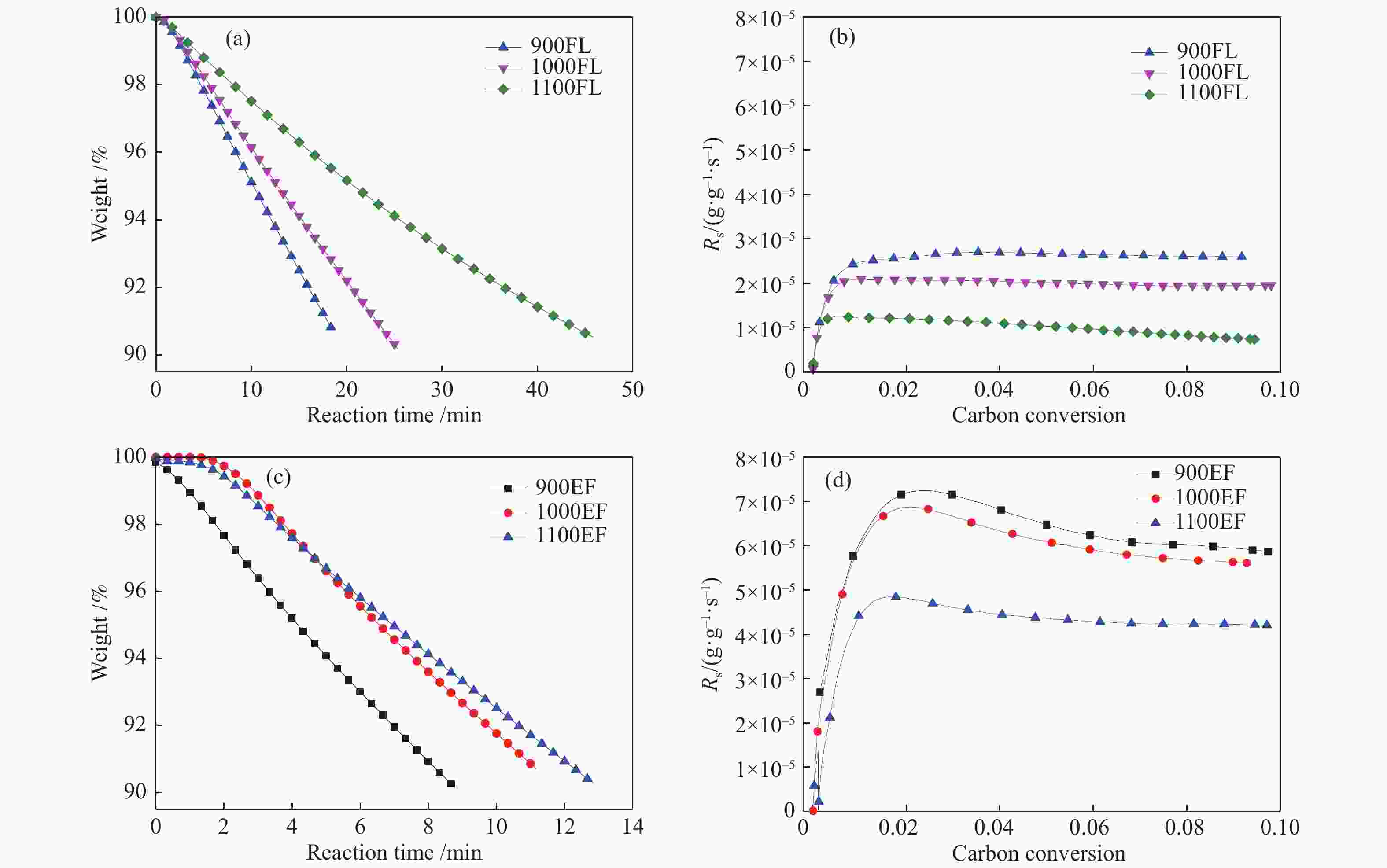

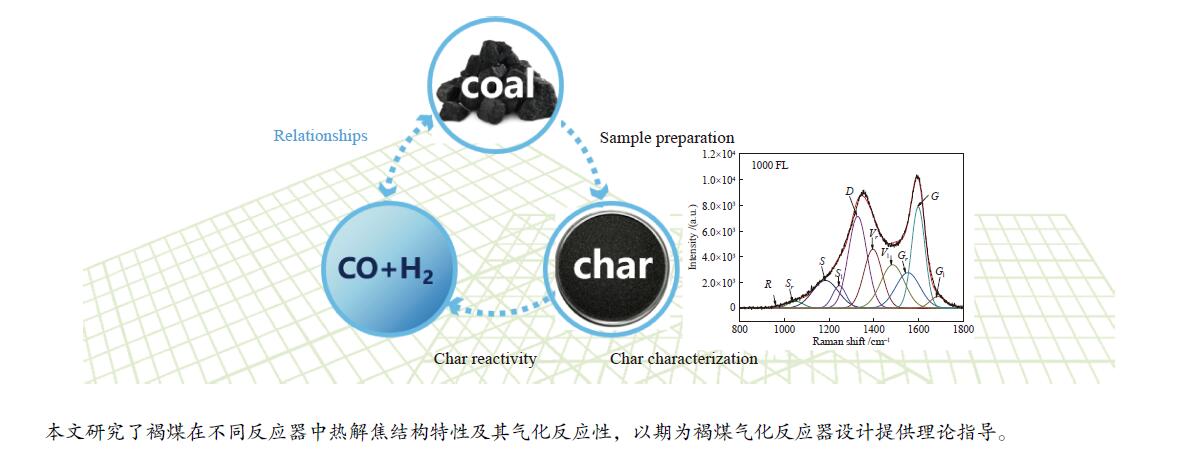

$ {I_{\rm{D}}}/{I_{({{\rm{G}}_{\rm{r}}}{\rm{ + }}{{\rm{V}}_{\rm{r}}}{\rm{ + }}{{\rm{V}}_{\rm{1}}})}} $ 升高,气化反应性降低。相较于下落床反应器,相同热解温度下流化床反应器中煤焦微晶尺寸、大环与小环比$ {I_{\rm{D}}}/{I_{({{\rm{G}}_{\rm{r}}}{\rm{ + }}{{\rm{V}}_{\rm{r}}}{\rm{ + }}{{\rm{V}}_{\rm{1}}})}} $ 均较低且其随热解温度升高变化程度较小,导致煤焦气化反应性较低且随热解温度升高变化幅度相对较小。这主要归因于流化床反应器中煤焦停留时间长,同时存在较强的煤焦与挥发分相互作用,加深了煤焦缩聚反应程度。Abstract: Char gasification reactivity plays a vital role in the design of a gasifier. In this paper, a series of char were prepared by pyrolysis at 900−1100 ℃ in a fluidized bed and a drop tube reactor with a lignite as the sample, and the physico-chemical structure and CO2 gasification reactivity of chars were studied by X-ray diffractometer (XRD), Raman spectrometer, static physical adsorption instrument and fixed-bed reactor. The results showed that the gasification reactivity of char in the fluidized bed and drop tube reactors mainly depended on its chemical structure. In the two reactors, as pyrolysis temperature increased, the polycondensation reactions of char deepened, resulting in the increasing crystalline size (aromatic sheet stacking height Lc, average diameter La) and larger ring to smaller ring ratio$ {I_{\rm{D}}}/{I_{({{\rm{G}}_{\rm{r}}}{\rm{ + }}{{\rm{V}}_{\rm{r}}}{\rm{ + }}{{\rm{V}}_{\rm{1}}})}} $ of char. Therefore, the gasification reactivity of char decreased with increasing pyrolysis temperature. Compared with in the drop tube reactor, the crystalline size and larger ring to smaller ring ratio$ {I_{\rm{D}}}/{I_{({{\rm{G}}_{\rm{r}}}{\rm{ + }}{{\rm{V}}_{\rm{r}}}{\rm{ + }}{{\rm{V}}_{\rm{1}}})}} $ of char in the fluidized bed reactor were lower at the same pyrolysis temperature, and their variations with increasing pyrolysis temperature were smaller, resulting in the lower gasification reactivity of char and the smaller change of gasification reactivity of char with increasing pyrolysis temperature. Those were mainly due to the long residence time of char and strong interactions of char and volatiles in the fluidized bed reactor, deepening the degree of polycondensation reaction of char.-

Key words:

- different reactor /

- char /

- structure /

- gasification reactivity

-

表 1 煤样的元素工业分析和元素分析

Table 1 Proximate and ultimate analyses of coal samples

Proximate analysis wad/% Ulitimate analysis wdaf/% M A V C H O* N S 8.62 3.69 26.70 78.22 3.77 16.08 1.74 0.19 ad: air dry base; daf: dry and ash free; *: by difference 表 2 不同热解反应器中煤焦样品的碳微晶参数

Table 2 Microcrystalline structural parameters of chars at different reactors

Sample d002/nm Lc/nm La/nm 900FL 0.400 1.782 0.835 1000FL 0.326 1.789 0.891 1100FL 0.323 1.795 0.926 900EF 0.427 1.776 1.159 1000EF 0.373 1.790 1.199 1100EF 0.333 1.805 1.377 -

[1] 王永刚, 孙加亮, 张书. 反应气氛对褐煤气化反应性及半焦结构的影响[J]. 煤炭学报,2014,39(8):1765−1771.WANG Yong-gang, SUN Jiang-liang, ZHANG Shu. Impacts of the gas atmosphere on the gasification reactivity and char structure of the brown coal[J]. J China Coal Soc,2014,39(8):1765−1771. [2] OCHOA J, CASSANELLO M C, BONELLI P R, CUKIERMAN A L. CO2 gasification of Argentinean coal chars: A kinetic characterization[J]. Fuel Process Technol,2001,74(3):161−176. doi: 10.1016/S0378-3820(01)00235-1 [3] 李润, 周敏, 王姗. 灰分和气化温度对胜利褐煤煤焦CO2气化反应性和结构特性的影响[J]. 煤炭转化,2020,43(6):27−31.LI Run, ZHOU Min, WANG Shan. Effects of ash and temperature on CO2 gasification reactivity and structure characteristics of Shengli lignite[J]. Coal Convers,2020,43(6):27−31. [4] 汪大千, 赵 创, 吴 阳, 杨海平. 加压热解煤焦的气化反应动力学研究[J]. 华中科技大学学报(自然科学版),2019,47(7):45−49.WANG Da-qian, ZHAO Chuang, WU Yang, YANG Hai-ping. Study on gasification reaction kinetics of coal char obtained by pressured pyrolysis[J]. J Huazhong Univ Sci Technol (Nat Sci Ed),2019,47(7):45−49. [5] 温雨鑫, 徐祥, 肖云汉. 热解条件对煤焦孔结构和反应性的影响[J]. 中国电机工程学报,2013,33(29):63−68.WEN Yu-xin, XU Xiang, XIAO Yun-han. Effects of pyrolysis conditions on the pore structure and reactivity of chars[J]. Proc CSEE,2013,33(29):63−68. [6] 徐秀峰, 崔洪, 顾永达, 陈诵英, 吴东. 煤焦制备条件对其气化反应性的影响[J]. 燃料化学学报,1996,24(5):404−410.XU Xiu-feng, CUI Hong, GU Yong-da, CHEN Song-ying, WU Dong. Influence of charring conditiongs of coal chars their gasification reactivity by air[J]. J Fuel Chem Technol,1996,24(5):404−410. [7] 方顺利, 姚伟, 刘家利, 姚斌, 杨忠灿, 王桂芳. 乌拉盖褐煤半焦气化特性试验[J]. 热力发电,2017,46(12):75−79.FANG Shun-li, YAO Wei, LIU Jia-li, YAO Bing, YANG Zhong-can, WANG Gui-fang. Experimental study on gasification characteristics of Wulagai lignite semi-coke[J]. Therm Power Gen,2017,46(12):75−79. [8] YEASMIN H, MATHEWS J F, OUYANG S. Rapid devolatisation of yallourn brown coal at high pressures and temperatures[J]. Fuel,1999,78(1):11−24. doi: 10.1016/S0016-2361(98)00119-7 [9] 吕洁, 宗志敏, 谢瑞伦, 姚子硕, 魏晴, 郄丽曼, 芦海云, 魏贤勇. 淮南煤焦结构及其高温气化反应性研究[J]. 武汉科技大学学报,2010,33(2):191−195.LÜ Jie, ZONG Zhi-min, XIE Rui-lun, YAO Zi-shuo, WEI Qing, QIE Li-man, LU Hai-yun, WEI Xian-yong. Structure and gasification reactivity of Huainan coal chars at elevated temperatures[J]. J Wuhan Univ Sci Technol,2010,33(2):191−195. [10] 范冬梅. 低阶煤热解半焦的气化反应特性研究[D]. 北京: 中国科学院工程热物理研究所, 2013.FAN Dong-mei. Characteristics study on pyrolysis and gasification of low rank coal[D]. Beijing: Institute of Engineering Thermophysics, Chinese Academy of Sciences, 2013. [11] 王美君, 于彦旭, 王欢, 孔娇, 常丽萍, 鲍卫仁. 一种微型流化床上吸式粉体物料喂料装置及喂料方法[P]. CN: 109230541 B, 2021.WANG Mei-jun, YU Yan-xu, WANG Huan, KONG Jiao, CHANG Li-ping, BAO Wei-ren. A feeding device and method of a up-suction micro-fluidized bed for powder material[P]. CN: 109230541 B, 2021. [12] 白永辉. CO2作为气化剂对煤焦-H2O气化反应的影响机制[D]. 太原: 太原理工大学, 2014.BAI Yong-hui. Influence of CO2 on char-steam gasification reaction mechanism[D]. Taiyuan: Taiyuan University of Technology, 2014. [13] SENNECA O, CORTESE L. Thermal annealing of coal at high temperature and high pressure. Effects on fragmentation and on rate of combustion, gasification and oxy-combustion[J]. Fuel,2014,116:221−228. doi: 10.1016/j.fuel.2013.07.065 [14] LU L, SAHAJWALLA V, KONG C, HARRIS D. Quantitative X-ray diffraction analysis and its application to various coals[J]. Carbon,2001,39(12):1821−1833. doi: 10.1016/S0008-6223(00)00318-3 [15] WANG M J, TIAN J L, ROBERTS D G, CHANG L P, XIE K C. Interactions between corncob and lignite during temperature-programmed co-pyrolysis[J], Fuel, 2015, 142: 102-108. [16] TAY H L, KAJITANI S, ZHANG S, LI C Z. Inhibiting and other effects of hydrogen during gasification: Further insights from FT-Raman spectroscopy[J]. Fuel,2014,116:1−6. doi: 10.1016/j.fuel.2013.07.066 [17] ZHANG L, LI T, QUYN D, DONG L, LI C Z. Structural transformation of nascent char during the fast pyrolysis of mallee wood and low-rank coals[J]. Fuel Process Technol,2015,138:390−396. doi: 10.1016/j.fuproc.2015.05.003 [18] LI X J, HAYASHI J I, LI C Z. FT-Raman spectroscopic study of the evolution of char structure during the pyrolysis of a Victorian brown coal[J]. Fuel,2006,85(12/13):1700−1707. doi: 10.1016/j.fuel.2006.03.008 [19] ZHANG S, CHEN Z D, HAI Y, WANG Y G, XU X Q, CHEN L, YU M. The catalytic reforming of tar from pyrolysis and gasification of brown coal: Effects of parental carbon materials on the performance of char catalysts[J]. Fuel Process Technol,2018,174:142−148. doi: 10.1016/j.fuproc.2018.02.022 [20] 郭沛, 赵慧明, 贾挺豪, 王美君, 常丽萍. 共热解过程对褐煤焦和生物质焦氧化特性的影响[J]. 燃料化学学报,2015,43(10):1188−1194. doi: 10.3969/j.issn.0253-2409.2015.10.006GUO Pei, ZHAO Hui-ming, JIA Ting-hao, WANG Mei-jun, CHANG Li-ping. Effect of co-pyrolysis process on the oxidation reactivity of lignite char and biomass char[J]. J Fuel Chem Technol,2015,43(10):1188−1194. doi: 10.3969/j.issn.0253-2409.2015.10.006 [21] 曾鑫, 张静, 张永发, 安英保, 郑琪. 高温, 高压, 快速加氢热解煤残渣的结构和CO2气化反应性研究[J]. 现代化工,2020,40(9):116−125.ZENG Xin, ZHANG Jing, ZHANG Yong-fa, AN Ying-bao, ZHENG Qi. Study on structure and CO2 gasification reactivity of coal pyrolysis residue at high temperature, high pressure and rapid hydrogenation[J]. Mod Chem Ind,2020,40(9):116−125. [22] 郭沛. 生物质焦和煤焦在气化过程中的结构演变及其与反应性的关联[D]. 太原: 太原理工大学, 2015.GUO Pei. Links between reactivity and structure evolution during gasification of biomass char and coal chars[D]. Taiyuan: Taiyuan University of Technology, 2015. -

下载:

下载: