Preparation of nitrogen and oxygen co-doped porous carbon and study on the performance of Zn-ion hybrid supercapacitors

-

摘要:

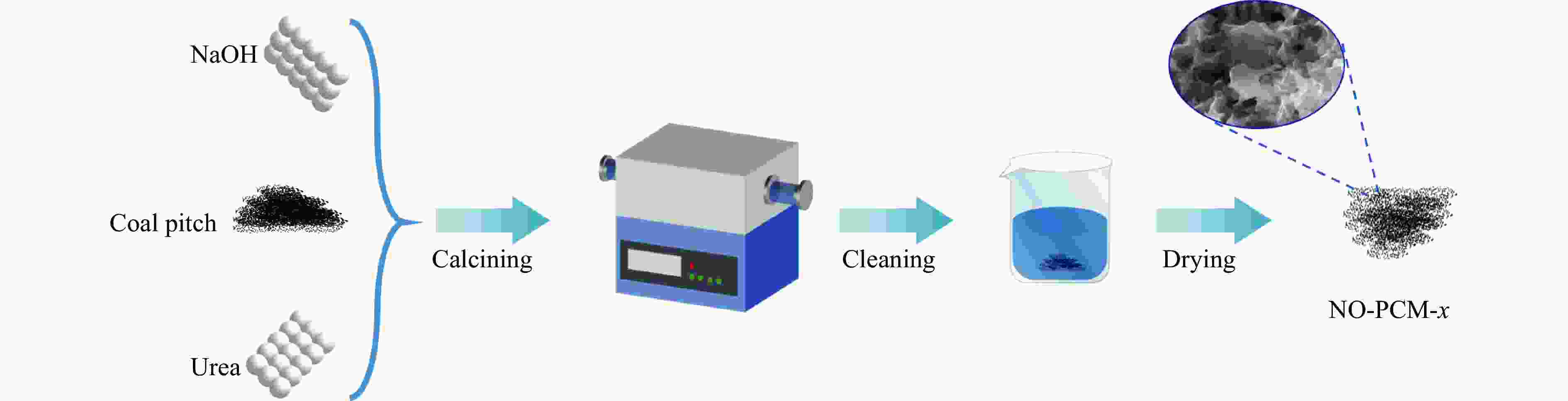

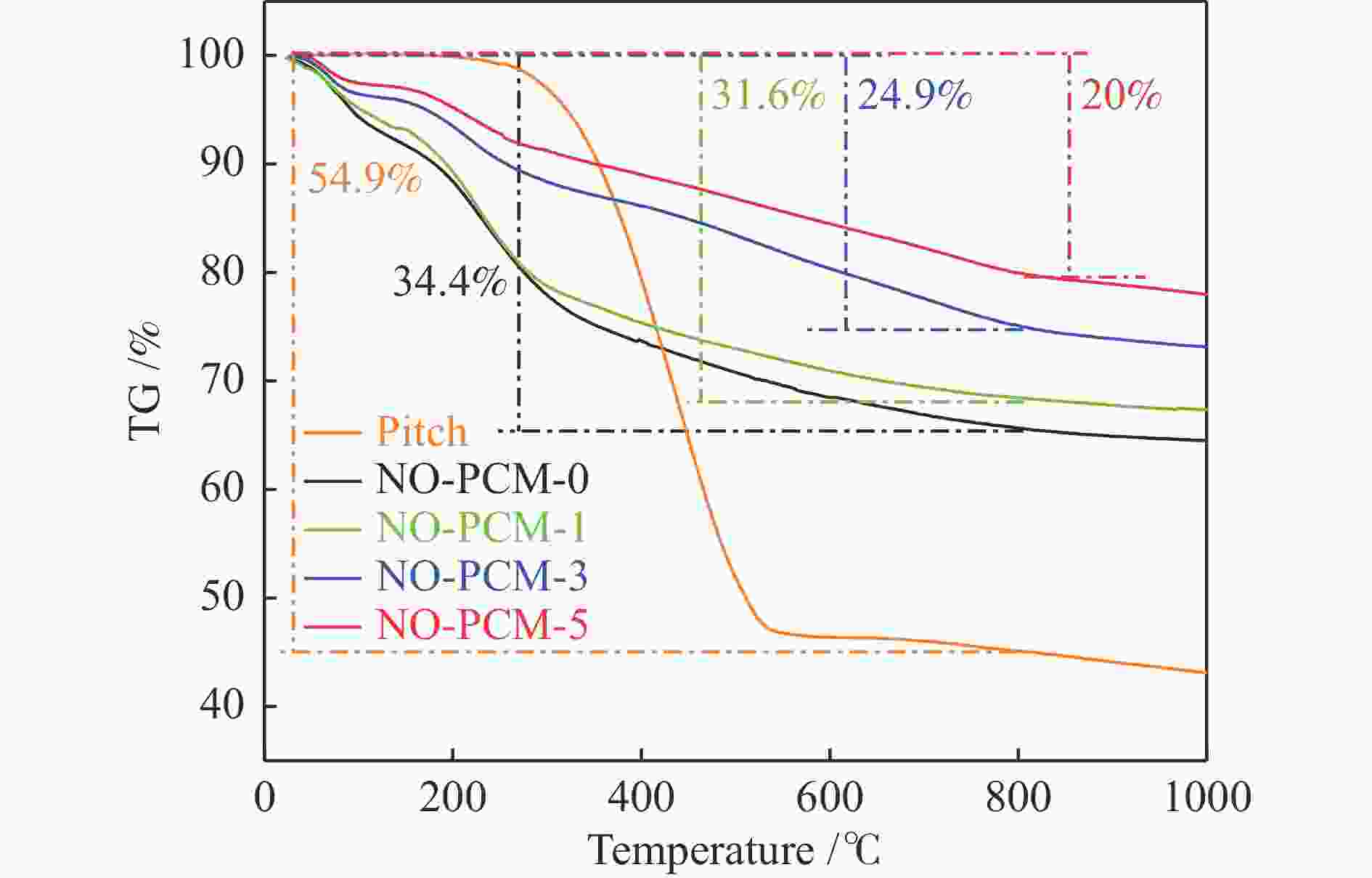

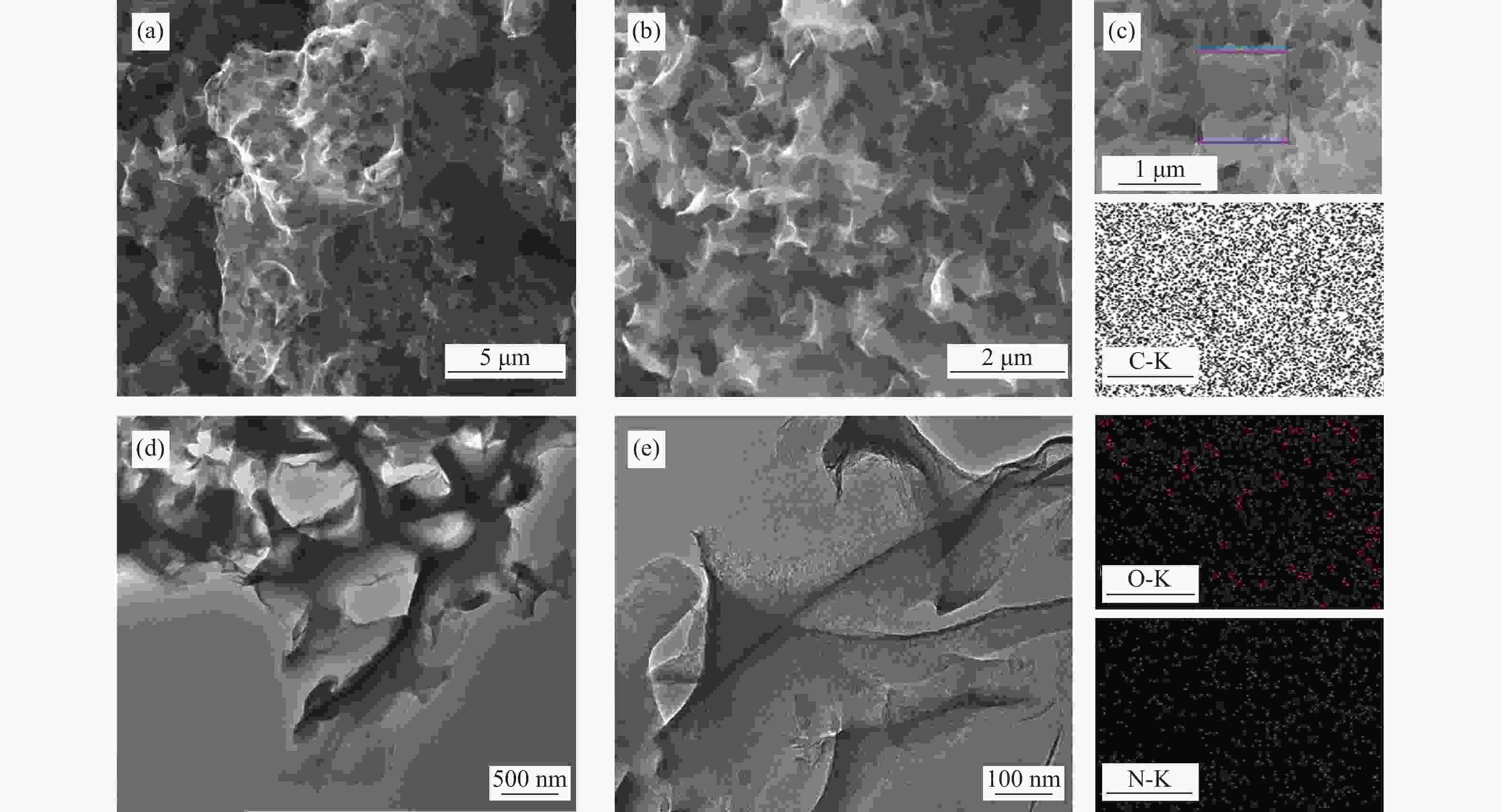

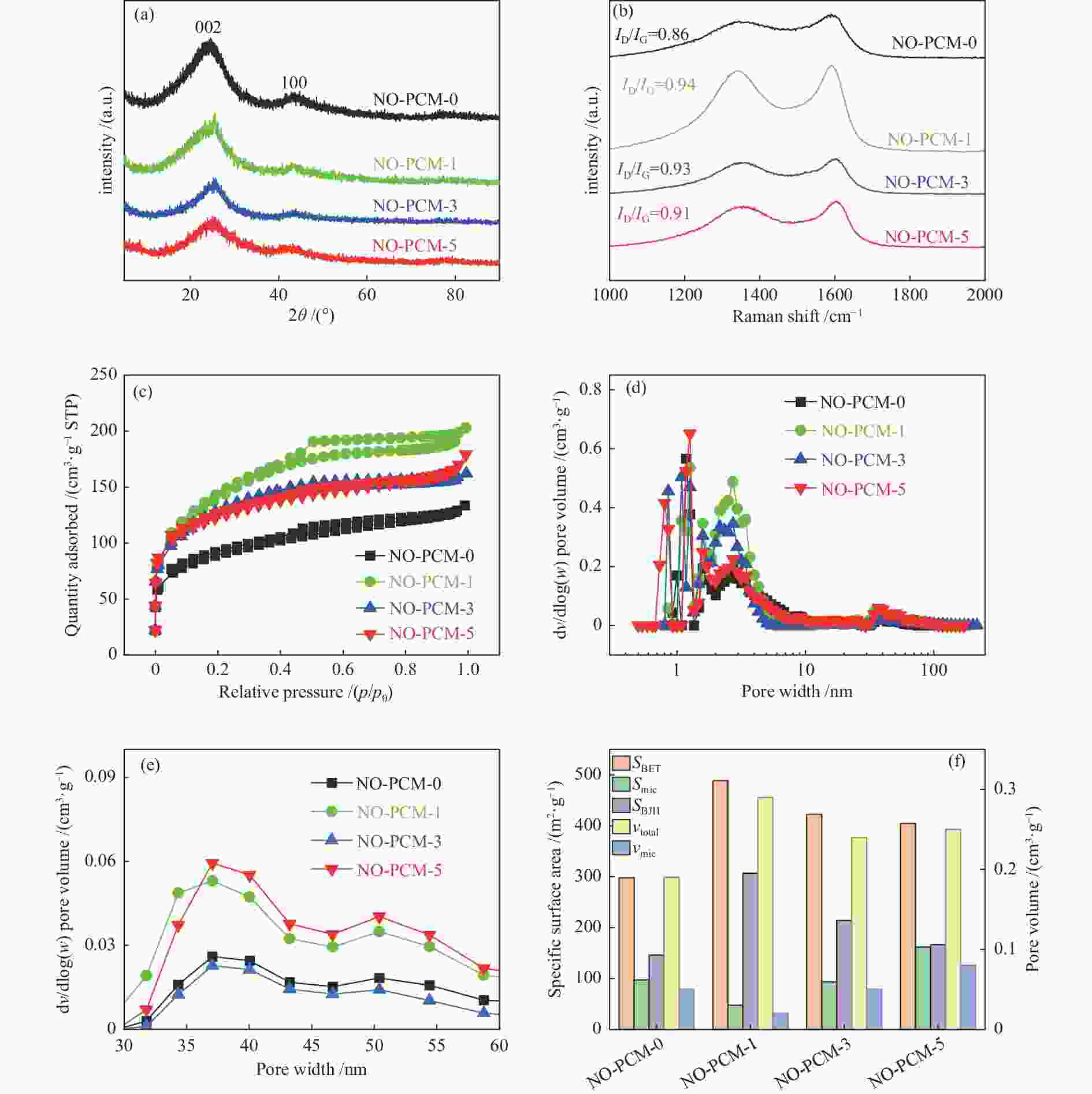

本研究以价格低廉、来源广泛的煤沥青作为炭前驱体、尿素作为氮源和模板、氢氧化钠作为活化剂,通过结合模板法与化学活化法成功制备了具有纳米片状结构的氮氧共掺杂的多孔炭材料。多孔炭电极在0.05 A/g时最大比容量高达255.5 mA·h/g,在电流密度为1 A/g时,放电比容量达到78 mA·h/g。经过12000次循环,容量保持率仍有72.4%,并且能量密度最高达到99.6 W·h/kg,展现出作为正极材料的巨大潜力。以煤沥青为原料制备的氮氧共掺杂多孔炭材料作为锌离子混合超级电容器的正极材料表现出了优异的电化学性能。

-

关键词:

- 锌离子混合超级电容器 /

- 煤沥青 /

- 多孔炭 /

- 氮氧共掺杂 /

- 电极材料

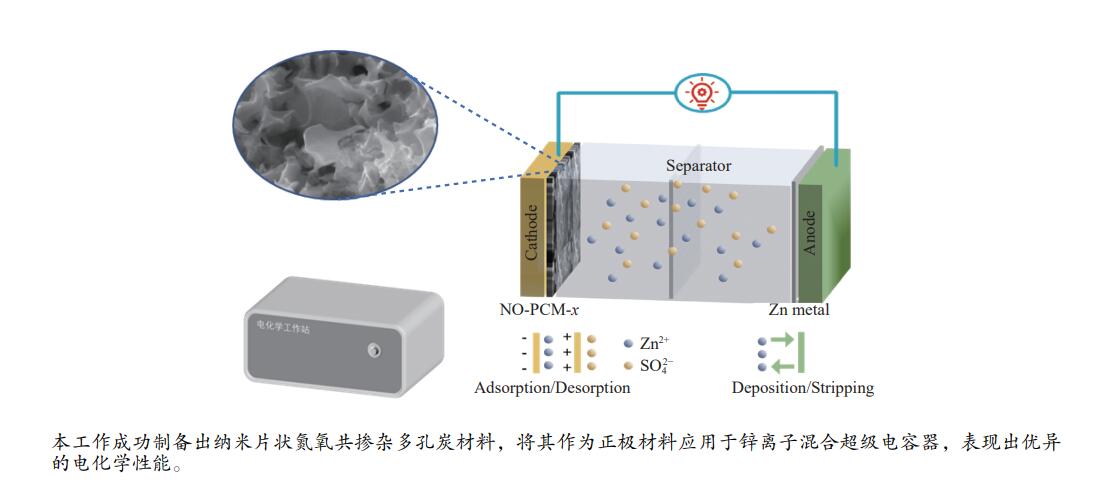

Abstract:In this study, nitrogen-oxygen co-doped porous carbon materials with nano-sheet structure were successfully prepared by template method and chemical activation method using coal pitch with low cost and abundant sources as carbon precursor, urea as nitrogen source and template, and sodium hydroxide as activator. The porous carbon electrodes exhibit a maximum specific capacity of 255.5 mA·h/g at 0.05 A/g and a discharge specific capacity of 78 mA·h/g at 1 A/g. Moreover, the porous carbon electrodes deliver about 72.4% capacitance retention after 12000 cycles and a high energy density of 99.6 W·h/kg, showing great potential as cathode material. The nitrogen-oxygen co-doped porous carbon materials prepared from coal pitch display an excellent electrochemical performance as cathode material for zinc ion hybrid supercapacitors.

-

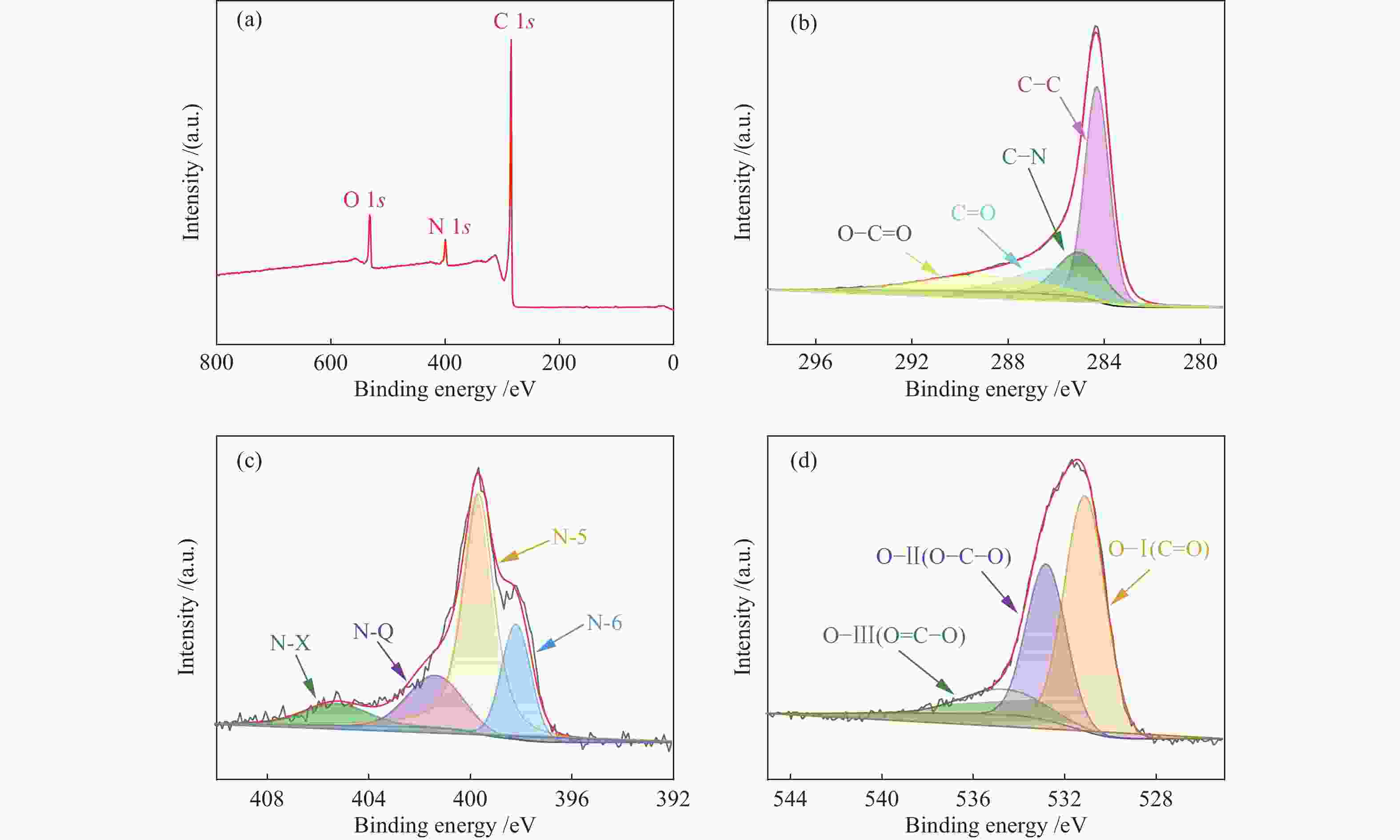

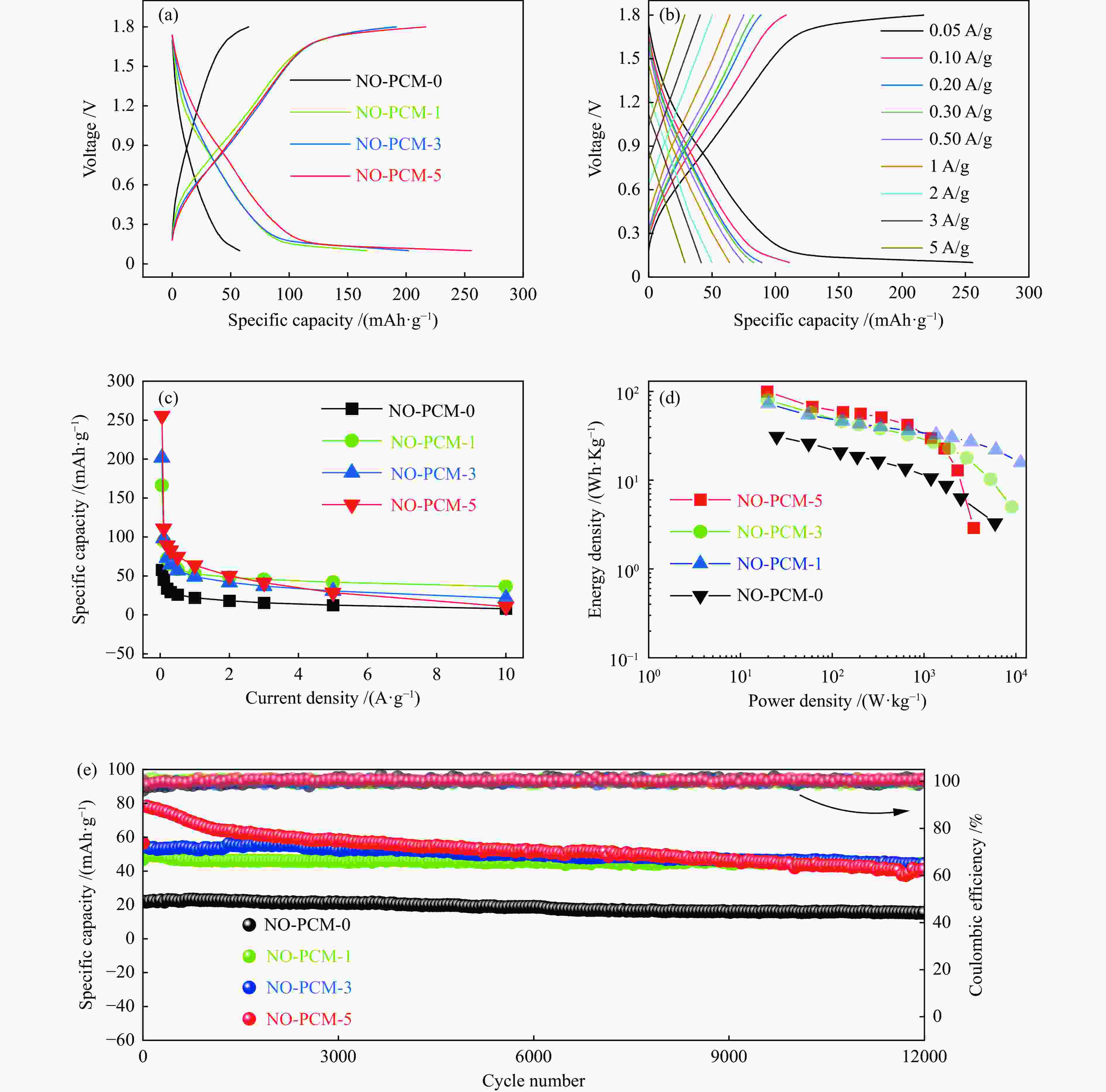

图 6 (a)充放电电流为0.05 A/g时的GCD曲线对比,(b)NO-PCM-5在不同电流密度下的GCD曲线,(c)NO-PCM-x在不同电流密度下的放电比容量,(d)NO-PCM-x//3 mol/L ZnSO4 (aq.)//Zn的Ragone图,(e)NO-PCM-x在1 A/g时的放电比容量和库伦效率

Figure 6 (a) GCD curve comparison plot at charge/discharge current of 0.05 A/g, (b) GCD curve of NO-PCM-5 at different current densities, (c) discharge specific capacity of NO-PCM-x at different current densities, (d) Ragone plot of NO-PCM-x//3 mol/L ZnSO4 (aq.) //Zn, (e) discharge specific capacity and coulomb efficiency of NO-PCM-x at 1 A/g

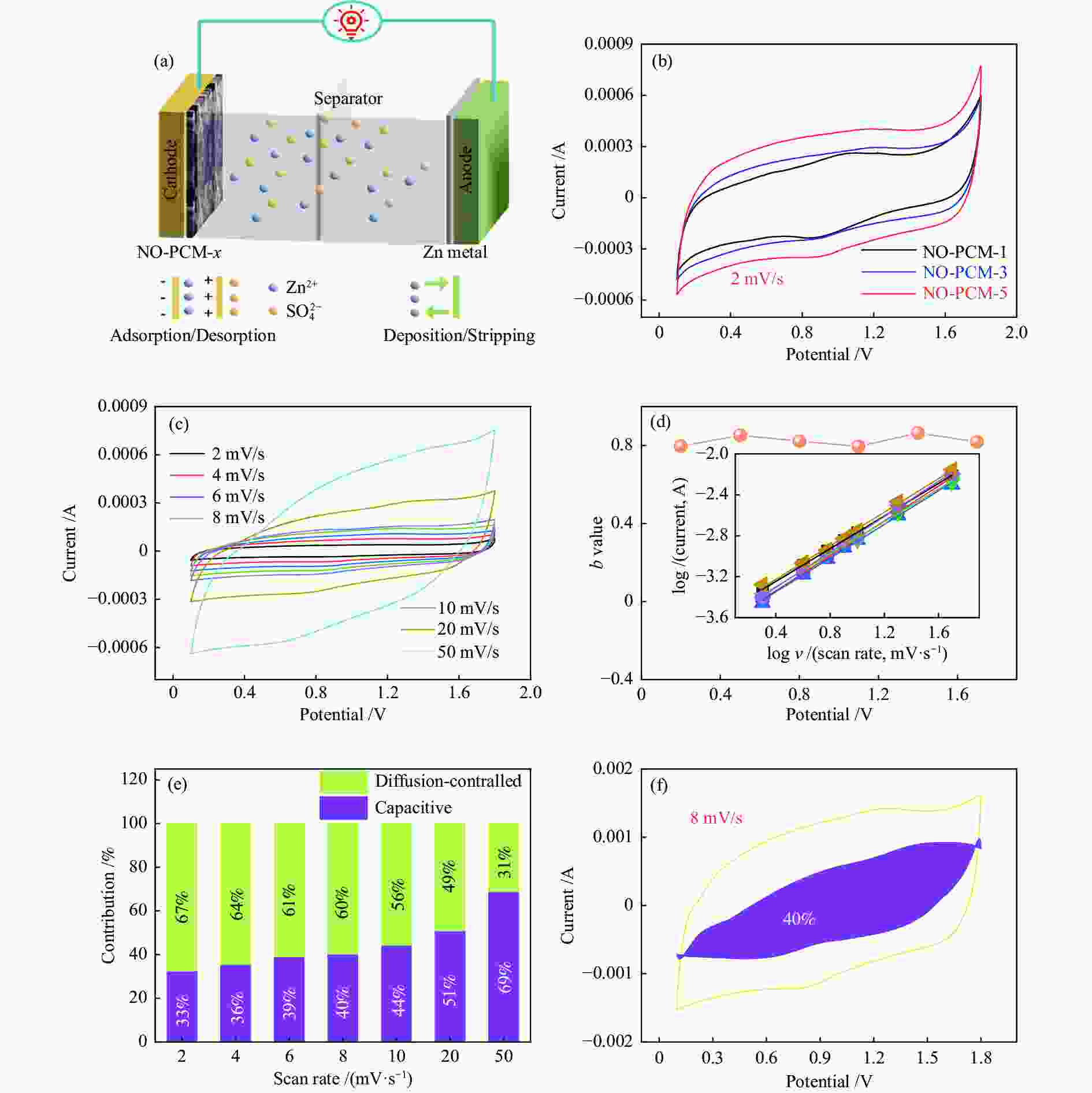

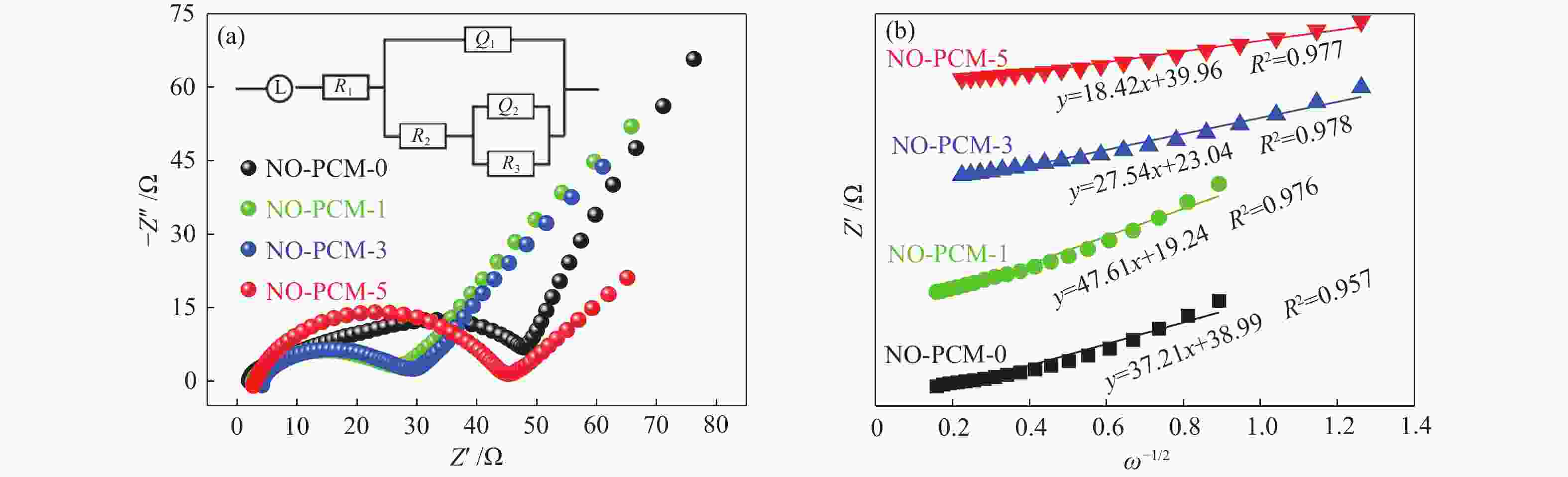

图 7 (a)NO-PCM-x//3 mol/L ZnSO4 (aq.)//Zn储能系统示意图,(b)NO-PCM-x在2 mV/s时的CV曲线,(c)NO-PCM-5在2–50 mV/s的CV曲线,(d)在特定电位下的b值,(e)在不同扫描速率下电容控制和离子扩散控制对电容贡献的百分比,(f)NO-PCM-5在8 mV/s时的电容贡献

Figure 7 (a) Schematic diagram of NO-PCM-x//3 mol/L ZnSO4 (aq.)//Zn energy storage system, (b) CV curves of NO-PCM-x at 2 mV/s, (c) CV curves of NO-PCM-5 at 2–50 mV/s, (d) b values at specific potentials, (e) percentage contribution of capacitance control and ion diffusion control to capacitance at different scan rates, (f) capacitance contribution of NO-PCM-5 at 8 mV/s

表 1 原料煤沥青的工业分析和元素分析

Table 1 Proximate analysis and ultimate analyses of raw coal pitch

Proximate analysis w/% Ultimate analysis wdaf/% Mad Ad Vdaf FCdaf* C H N S O* 0.08 1.00 55.80 43.12 91.34 4.01 1.03 0.43 3.19 *: by difference -

[1] SIMON P, GOGOTSI Y. Perspectives for electrochemical capacitors and related devices[J]. Nat Mater,2020,19(11):1151−1163. doi: 10.1038/s41563-020-0747-z [2] ZHANG Y, LI X, FAN L S, SHUAI Y, ZHANG N Q. Ultrathin and super-tough membrane for anti-dendrite separator in aqueous zinc-ion batteries[J]. Cell Rep Phys Sci,2022,100824. [3] SEHRAWAT P, JULIEN C, ISLAM S S. Carbon nanotubes in Li-ion batteries: A review[J]. Mat Sci Eng B,2016,213:12−40. doi: 10.1016/j.mseb.2016.06.013 [4] ZHANG Y Z, WANG Y, CHENG T, YAO L Q, LI X, LAI W Y, HUANG W. Printed supercapacitors: Materials, printing and applications[J]. Chem Soc Rev,2019,48(12):3229−3264. doi: 10.1039/C7CS00819H [5] TANG B Y, SHAN L T, LIANG S Q, ZHOU J. Issues and opportunities facing aqueous zinc-ion batteries[J]. Energy Environ Sci,2019,12(11):3288−3304. doi: 10.1039/C9EE02526J [6] HOU R L, LIU B, SUN Y L, LIU L Y, MENG J N, LEVI M D, JI H X, YAN X B. Recent advances in dual-carbon based electrochemical energy storage devices[J]. Nano Energy,2020,72:104728. doi: 10.1016/j.nanoen.2020.104728 [7] YABUUCHI N, KUBOTA K, DAHBI M, KOMABA S. Research development on sodium-ion batteries[J]. Chem Rev,2014,114(23):11636−11682. doi: 10.1021/cr500192f [8] 黄玲, 王帅, 张宇, 黄祥红, 彭俊军, 杨锋. 氮/磷共掺杂废旧棉织物基活性炭的制备及其超级电容器性能[J]. 新型炭材料,2021,36(6):1128−1135. doi: 10.1016/S1872-5805(21)60054-9HUANG Ling, WANG Shuai, ZHANG Yu, HUANG Xiang-hong, PENG Jun-jun, YANG Feng. Preparation of a N/P co-doped waste cotton fabric-based activated carbon for supercapacitor electrodes[J]. New Carbon Mater,2021,36(6):1128−1135. doi: 10.1016/S1872-5805(21)60054-9 [9] 王满, 车晓刚, 刘思宇, 杨卷. 锌离子电容器用碳基正极材料的研究进展[J]. 新型炭材料,2021,177(1):429−166. doi: 10.19869/j.ncm.1007-8827.20200264WANG Man, CHE Xiao-gang, LIU Si-yu, YANG Juan. A review of carbon-based cathode materials for zinc-ion capacitors[J]. New Carbon Mater,2021,177(1):429−166. doi: 10.19869/j.ncm.1007-8827.20200264 [10] TIAN Y H, AMAL R, WANG D W. An aqueous metal-ion capacitor with oxidized carbon nanotubes and metallic zinc electrodes[J]. Front Energy Res,2016,4:34. [11] SONG J H, XU K, LIU N, REED D, LI X L. Crossroads in the renaissance of rechargeable aqueous zinc batteries[J]. Mater Today,2021,45:191−212. doi: 10.1016/j.mattod.2020.12.003 [12] WU S L, CHEN Y T, JIAO T P, ZHOU J, CHENG J Y, LIU B, YANG S R, ZHANG K L, ZHANG W J. An aqueous Zn-Ion hybrid supercapacitor with high energy density and ultrastability up to 80 000 cycles[J]. Adv Energy Mater,2019,9(47):1902915. doi: 10.1002/aenm.201902915 [13] ZHANG X, PEI Z, WANG C, YUAN Z, WEI L, PAN Y, MAHMOOD A, SHAO Q, CHEN Y. Flexible zinc-ion hybrid fiber capacitors with ultrahigh energy density and long cycling life for wearable electronics[J]. Small,2019,15(47):1903817. doi: 10.1002/smll.201903817 [14] ZHAO Y, WANG Y N, ZHAO Z M, ZHAO J W, XIN T, WANG N, LIU J Z. Achieving high capacity and long life of aqueous rechargeable zinc battery by using nanoporous-carbon-supported poly(1, 5-naphthalenediamine) nanorods as cathode[J]. Energy Storage Mater,2020,28:64−72. doi: 10.1016/j.ensm.2020.03.001 [15] LI Z W, CHEN D H, AN Y F, CHEN C L, WU L Y, CHEN Z J, SUN Y, ZHANG X G. Flexible and anti-freezing quasi-solid-state zinc ion hybrid supercapacitors based on pencil shavings derived porous carbon[J]. Energy Storage Mater,2020,28:307−314. doi: 10.1016/j.ensm.2020.01.028 [16] 张晓虎, 孙现众, 张熊, 安亚斌, 王凯, 韦统振, 马衍伟. 锂离子电容器在新能源领域应用展望[J]. 电工电能新技术,2020,39(11):48−58. doi: 10.12067/ATEEE2001022ZHANG Xiao-hu, SUN Xian-zhong, ZHANG Xiong, AN Ya-bin, WANG Kai, WEI Tong-zhen, MA Yan-wei. Prospect of lithium-ion capacitor application in new energy field[J]. Adv Technol Electr Eng Energy,2020,39(11):48−58. doi: 10.12067/ATEEE2001022 [17] ZHANG X, CAO E D, TIAN Y J, ZHANG M M, LIU X C, LEI Z, ZHAO Z G, CUI P, LING Q, XIE R L. Synthesis of coal tar pitch-derived heteroatom-doped porous carbon materials for aqueous zinc-ion hybrid supercapacitors[J]. Carbon Res Convers,2022,5(3):193−199. doi: 10.1016/j.crcon.2022.05.002 [18] WANG D W, PAN Z M, LU Z M. From starch to porous carbon nanosheets: Promising cathodes for high-performance aqueous Zn-ion hybrid supercapacitors[J]. Microporous Mesoporous Mater,2020,306:110445. doi: 10.1016/j.micromeso.2020.110445 [19] WEI F, ZHANG H F, WANG J F, ZHUANG J L, LV Y H. N, S co-doped porous carbons with well-developed pores for supercapacitor and zinc ion hybrid capacitor[J]. J Alloys Compd,2022,907:164536. doi: 10.1016/j.jallcom.2022.164536 [20] WANG J M, HUANG Y, HAN X P, LI Z Y, ZHANG S, ZONG M. A flexible zinc-ion hybrid supercapacitor constructed by porous carbon with controllable structure[J]. Appl Surf Sci,2022,579:152247. doi: 10.1016/j.apsusc.2021.152247 [21] WANG D W, PAN Z M, CHEN G X, LU Z M. Glycerol derived mesopore-enriched hierarchically carbon nanosheets as the cathode for ultrafast zinc ion hybrid supercapacitor applications[J]. Electrochim Acta,2021,379:138170. doi: 10.1016/j.electacta.2021.138170 [22] ZHENG Y W, ZHAO W, JIA D D, LIU Y, CUI L, WEI D, ZHENG R K, LIU J Q. Porous carbon prepared via combustion and acid treatment as flexible zinc-ion capacitor electrode material[J]. Chem Eng J,2020,387:124161. doi: 10.1016/j.cej.2020.124161 [23] ZHAO S Y, KANG X H, FAN H H, SI C L, SONG X P. Preparation of zinc-doped bagasse-based activated carbon multilayer composite and its electrochemical performance as a supercapacitor[J]. Microporous Mesoporous Mater,2022,329:111518. doi: 10.1016/j.micromeso.2021.111518 [24] YANG W, WANG P, TU Z Q, HOU L, YAN L, JIANG B, ZHANG C X, HUANG G Y, YANG F, LI Y F. Heteroatoms-doped hierarchical porous carbon with multi-scale structure derived from petroleum asphalt for high-performance supercapacitors[J]. Carbon,2022,187:338−348. doi: 10.1016/j.carbon.2021.11.008 [25] DENG X Y, LI J J, SHAN Z, SHA J W, MA L Y, ZHAO N Q. A N, O co-doped hierarchical carbon cathode for high-performance Zn-ion hybrid supercapacitors with enhanced pseudocapacitance[J]. J Mater Chem A,2020,8(23):11617−11625. doi: 10.1039/D0TA02770G [26] WANG D W, WANG S Y, LU Z M. S-doped 3D porous carbons derived from potassium thioacetate activation strategy for zinc-ion hybrid supercapacitor applications[J]. Int J Energy Res,2021,45(2):2498−2510. doi: 10.1002/er.5944 [27] WANG K Y, CHEN Y, LIU Y B, ZHANG H, SHEN Y X, PU Z Y, QIU H L, LI Y M. Plasma boosted N, P, O co-doped carbon microspheres for high performance Zn ion hybrid supercapacitors[J]. J Alloys Compd,2022,901:163588. doi: 10.1016/j.jallcom.2021.163588 [28] ZHUANG Q Q, CAO J P, WU Y, ZHAO X Y, WEI Y L, YANG Z H, ZHOU Z, HE Z M, ZHAO Y P, BAI H C. Direct synthesis of oxygen-enriched 3D porous carbons via NaCl template derived from oxidized coal tar pitch for excellent cycling stability electric double layer capacitor[J]. J Power Sources,2021,508:230330. doi: 10.1016/j.jpowsour.2021.230330 [29] YI Z H, CHEN G Y, HOU F, WANG L Q, LIANG J. Strategies for the stabilization of Zn metal anodes for Zn-ion batteries[J]. Adv Energy Mater,2021,11(1):2003065. doi: 10.1002/aenm.202003065 [30] ZHANG P, LI Y, WANG G, WANG F, YANG S, ZHU F, ZHUANG X, SCHMIDT O G, FENG X. Zn-ion hybrid micro-supercapacitors with ultrahigh areal energy density and long-term durability[J]. Adv Mater,2019,31(3):1806005. doi: 10.1002/adma.201806005 [31] LU Y Y, LI Z W, BAI Z Y, MI H Y, JI C C, PANG H, YU C, QIU J S. High energy-power Zn-ion hybrid supercapacitors enabled by layered B/N co-doped carbon cathode[J]. Nano Energy,2019,66:104132. doi: 10.1016/j.nanoen.2019.104132 [32] WANG D W, FANG G L, XUE T, MA J F, GENG G H. A melt route for the synthesis of activated carbon derived from carton box for high performance symmetric supercapacitor applications[J]. J Power Sources,2016,307:401−409. doi: 10.1016/j.jpowsour.2016.01.009 [33] HOU J, CAO C, IDREES F, MA X. Hierarchical porous nitrogen-doped carbon nanosheets derived from silk for ultrahigh-capacity battery anodes and supercapacitors[J]. ACS Nano,2015,9(3):2556−2564. doi: 10.1021/nn506394r [34] 雷杰, 王韬翔, 李治, 陈辉, 杨松, 韩海波, 李康. 大碳层间距的煤沥青基多级孔碳材料的制备及其在超级电容器中的应用[J]. 无机化学学报,2021,37(7):1218−1226.LEI Jie, WANG Tao-xiang, LI Zhi, CHEN Hui, YANG Song, HAN Hai-bo, LI Kang. Synthesis of multi-stage pore carbon material with large spacing of carbon layers from asphalt for supercapacitors[J]. Chin J Inorg Chem,2021,37(7):1218−1226. [35] THOMMES M, KANEKO K, NEIMARK A V, OLIVIER J P, RODRIGUEZ-REINOSO F, ROUQUEROL J, SING K S W. Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC Technical Report) [J]. Pure Appl Chem, 2015, 87(9/10): 1051–1069. [36] CHEN G X, HU Z W, PAN Z M, WANG D W. Design of honeycomb-like hierarchically porous carbons with engineered mesoporosity for aqueous zinc-ion hybrid supercapacitors applications[J]. J Energy Storage,2021,38:102534. doi: 10.1016/j.est.2021.102534 [37] LI H X, WU J, WANG L T, LIAO Q X, NIU X H, ZHANG D Y, WANG K J. A zinc ion hybrid capacitor based on sharpened pencil–like hierarchically porous carbon derived from metal–organic framework[J]. Chem Eng J,2022,428:131071. doi: 10.1016/j.cej.2021.131071 [38] LIU P G, LIU W F, HUANG Y P, LI P L, YAN J, LIU K Y. Mesoporous hollow carbon spheres boosted, integrated high performance aqueous Zn–Ion energy storage[J]. Energy Storage Mater,2020,25:858−865. doi: 10.1016/j.ensm.2019.09.004 [39] YUAN M, CAO B, MENG C Y, ZUO H M, LI A, MA Z K, CHEN X H, SONG H H. Preparation of pitch–based carbon microbeads by a simultaneous spheroidization and stabilization process for lithium-ion batteries[J]. Chem Eng J,2020,400:125948. doi: 10.1016/j.cej.2020.125948 [40] SHI M L, CHEN Z Y, SUN J. Determination of chloride diffusivity in concrete by AC impedance spectroscopy[J]. Cem Concr Res,1999,29(7):1111−1115. doi: 10.1016/S0008-8846(99)00079-4 -

下载:

下载: