Study on fusibility and viscosity-temperature characteristics of municipal solid waste ash

-

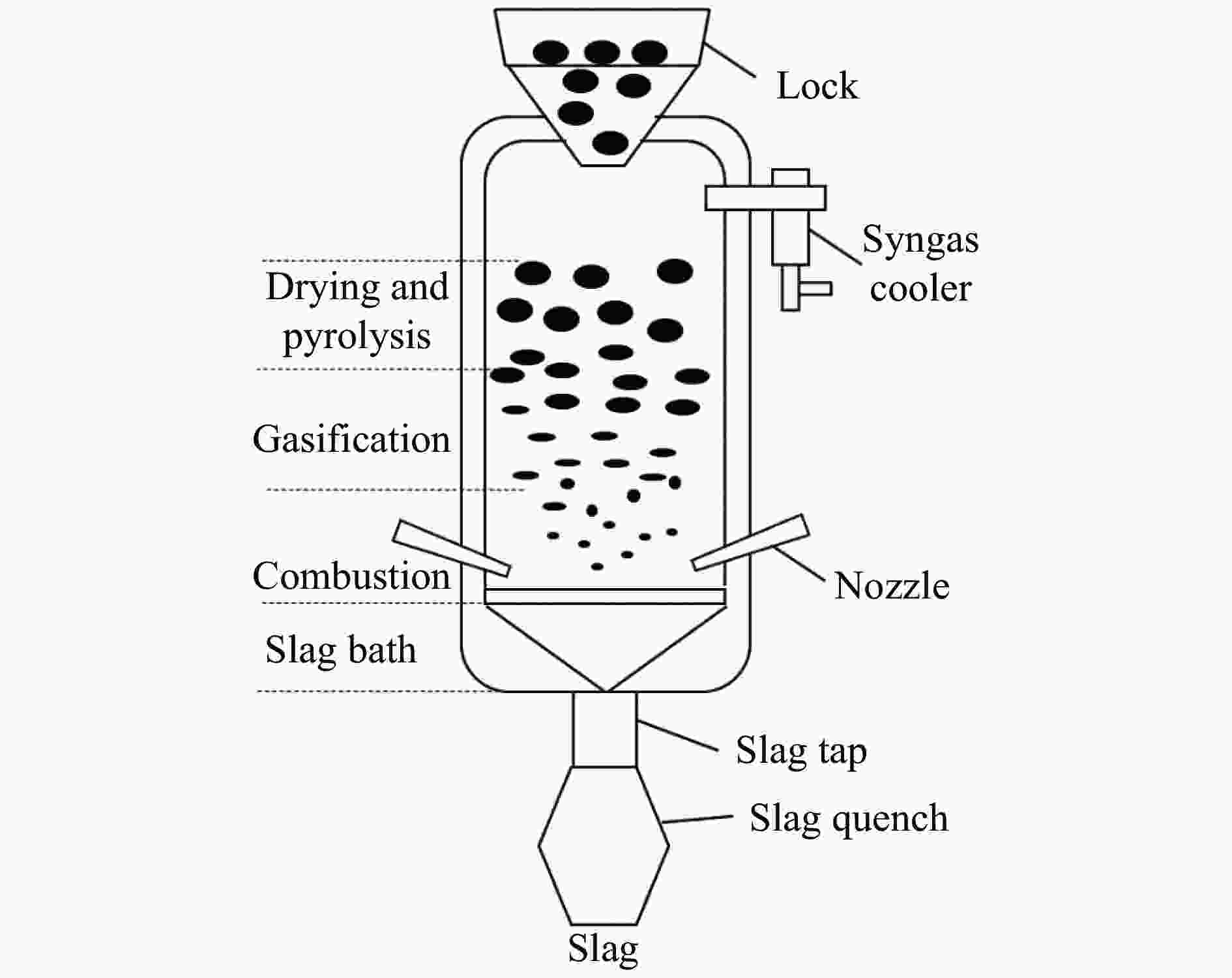

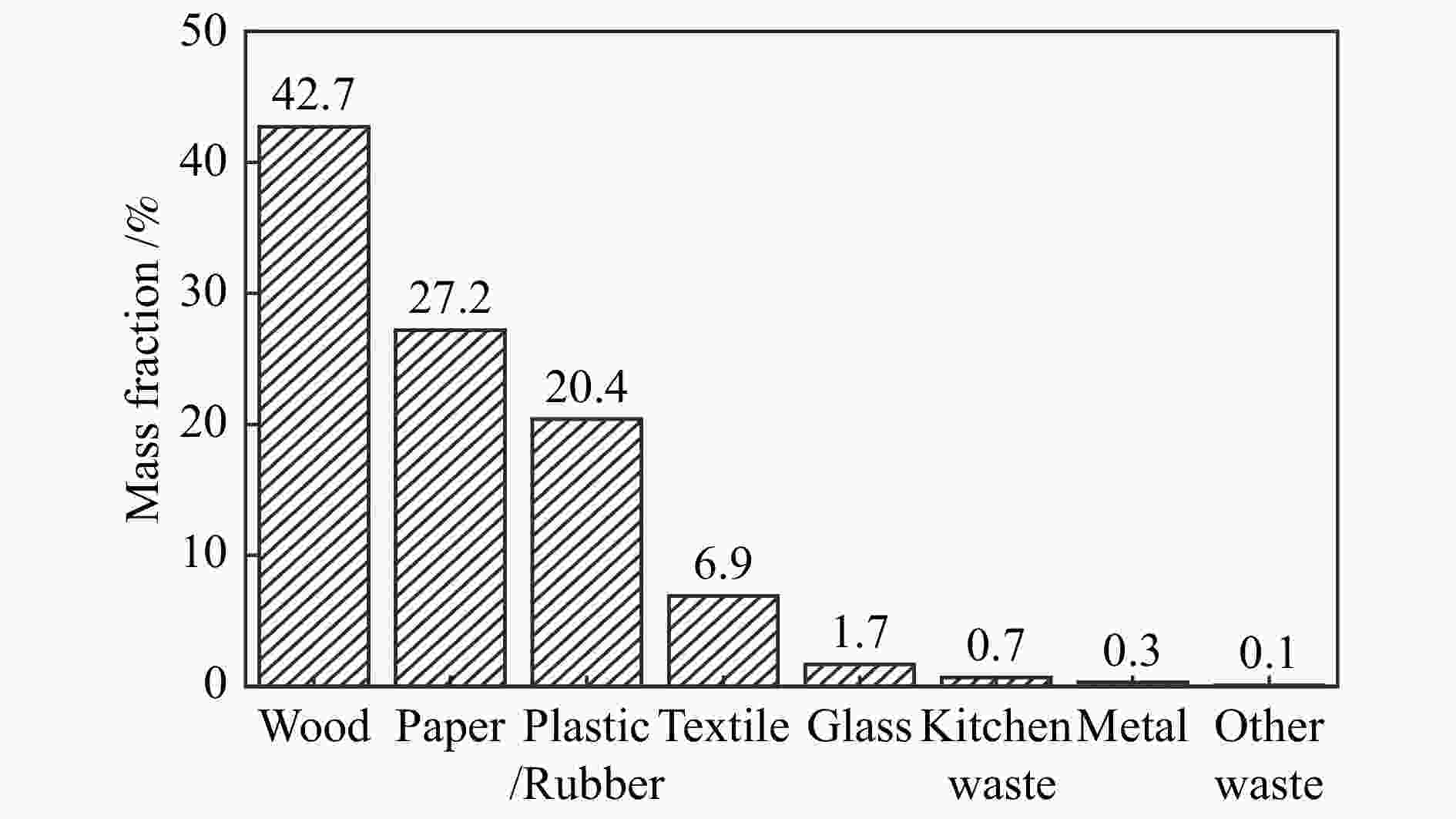

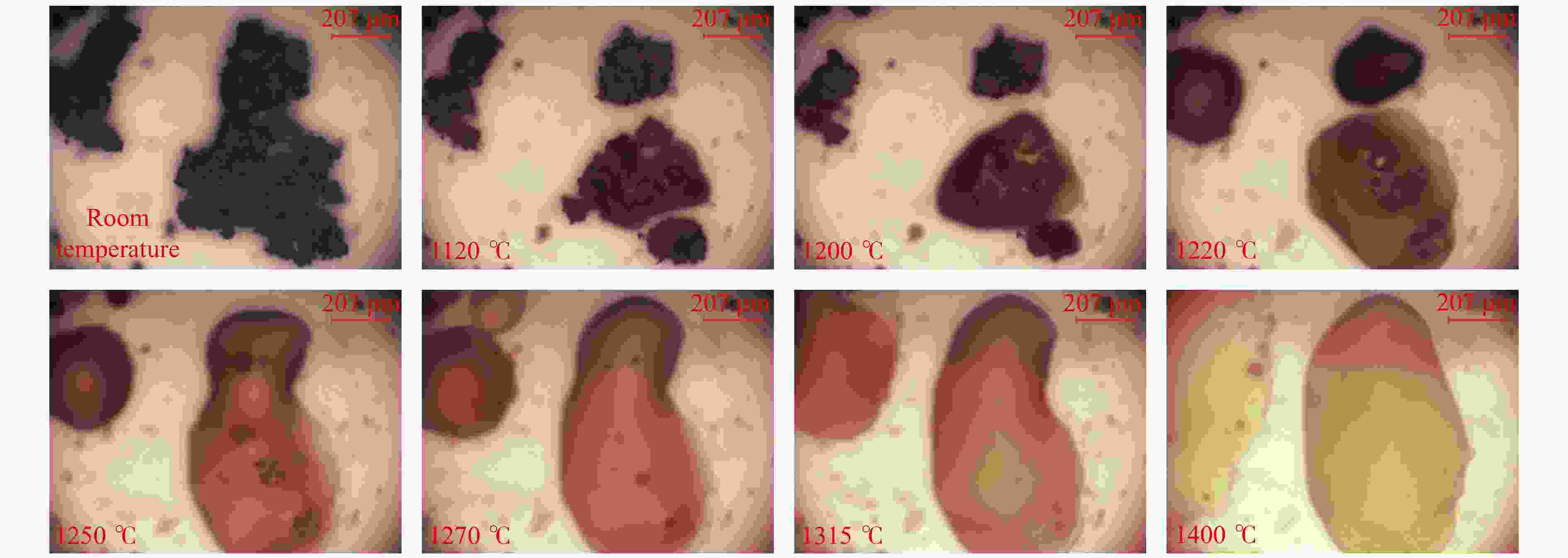

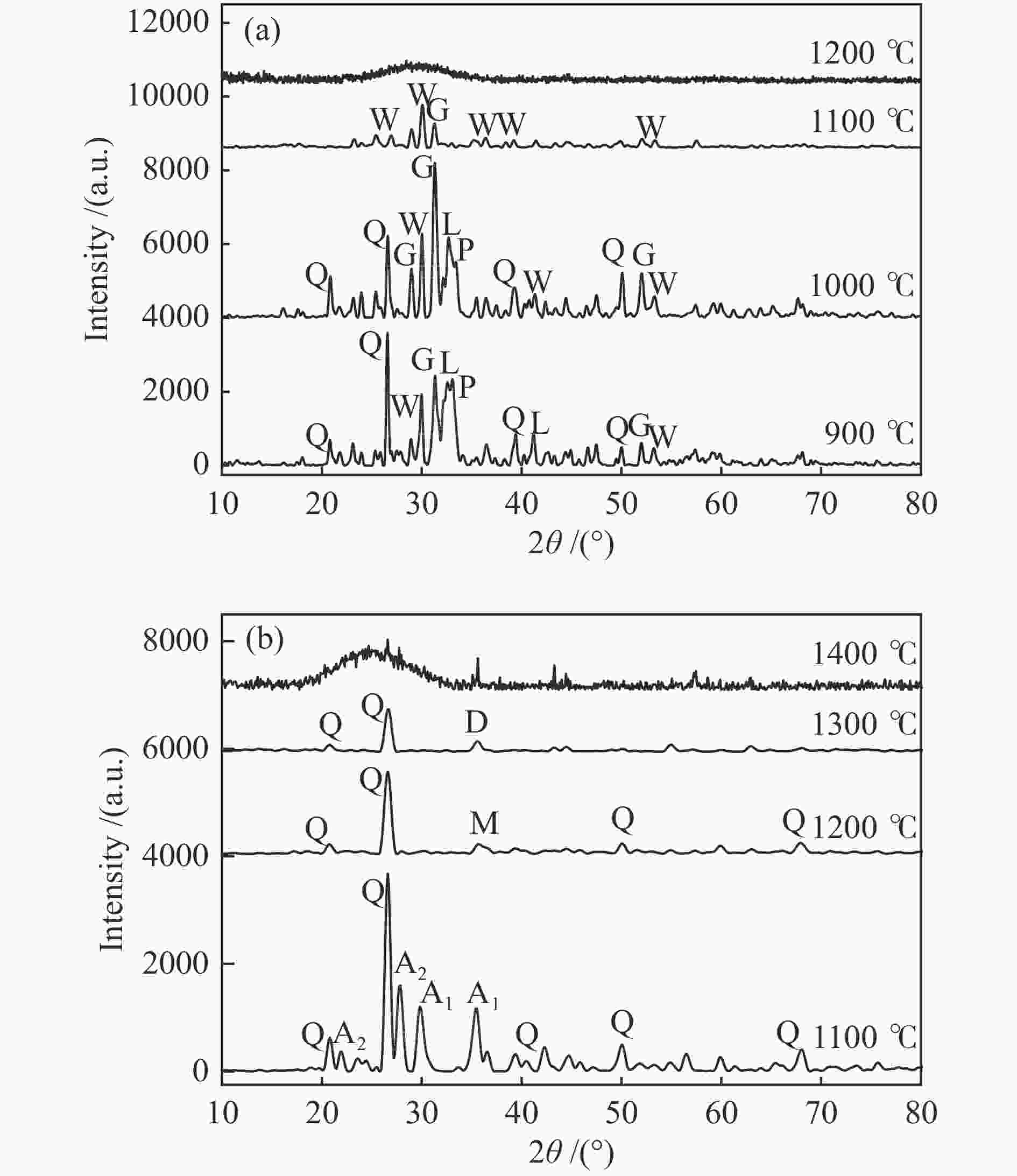

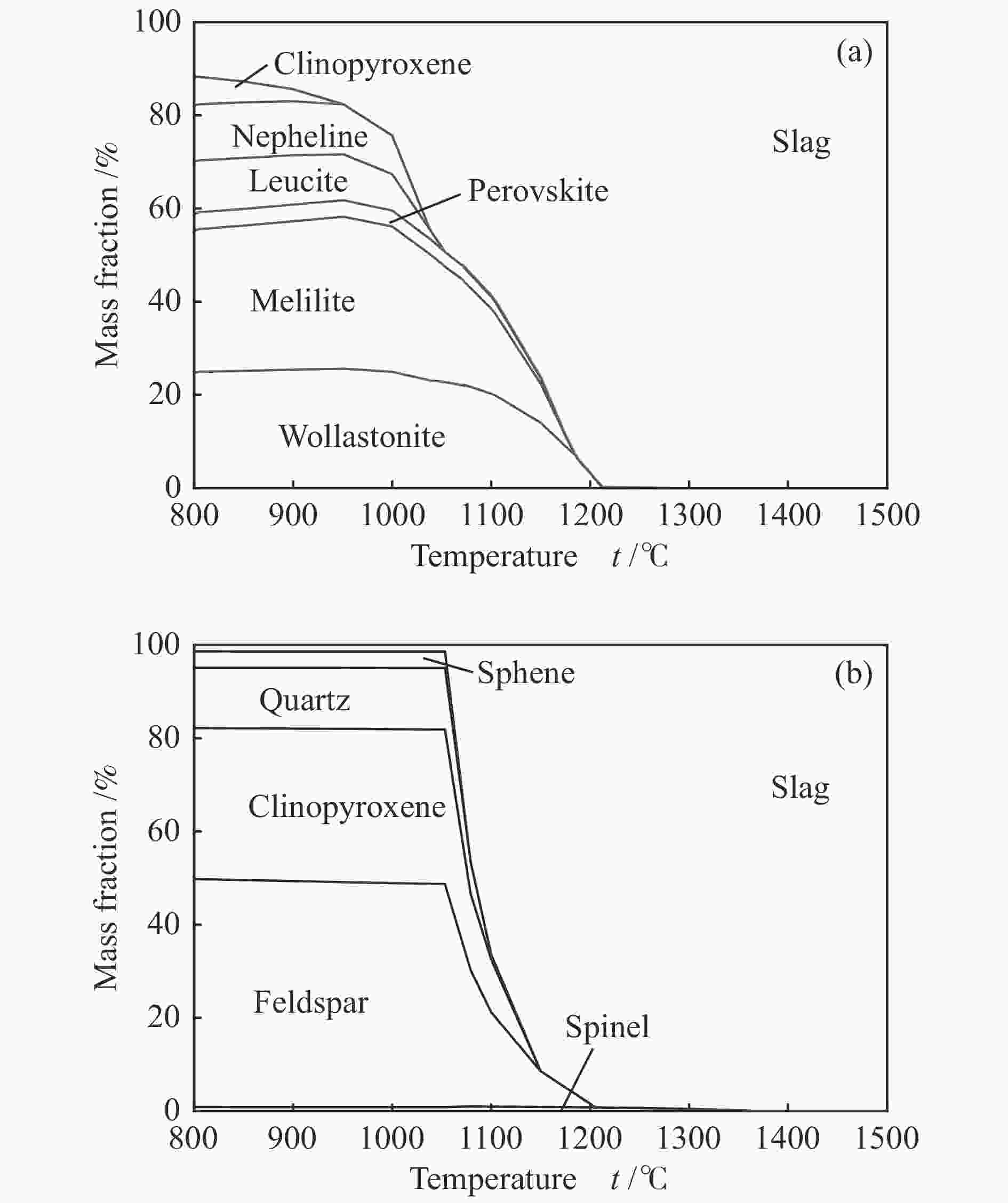

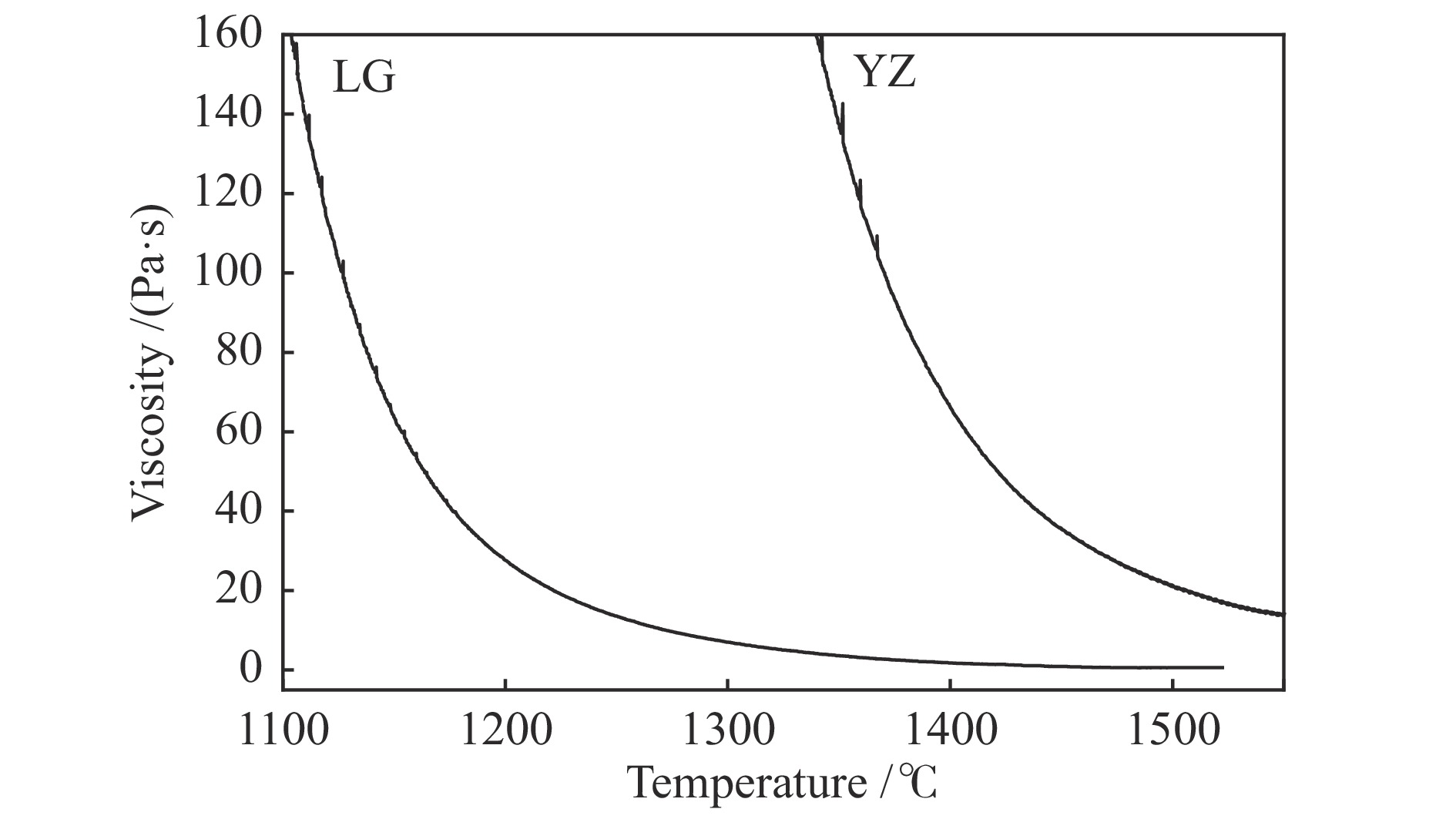

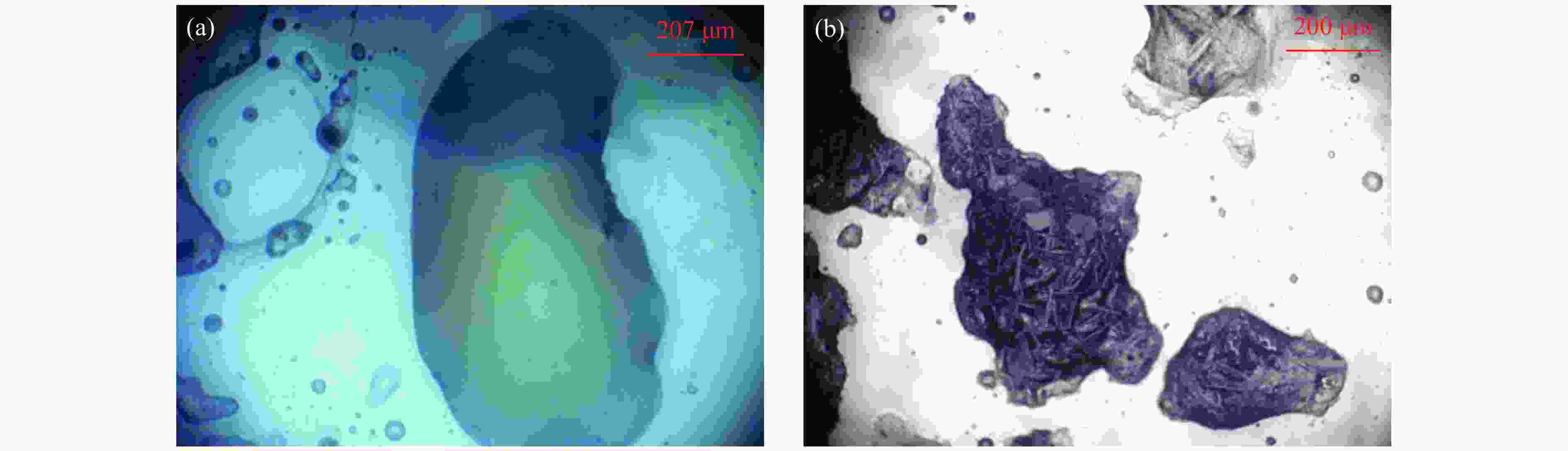

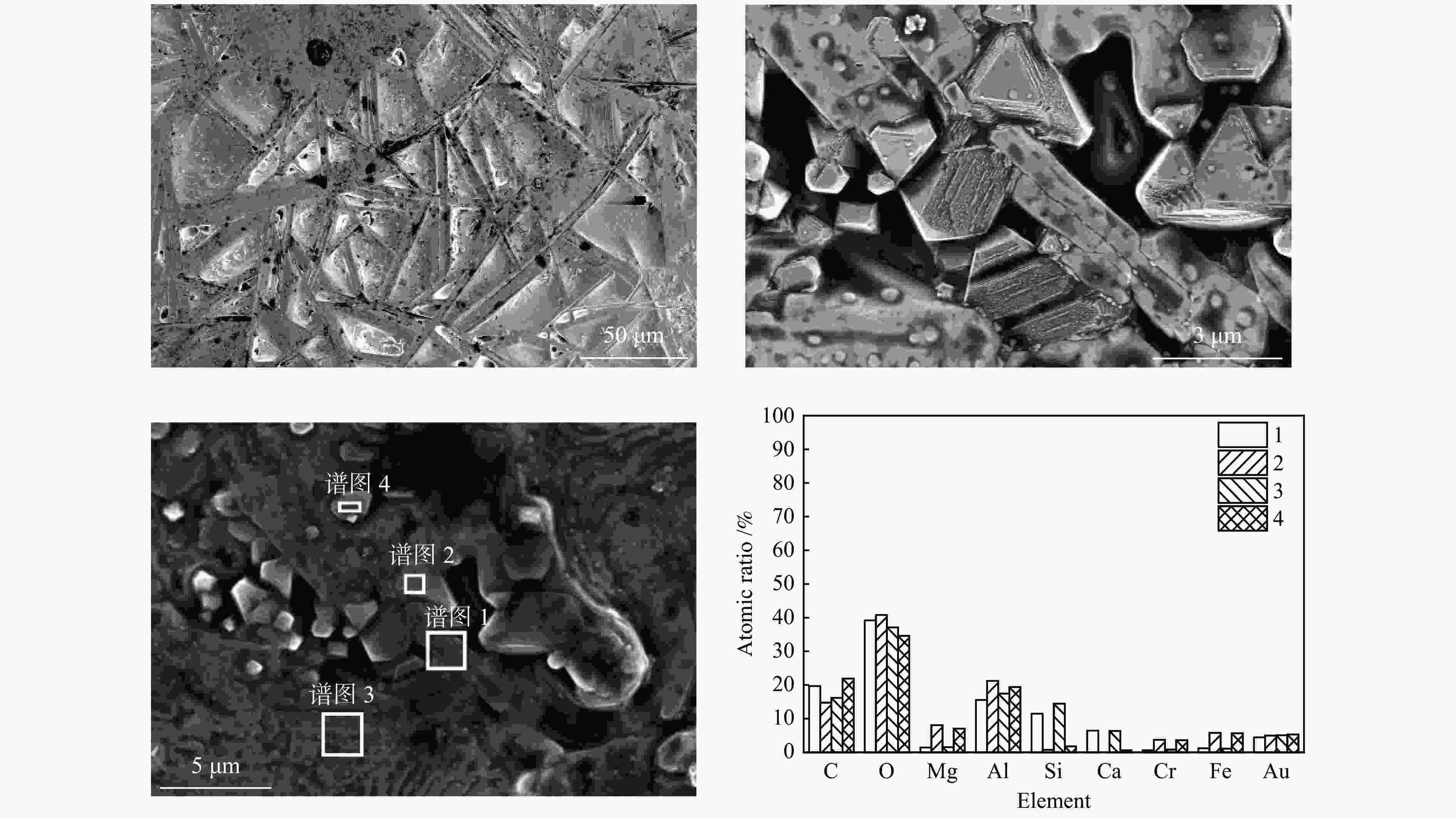

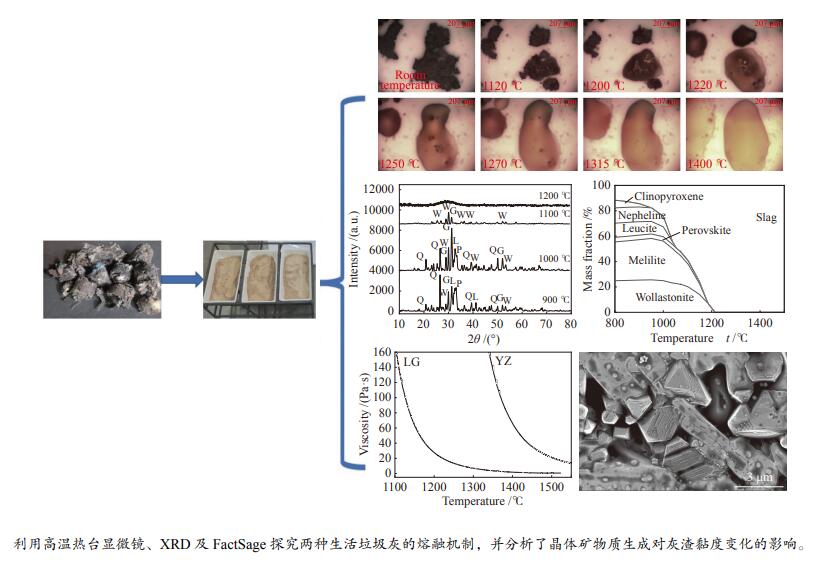

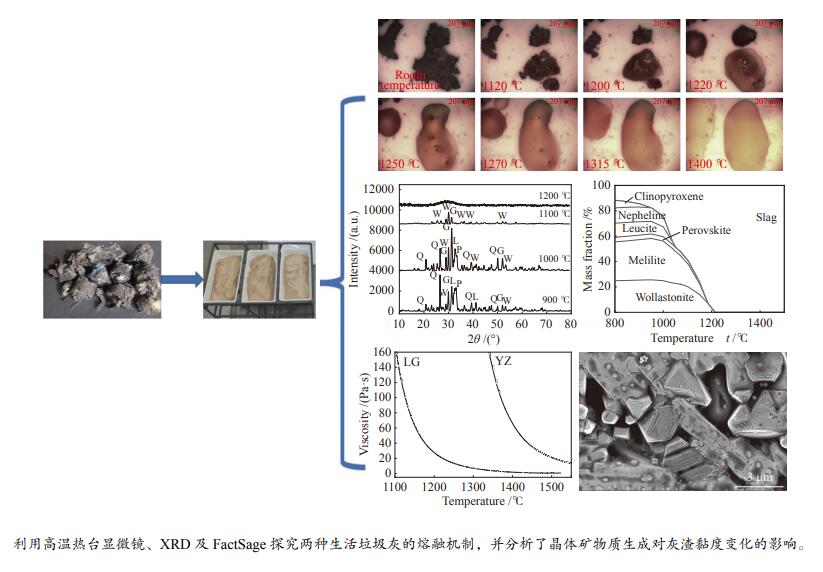

摘要: 城市生活垃圾灰渣的熔融及黏温特性对其固定床熔渣气化炉的优化设计和操作具有重要指导意义。本文分析了上海老港垃圾(LG)和扬州成型垃圾(YZ)的灰成分特征,利用高温热台显微镜、X射线衍射仪(XRD)及FactSage模拟探究了垃圾灰的熔融机制,同时结合高温黏度计、扫描电镜-能谱分析仪(SEM-EDS)和XRD分析晶体矿物质生成对灰渣黏度变化的影响。结果表明,两种生活垃圾灰的硅铝比均较高,但铝钙含量差异较大。YZ灰流动温度比LG灰约高150 ℃,与LG灰中形成易低温共熔的硅灰石,而YZ灰在高温下仍存在石英及尖晶石有关。两种灰渣的熔融均符合“熔融-溶解”机制,且随温度升高均经历收缩、熔融和扩散过程。两条黏温曲线均呈现玻璃渣的特征,但YZ灰的黏度增长较快,与其降温过程产生长条状钙长石晶体有关。以YZ为气化原料需较高的排渣温度,而LG灰的熔融特性和黏温特性均较好,应用此原料气化炉可操作温度范围大。Abstract: The fusibility and viscosity-temperature characteristics of municipal solid waste (MSW) ash slag are important to the optimize design and operation of fixed bed slag gasifier. In this paper, the ash composition characteristics of two MSW samples were analyzed, and the melting mechanism of MSW ash was explored by high temperature heating stage microscope (HTSM), X-ray diffraction (XRD) and FactSage. At the same time, the effect of crystal mineral formation on ash viscosity was analyzed by high-temperature viscometer, SEM-EDS and XRD. The results show that the silica to aluminum ratio of MSW ash are both high, but the contents of aluminum and calcium are different. The flow temperature of YZ ash is about 150 ℃ higher than that of LG ash. Low temperature eutectic of wollastonite is the reason for the lower melting point of LG ash, and the existence of quartz and spinel at high temperature leads to a higher melting point of YZ ash. Ash melting behavior of LG and YZ are both "melt-dissolution" mechanism, and they both undergo shrinkage, melting and diffusion processes with the increase of temperature. The viscosity-temperature curves of LG and YZ are both glassy slag. However, the viscosity-temperature characteristics of YZ ash are relatively poor, which is related to the formation of anorthite during the cooling process. So the application of YZ requires a high slag discharge temperature. LG ash has good fusibility characteristics and viscosity-temperature characteristics, so the gasifier with this material can operate in a wide temperature range.

-

表 1 原料的工业分析、元素分析和热值

Table 1 Proximate analysis, ultimate analysis and calorific value of sample

Sample Proximate analysis wd/% Ultimate analysis wd/% QHHV/(MJ·kg−1) A V FC C H O N S LG 20.27 75.35 4.38 47.50 6.18 23.75 2.03 0.27 19.45 YZ 31.20 61.70 7.10 29.01 3.47 32.30 1.33 2.69 16.32 表 2 样品灰的化学组成

Table 2 Chemical composition of ash

Sample Content w/% A/B S/A SiO2 Al2O3 CaO Fe2O3 SO3 MgO K2O TiO2 Na2O P2O5 Cr2O3 Cl ZnO CuO SrO others LG 39.01 6.73 27.80 4.61 3.49 3.26 2.59 1.99 3.82 3.69 0.19 2.34 0.17 0.13 0.03 0.15 1.13 5.80 YZ 55.89 14.22 14.00 6.08 0.88 2.58 2.18 1.41 1.18 0.52 0.68 0.08 0.23 0.01 0.02 0.04 2.75 3.93 表 3 样品灰的熔融温度

Table 3 Ash fusion temperature of sample

Sample Temperature /℃ DT ST HT FT FT-DT FT-ST LG 1132 1156 1160 1173 41 17 YZ 1147 1174 1196 1310 163 136 表 4 灰渣黏温曲线特征参数

Table 4 Characteristic parameters of ash slag viscosity temperature curve

Sample FT/℃ t25/℃ tcv/℃ ηcv/(Pa·s) LG 1173 1206 1160 54.57 YZ 1310 1483 1380 86.73 -

[1] 王旻烜, 张佳, 何皓, 张家仁. 城市生活垃圾处理方法概述[J]. 环境与发展,2020,32(2):51−52.WANG Min-xuan, ZHANG Jia, HE Hao, ZHANG Jia-ren. Overview of municipal solid waste disposal methods[J]. Environ Dev,2020,32(2):51−52. [2] 李海丹, 郑丽萍, 周涵, 孙煜璨, 张涛, 陈坦, 杨婷, 张冰. 我国生活垃圾组分的时空分布特征回顾[J/OL]. 环境工程, 2022, 40(9): 126−134. http://kns.cnki.net/kcms/detail/11.2097.X.20220325.1608.002.html, 2022-03-28.LI Hai-dan, ZHENG Li-ping, ZHOU Han, SUN Yu-can, ZHANG Tao, CHEN Tan, YANG Ting, ZHANG Bing. Review on spatial-temporal distribution characteristics of municipal solid waste components in China[J]. Environ Eng, 2022, 40(9): 126−134. http://kns.cnki.net/kcms/detail/11.2097.X.20220325.1608.002.html, 2022-03-28. [3] SUN Y, QIN Z, TANG Y, HUANG T, DING S, MA X. Techno-environmental-economic evaluation on municipal solid waste (MSW) to power / fuel by gasification-based and incineration-based routes[J]. J Environ Chem Eng,2021,9(5):106108. doi: 10.1016/j.jece.2021.106108 [4] DU Y, JU T, MENG Y, LAN T, HAN S, JIANG J. A review on municipal solid waste pyrolysis of different composition for gas production[J]. Fuel Process Technol,2021,224:107026. doi: 10.1016/j.fuproc.2021.107026 [5] 郑剑平. 我国煤炭的单位热值碳含量研究[J]. 煤炭加工与综合利用,2022, ,(1):58−62. doi: 10.16200/j.cnki.11-2627/td.2022.01.011ZHENG Jian-ping. Study on carbon content per unit calorific value of coals in China[J]. Coal Process Compr Util,2022, ,(1):58−62. doi: 10.16200/j.cnki.11-2627/td.2022.01.011 [6] WANG J, KONG L, BAI J, XUE K, ZHU X, LUO Y, ZHAO X, LI H, GUO Z, BAI Z, LI W. Characterization of slag from anthracite gasification in moving bed slagging gasifier[J]. Fuel,2021,292:120390. doi: 10.1016/j.fuel.2021.120390 [7] 陈江明. 固定床熔渣气化炉排渣影响因素及其控制方法[J]. 洁净煤技术,2018,24(4):84−89.CHEN Jiang-min. Influence factors and slagging control methods of fixed bed slag gasifier[J]. Clean Coal Technol,2018,24(4):84−89. [8] SCHWITALLA D H, GUHL S, LAABS M, REINMÖLLER M, BAI J, MEYER B. Thermochemical and analytical approach to describe secondary slag phase formation and local process conditions in a full-scale BGL gasifier[J]. Fuel Process Technol,2021,217:106833. doi: 10.1016/j.fuproc.2021.106833 [9] 王冀, 孔令学, 白进, 李怀柱, 郭振兴, 白宗庆, 李文. 煤气化灰渣中残炭对灰渣流动性影响的研究进展[J]. 洁净煤技术,2021,27(1):181−192.WANG Ji, KONG Ling-xue, BAI Jin, LI Huai-zhu, GUO Zhen-xing, BAI Zong-qing, LI Wen. Research progress on the effect of residual carbon in coal gasification slag on ash and slag flow property[J]. Clean Coal Technol,2021,27(1):181−192. [10] MA W, SHI W, SHI Y, CHEN D, LIU B, CHU C, LI D, LI Y, CHEN G. Plasma vitrification and heavy metals solidification of MSW and sewage sludge incineration fly ash[J]. J Hazard Mater,2021,408:124809. doi: 10.1016/j.jhazmat.2020.124809 [11] WANG P, HU Y, CHENG H. Municipal solid waste (MSW) incineration fly ash as an important source of heavy metal pollution in China[J]. Environ Pollut,2019,252:461−475. doi: 10.1016/j.envpol.2019.04.082 [12] 孙进, 谭欣, 纪涛. 助熔物质对生活垃圾焚烧飞灰熔融特性的影响[J]. 节能与环保,2021, ,(5):80−81. doi: 10.3969/j.issn.1009-539X.2021.05.030SUN Jin, TAN Xin, JI Tao. Effect of fluxing agent on melting characteristics of municipal solid waste incineration fly ash[J]. Energy Conserv Environ Prot,2021, ,(5):80−81. doi: 10.3969/j.issn.1009-539X.2021.05.030 [13] 王学涛, 金保升, 徐斌, 屈成锐. 不同氧化物对焚烧飞灰旋风熔融过程中重金属迁移行为的影响[J]. 中国电机工程学报,2014,34(17):2754−2760.WANG Xue-tao, JIN Bao-sheng, XU Bin, QU Cheng-rui. Effect of different oxide additives on migration behavior of heavy metals of MSWI fly ash in swirling melting furnace[J]. Proc CSEE,2014,34(17):2754−2760. [14] QIN J, ZHANG Y, HEBERLEIN S, LISAK G, YI Y. Characterization and comparison of gasification and incineration fly ashes generated from municipal solid waste in Singapore[J]. Waste Manage,2022,146:44−52. doi: 10.1016/j.wasman.2022.04.041 [15] LIN C, ZHANG J, ZHAO P, WANG Z, YANG M, CUI X, TIAN H, GUO Q. Gasification of real MSW-derived hydrochar under various atmosphere and temperature[J]. Thermochim Acta,2020,683:178470. doi: 10.1016/j.tca.2019.178470 [16] LEE D J. Gasification of municipal solid waste (MSW) as a cleaner final disposal route: A mini-review[J]. Bioresour Technol,2022,344:126217. doi: 10.1016/j.biortech.2021.126217 [17] QING M, LONG Y, LUO Y, LUO Z, LI W, TIAN H, YIN Y, HE J, LIU L, XIANG J. Insights into the slagging process during the utilization of food waste: Ash-making temperature and additives[J]. Chem Eng Sci,2022,255:117680. doi: 10.1016/j.ces.2022.117680 [18] 马修卫, 李风海, 马名杰, 房倚天. 长治煤与生物质混合灰熔融特性研究[J]. 燃料化学学报,2018,46(2):129−137. doi: 10.3969/j.issn.0253-2409.2018.02.001MA Xiu-wei, LI Feng-hai, MA Ming-jie, FANG Yi-tian. Fusion characteristics of blended ash from Changzhi coal and biomass[J]. J Fuel Chem Technol,2018,46(2):129−137. doi: 10.3969/j.issn.0253-2409.2018.02.001 [19] 吉恒松, 李振强, 周言, 戚奕, 何志霞. 生物质与烟煤混合灰渣黏温特性研究[J]. 燃料化学学报,2021,49(1):11−19.JI Heng-song, LI Zhen-qiang, ZHOU Yan, QI Yi, HE Zhi-xia. The research on viscosity-temperature characteristics of the mixed slag of biomass and bituminous coal[J]. J Fuel Chem Technol,2021,49(1):11−19. [20] XU J, WANG J, DU C, LI S, LIU X. Understanding fusibility characteristics and flow properties of the biomass and biomass-coal ash samples[J]. Renew Energy,2020,147:1352−1357. doi: 10.1016/j.renene.2019.09.066 [21] KONG L, BAI J, LI W. Viscosity-temperature property of coal ash slag at the condition of entrained flow gasification: A review[J]. Fuel Process Technol,2021,215:106751. doi: 10.1016/j.fuproc.2021.106751 [22] 赵锋, 龚岩, 刘霞, 许洁, 于广锁. 神府煤低温灰与高温灰的高温熔融特征[J]. 中国电机工程学报,2015,35(5):1161−1168. doi: 10.13334/j.0258-8013.pcsee.2015.05.017ZHAO Feng, GONG Yan, LIU Xia, XU Jie, YU Guang-suo. Fusion characteristics at high temperature of low temperature ash and high temperature ash of shenfu coal[J]. Proc CSEE,2015,35(5):1161−1168. doi: 10.13334/j.0258-8013.pcsee.2015.05.017 [23] 许洁, 刘霞, 张庆, 赵锋, 郭庆华, 于广锁, 王辅臣. 高钙山鑫煤灰熔融及黏温特性分析[J]. 中国电机工程学报,2013,33(20):46−51.XU Jie, LIU Xia, ZHANG Qing, ZHAO Feng, GUO Qing-hua, YU Guang-suo, WANG Fu-chen. Research on ash fusibility and viscosity-temperature characteristics of high-calcium shanxin coal ash[J]. Proc CSEE,2013,33(20):46−51. [24] SONG W J, TANG L H, Zhu X D, WU Y Q, ZHU Z B, KOYAMA S. Effect of coal ash composition on ash fusion temperature.[J]. Energy Fuels,2010,24(1):182−189. doi: 10.1021/ef900537m [25] HEBERLEIN S, CHAN W P, VEKSHA A, GIANNIS A, HUPA L, LISAK G. High temperature slagging gasification of municipal solid waste with biomass charcoal as a greener auxiliary fuel[J]. J Hazard Mater,2022,423:127057. doi: 10.1016/j.jhazmat.2021.127057 [26] 洪千惠, 刘霞, 唐龙飞, 陈雪莉. 农林废弃生物质与煤共气化灰渣的理化特性研究进展[J]. 燃料化学学报,2022,50(6):641−651. doi: 10.1016/S1872-5813(21)60197-4HONG Qian-hui, LIU Xia, TANG Long-fei, CHEN Xue-li. Progress in physicochemical properties of ash/slag from co-gasification of agroforestry waste biomass and coal[J]. J Fuel Chem Technol,2022,50(6):641−651. doi: 10.1016/S1872-5813(21)60197-4 [27] SHI W, LAABS M, REINMöLLER M, BAI J, GUHL S, KONG L, LI H, MEYER B, LI W. In-situ analysis of the effect of CaO/Fe2O3 addition on ash melting and sintering behavior for slagging-type applications[J]. Fuel,2021,285:119090. doi: 10.1016/j.fuel.2020.119090 [28] 李文, 白进. 煤的灰化学[M]. 北京: 科学出版社, 2013.LI Wen, BAI Jin. Ash Chemistry of Coal[M]. Beijing: Science Press, 2013. [29] QIN Y H, FENG M M, ZHAO Z B, VASSILEV S V, FENG J, VASSILEVA C G, LI W Y. Effect of biomass ash addition on coal ash fusion process under CO2 atmosphere[J]. Fuel,2018,231:417−426. doi: 10.1016/j.fuel.2018.05.110 [30] HE C, ILYUSHECHKIN A, BAI J, HLA S S, KONG L-X, LI W. Viscosity and crystallisation behaviour of coal ash slag from the primary phase of anorthite[J]. Fuel Process Technol,2021,213:106680. doi: 10.1016/j.fuproc.2020.106680 -

下载:

下载: