Effect of gas-pressurized torrefaction on the upgrading and pyrolysis characteristics of corn stalk

-

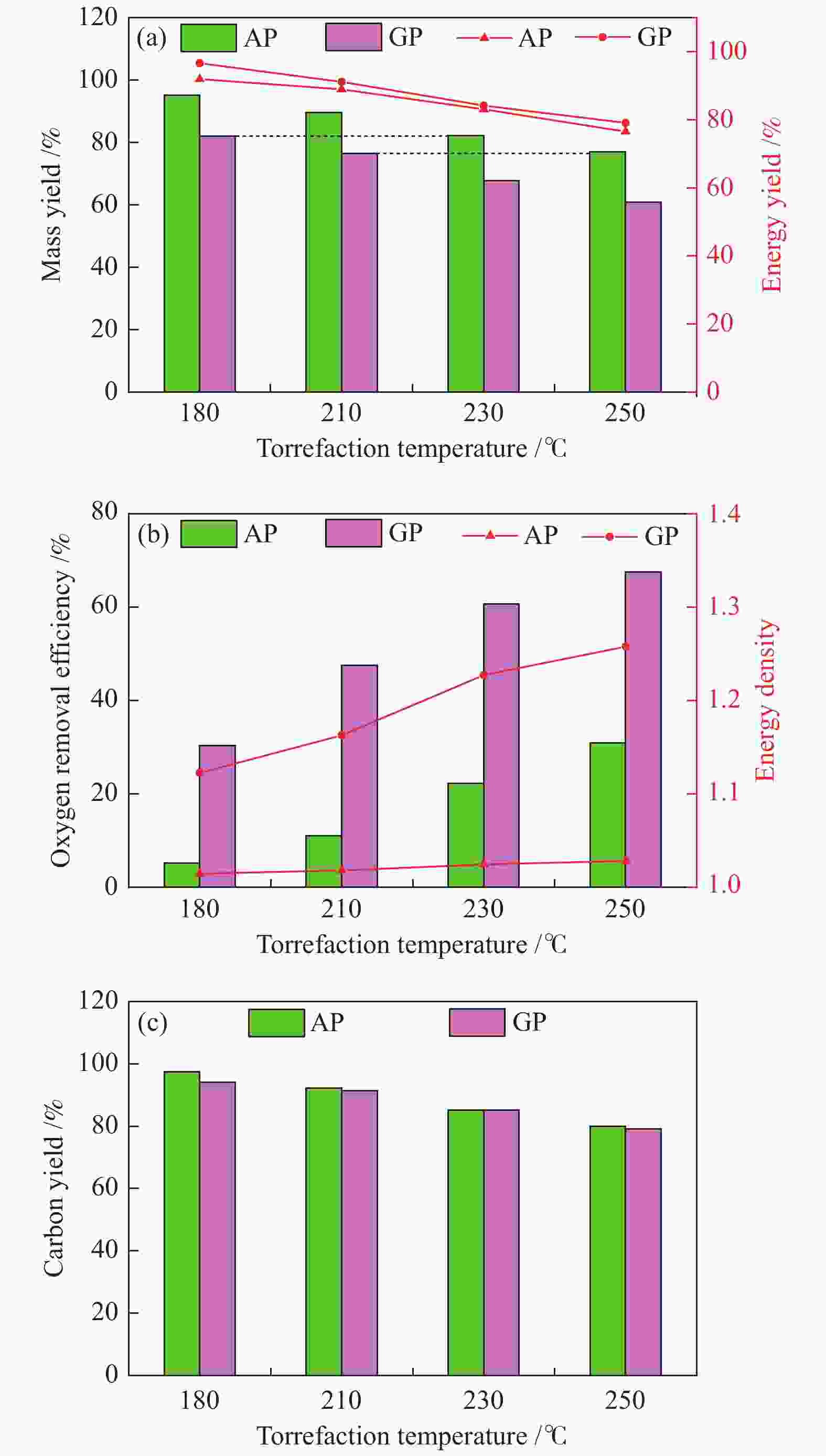

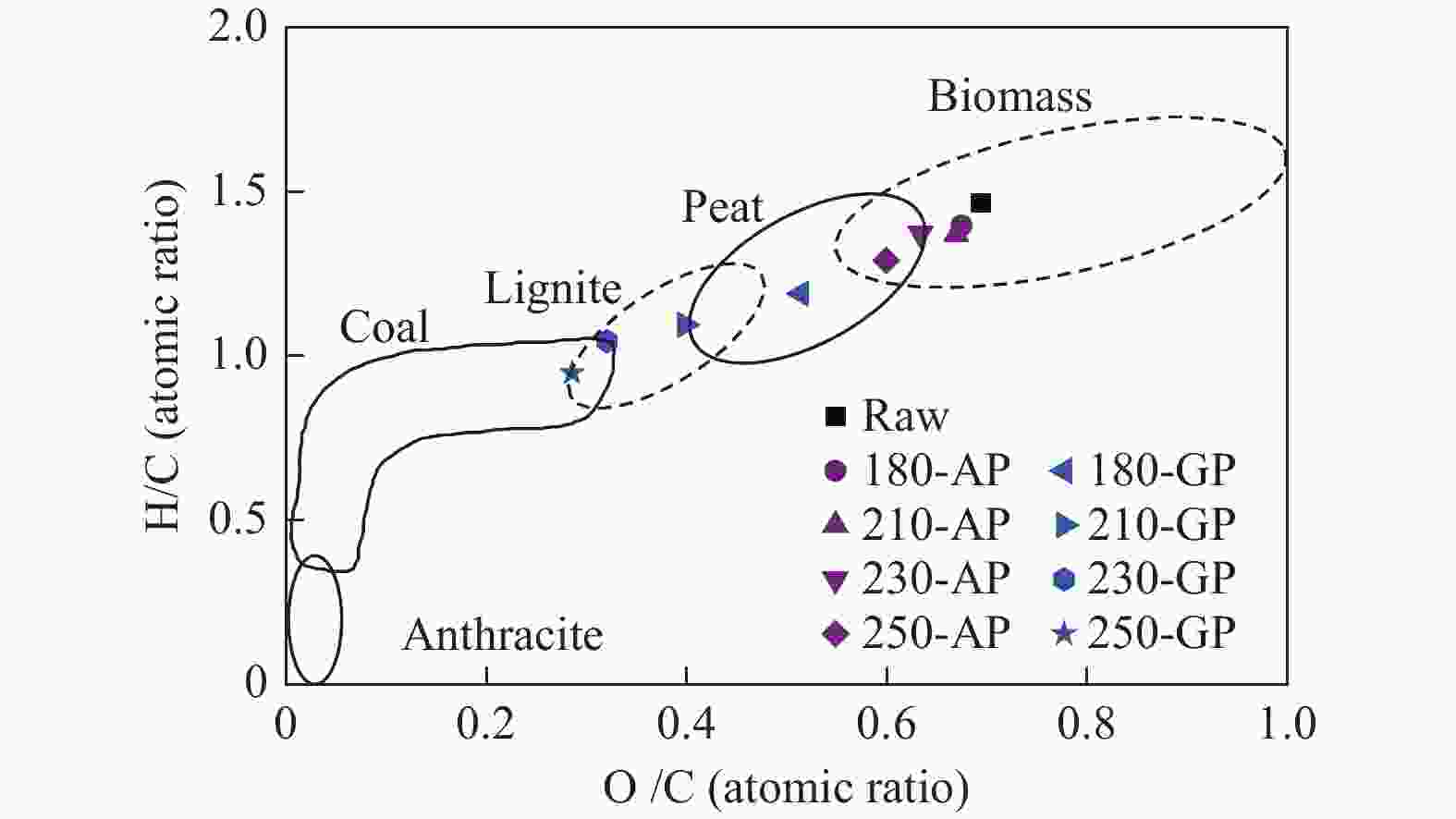

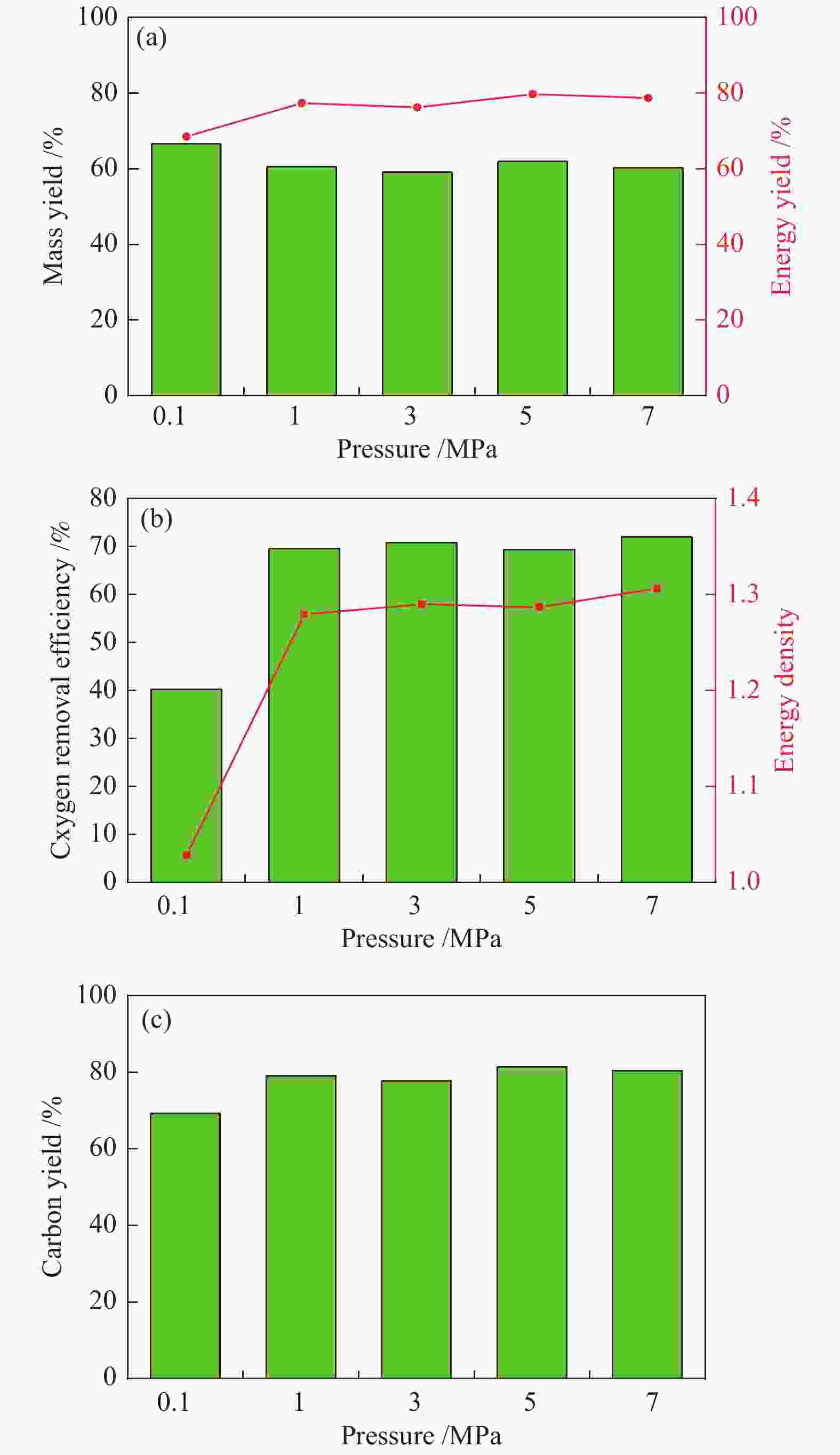

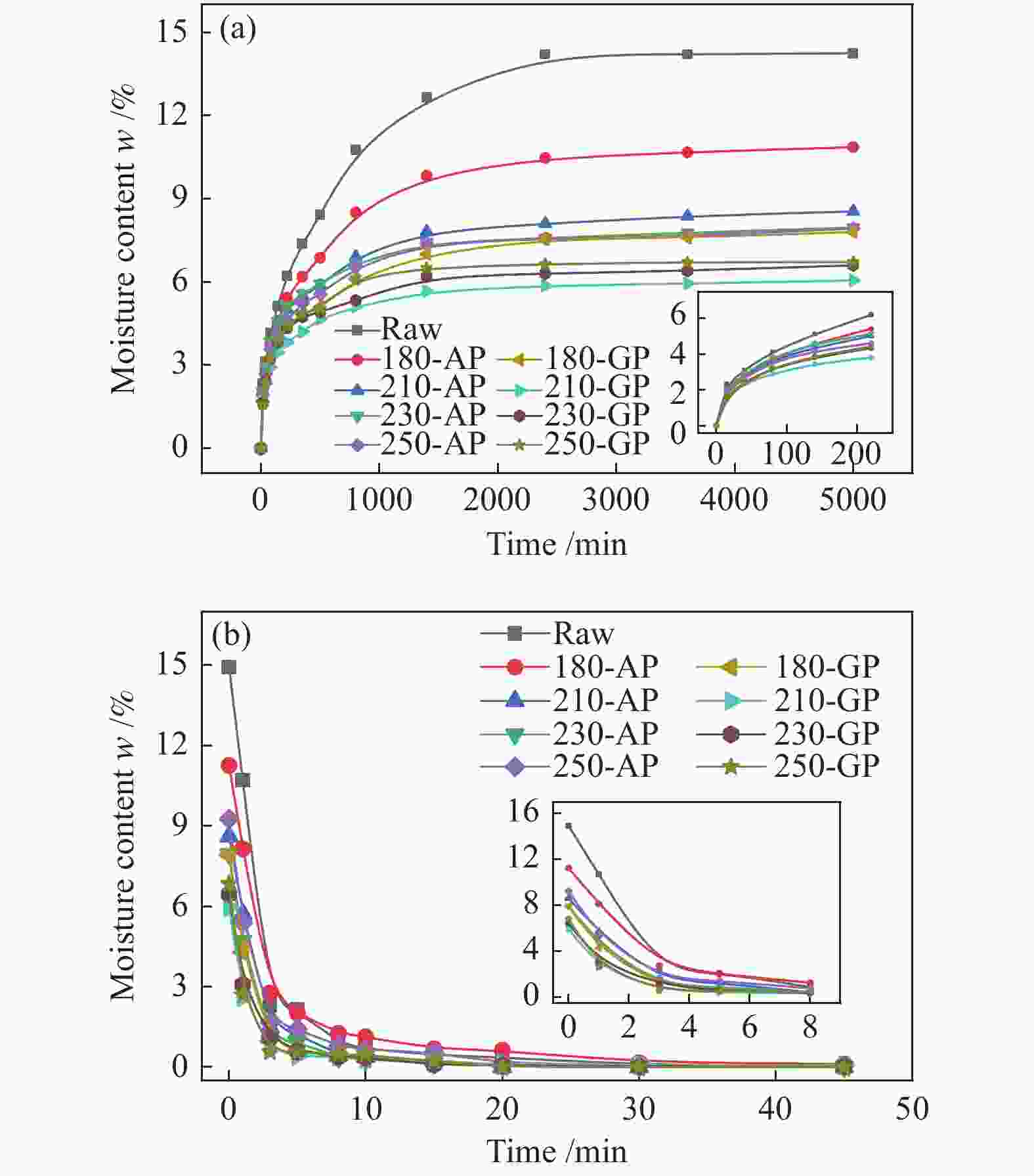

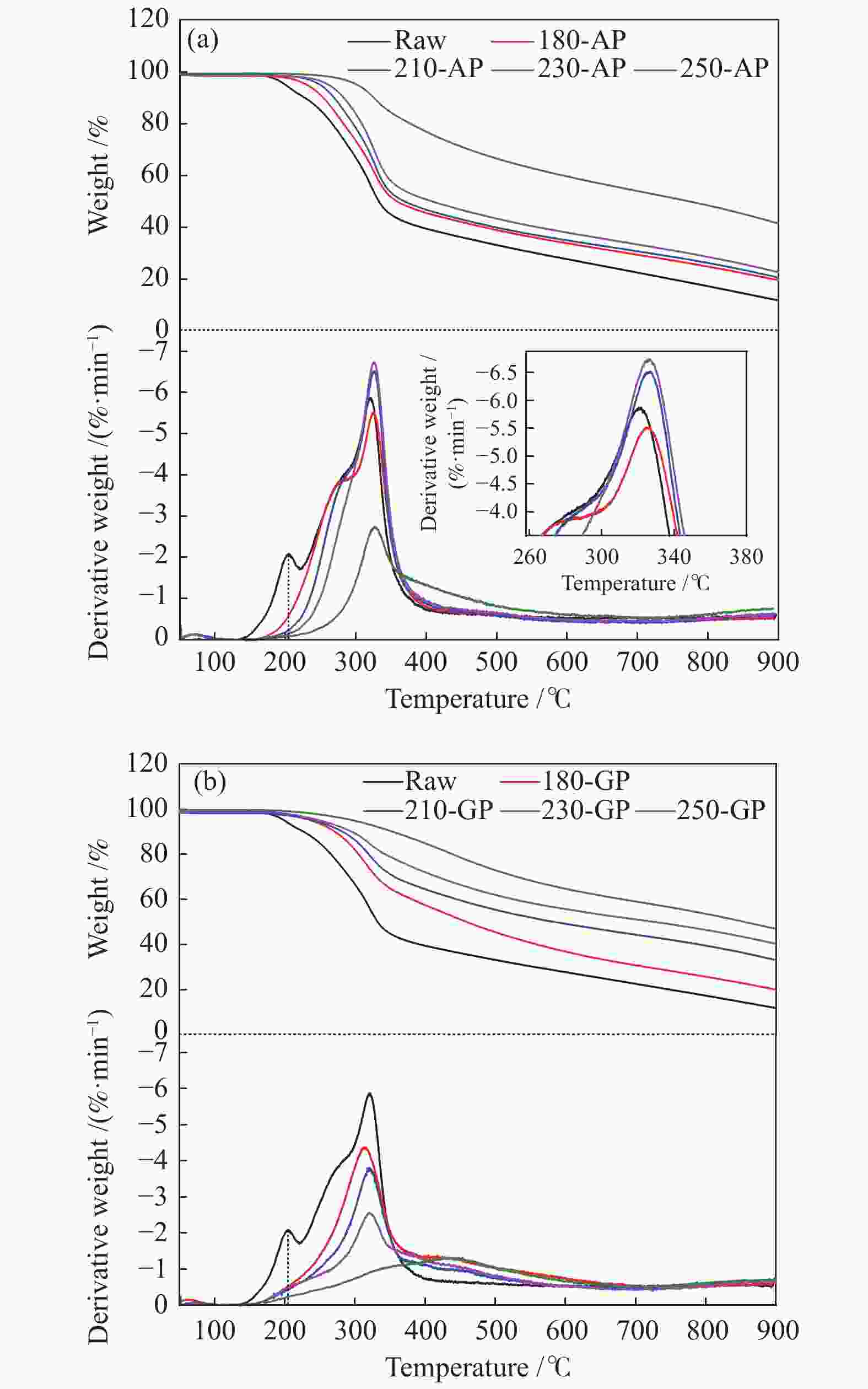

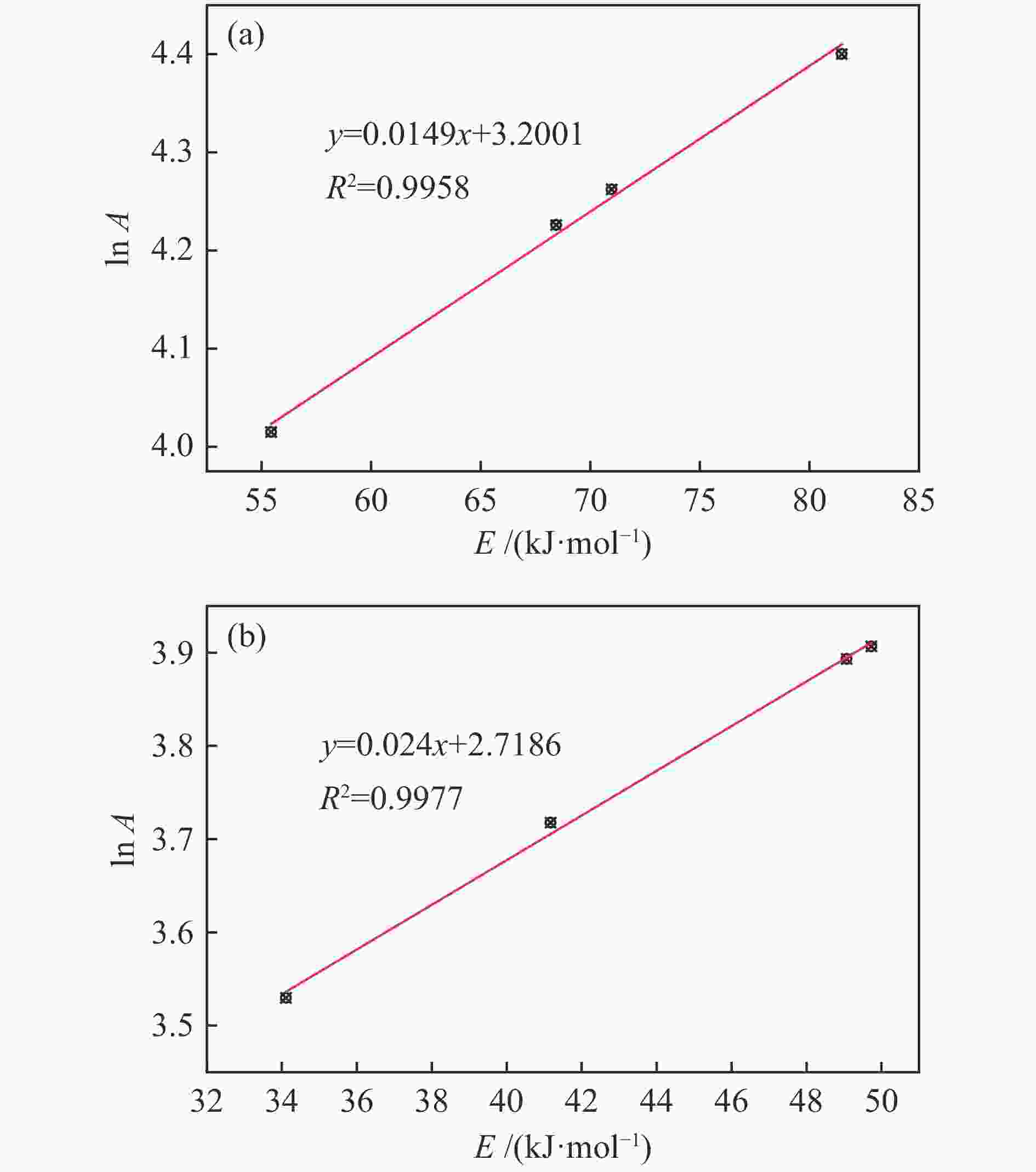

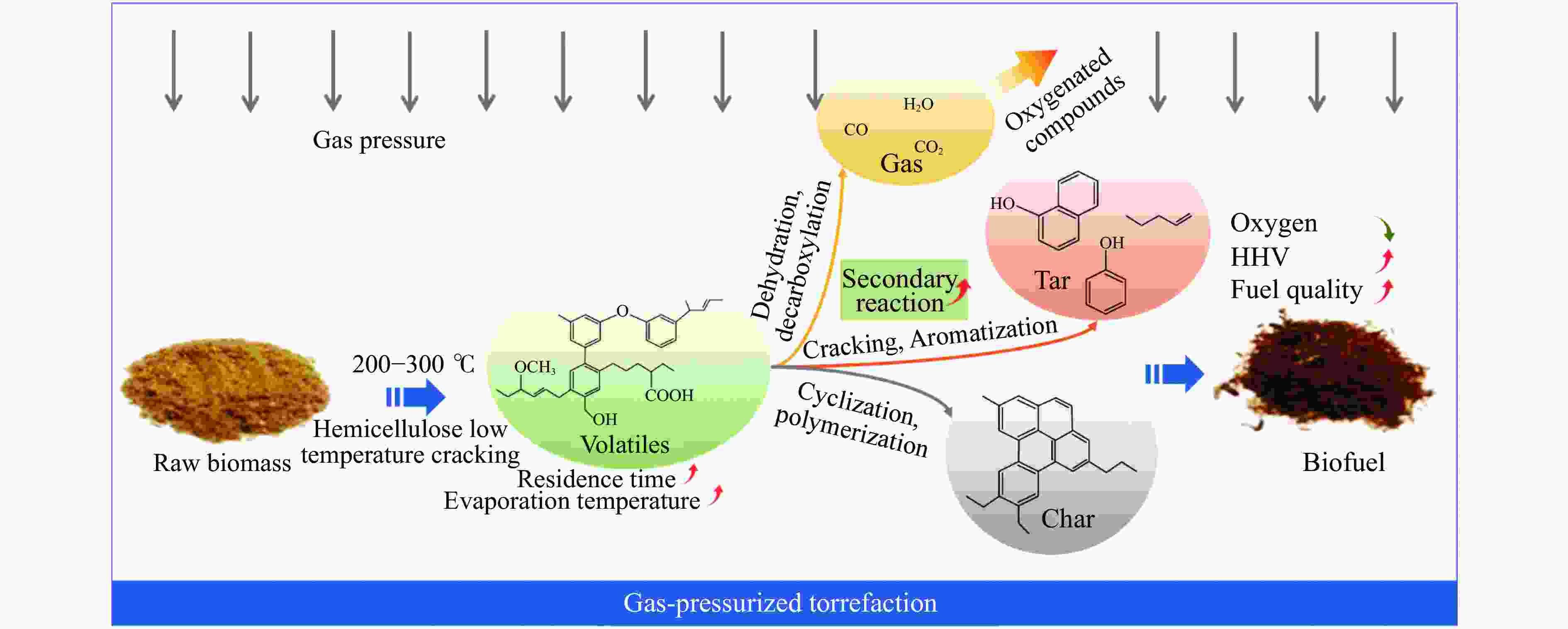

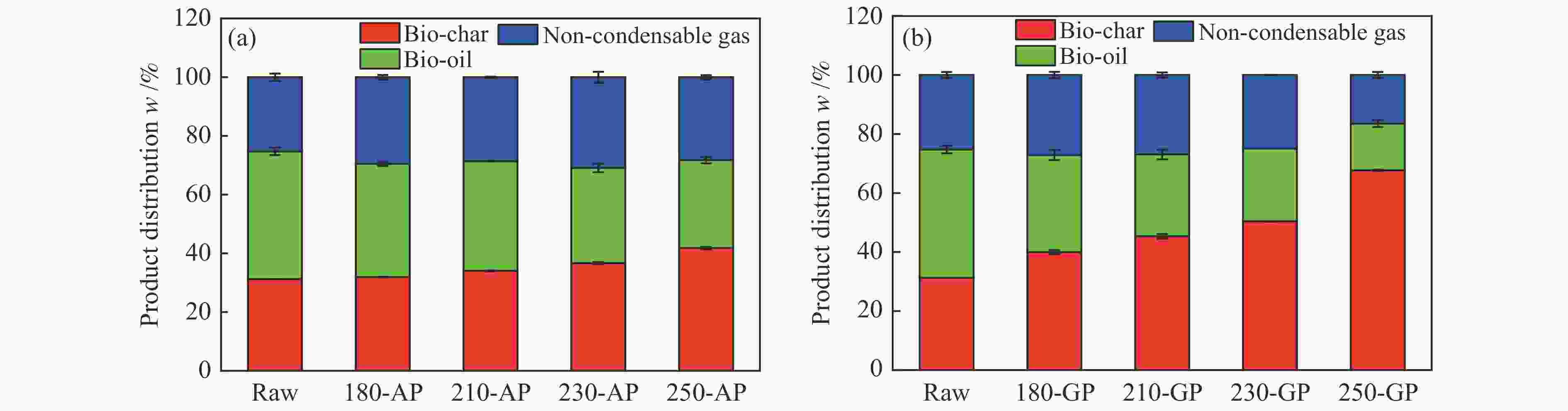

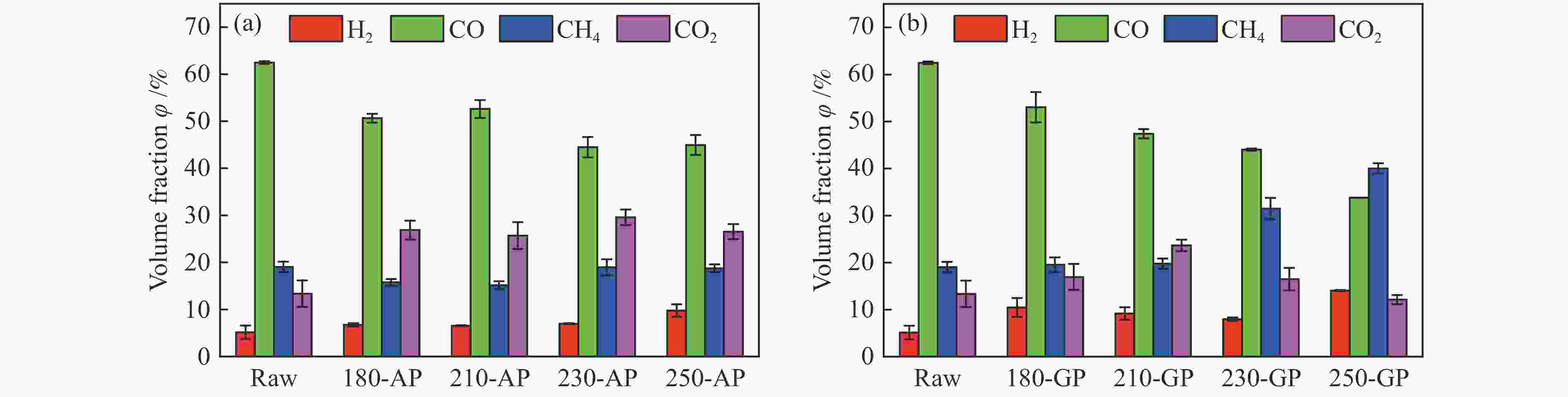

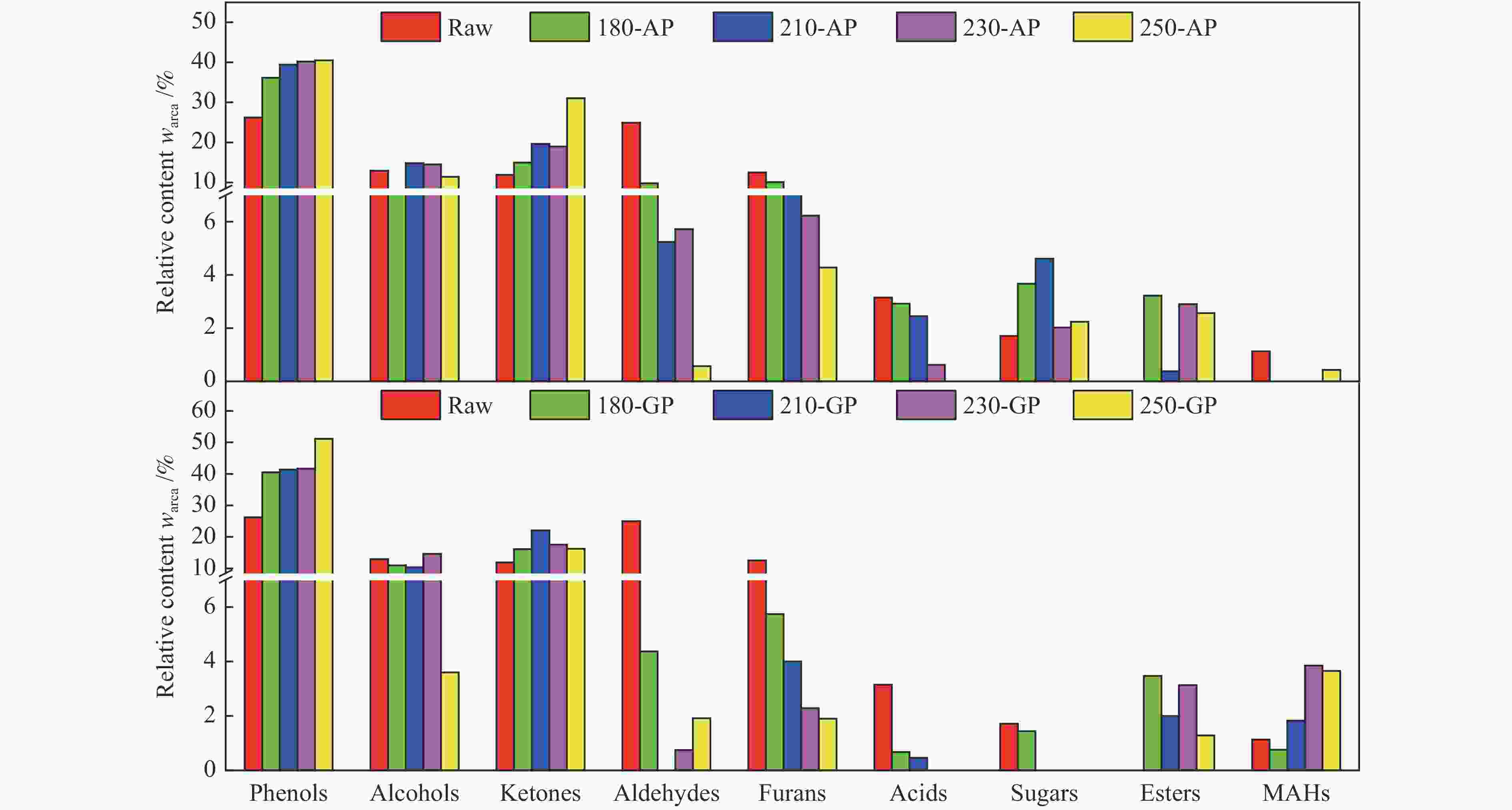

摘要: 在不同温度及压力下对玉米秸秆进行了烘焙,通过元素分析、FT-IR、TGA以及固定床热解等方式分析了烘焙产物的理化特性与热解特性,研究了气体加压烘焙对生物质燃料特性及热转化行为的影响,结果表明,烘焙样品的脱氧效率及能量密度均随烘焙温度的升高而增加;在相同质量收率时,加压烘焙所需温度比常压烘焙低约40 ℃,且能量收率、碳收率、脱氧效率以及烘焙产物的能量密度分别为常压烘焙的1.125、1.142、1.539和1.131倍;加压烘焙样品比常压烘焙表现出更好的疏水性,且更易于脱水;当烘焙温度为250 ℃时,加压烘焙样品热解气相产物中CH4和H2含量分别为常压烘焙的2.135和1.439倍;加压烘焙样品热解液相产物中酚类相对含量增加,最高可达51.11%,而呋喃类和酸类物质含量则明显下降。相较于常压烘焙,加压烘焙在相同温度下对生物质具有更好的提质效果。Abstract: Corn straw was torrefied under at different temperatures and the torrefied products were characterized by proximate analysis, ultimate analysis, FT-IR, TGA and pyrolysis experiments; the effect of gas-pressurized torrefaction on the upgrading and pyrolysis characteristics of corn stalk was investigated. The results indicate that the deoxidation efficiency and energy density of torrefied products under both atmospheric pressure (AP) and gas pressured (GP) conditions increase with the increase of torrefaction temperature. The temperature required for GP torrefaction is almost 40 °C lower than that for AP torrefaction to obtain the same mass yield. The energy yield, carbon yield, deoxidation efficiency and the energy density of GP-torrefied corn straw are 1.125, 1.142, 1.539 and 1.131 times higher than those of AP-torrefied one, respectively. The GP-torrefied corn straw shows better hydrophobicity and is easier to dehydrate. In addition, the pyrolysis of GP-torrefied corn straw produces significantly higher fractions of CH4 and H2 in the gaseous product than the pyrolysis of AP-torrefied one; meanwhile, the relative content of phenols in the liquid products for the pyrolysis of GP-torrefied samples also increases up to 51.11%, whereas the contents of furans and acids decrease considerably. All these suggest that GP torrefaction performs better in biofuel upgrading than AP torrefaction under the same temperature.

-

Key words:

- corn stalk /

- gas-pressurized torrefaction /

- upgrading /

- pyrolysis characteristics

-

表 1 玉米秸秆灰分的XRF成分分析

Table 1 XRF analysis of corn stalk ash

Sample Content w/% SiO2 K2O CaO2 MgO P2O5 Al2O3 Fe2O3 Na2O Corn stalk 44.01 17.97 9.48 7.13 5.92 3.13 2.47 0.59 表 2 原生及烘焙玉米秸秆的基本性质

Table 2 Basic properties of raw and torrefied biomass samples

Sample Proximate analysis w/ %(dry base) Elemental analysis w/%(dry base) QHHV/(MJ·kg−1) V FC A C H O* N Raw 72.67 19.63 7.70 43.70 5.34 40.43 2.83 17.65 180-AP 72.42 19.84 7.74 44.73 5.21 40.23 2.09 17.91 210-AP 71.09 21.12 7.79 44.95 5.14 40.12 2.00 17.97 230-AP 68.06 22.63 9.31 45.25 5.18 38.22 2.04 18.09 250-AP 66.56 22.30 11.14 45.42 4.89 36.29 2.26 18.15 180-GP-5 65.40 26.0 8.60 50.12 4.97 34.36 1.95 19.82 210-GP-5 55.51 31.22 13.27 52.14 4.76 27.69 2.14 20.53 230-GP-5 53.82 31.58 14.60 55.00 4.79 23.49 2.12 21.67 250-GP-5 48.96 35.79 15.25 57.37 4.80 19.97 2.62 22.71 250-GP-1 48.49 36.38 15.13 57.02 4.80 20.36 2.69 22.58 250-GP-3 48.92 36.02 15.06 57.48 4.81 20.02 2.63 22.77 250-GP-7 48.53 35.88 15.59 58.20 4.79 18.79 2.63 23.06 O*:calculated by difference 表 3 不同温度5 MPa加压烘焙需要的初始压力与加压能耗

Table 3 Initial pressure and energy consumption for 5 MPa GP torrefaction at different temperatures

Torrefaction temperature/℃ Initial pressure/MPa Energy consumption/MJ 180 3.29 2.87 210 3.09 2.65 230 2.96 2.51 250 2.85 2.39 表 4 原生及烘焙样品的热解特性参数

Table 4 Pyrolysis parameters of the raw and torrefied corn stalk samples

Sample ti/℃ tp/℃ Rmax/(%·min−1) Rv/(%·min−1) wf/% Δt1/2/℃ Di/10−7 Raw 199.00 320.40 5.88 0.92 12.06 252.67 3.65 180-AP 231.00 325.96 5.52 0.93 19.75 250.00 2.93 210-AP 247.71 327.28 6.52 0.92 20.65 268.55 2.99 230-AP 260.99 326.69 6.74 0.90 22.68 286.56 2.76 250-AP 287.49 326.45 2.74 0.61 41.73 299.33 0.98 180-GP 235.64 316.11 4.38 0.93 20.04 272.83 2.15 210-GP 240.74 320.46 3.81 0.77 32.88 285.45 1.73 230-GP 237.19 319.87 2.56 0.69 40.05 283.15 1.19 250-GP 267.92 432.99 1.32 0.55 47.16 288.87 0.40 表 5 原生及烘焙样品的动力学参数

Table 5 Kinetic parameters for the pyrolysis of raw and torrefied corn straw samples.

Sample Temperature range/℃ E/(kJ·mol−1) A/min−1 R² Raw 220−350 37.99 1.14×104 0.9989 180-AP 220−350 55.43 5.09×105 0.9849 210-AP 220−350 70.97 1.32×107 0.9900 230-AP 220−350 81.47 9.89×107 0.9970 250-AP 220−350 68.44 1.15×107 0.9929 180-GP 220−350 49.07 7.61×104 0.9974 210-GP 220−350 49.73 7.79×104 0.9985 230-GP 220−350 41.17 9.38×103 0.9984 250-GP 220−450 34.11 8.05×102 0.9851 -

[1] ZENG K, HE X, YANG H P, WANG X H, CHEN H P. The effect of combined pretreatments on the pyrolysis of corn stalk[J]. Bioresour Technol,2019,281:309−317. doi: 10.1016/j.biortech.2019.02.107 [2] DAI L L, WANG Y P, LIU Y H, RUAN R, HE C, YU Z T, JIANG L, ZENG Z H, TIAN X J. Integrated process of lignocellulosic biomass torrefaction and pyrolysis for upgrading bio-oil production: A state-of-the-art review[J]. Renewable Sustainable Energy Rev,2019,107:20−36. doi: 10.1016/j.rser.2019.02.015 [3] CHEN Z W, WANG M F, JIANG E C, WANG D H, ZHANG K, REN Y Z, JIANG Y. Pyrolysis of Torrefied Biomass[J]. Trends Biotechnol,2018,36(12):1287−1298. doi: 10.1016/j.tibtech.2018.07.005 [4] CHEN W H, PENG J H, BI X T T. A state-of-the-art review of biomass torrefaction, densification and applications[J]. Renewable Sustainable Energy Rev,2015,44:847−866. doi: 10.1016/j.rser.2014.12.039 [5] HE Q, DING L, GONG Y, LI W F, WEI J T, YU G S. Effect of torrefaction on pinewood pyrolysis kinetics and thermal behavior using thermogravimetric analysis[J]. Bioresour Technol,2019,280:104−111. doi: 10.1016/j.biortech.2019.01.138 [6] YUE Y, SINGH H, SINGH B, MANI S. Torrefaction of sorghum biomass to improve fuel properties[J]. Bioresour Technol,2017,232:372−379. doi: 10.1016/j.biortech.2017.02.060 [7] LI S X, CHEN C Z, LI M F, XIAO X. Torrefaction of corncob to produce charcoal under nitrogen and carbon dioxide atmospheres[J]. Bioresour Technol,2018,249:348−353. doi: 10.1016/j.biortech.2017.10.026 [8] WANG Z L, LIM C J, GRACE J R, LI H, PARISE M R. Effects of temperature and particle size on biomass torrefaction in a slot-rectangular spouted bed reactor[J]. Bioresour Technol,2017,244(Pt 1):281−288. [9] LI S X, ZOU J Y, LI M F, WU X F, BIAN J, XUE Z M. Structural and thermal properties of Populus tomentosa during carbon dioxide torrefaction[J]. Energy,2017,124:321−329. doi: 10.1016/j.energy.2017.02.079 [10] XIN S Z, HUANG F, LIU X Y, MI T, XU Q L. Torrefaction of herbal medicine wastes: Characterization of the physicochemical properties and combustion behaviors[J]. Bioresour Technol,2019,287:121408. doi: 10.1016/j.biortech.2019.121408 [11] XIN S Z, MI T, LIU X Y, HUANG F. Effect of torrefaction on the pyrolysis characteristics of high moisture herbaceous residues[J]. Energy,2018,152:586−593. doi: 10.1016/j.energy.2018.03.104 [12] MENG J J, MOORE A, TILOTTA D C, KELLEY S S, ADHIKARI S, PARKT S. Thermal and storage stability of bio-oil from pyrolysis of Torrefied wood[J]. Energy Fuels,2015,29(8):5117−5126. doi: 10.1021/acs.energyfuels.5b00929 [13] CHEN D Y, ZHENG Z C, FU K X, ZENG Z, WANG J J, LU M T. Torrefaction of biomass stalk and its effect on the yield and quality of pyrolysis products[J]. Fuel,2015,159:27−32. doi: 10.1016/j.fuel.2015.06.078 [14] ONSREE T, TIPPAYAWONG N, WILLIAMS T, MCCULLOUGH K, BARROW E, POGAKU R, LAUTERBACH J. Torrefaction of pelletized corn residues with wet flue gas[J]. Bioresour Technol,2019,285:121330. doi: 10.1016/j.biortech.2019.121330 [15] BERRUECO C, RECARI J, GÜELL B M, DEL ALAMO G. Pressurized gasification of torrefied woody biomass in a lab scale fluidized bed[J]. Energy,2014,70:68−78. doi: 10.1016/j.energy.2014.03.087 [16] CHEN Y J, ZHANG L, ZHANG Y T, LI A M. Pressurized pyrolysis of sewage sludge: Process performance and products characterization[J]. J Anal Appl Pyrolysis,2019,139:205−212. doi: 10.1016/j.jaap.2019.02.007 [17] MANYÀ J J, AZUARA M, MANSO J A. Biochar production through slow pyrolysis of different biomass materials: Seeking the best operating conditions[J]. Biomass Bioenergy,2018,117:115−123. doi: 10.1016/j.biombioe.2018.07.019 [18] WANNAPEERA J, WORASUWANNARAK N. Upgrading of woody biomass by torrefaction under pressure[J]. J Anal Appl Pyrolysis,2012,96:173−180. doi: 10.1016/j.jaap.2012.04.002 [19] TONG S, XIAO L, LI X, ZHU X Q, LIU H, LUO G Q, WORASUWANNARAK N, KERDSUWAN S, FUNGTAMMASAN B, YAO H. A gas-pressurized torrefaction method for biomass wastes[J]. Energy Convers Manage,2018,173:29−36. doi: 10.1016/j.enconman.2018.07.051 [20] SUN Y M, TONG S, LI X, WANG F, HU Z Z, DACRES O D, EDREIS E M A, WORASUWANNARAK N, SUN M Y, LIU H. Gas-pressurized torrefaction of biomass wastes: The optimization of pressurization condition and the pyrolysis of torrefied biomass[J]. Bioresour Technol,2021,319:124216. doi: 10.1016/j.biortech.2020.124216 [21] AGAR D, DEMARTINI N, HUPA M. Influence of Elevated Pressure on the Torrefaction of Wood[J]. Energy Fuels,2016,30(3):2127−2136. doi: 10.1021/acs.energyfuels.5b01352 [22] NHUCHHEN D R, BASU P. Experimental Investigation of Mildly Pressurized Torrefaction in Air and Nitrogen[J]. Energy Fuels,2014,28(5):3110−3121. doi: 10.1021/ef4022202 [23] ZHANG Y, SONG K Y. Thermal and chemical characteristics of torrefied biomass derived from a generated volatile atmosphere[J]. Energy,2018,165:235−245. [24] ITOH T, IWABUCHI K, MAEMOKU N, SASAKI I, TANIGURO K. A new torrefaction system employing spontaneous self-heating of livestock manure under elevated pressure[J]. Waste Manag,2019,85:66−72. doi: 10.1016/j.wasman.2018.12.018 [25] MEDIC D, DARR M, SHAH A, RAHN S. Effect of torrefaction on water vapor adsorption properties and resistance to microbial degradation of corn stover[J]. Energy Fuels,2012,26(4):2386−2393. doi: 10.1021/ef3000449 [26] CHENG X X, HUANG Z, WANG Z Q, MA C Y, CHEN S Y. A novel on-site wheat straw pretreatment method: Enclosed torrefaction[J]. Bioresour Technol,2019,281:48−55. doi: 10.1016/j.biortech.2019.02.075 [27] YAN W, PEREZ S, SHENG K C. Upgrading fuel quality of moso bamboo via low temperature thermochemical treatments: Dry torrefaction and hydrothermal carbonization[J]. Fuel,2017,196:473−480. doi: 10.1016/j.fuel.2017.02.015 [28] UEMURA Y, SAADON S, OSMAN N, MANSOR N, TANOUE K. Torrefaction of oil palm kernel shell in the presence of oxygen and carbon dioxide[J]. Fuel,2015,144:171−179. doi: 10.1016/j.fuel.2014.12.050 [29] SUN Y M, TONG S, LI X, HU Z Z, SUN M Y, GUO L LIU H, HU H Y, LUO G Q, YAO H. Gas-pressurized torrefaction of biomass wastes: Self-promoted deoxygenation of rice straw at low temperature[J]. Fuel,2022,308:122029. doi: 10.1016/j.fuel.2021.122029 [30] YANG H P, LIU M, CHEN Y Q, XIN S Z, ZHANG X, WAMG X H, CHEN H P. Vapor–solid interaction among cellulose, hemicellulose and lignin[J]. Fuel,2020,263:116681. doi: 10.1016/j.fuel.2019.116681 [31] WANNAPEERA J, WORASUWANNARAK N. Examinations of chemical properties and pyrolysis behaviors of torrefied woody biomass prepared at the same torrefaction mass yields[J]. J Anal Appl Pyrolysis,2015,115:279−287. doi: 10.1016/j.jaap.2015.08.007 [32] MA Z Q, WANG J H, YANG Y Y, ZHANG Y, ZHAO C, YU Y M, WANG S R. Comparison of the thermal degradation behaviors and kinetics of palm oil waste under nitrogen and air atmosphere in TGA-FTIR with a complementary use of model-free and model-fitting approaches[J]. J Anal Appl Pyrolysis,2018,134:12−24. doi: 10.1016/j.jaap.2018.04.002 [33] WIGLEY T, YIP A C K, PANG S S. The use of demineralisation and torrefaction to improve the properties of biomass intended as a feedstock for fast pyrolysis[J]. J Anal Appl Pyrolysis,2015,113:296−306. doi: 10.1016/j.jaap.2015.02.007 [34] HAN Z, ZENG X, YAO C, XU G. Oxygen migration in torrefaction of eupatorium adenophorum spreng. and its improvement on fuel properties[J]. Energy Fuels,2015,29(11):7275−7283. doi: 10.1021/acs.energyfuels.5b01318 [35] CHEN D Y, GAO A J, CEN K H, ZHANG J, CAO X B, MA Z Q. Investigation of biomass torrefaction based on three major components: Hemicellulose, cellulose, and lignin[J]. Energy Convers Manage,2018,169:228−237. doi: 10.1016/j.enconman.2018.05.063 -

下载:

下载: