Recent progress in regulating of zeolite-based catalysts by atomic layer deposition technology

-

摘要: 分子筛基催化剂在多相催化研究领域具有重要的应用,但调控活性中心粒子的结构及其在分子筛上的空间位置仍比较困难,是科研界和工业界共同面临的巨大挑战。原子层沉积(ALD)是一种先进的薄膜沉积技术,利用其自限制生长优势,可在原子级别实现对金属粒子生长过程的精准调控。本工作综述了ALD技术在制备分子筛基催化剂方面的应用,主要包括利用ALD技术控制活性位点在分子筛上的生长落位、修饰分子筛骨架结构以及选择性沉积膜调变分子筛表面结构。利用ALD技术设计和调控活性组分结构促进了分子筛基催化剂的发展,但由于分子筛孔道结构复杂且存在缺陷位,因此,ALD技术在分子筛基催化剂的设计调控及大规模应用方面仍具有挑战性,也是今后研究工作的重点。Abstract: Zeolite-based catalysts have been widely used in the field of heterogeneous catalysis, but it is still difficult to control the structure and location of active sites on zeolite, which also confronts with great challenge both from academia and industry. Atomic layer deposition (ALD) is an advanced thin film deposition technique, owing to its advantages of self-limiting surface reactions, which can precisely tailor the growth process of metallic particles in atomic scale. In this review, we present a comprehensive summary of regulating the location of active sites on zeolite, modifying the framework structure and regioselective depositing of metal on special sites to engineering the surface structures of zeolites via ALD method. The design and regulation the structures of active component by ALD technology are beneficial to the development of zeolite-based catalysts. However, due to the complex of zeolite channels and the existence of defects, it is still challenging for the ALD technology to design, regulate and apply with large-scale for zeolite-based catalysts, and it will be the focus in the future research.

-

Key words:

- zeolite /

- atomic layer deposition /

- catalyst /

- regulation /

- selectivity deposition

-

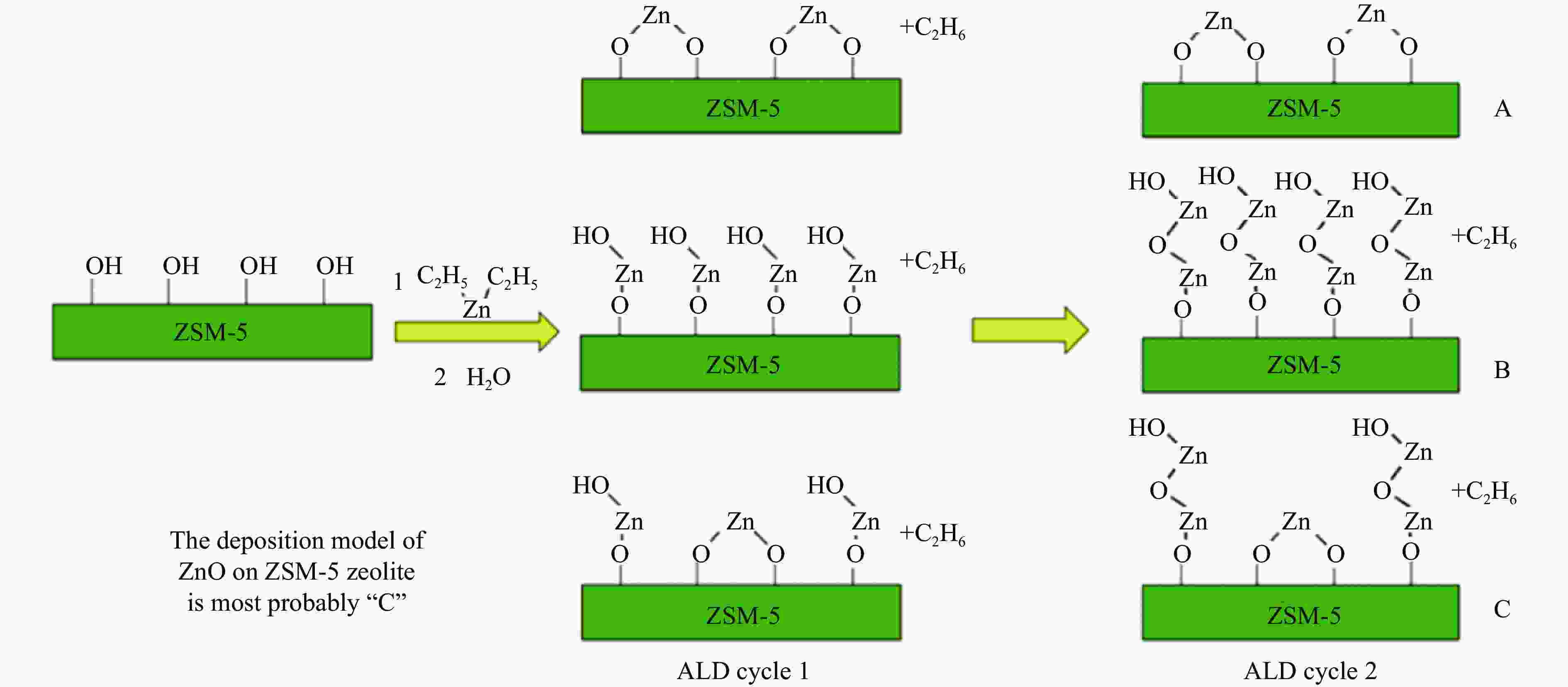

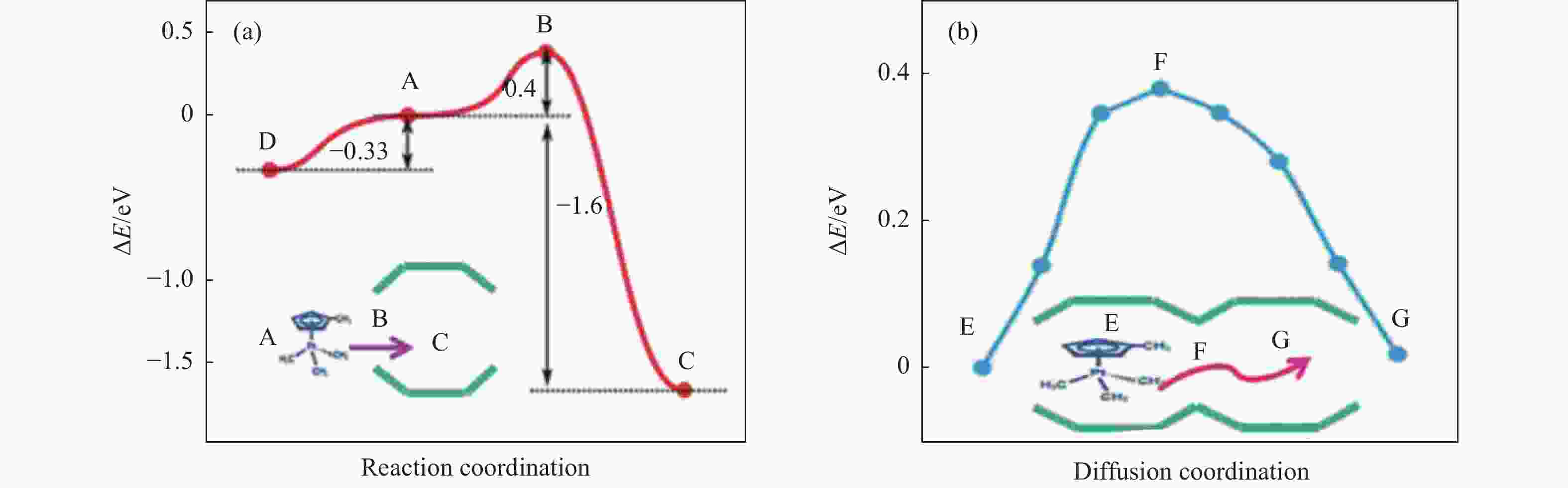

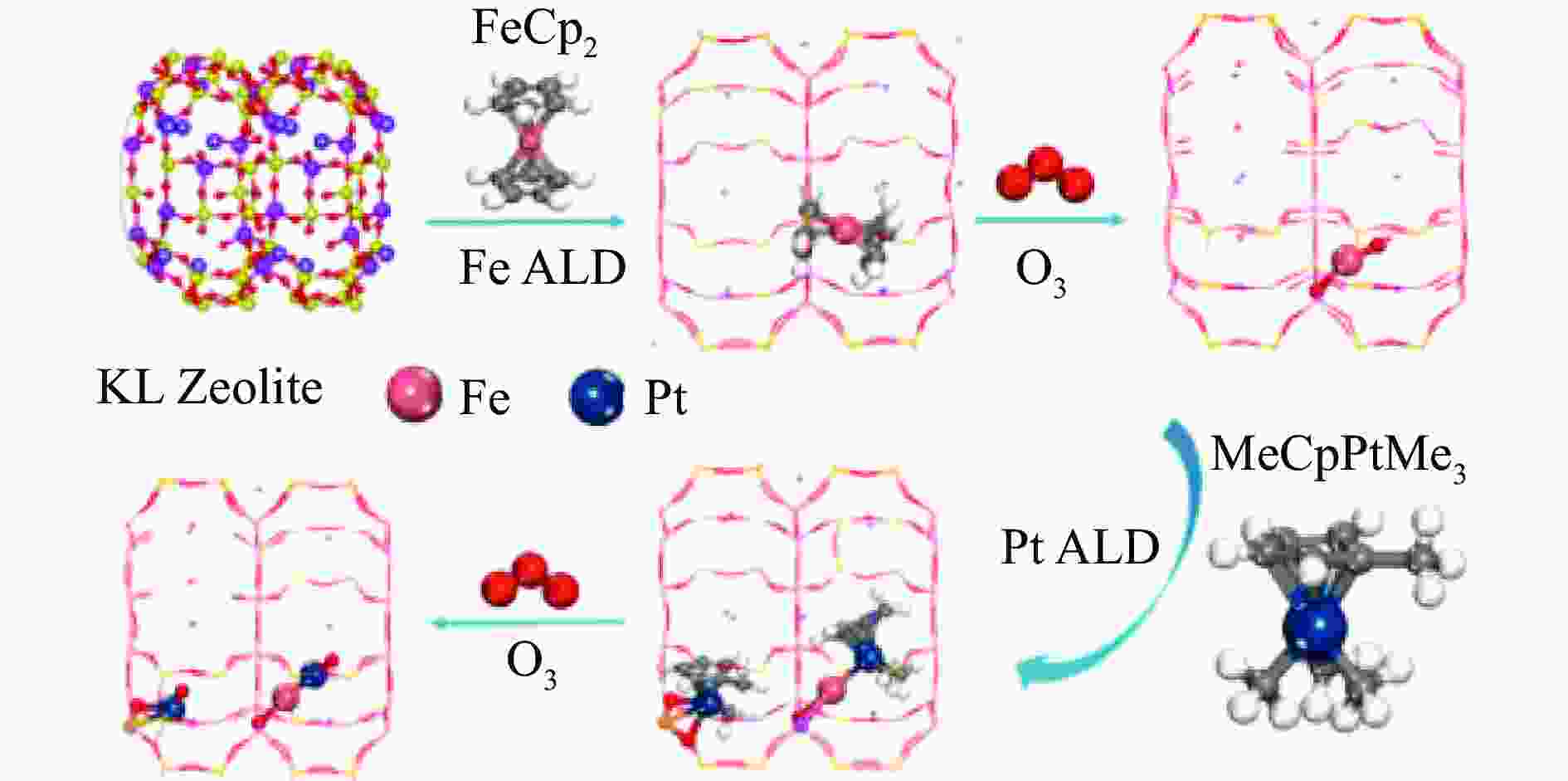

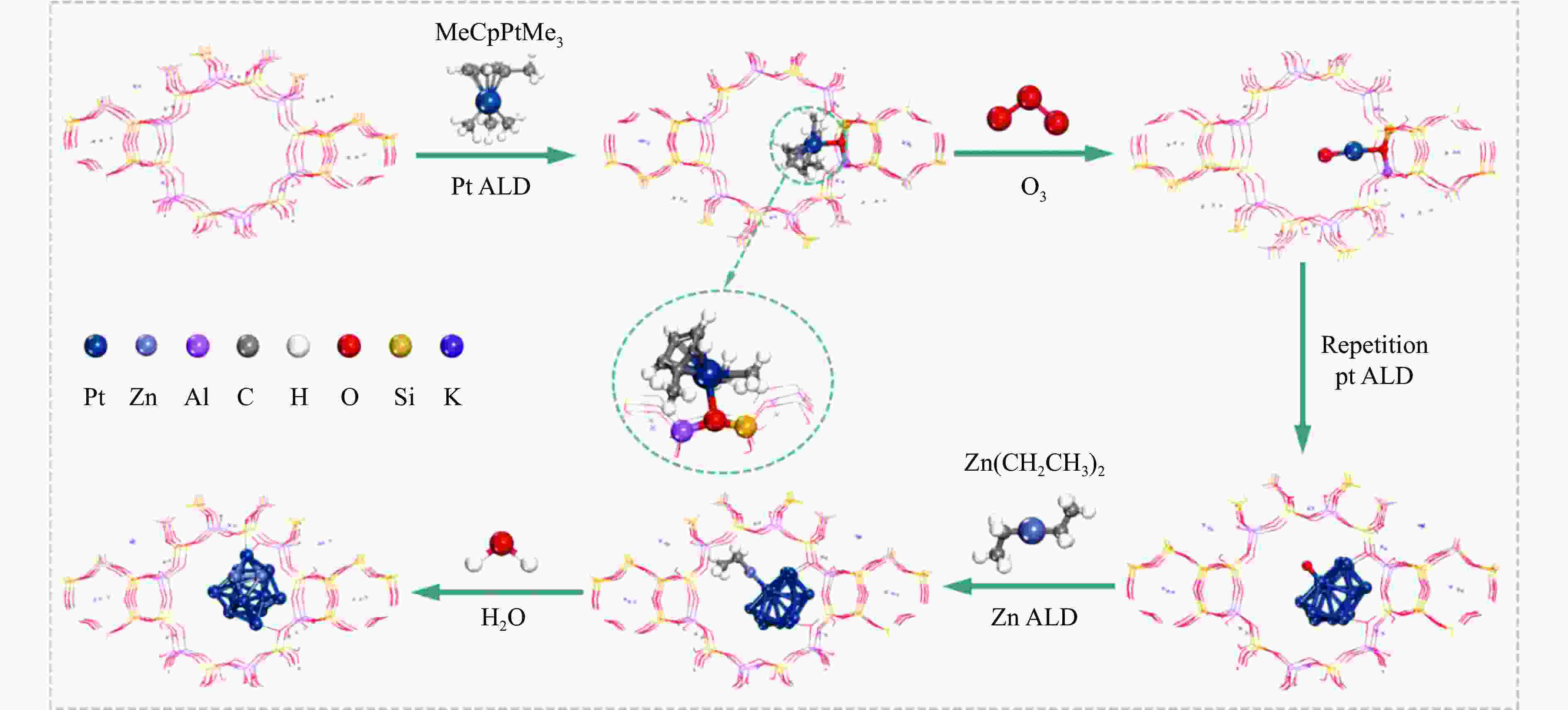

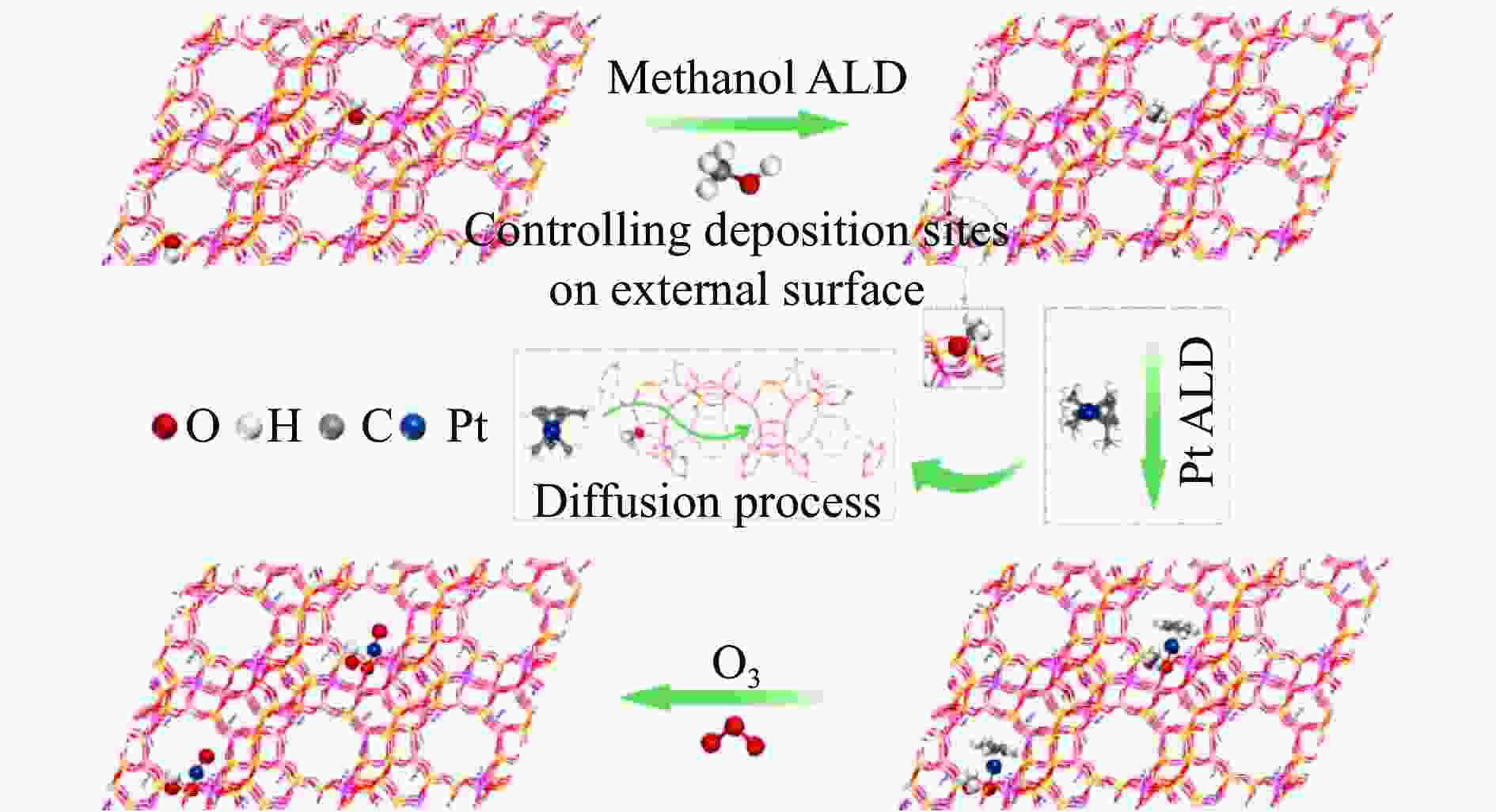

图 2 MeCpPtMe3分子在KL分子筛内的吸附-扩散行为[18]

Figure 2 The energetics of diffusion progress of the MeCpPtMe3 through a KL zeolite channel:(a) the energetics of MeCpPtMe3 in the inner and outer surfaces of KL zeolite, (b) diffusion energetics of MeCpPtMe3 into/between KL zeolite cages[18](with permission from Royal Society of Chemistry)

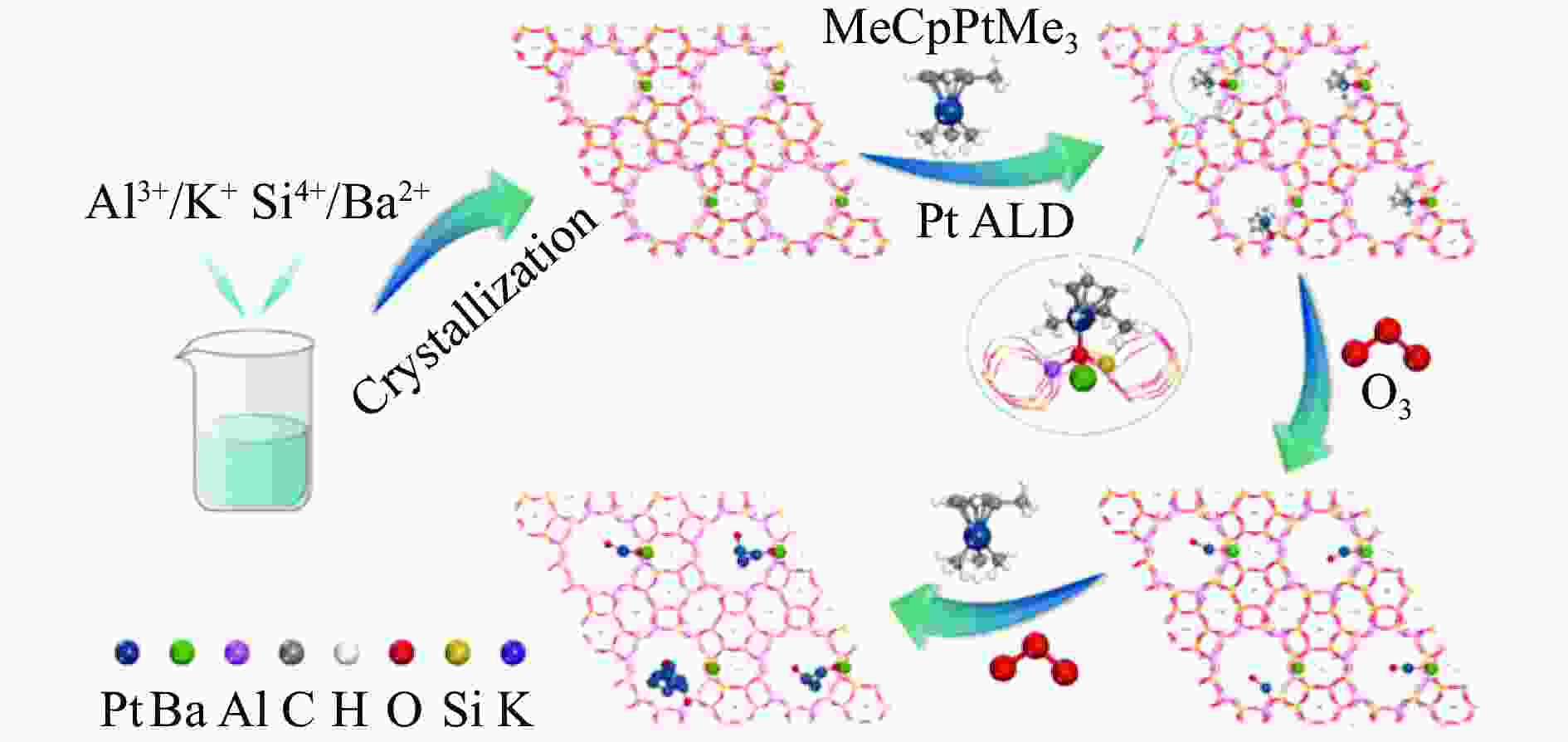

图 6 (a)−(f) Pt/KL和Pt/BKL催化剂的HAADF-TEM图及尺寸分布;(g)、(h)n-C7芳构化活性评价[34]

Figure 6 (a)−(f) High angle annular dark field scanning transmission electron microscopy (HAADF-STEM) image of Pt/KL and Pt/BKL catalysts with size distribution of Pt; (g), (h) Catalytic performance on n-C7 aromatization[34](with permission from Elsevier)

-

[1] KOSINOV N, LIU C, HENSEN E J M, et al. Engineering of transition metal catalysts confined in zeolites[J]. Chem Mater,2018,30:3177−3198. doi: 10.1021/acs.chemmater.8b01311 [2] O’NEILL B J, JACKSON D H K, LEE J, et al. Catalyst design with atomic layer deposition[J]. ACS Catal,2015,5:1804−1825. doi: 10.1021/cs501862h [3] 高亚, 徐丹, 王树元, 等. 原子层沉积构建高性能催化剂的研究进展[J]. 化工进展,2021,40:4242−4252. doi: 10.16085/j.issn.1000-6613.2020-1960GAO Ya, XU Dan, WANG Shuyuan, et al. Recent progress in fabrication of high efficient catalysts by atomic layer deposition[J]. Chem Ind Eng Prog,2021,40:4242−4252. doi: 10.16085/j.issn.1000-6613.2020-1960 [4] GAO Z, QIN Y. Design and properties of confined nanocatalysts by atomic layer deposition[J]. Accounts Chem Res,2017,50:2309−2316. doi: 10.1021/acs.accounts.7b00266 [5] DETAVERNIER C, DENDOOVEN J, SREE S P, et al. Tailoring nanoporous materials by atomic layer deposition[J]. Chem Soc Rev,2011,40:5242−5253. doi: 10.1039/c1cs15091j [6] XU D, WANG S, WU B, et al. Highly dispersed single-atom Pt and Pt clusters in the Fe-modified KL zeolite with enhanced selectivity for n-heptane aromatization[J]. ACS Appl Mater Inter,2019,11:29858−29867. doi: 10.1021/acsami.9b08137 [7] JIANG F, HUANG J, NIU L, et al. Atomic layer deposition of ZnO thin films on ZSM-5 zeolite and its catalytic performance in chichibabin reaction[J]. Catal Lett,2015,145:947−954. doi: 10.1007/s10562-014-1472-5 [8] ZHANG J, LU Z, WU W, et al. Mesopore differences between pillared lamellar MFI and MWW zeolites probed by atomic layer deposition of titania and consequences on photocatalysis[J]. Microporous Mesoporous Mater,2019,276:260−269. doi: 10.1016/j.micromeso.2018.10.009 [9] WANG F, XIAO W, GAO L, et al. The growth mode of ZnO on HZSM-5 substrates by atomic layer deposition and its catalytic property in the synthesis of aromatics from methanol[J]. Catal Sci Technol,2016,6:3074−3086. doi: 10.1039/C5CY01651G [10] HWANG S, PARDITKA B, CSERHáTI C, et al. IR microimaging of direction-dependent uptake in MFI-type crystals[J]. Chem Ing Technol,2017,89:1686−1693. doi: 10.1002/cite.201700128 [11] CAO L, LIU W, LUO Q, et al. Atomically dispersed iron hydroxide anchored on Pt for preferential oxidation of CO in H2[J]. Nature,2019,565:631−635. doi: 10.1038/s41586-018-0869-5 [12] DING K, GULEC A, JOHNSON A M, et al. Identification of active sites in CO oxidation andwater-gas shift over supported Pt catalysts[J]. Science,2015,350:189−192. doi: 10.1126/science.aac6368 [13] SUN S H, ZHANG G X, GAUQUELIN N, et al. Single-atom catalysis using Pt/graphene achieved through atomic Layer deposition[J]. Sci Rep,2013,3:1775−1783. doi: 10.1038/srep01775 [14] SHAMZHY M, OPANASENKO M, CONCEPCIÓN P, et al. New trends in tailoring active sites in zeolite-based catalysts[J]. Chem Soc Rev,2019,48:1095−1149. doi: 10.1039/C8CS00887F [15] VUORI H, SILVENNOINEN R J, LINDBLAD M, et al. Beta zeolite-supported iridium catalysts by gas phase deposition[J]. Catal Lett,2009,131:7−15. doi: 10.1007/s10562-009-0068-y [16] VUORI H, PASANEN A, LINDBLAD M, et al. The effect of iridium precursor on oxide-supported iridium catalysts prepared by atomic layer deposition[J]. Appl Surf Sci,2011,257:4204−4210. doi: 10.1016/j.apsusc.2010.12.021 [17] GU X-M, ZHANG B, LIANG H-J, et al. Pt/HZSM-5 catalyst synthesized by atomic layer deposition for aqueous-phase hydrogenation of levulinic acid to valeric acid[J]. J Fuel Chem Technol,2017,45:714−722. doi: 10.1016/S1872-5813(17)30035-X [18] XU D, WU B S, REN P J, et al. Controllable deposition of Pt nanoparticles into a KL zeolite by atomic layer deposition for highly efficient reforming of n-heptane to aromatics[J]. Catal Sci Technol,2017,7:1342−1350. doi: 10.1039/C6CY02652D [19] XU D, WANG S Y, WU B S, et al. Tailoring Pt locations in KL zeolite by improved atomic layer deposition for excellent performance in n-heptane aromatization[J]. J Catal,2018,365:163−173. doi: 10.1016/j.jcat.2018.07.001 [20] YAN M, XU D, WU B, et al. Insight into the performance of different Pt/KL catalysts for n-alkane (C6–C8) aromatization: catalytic role of zeolite channels[J]. Catal Sci Technol,2022,12:1610−1618. doi: 10.1039/D1CY02090K [21] WANG S, GAO Y, WEI L, et al. Engineering spatial locations of Pt in hierarchically porous KL zeolite by atomic layer deposition with enhanced n-heptane aromatization[J]. Fuel,2023,337:126852. doi: 10.1016/j.fuel.2022.126852 [22] WANG S, ZHANG D, MA Y, et al. Aqueous solution synthesis of Pt-M (M = Fe, Co, Ni) bimetallic nanoparticles and their catalysis for the hydrolytic dehydrogenation of ammonia borane[J]. ACS Appl Mater Inter,2014,6:12429−12435. doi: 10.1021/am502335j [23] ZHANG B, GUO X, LIANG H, et al. Tailoring Pt-Fe2O3 interfaces for selective reductive coupling reaction to synthesize imine[J]. ACS Catal,2016,6:6560−6566. doi: 10.1021/acscatal.6b01756 [24] LIU L, LOPEZ-HARO M, LOPES C W, et al. Regioselective generation and reactivity control of subnanometric platinum clusters in zeolites for high-temperature catalysis[J]. Nat Mater,2019,18:866−873. doi: 10.1038/s41563-019-0412-6 [25] YANG H, CHEN Y, QIN Y. Application of atomic layer deposition in fabricating high-efficiency electrocatalysts[J]. Chin J Catal,2020,41:227−241. doi: 10.1016/S1872-2067(19)63440-6 [26] SONG J, MA H, TIAN Z, et al. The effect of Fe on Pt particle states in Pt/KL catalysts[J]. Appl Catal A: Gen,2015,492:31−37. doi: 10.1016/j.apcata.2014.12.017 [27] GOULD T D, LUBERS A M, CORPUZ A R, et al. Controlling nanoscale properties of supported platinum catalysts through atomic layer deposition[J]. ACS Catal,2015,5:1344−1352. doi: 10.1021/cs501265b [28] HACKLER R A, MCANALLY M O, SCHATZ G C, et al. Identification of dimeric methylalumina surface species during atomic layer deposition using operando surface-enhanced Raman spectroscopy[J]. J Am Chem Soc,2017,139:2456−2463. doi: 10.1021/jacs.6b12709 [29] YAN H, LIN Y, WU H, et al. Bottom-up precise synthesis of stable platinum dimers on graphene[J]. Nat Commun,2017,8:1070−1081. doi: 10.1038/s41467-017-01259-z [30] GEERTS L, RAMACHANDRAN R K, DENDOOVEN J, et al. Creation of gallium acid and platinum metal sites in bifunctional zeolite hydroisomerization and hydrocracking catalysts by atomic layer deposition[J]. Catal Sci Technol,2020,10:1778−1788. doi: 10.1039/C9CY02610J [31] WANG F, KANG X, ZHOU M, et al. Sn and Zn modified HZSM-5 for one-step catalytic upgrading of glycerol to value-added aromatics: Synergistic combination of impregnated Sn particles, ALD introduced ZnO film and HZSM-5 zeolite[J]. Appl Catal A: Gen,2017,539:80−89. doi: 10.1016/j.apcata.2017.04.005 [32] YAN M, WU B, YANG Y, et al. Highly efficient Sn-modified Pt/KY catalyst for n-octane reforming: the synergistic effect of Pt in different electronic states[J]. Catal Sci Technol,2023,13:1677−1685. doi: 10.1039/D3CY00011G [33] WANG S, XU D, ZHU D, et al. Elucidating the restructuring-induced highly active bimetallic Pt-Co/KL catalyst for the aromatization of n-heptane[J]. Chem Commun,2020,56:892−895. doi: 10.1039/C9CC08845H [34] WANG S, GAO Y, YI F, et al. Regulation of sub-nanometric platinum on BaKL zeolite for boosting n-heptane aromatization[J]. Fuel,2022,328:125281. doi: 10.1016/j.fuel.2022.125281 [35] XU D, WEI L, YAN M, et al. Zinc-assisted nanometric Pt cluster stabilized on KL zeolite via atomic layer deposition for the n-heptane aromatization[J]. Appl Catal A: Gen,2023,663:119308. doi: 10.1016/j.apcata.2023.119308 [36] MA Y, CHEN X, GUAN Y, et al. Skeleton-Sn anchoring isolated Pt site to confine subnanometric clusters within *BEA topology[J]. J Catal,2021,397:44−57. doi: 10.1016/j.jcat.2021.03.022 [37] RYOO R, KIM J, JO C, et al. Rare-earth-platinum alloy nanoparticles in mesoporous zeolite for catalysis[J]. Nature,2020,585:221−224. doi: 10.1038/s41586-020-2671-4 [38] LIU S, REN J, ZHU S, et al. Synthesis and characterization of the Fe-substituted ZSM-22 zeolite catalyst with high n-dodecane isomerization performance[J]. J Catal,2015,330:485−496. doi: 10.1016/j.jcat.2015.07.027 [39] WANG Y, TAO Z, WU B, et al. Effect of metal precursors on the performance of Pt/ZSM-22 catalysts for n-hexadecane hydroisomerization[J]. J Catal,2015,322:1−13. doi: 10.1016/j.jcat.2014.11.004 [40] SREE S P, DENDOOVEN J, KORÁNYI T I, et al. Aluminium atomic layer deposition applied to mesoporous zeolites for acid catalytic activity enhancement[J]. Catal Sci Technol, 2011, 1: 218−221. [41] SREE S P, DENDOOVEN J, MAGUSIN P C M M, THOMAS K, et al. Hydroisomerization and hydrocracking activity enhancement of a hierarchical ZSM-5 zeolite catalyst via atomic layer deposition of aluminium[J]. Catal Sci Technol,2016,6:6177−6186. doi: 10.1039/C6CY00780E [42] ZHAI L, ZHANG B, LIANG H, et al. The selective deposition of Fe species inside ZSM-5 for the oxidation of cyclohexane to cyclohexanone[J]. Sci China Chem,2021,64:1088−1095. doi: 10.1007/s11426-020-9968-x [43] YAN M, XU D, WANG S, et al. Selective regulation of Pt clusters inside KY zeolite using atomic layer deposition for n-octane reforming[J]. Fuel,2022,330:125671. doi: 10.1016/j.fuel.2022.125671 [44] VERHEYEN E, PULINTHANATHU SREE S, THOMAS K, et al. Catalytic activation of OKO zeolite with intersecting pores of 10- and 12-membered rings using atomic layer deposition of aluminium[J]. Chem Commun,2014,50:4610−4612. doi: 10.1039/C3CC49028A [45] MIES M, REBROV E, JANSEN J, et al. Method for the in situ preparation of a single layer of zeolite Beta crystals on a molybdenum substrate for microreactor applications[J]. J Catal,2007,247:328−338. doi: 10.1016/j.jcat.2007.02.007 [46] MURAZA O, REBROV E, CHEN J, et al. Microwave-assisted hydrothermal synthesis of zeolite Beta coatings on ALD-modified borosilicate glass for application in microstructured reactors[J]. Chem Eng J,2008,135:S117−S120. doi: 10.1016/j.cej.2007.07.003 -

下载:

下载: