Influence of hydrothermal upgrading on the fuel characteristics and combustion behavior of herb wastes

-

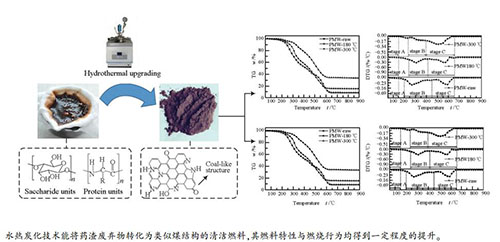

摘要: 以中药药渣(HTW)与抗生素药渣(PMW)为对象,采用X射线光电子能谱、热重分析仪、量热仪与傅里叶红外分光光度计等技术分析两类药渣的差异并探究水热处理对药渣的提质效果与作用机理。结果表明,HTW含有大量木质纤维类成分,而PMW则以蛋白质与多糖为主;尽管这两类组分在水热提质中的转化途径有所区别,但均能提高药渣的热值(HTW:从19.4到26.2 MJ/kg;PMW:从19.1到29.3 MJ/kg)。同时,药渣的煤化程度随温度的上升而增加,甚至能接近烟煤水平。此外,由于水热过程中的脱挥发分与芳构化作用使得药渣中低能量的碳氢键转变为高能量的碳碳双键,不仅改善了药渣的燃烧性能,还使药渣在燃烧过程更为稳定且充分。Abstract: Based on two kinds of biowastes (penicillin mycelia waste, PMW; herbal tea waste, HTW), the difference of biowastes derived from various sources and their fuel characteristics and combustion behavior after hydrothermal upgrading were investigated with the assistance of XPS, TGA and FTIR analyses. The results show that HTW mainly contains lignocelluloses, while PMW mostly consists of protein and polysaccharides. Although the specific conversion paths of various components are slightly different during hydrothermal process, both the higher heating values (HHV) of biowastes are improved (HTW:from 19.4 to 26.2 MJ/kg; PMW:from 19.1 to 29.3 MJ/kg); meanwhile, the coalification degree of biowastes increases with the growing temperature, even reaching the degree of bituminite at 300℃. In addition, the variation in carbon content and structure reflects that the reaction of devolatilization and aromatization during hydrothermal process can improve not only the fuel characteristics but also the combustion behavior.

-

Key words:

- medicinal biowastes /

- hydrothermal upgrading /

- incineration /

- fuel characteristics

-

表 1 两类药渣的原料特性

Table 1 Properties of herb residues

Sample Proximate analysis wd/% Ultimate analysis wdaf/% QHHV/(J·g-1) V FC A C H O N S HTW 68.73 17.37 13.90 52.36 6.87 37.44 3.03 0.30 19367 PMW 78.06 15.42 6.52 47.90 6.59 36.97 7.95 0.59 19061 Ash analysis (expressed as w/% of metal oxides) SiO2 Al2O3 MgO Na2O Fe2O3 P2O5 CaO K2O TiO2 ZnO CuO SrO 21.98 7.92 7.66 0.40 4.82 4.56 20.78 7.64 0.44 0.09 0.03 0.08 0.39 0.14 3.62 2.85 0.50 30.82 22.64 19.15 0.01 0.09 0.02 0.03 note: V, volatile matters; A, ash; FC, fixed carbon; O (oxygen) was calculated by difference based on dry ash-free base; QHHV, higher heating value 表 2 水热燃料的工业与元素分析

Table 2 Proximate and ultimate analyses of hydrochars derived from HTW and PMW

Sample Proximate analysis wd/% Ultimate analysis wdaf/% Fuel ratio Yield w/% V FC A C H O N S HTW 120 ℃ 67.47 17.22 15.31 54.20 6.86 35.77 2.91 0.27 0.26 89.88 150 ℃ 67.85 16.36 15.79 54.62 6.79 35.55 2.83 0.21 0.24 82.97 180 ℃ 65.81 16.04 18.15 57.38 6.88 33.01 2.56 0.17 0.24 69.88 210 ℃ 64.40 15.58 20.02 62.13 7.01 28.20 2.50 0.16 0.24 62.13 240 ℃ 58.38 19.15 22.47 68.60 7.04 21.90 2.30 0.16 0.33 52.81 270 ℃ 47.54 26.35 26.11 75.86 7.15 14.55 2.28 0.16 0.55 37.38 300 ℃ 45.11 27.05 27.84 83.34 6.93 7.36 2.20 0.17 0.60 34.06 PMW 120 ℃ 77.54 15.33 7.13 49.14 6.62 36.49 7.18 0.56 0.20 67.51 150 ℃ 76.94 14.35 8.71 50.47 6.69 35.18 7.10 0.56 0.19 60.38 180 ℃ 73.61 15.89 10.50 54.82 6.76 30.79 7.09 0.54 0.22 37.91 210 ℃ 68.24 17.15 14.61 64.01 7.01 21.34 7.10 0.54 0.25 28.36 240 ℃ 63.87 18.94 17.19 68.63 7.14 16.65 7.08 0.51 0.30 23.92 270 ℃ 59.17 21.85 18.98 72.29 7.17 13.10 6.95 0.49 0.37 18.68 300 ℃ 52.20 27.28 20.52 75.38 7.19 10.37 6.62 0.49 0.52 12.79 note: V, volatile matters; A, ash; FC, fixed carbon; O (oxygen) was calculated by difference based on dry ash-free base; fuel ratio was defined as the quotient of FC and V 表 3 药渣及其水热焦的燃烧阶段和特征温度点

Table 3 Combustion stages and characteristic temperatures of herb wastes and its derived hydrochar

Sample Temperature range t/℃ Weight loss w/% Residues w/% Characteristic temperatures t/℃ stage A stage B stage C stage B stage C ti tm tb HTW 50-170 170-410 410-575 62.2 23.2 10.2 262 314 570 HTW-120 50-170 170-405 405-580 64.1 23.0 10.5 279 325 588 HTW-150 50-170 170-405 405-580 64.8 21.9 11.3 283 323 580 HTW-180 50-150 170-365 365-580 60.2 27.4 12.8 288 325 590 HTW-210 50-145 170-360 360-580 51.8 33.9 13.0 295 320 585 HTW-240 50-140 170-345 345-580 43.1 42.4 13.3 292 320 580 HTW-270 - 155-330 330-580 20.8 54.9 23.4 305 367 585 HTW-300 - 160-325 325-580 19.6 52.0 27.5 308 360 590 PMW 50-150 150-480 480-660 58.5 31.7 8.5 235 271 645 PMW-120 50-160 160-435 435-640 52.7 36.0 8.8 255 295 660 PMW-150 50-150 150-425 425-650 48.3 40.1 6.6 253 295 650 PMW-180 50-160 160-430 430-665 48.8 41.6 8.4 260 306 665 PMW-210 - 150-400 400-660 41.6 42.6 15.5 270 315 660 PMW-240 - 145-405 405-655 37.2 49.1 13.4 270 322 655 PMW-270 - 145-400 400-665 35.8 50.8 13.1 300 338 665 PMW-300 - 145-390 390-650 20.0 45.8 33.8 350 505 660 -

[1] 许光文, 纪文峰, 刘周恩, 万印华, 张小勇.轻工生物质过程残渣高值化利用必要性与技术路线分析[J].过程工程学报, 2009, 9(3):618-624. http://www.cqvip.com/qk/94710A/200903/30985170.htmlXU Guang-wen, JI Wen-feng, LIU Zhou-en, WAN Yin-hua. ZHANG Xiao-yong. Necessity and technical route of value-added utilization of biomass proces residue in light industry[J]. Chin J Process Eng, 2009, 9(3):618-624. http://www.cqvip.com/qk/94710A/200903/30985170.html [2] ZENG X, SHAO R Y, WANG F, DONG P W, YU J, XU G W. Industrial demonstration plant for the gasification of herb residue by fluidized bed two-stage process[J]. Bioresour Technol, 2016, 206:93-98. doi: 10.1016/j.biortech.2016.01.075 [3] 詹昊, 林均衡, 黄艳琴, 阴秀丽, 刘华财, 袁洪友, 吴创之.抗生素菌渣热解N官能团变化特征及其与NOx前驱物关系研究[J].燃料化学学报, 2017, 45(10):1219-1229. doi: 10.3969/j.issn.0253-2409.2017.10.009ZHAO Hao, LIN Jun-heng, HUANG Yan-qin, YIN Xiu-li, LIU Hua-cai, YUAN Hong-you, WU Chuang-zhi. Evolution of nitrogen functionalities and their relation to NOx precursors during pyrolysis of antibiotic mycelia wastes[J]. J Fuel Chem Technol, 2017, 45(10):1219-1229. doi: 10.3969/j.issn.0253-2409.2017.10.009 [4] 詹昊, 阴秀丽, 黄艳琴, 张晓鸿, 袁洪友, 谢建军, 吴创之.药渣热解过程NOx前驱物生成特征及规律研究[J].燃料化学学报, 2017, 45(3):279-288. http://manu60.magtech.com.cn/rlhxxb/CN/abstract/abstract18990.shtmlZHAO Hao, YIN Xiu-li, HUANG Yan-qin, ZHANG Xiao-hong, YUAN Hong-you, XIE Jian-jun, WU Chuang-zhi. Characteristics of NOx precursors and their formation mechanism during pyrolysis of herb residues[J]. J Fuel Chem Technol, 2017, 45(3):279-288. http://manu60.magtech.com.cn/rlhxxb/CN/abstract/abstract18990.shtml [5] 张光义, 马大朝, 彭翠娜, 许光文.水热处理抗生素菌渣制备固体生物燃料[J].化工学报, 2013, 64(10):3741-3749. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hgxb201310035ZHANG Guang-yi, MA Da-zhao, PENG Cui-na, XU Guang-wen. Hydrothermal treatment of antibiotic mecelial dregs for solid bio-fuel preperation[J]. J Chem Ind Eng, 2013, 64(10):3741-3749. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hgxb201310035 [6] 庄修政, 黄艳琴, 阴秀丽, 吴创之.污泥水热处理制备清洁燃料的研究进展[J].化工进展, 2018, 37(1):311-318. http://www.cnki.com.cn/Article/CJFDTOTAL-ZGGX201219010.htmZHUANG Xiu-zheng, HUANG Yan-qin, YIN Xiu-li, WU Chuang-zhi. Research on clean solid fuel derived from sludge employing hydrothermal treatment[J]. Chem Ind Eng Prog, 2018, 37(1):311-318. http://www.cnki.com.cn/Article/CJFDTOTAL-ZGGX201219010.htm [7] ZHUANG X Z, HUANG Y Q, LIU H C, YUAN H Y, YIN X L, WU C Z. Relationship between physicochemical properties and dewaterability of hydrothermal sludge derived from different source[J]. J Environ Sci, 2018, 69:261-270. doi: 10.1016/j.jes.2017.10.021 [8] 庄修政, 黄艳琴, 阴秀丽, 吴创之.基于响应面法优化污泥燃料的水热制备工艺[J].新能源进展, 2017, 5(5):325-332. http://www.cnki.com.cn/Article/CJFDTotal-LYKE201411016.htmZHUANG Xiu-zheng, HUANG Yan-qin, YIN Xiu-li, WU Chuang-zhi. Optimization of hydrothermal process for solid fuel derived from sewage sludge by response surface methodology[J]. Adv New Renew Energy, 2017, 5(5):325-332. http://www.cnki.com.cn/Article/CJFDTotal-LYKE201411016.htm [9] ZHAO P T, SHEN Y F, GE S F, CHEN Z Q, YOSHIKAWA K. Clean solid biofuel production from high moisture content waste biomass employing hydrothermal treatment[J]. Appl Energy, 2014, 131:345-367. doi: 10.1016/j.apenergy.2014.06.038 [10] MA D C, ZHANG G Y, ZHAO P T, AREEPRASERT C, SHEN Y F, YOSHIKAWA K, XU G W. Hydrothermal treatment of antibiotic mycelial dreg:More understanding from fuel characteristics[J]. Chem Eng J, 2015, 273:147-155. doi: 10.1016/j.cej.2015.01.041 [11] GAO Y, WANG X H, WANG J, LI X P, CHENG J J, YANG H P, CHEN H P. Effect of residence time on chemical and structural properties of hydrochar obtained by hydrothermal carbonization of water hyacinth[J]. Energy, 2013, 58:376-383. doi: 10.1016/j.energy.2013.06.023 [12] HE C, ZHAO J, YANG Y H, WANG J Y. Multiscale characteristics dynamics of hydrochar from hydrothermal conversion of sewage sludge under sub-and near-critical water[J]. Bioresour Technol, 2016, 211:486-493. doi: 10.1016/j.biortech.2016.03.110 [13] ZHUANG X Z, HUANG Y Q, SONG Y P, ZHAN H, YIN X L, WU C Z. The transformation pathways of nitrogen in sewage sludge during hydrothermal treatment[J]. Bioresour Technol, 2017, 245:463-470. doi: 10.1016/j.biortech.2017.08.195 [14] BALAT M. Mechanisms of thermochemical biomass conversion processes. Part 1:Reactions of pyrolysis[J]. Energy Source Part A, 2008, 30(7):620-635. doi: 10.1080/15567030600817258 [15] AKHTAR J, AMIN N A S. A review on process conditions for optimum bio-oil yield in hydrothermal liquefaction of biomass[J]. Renewable Sustainable Energy Rev, 2011, 15(3):1615-1624. doi: 10.1016/j.rser.2010.11.054 [16] CHANGI S M, FAETH J L, MO N, SAVAGE P E. Hydrothermal reactions of biomolecules relevant for microalgae liquefaction[J]. Ind Eng Chem Res, 2015, 54(47):11733-11758. doi: 10.1021/acs.iecr.5b02771 [17] SMITH A M, SINGH S, ROSS A B. Fate of inorganic material during hydrothermal carbonisation of biomass:Influence of feedstock on combustion behaviour of hydrochar[J]. Fuel, 2016, 169:135-145. doi: 10.1016/j.fuel.2015.12.006 [18] HE C, WANG K, GIANNIS A, YANG Y H, WANG J Y. Products evolution during hydrothermal conversion of dewatered sewage sludge in sub-and near-critical water:Effects of reaction conditions and calcium oxide additive[J]. Int J Hydrogen Energy, 2015, 40(17):5776-5787. doi: 10.1016/j.ijhydene.2015.03.006 [19] SABIO E, ALVAREZ-MURILLO A, ROMAN S, LEDESMA B. Conversion of tomato-peel waste into solid fuel by hydrothermal carbonization:Influence of the processing variables[J]. Waste Manage, 2016, 47:122-132. doi: 10.1016/j.wasman.2015.04.016 [20] MURSITO A T, HIRAJIMA T, SASAKI K. Upgrading and dewatering of raw tropical peat by hydrothermal treatment[J]. Fuel, 2010, 89(3):635-641. doi: 10.1016/j.fuel.2009.07.004 [21] HE C, GIANNIS A, WANG J Y. Conversion of sewage sludge to clean solid fuel using hydrothermal carbonization:Hydrochar fuel characteristics and combustion behavior[J]. Appl Energy, 2013, 111:257-266. doi: 10.1016/j.apenergy.2013.04.084 [22] HE C, WANG K, YANG Y H, WANG J Y. Utilization of sewage-sludge-derived hydrochars toward efficient cocombustion with different-rank coals:Effects of subcritical water conversion and blending scenarios[J]. Energy Fuels, 2014, 28(9):6140-6150. doi: 10.1021/ef501386g [23] PENG C, ZHAI Y B, ZHU Y, XU B B, WANG T F, LI C T, ZENG G M. Production of char from sewage sludge employing hydrothermal carbonization:Char properties, combustion behavior and thermal characteristics[J]. Fuel, 2016, 176:110-118. doi: 10.1016/j.fuel.2016.02.068 -

下载:

下载: