Synthesis and electrochemical evaluation of nano-NiO-Y composite cathode material for hydrogen evolution in microbial electrolysis cell

-

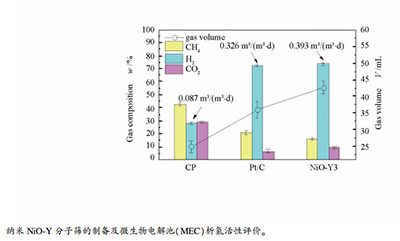

摘要: 在Y分子筛的溶胶反应体系中加入碳球,经老化、水热晶化反应得到纳米Y分子筛,通过等体积浸渍(incipient-wetness impregnation,IWI)方式负载镍盐前驱体,经焙烧制备纳米NiO-Y复合材料,采用XRD、SEM、TEM、XPS、TG-DTG和N2吸附-脱附等手段对其物理化学性质进行表征。结果表明,合成的NiO-Y复合材料样品的晶粒粒径为500 nm,具有微-介孔多级孔道结构。总比表面积达到774.3 m2/g,孔容为0.495 cm3/g,有利于暴露更多的活性位。通过线性扫描和塔菲尔曲线电化学测试评价发现,当镍盐负载量为30%(质量分数)时,纳米NiO-Y复合材料作为微生物电解池阴极具有较高的电催化活性。在运行周期内,样品的最大析氢电流密度达到22.87 A/m2,产气总量中H2含量占73.71%,产氢效率为0.393 m3/(m3·d),与Pt/C阴极产氢效率相近。

-

关键词:

- 纳米NiO-Y复合材料 /

- 多级孔 /

- 活性位 /

- 微生物电解池 /

- 阴极材料

Abstract: Nano Y zeolites were synthesized by adding carbon spheres into the synthesis sol of Y zeolites subjected to aging and hydrothermal crystallization; nickel-salt precursors were then loaded by using an incipient-wetness impregnation (IWI) method. After calcination, the nano-NiO-Y composite were then characterized by means of XRD, SEM, TEM, XPS, TG-DTG, and N2 adsorption-desorption techniques and its performance as the cathode material for hydrogen evolution in microbial electrolysis cell was then investigated. The results show that the nano-NiO-Y composite has a crystal size of 500 nm of size and multiple porous structure including micro and mesopores; the total surface area and pore volume of nano-NiO-Y composites are 774.3 m2/g and 0.495 cm3/g, respectively. The electrochemical tests of linear scanning voltammetry and Tafel plots show that as microbial electrolytic cell (MEC) cathode, the nano-NiO-Y composite with a nickel-salt loading of 30% exhibits high electrocatalytic activity. In a continuous operation cycle, the largest hydrogen evolution current density of the nano-NiO-Y composites reaches 22.87 A/m2, and the H2 content is about 73.71% in total gas. The hydrogen production efficiency is 0.393 m3/(m3·d), comparable to that of Pt/C cathode.-

Key words:

- nano-NiO-Y composites /

- multiple porous /

- active sites /

- microbial electrolysis cell /

- cathode materials

-

表 1 样品的孔结构参数

Table 1 Pore structure parameters of the nano-NiO-Y3 composite

Sample ABET/(m2·g-1) Amic/(m2·g-1) Ameso/(m2·g-1) vtotal/(cm3·g-1) vmicro/(cm3·g-1) NiO-Y3 744.3 679.4 64.9 0.495 0.350 -

[1] 韩成, 雷永鹏, 王应德.纳米异质结光催化材料制取太阳能燃料研究进展[J].无机材料学报, 2015, 30(11):1121-1130. http://www.cnki.com.cn/Article/CJFDTOTAL-WGCL201511001.htmHAN Cheng, LEI Yong-peng, WANG Ying-de. Rent progress on nano-heterostructure photocatalysts for solar fuels generation[J]. J Inor Mater, 2015, 30(11):1121-1130. http://www.cnki.com.cn/Article/CJFDTOTAL-WGCL201511001.htm [2] WANG B, WANG Y D, LEI Y P, WANG B, WU N, SHI Q, LI Q. In situ synthesis of graphitic-C3N4 nanosheet hybridized N-doped TiO2 nanofibers for efficient photocatalytic H2 production and degradation[J]. Nano Res, 2015, 8(4):1199-1209. doi: 10.1007/s12274-014-0600-2 [3] CHENG S, LODAN B E. High hydrogen production rate of microbial electrolysis cell (MEC) with reduced electrode spacing[J]. Bioresour Technol, 2011, 102(3):3571-3574. doi: 10.1016/j.biortech.2010.10.025 [4] ZHANG K, KIM J K, PARK B, QIAN S F, JIN B J, SHENG X W, ZENG H B, SHIN H J, OH S H, LEE C L, PARK J H. Defect-induced epitaxial growth for efficient solar hydrogen production[J]. Nano Lett, 2017, 17(11):6676-6683. doi: 10.1021/acs.nanolett.7b02622 [5] ZHAO W, FIERRO V, FERNÁNDEZ-HUERTA N, IZQUIERDO M T, CELZARD A. Hydrogen uptake of high surface area-activated carbons doped with nitrogen[J]. Int J Hydrogen Energy, 2013, 38(25):10453-10460. doi: 10.1016/j.ijhydene.2013.06.048 [6] GRUBLE T, DORÉ L, HOFFRICHTER A, HOMBACH L E, RATHS S, ROBINIUS M, NOBIS M, SCHIEBAHN S, TIETZE V, SCHNETTLER A, WALTHER G, STOLTEN D. An option for stranded renewables:Electrolytic-hydrogen in future energy systems[J]. Sustainable Energy Fuels, 2018, 2(5):1500-1515. http://cn.bing.com/academic/profile?id=86a74394e20b8ec6b7282e881b6fe5a6&encoded=0&v=paper_preview&mkt=zh-cn [7] KUMAR G, LIN C Y. Biogenic hydrogen conversion of de-oiled Jatropha waste (DJW) via anaerobic sequencing batch reactor operation:Process performance, microbial insights and CO2 reduction efficiency[J]. Sci World J, 2014, 1-9. [8] SIRISINUDOMKIT P, IAMPRASERTKUN P, KRITTAYAVATHANANON A, PETTONG T, DITTANET P, KIDKHUNTHOD P, SAWANGPHRUK M. Hybrid energy storage of battery-type nickel hydroxide and supercapacitor-type graphene:Redox additive and charge storage mechanism[J]. Sustainable Energy Fuels, 2017, 1:275-279. doi: 10.1039/C7SE00052A [9] WANG B, WANG Y D, LEI Y P, WU N, GOU Y Z, HAN C, XIE S, FANG D. Mesoporous silicon carbide nanofibers with in situ embedded carbon for co-catalyst free photocatalytic hydrogen production[J]. Nano Res, 2016, 9(3):886-898. doi: 10.1007/s12274-015-0971-z [10] KHAIRY M, ELSAFTY S A. Mesoporous NiO nanoarchitectures for electrochemical energy storage:Influence of size, porosity, and morphology[J]. Rsc Adv, 2013, 3(45):23801-23809. doi: 10.1039/c3ra44465a [11] ZHOU Y X, LEI Y P, WANG D S, CHEN C, PENG Q, LI Y D. Ultra-thin Cu2S nanosheets:Effective cocatalysts for photocatalytic hydrogen production[J]. Chem Commun, 2015, 51(68):13305-13308. doi: 10.1039/C5CC05156H [12] DAI H Y, YANG H M, LIU X, JIAN X, LIANG Z H. Electrochemical evaluation of nano-Mg(OH)2/graphene as a catalyst for hydrogen evolution in microbial electrolysis cell[J]. Fuel, 2016, 174:251-256. doi: 10.1016/j.fuel.2016.02.013 [13] LU L, XING G F, XIE T H, REN N Q, LOGAN B E. Hydrogen production from proteins via electrohydrogenesis in microbial electrolysis cells[J]. Biosens Bioelectron, 2010, 25(12):2690-2695. doi: 10.1016/j.bios.2010.05.003 [14] DONG Z S, ZHAO Y, FAN L, WANG Y X, WANG J W, ZHANG K. Simultaneous sulfide removal and hydrogen production in a microbial electrolysis cell[J]. Int J Electrochem Sci, 2017, 12(11):10553-10566. http://cn.bing.com/academic/profile?id=2ec45efc1ed122dfb6238c759d56b4d3&encoded=0&v=paper_preview&mkt=zh-cn [15] ALHAJRI N, ANJUM D, TAKANABE K. Molybdenum carbide-carbon nanocomposites synthesized from a reactive template for electrochemical hydrogen evolution[J]. J Mater Chem A, 2014, 2(27):10548-10556. doi: 10.1039/C4TA00577E [16] CHEN W F, WANG C H, SASAKI K, MARINKOVIC N, XU W, MUCKERMAN J T, ZHU Y, ADZIC R R. Highly active and durable nanostructured molybdenum carbide electrocatalysts for hydrogen production[J]. Energy Environ Sci, 2013, 6(3):943-951. doi: 10.1039/c2ee23891h [17] 麹永亮. Y型分子筛制备过程的技术改造研究[D].北京: 北京化工大学, 2015. http://cdmd.cnki.com.cn/Article/CDMD-10010-1015725684.htmQU Yong-liang. Technological innovation research of Y zeolite preparation process[D]. Beijing: Beijing University of Chemical Technology, 2015. http://cdmd.cnki.com.cn/Article/CDMD-10010-1015725684.htm [18] 胡丽, 杨冬花, 赵煜, 董志帅, 王改, 薄琼. NiY分子筛的合成及在微生物电解池阴极的析氢性能研究[J].燃料化学学报, 2018, 46(5):106-113. http://manu60.magtech.com.cn/rlhxxb/CN/abstract/abstract19219.shtmlHU Li, YANG Dong-hua, ZHAO Yu, DONG Zhi-shuai, WANG Gai, BO Qiong. Synthesis of NiY zeolite for hydroden evolution performance study in cathode of microbial electrolysis cell[J]. J Fuel Chem Technol, 2018, 46(5):106-113. http://manu60.magtech.com.cn/rlhxxb/CN/abstract/abstract19219.shtml [19] ZHENG Z L, SUN C, DAI R, WANG S Y, WU X, AN X, XIE X M. Organotemplate-free synthesis of hollow Beta zeolite supported Pt-based catalysts for low-temperature ethanol steam reforming[J]. Catal Sci Technol, 2016, 6(17):6472-6475. doi: 10.1039/C6CY01354F [20] ZHOU W W, ZHOU Y S, WEI Q W, DING S J, JIANG S J, ZHANG Q, LIU M F. Continuous synthesis of mesoporous Y zeolites from normal inorganic aluminosilicates and their high adsorption capacity for dibenzothiophene(DBT) and 4, 6-dimethyldibenzothiophene (4, 6-DMDBT)[J]. Chem Eng J, 2017, 330(8):605-615. http://cn.bing.com/academic/profile?id=56fd4eb68b50e7bbb694a8f042f389f7&encoded=0&v=paper_preview&mkt=zh-cn [21] 刘爱元, 张溪文, 韩高荣.溶胶凝胶旋涂法制备NiO薄膜及其电致变色性能[J].材料科学与工程学报, 2010, 28(6):896-899. http://cdmd.cnki.com.cn/Article/CDMD-10335-1011083610.htmLIU Ai-yuan, ZHANG Xi-wen, HAN Gao-rong. Preparation and properties of NiO films via sol-gel process and spin-coating[J]. J Mater Sci Eng, 2010, 28(6):896-899. http://cdmd.cnki.com.cn/Article/CDMD-10335-1011083610.htm [22] ZHENG Z L, YANG D H, LI T T, YIN X M, WANG S Y, WU X, AN X, XIE X M. A novel BEA-type zeolite core-shell multiple catalyst for hydrogen-rich gas production from ethanol steam reforming[J]. Catal Sci Technol, 2016, 6(14):5427-5439. doi: 10.1039/C6CY00119J [23] 任斌.基于碳球模板法的功能型纳米材料的合成与应用[D].重庆: 重庆大学, 2016. http://cdmd.cnki.com.cn/Article/CDMD-10611-1016765694.htmREN Bin. Characterization and application of functional nanomaterials prepared by using carbon spheres as templates[D]. Chongqing: Chongqing University, 2016. http://cdmd.cnki.com.cn/Article/CDMD-10611-1016765694.htm [24] 李德宝, 郗宏娟, 侯博, 林明桂, 贾丽涛.一种小晶粒ZSM-22分子筛的制备方法: 中国, 105565339A[P]. 2016-05-11. http://www.wanfangdata.com.cn/details/detail.do?_type=patent&id=CN201610119519.0LI De-bao, XI Hong-Juan, HOU Bo, LIN Ming-gui, JIA Li-tao. A Preparation method of smallgrain ZSM-22 molecular sieve. CN, 105565339A[P]. 2016-05-11. http://www.wanfangdata.com.cn/details/detail.do?_type=patent&id=CN201610119519.0 [25] 杨冬花, 石宝宝, 王新波, 武正簧, 窦涛, 郑子良, 代蓉.新型磷酸硅铝分子筛SAPO-53的合成与表征[J].燃料化学学报, 2014, 42(5):625-634. http://manu60.magtech.com.cn/rlhxxb/CN/abstract/abstract18421.shtmlYANG Dong-hua, SHI Bao-bao, WANG Xin-bo, WU Zheng-huang, DOU Tao, ZHENG Zi-liang, DAI Rong. Synthesis and characterization of a new type silicoaluminophophate SAPO-53 molecular sieves[J]. J Fuel Chem Technol, 2014, 42(5):625-634. http://manu60.magtech.com.cn/rlhxxb/CN/abstract/abstract18421.shtml [26] 崔振珍, 殷好勇, 赵红挺, 聂秋林.核壳结构氧化镍/碳微球的制备及葡萄糖传感性能[J].无机材料学报, 2015, 30(3):305-310. http://www.cnki.com.cn/Article/CJFDTotal-WGCL201503015.htmCUI Zhen-zhen, YIN Hao-yong, ZHAO Hong-ting, NIE Qiu-lin. Preparation and glucose sensing property of core-shelled nikel oxide/carbon microspheres[J]. J Inorg Mater, 2015, 30(3):305-310. http://www.cnki.com.cn/Article/CJFDTotal-WGCL201503015.htm [27] ZHAO Q, ZHONG D, LIU L, LI D D, HAO G Y, LI J P. Facile fabrication of robust 3D Fe-NiSe nanowires supported on nickel foam as a highly efficient, durable oxygen evolution catalyst[J]. J Mater Chem A, 2017, 5(28):14639-14645. doi: 10.1039/C7TA03095A [28] SOLEIMANI E, MOHAMMADI M. Synthesis, characterization and properties of polystyrene/NiO nanocomposites[J]. J Mater Sci Mater Electron, 2018, 29(11):9494-9508. doi: 10.1007/s10854-018-8983-6 [29] 代红艳, 杨慧敏, 刘宪, 简选, 郭敏敏, 曹乐乐, 梁镇海. MoS2/石墨烯复合阴极材料的制备及微生物电解池催化产氢性能[J].高等学校化学学报, 2018, 39(2):351-358. http://www.cnki.com.cn/Article/CJFDTOTAL-GDXH201802023.htmDAI Hong-yan, YANG Hui-min, LIU Xian, JIAN Xuan, GUO Min-min, CAO Le-le, LIANG Zhen-hai. Preparation and electrochemical evaluation of MoS2/graphene as a catalyst for hydrogen evolution in microbial electrolysis cell[J]. Chem J Chin Univ, 2018, 39(2):351-358. http://www.cnki.com.cn/Article/CJFDTOTAL-GDXH201802023.htm [30] CHO G, KIM H, PARK Y S, HONG Y K, HA D H. Phase transformation of iron phosphide nanoparticles for hydrogen evolution reaction electrocatalysis[J]. Int J Hydrogen Energy, 2018, 43(24):11326-11334. doi: 10.1016/j.ijhydene.2018.02.197 [31] LI Z C, MA J J, ZHOU Y, YIN Z G, TANG Y B, MA Y X, WANG D B. Synthesis of sulfur-rich MoS2, nanoflowers for enhanced hydrogen evolution reaction performance[J]. Electrochim Acta, 2018, 283(1):306-312. http://cn.bing.com/academic/profile?id=ee10974d04ae360ceb73c9e4baf3402d&encoded=0&v=paper_preview&mkt=zh-cn [32] WANG A, LIU W, CHENG S, XING D F, ZHOU J Z, LOGAN B E. Source of methane and methods to control its formation in single chamber microbial electrolysis cells[J]. Int J Hydrogen Energy, 2009, 34(9):3653-3658. doi: 10.1016/j.ijhydene.2009.03.005 -

下载:

下载: