Improvement in the performance of streptomycin wastewater MFC treatment and electricity generation by co-substrate addition

-

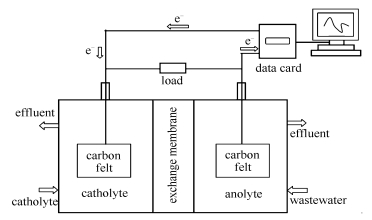

摘要: 以K3[Fe(CN)6]和NaCl混合溶液为阴极液,以驯化的人工湖泊底泥为微生物菌种,以链霉素废水为阳极液,构建微生物燃料电池实验系统,研究添加共基质前后微生物燃料电池的废水处理效果与同步发电性能。结果表明,以链霉素废水为阳极液的微生物燃料电池的产电能力及废水处理效果均较差,并且随着链霉素浓度的增大而进一步恶化;但将葡萄糖作为共基质添加至阳极链霉素废水后,微生物燃料电池的产电能力和废水处理效果均显著提高。链霉素浓度为50 mg/L时,未添加共基质的微生物燃料电池处理链霉素废水的COD去除率为52%,产电电流密度为25 mA/m2,输出电压为4.72 mV;添加共基质后,COD去除率为92%,稳态产电电流密度为300 mA/m2,稳态输出电压为54 mV。Abstract: A microbial fuel cell system was built by using the mixed solution of K3[Fe (CN)6] and NaCl as catholyte, acclimated sediment of an artificial lake as the source of microbial species, and streptomycin wastewater as anolyte; the effect of co-substrate addition on the purification effect and electricity generation ability of the microbial fuel cell was investigated. The results show that the electricity generation ability and wastewater treatment effect of microbial fuel cell with streptomycin wastewater as anolyte are quite poor and deteriorate even further with the increase of the streptomycin concentration. However, the electricity generation ability and wastewater treatment effect of the microbial fuel cell can be significantly improved by adding glucose as a co-substrate to the anode streptomycin wastewater. In case without the co-substrate, the COD removal rate is only 52% when the concentration of streptomycin is 50 mg/L, with a steady electric current density of 25 mA/m2 and a steady output voltage of 4.72 mV; by adding the co-substrate, the COD removal rate reaches 92%, with a steady electric current density of 300 mA/m2 and a steady output voltage of 54 mV.

-

表 1 不同链霉素浓度下MFC的稳态电压

Table 1 Steady voltage of MFC with streptomycin of different concentrations

Concentrations c/(mg·L-1) 0 5 80 290 730 2 190 3 640 4 370 5 100 Voltage U/mV 4.8 4.8 4.7 4.6 4.5 4.2 3.3 2.7 1.8 表 2 链霉素浓度下MFC的COD去除率

Table 2 COD removal rate of MFC with streptomycin of different concentrations

Concentrations c/(mg·L-1) 0 5 80 290 730 2 190 3 640 4 370 5 100 COD removal rate η/% 25.56 25.3 24.8 24.10 23.96 19.54 9.15 2.32 0.08 表 3 未添加共基质时MFC反应室的pH值

Table 3 pH value of reaction system corresponding to MFC without co-substrates

Concentration of streptomycin c/(mg·L-1) Cathode chamber Anode chamber before running after running before running after running 10 6.61 6.73 6.78 6.65 20 6.61 6.72 6.82 6.73 30 6.60 6.69 6.87 6.77 40 6.60 6.69 6.91 6.79 50 6.62 6.72 6.96 6.85 表 4 添加共基质后MFC反应室的pH值

Table 4 pH value of reaction system corresponding to MFC with co-substrates

Concentration of streptomycin c/(mg·L-1) Cathode chamber Anode chamber before running after running before running after running 10 6.60 6.90 6.87 6.55 20 6.62 6.90 6.92 6.62 30 6.61 6.88 6.95 6.66 40 6.60 6.93 7.02 6.67 50 6.60 6.97 7.06 6.66 -

[1] KEEN P L, PATRICK D M. Tracking change:A look at the ecological footprint of antibiotics and antimicrobial resistance[J]. Antibiotics, 2013, 2(2):191-205. doi: 10.3390/antibiotics2020191 [2] LIEN L T, HOA N Q, CHUC N T, THOA N T, PHUC H D, DIWAN V, DAT N T, TAMHANKAR A J, LUNDBORG C S. Antibiotics in wastewater of a rural and an urban hospital before and after wastewater treatment, and the relationship with antibiotic use-a one year study from vietnam[J]. Int J Environ Res Public Health, 2016, 13(6):588. doi: 10.3390/ijerph13060588 [3] WANG Y, LU J, WU J, LIU Q, ZHANG H, JIN S. Adsorptive removal of fluoroquinolone antibiotics using bamboo biochar[J]. Sustainability, 2015, 7(9):12947-12957. doi: 10.3390/su70912947 [4] 令狐文生.抗生素废水处理及分析技术研究进展[J].化学试剂, 2015, 37(2):127-131. http://www.cnki.com.cn/Article/CJFDTOTAL-HXSJ201502009.htmLINGHU Wen-sheng. Progress on treatment and analysis of antibiotic wastewater[J]. Chem Reagents, 2015, 37(2):127-131. http://www.cnki.com.cn/Article/CJFDTOTAL-HXSJ201502009.htm [5] BRASCHI I, BLASIOLI S, GIGLI L, GESSA C E, ALBERTI A, MARTUCCI A. Removal of sulfonamide antibiotics from water:Evidence of adsorption into an organophilic zeolite Y by its structural modifications[J]. J Hazard Mater, 2010, 178(1/3):218-225. https://www.researchgate.net/publication/41407913_Removal_of_sulfonamide_antibiotics_from_water_Evidence_of_adsorption_into_an_organophilic_zeolite_Y_by_its_structural_modifications [6] DOLLIVER H, GUPTA S. Antibiotic losses in leaching and surface runoff from manure-amended agricultural land[J]. J Environ Qual, 2008, 37(3):1227-1237. doi: 10.2134/jeq2007.0392 [7] LI B, ZHANG T. Biodegradation and adsorption of antibiotics in the activated sludge process[J]. Environ Sci Technol, 2010, 44(9):3468-3473. doi: 10.1021/es903490h [8] AKBARPOUR-TOLOTI A, MEHRDADI N. Wastewater treatment from antibiotics plant (UASB reactor)[J]. Int J Environ Res, 2011, 5(1):241-246. [9] 林海龙, 宋鸽, 司亮, 余建平, 陈兆波, 吴玉凤.抗生素废水生物处理法的研究进展[J].中国农学通报, 2012, 28(11):258-261. http://www.cnki.com.cn/Article/CJFDTOTAL-ZNTB201211053.htmLIN Hai-Long, SONG Ge, SI Liang, YU Jian-Ping, CHEN Zhao-Bo, WU Yu-Feng. Advances in study on the biological treatment of antibiotic wastewater[J]. Chin Agri Sci Bull, 2012, 28(11):258-261. http://www.cnki.com.cn/Article/CJFDTOTAL-ZNTB201211053.htm [10] GULKOWSKA A, LEUNG H W, SO M K, TANIYASU S, YAMASHITA N, YEUNG L W, RICHARDSON B J, LEI A P, GIESY J P, LAM P K. Removal of antibiotics from wastewater by sewage treatment facilities in Hong Kong and Shenzhen, China[J]. Water Res, 2008, 42(1/2):395-403. https://www.researchgate.net/publication/6134100_Removal_of_antibiotics_from_wastewater_by_sewage_treatment_facilities_in_Hong_Kong_and_Shenzhen_China [11] CHEN Y S, ZHANG H B, LUO Y M, SONG J. Occurrence and dissipation of veterinary antibiotics in two typical swine wastewater treatment systems in east China[J]. Environ Monit Assess, 2012, 184(4):2205-2217. doi: 10.1007/s10661-011-2110-y [12] LI W W, YU H Q, HE Z. Towards sustainable wastewater treatment by using microbial fuel cells-centered technologies[J]. Energy Environ Sci, 2014, 7:911-924. https://www.researchgate.net/publication/270280815_Towards_sustainable_wastewater_treatment_by_using_microbial_fuel_cells-centered_technologies [13] LIU H, RAMNARAYANAN R, LOGAN B E. Production of electricity during wastewater treatment using a single chamber microbial fuel cell[J]. Environ Sci Technol, 2004, 38(7):2281-2285. doi: 10.1021/es034923g [14] PANDEY B K, MISHRA V, AGRAWAL S. Production of bio-electricity during wastewater treatment using a single chamber microbial fuel cell[J]. Int J Eng, Sci Technol, 2011, 3(4):42-47. https://www.researchgate.net/publication/8592071_Production_of_Electricity_During_Wastewater_Treatment_Using_a_Single_Chamber_Microbial_Fuel_Cell [15] MATHURIYA A S. Enhanced tannery wastewater treatment and electricity generation in microbial fuel cell by bacterial strains isolated from tannery waste[J]. Environ Eng Manag J, 2014, 13(12):2945-2954. [16] 程李钰, 徐龙君.电极面积对老龄垃圾渗滤液为底物的微生物燃料电池性能影响[J].燃料化学学报, 2015, 43(8):1011-1017. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract18683.shtmlCHENG Li-yu, XU Long-jun. Effects of electrode surface area on the performance of microbial fuel cells with the aging landfill leachate as substrate[J]. J Fuel Chem Technol, 2015, 43(8):1011-1017. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract18683.shtml [17] 樊立萍, 郑钰姣, 苗晓慧.阴极液及溶氧对微生物燃料电池性能的影响[J].高校化学工程学报, 2016, 30(2):491-496. http://www.cnki.com.cn/Article/CJFDTOTAL-GXHX201602035.htmFAN Li-ping, ZHENG Yu-jiao, MIAO Xiao-hui. Effects of catholyte and dissolved oxygen on microbial fuel cell performance[J]. J Chem Eng Chin Univ, 2016, 30(2):491-496. http://www.cnki.com.cn/Article/CJFDTOTAL-GXHX201602035.htm [18] BOUALLAGUI H, LAHDHEB H, ROMDAN E B, RACHDI B, HAMDI M. Improvement of fruit and vegetable waste anaerobic digestion performance and stability with co-substrates addition[J]. J Environ Manage, 2009, 90(5):1844-1849. doi: 10.1016/j.jenvman.2008.12.002 [19] LU H F, ZHANG G M, LU Y F, ZHANG Y H, LI B M, CAO W. Using co-metabolism to accelerate synthetic starch wastewater degradation and nutrient recovery in photosynthetic bacterial wastewater treatment technology[J]. Environ Technol, 2016, 37(7):775-784. doi: 10.1080/09593330.2015.1084050 [20] RASOOL K, MAHMOUD K A, LEE D S. Influence of co-substrate on textile wastewater treatment and microbial community changes in the anaerobic biological sulfate reduction process[J]. J Hazard Mater, 2015, 299(12):453-461. https://www.researchgate.net/publication/280254094_Influence_of_co-substrate_on_textile_wastewater_treatment_and_microbial_community_changes_in_the_anaerobic_biological_sulfate_reduction_process [21] NOZARI M, SAMAEI M R, DEHGHANI M. The effect of co-metabolism on removal of hexadecane by microbial consortium from soil in a slurry sequencing batch reactor[J]. J Health Sci Surveillance Sys, 2014, 2(3):113-124. https://www.researchgate.net/publication/271139061_The_Effect_of_Co-Metabolism_on_Removal_of_Hexadecane_by_Microbial_Consortium_from_Soil_in_a_Slurry_Sequencing_Batch_Reactor -

下载:

下载: