Leaching characteristics of trace elements in hetero-aggregation fly ash from coal-fired power plant

-

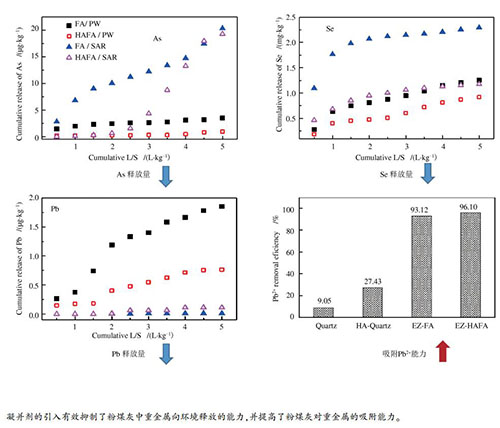

摘要: 采集了燃煤电厂的异相凝并后飞灰,分析了其物理化学特性。并通过淋滤实验研究了飞灰中重金属As、Se、Pb的环境稳定性。结果表明,凝并飞灰的粒径峰值为138.04 μm,而粉煤灰为60.26 μm;凝并后细颗粒凝聚成了较大的颗粒;凝并飞灰中重金属As、Se、Pb含量均高于同工况下粉煤灰中的含量,且后序脱硫环节所产生石膏中重金属的含量有所下降;批淋滤实验研究结果表明,凝并飞灰中的重金属浸出能力受淋滤液的pH值影响较大,温和环境和碱性条件抑制了As的浸出,酸性和碱性条件抑制了Se的浸出,而碱性条件抑制了Pb的浸出。柱淋滤实验研究结果表明,在酸性溶液和水溶液中,凝并飞灰的重金属浸出能力均受到了抑制。Abstract: This paper studied physicochemical and leaching characteristics of three hazardous trace elements As, Se and Pb in hetero-aggregation fly ash (HAFA) and coal fly ash (FA)samples which were collected from coal-fired power plant. The results show that the peak of particle size of HAFA is 138.04 and is 60.26 μm of FA; the fine particles agglomerate into large particles after agglomeration; the contents of heavy metals of As, Se and Pb in HAFA are all higher than those of in FA. The content of heavy metals in gypsum produced in the subsequent desulfurization process is decreased. The batch leaching experiments show that leaching concentrations of three metals in HAFA are suppressed by mild and alkaline condition for As, by acidic and alkaline condition for Se, and by alkaline condition for Pb. The column leaching experiments show that the leaching abilities of the trace elements in HAFA are inhibited in both acidic and aqueous solution.

-

Key words:

- fly ash /

- hetero-aggregation /

- particles /

- trace elements /

- leaching

-

表 1 飞灰的化学元素组成

Table 1 Concentration of elements of fly ash

Sample Content w/% SiO2 Al2O3 CaO Fe2O3 SO3 TiO2 others FA 53.78 34.00 3.48 4.09 0.31 1.34 2.99 HAFA 53.68 34.10 3.49 4.20 0.36 1.29 2.87 表 2 样品的重金属含量

Table 2 Concentration of trace elements in samples

Sample Content w/(μg·g-1) As Se Pb FA 17.96 8.09 234 HAFA 19.53 9.19 243.96 DG 11.10 6.76 15.56 HA-DG 7.52 2.19 10.89 表 3 元素累积浸出率

Table 3 Ratio of cumulative release

Element η/% As Se Pb FA/PW 0.02 15.51 0.0008 HAFA/PW 0.01 10.00 0.0003 FA/SAR 0.11 28.33 0.0000 HAFA/SAR 0.11 12.81 0.0000 -

[1] BP. BP Statistical Review of World Energy 2020[R]. London, June, 2020. [2] PUI D Y H, CHEN S C, ZUO Z. PM2.5 in China: Measurements, sources, visibility and health effects, andmitigation[J]. Particuology, 2014, 13: 1-26. doi: 10.1016/j.partic.2013.11.001 [3] 赵永椿, 张军营, 魏凤, 陈俊, 郑楚光.燃煤超细颗粒物团聚促进机制的实验研究[J].化工学报, 2007, 58(11): 2876-2881. doi: 10.3321/j.issn:0438-1157.2007.11.032ZHAO Yong-chun, ZHANG Jun-ying, WEI Feng, CHEN Jun, ZHENG Chu-guang. Experimental study on agglomeration of submicron particles from coal combustion[J]. J Chem Ind Eng (China), 2007, 58(11): 2876-2881. doi: 10.3321/j.issn:0438-1157.2007.11.032 [4] HU B, YI Y, LIANG C, YUAN Z, SZCZEPAN R, YANG L. Experimental study on particles agglomeration by chemical and turbulent agglomeration before electrostatic precipitators[J]. Powder Technol, 2018, 335: 186-194. doi: 10.1016/j.powtec.2018.04.016 [5] GUO Y, ZHANG J, ZHAO Y, WANG S, JIANG C, ZHENG C. Chemical agglomeration of fine particles in coal combustion flue gas: Experimental evaluation[J]. Fuel, 2017, 3: 557-569. https://www.sciencedirect.com/science/article/pii/S001623611730577X [6] ZHOU L, CHEN W, WU H, SHEN A, YUAN Z, YANG L. Investigation on the relationship of droplet atomization performance and fine particle abatement during the chemical agglomeration process[J]. Fuel, 2019, 245: 65-77. doi: 10.1016/j.fuel.2019.02.033 [7] SUN Z, YANG L, SHEN A, ZHOU L, WU H. Combined effect of chemical and turbulent agglomeration on improving the removal of fine particles by different coupling model[J]. Powder Technol, 2019, 344: 242-250. doi: 10.1016/j.powtec.2018.12.032 [8] 郭沂权, 张军营, 赵永椿, 王少龙, 江城, 郑楚光. 50 MW燃煤电站锅炉细颗粒物化学团聚示范工程试验研究[J].中国电机工程学报, 2016, 36(S1): 87-94. http://www.cnki.com.cn/Article/CJFDTotal-ZGDC2016S1011.htmGUO Yi-quan, ZHANG Jun-ying, ZHAO Yong-chun, WANG Shao-long, JIANG Cheng, ZHENG Chu-guang. Experimental research on fine particles chemical agglomeration demonstration project in a 50 MW coal-fired power plant boiler[J]. Proc CSEE, 2016, 36(S1): 87-94. http://www.cnki.com.cn/Article/CJFDTotal-ZGDC2016S1011.htm [9] 郭沂权, 赵永椿, 李高磊, 张军营. 300 MW燃煤电站化学团聚强化飞灰细颗粒物排放控制的研究[J].中国电机工程学报, 2019, 39(3): 754-763. http://www.cqvip.com/QK/90021X/20193/90716867504849574851484950.htmlGUO Yi-quan, ZHAO Yong-chun, LI Gao-lei, ZHANG Jun-ying. Research on enhanced fly ash fine particulate emission control by chemical agglomeration of 300 MW coal-fired power stations[J]. Proc CSEE, 2019, 39(3): 754-763. http://www.cqvip.com/QK/90021X/20193/90716867504849574851484950.html [10] KHODADOUST A P, NAITHANI P, THEIS T L, MURARKA I P. Leaching characteristics of arsenic from aged alkaline coal fly ash using column and sequential batch leaching[J]. Ind Eng Chem Res, 2011, 50(4): 2204-2213. doi: 10.1021/ie100909n [11] SU T, WANG J. Modeling batch leaching behavior of arsenic and selenium from bituminous coal fly ashes[J]. Chemosphere, 2011, 85(8): 1368-1374. doi: 10.1016/j.chemosphere.2011.08.002 [12] SARMIENTO L M, ROESSLER J G, TOWNSEND T G. Trace Element Mobility from Coal Combustion Residuals Exposed to Landfill Leachate[J]. J Hazard Mater, 2019, 365: 962-970. doi: 10.1016/j.jhazmat.2018.11.028 [13] KIM A G, HESBACH P. Comparison of fly ash leaching methods[J]. Fuel, 2009, 88(5): 926-937. doi: 10.1016/j.fuel.2008.11.013 [14] 龚勋, 郝炜, 张丹, 李琳, 乔瑜, 姚洪, 徐明厚.燃煤锅炉粉煤灰中典型痕量金属元素淋滤特性研究[J].工程热物理学报, 2009, 30(1): 156-160. doi: 10.3321/j.issn:0253-231X.2009.01.044GONG Xun, HAO Wei, ZHANG Dan, LI Lin, QIAO Yu, YAO Hong, XU Ming-hou. Leaching characteristics of heavy metals in fly ash from different ESPs of coal-fired power plant[J]. J Eng Thermo, 2009, 30(1): 156-160. doi: 10.3321/j.issn:0253-231X.2009.01.044 [15] GB/T 14848, 地下水质量标准[S].GB/T14848, Standard for groundwater quality[S]. [16] U.S. EPA. Method 1313, liquid-solid partitioning as a function of extract pH using a parallel batch procedure[S]. [17] U.S. EPA. Environmental fact sheet: Toxicity characteristic rule finalized. Washington DC: U. S. EPA, 1990[S]. [18] 赵汶, 刘勇, 鲍静静, 耿俊峰, 杨林军.化学团聚促进燃煤细颗粒物脱除的试验研究[J].中国电机工程学报, 2013, 33(20): 52-58. http://d.wanfangdata.com.cn/Periodical/zgdjgcxb201320024ZHAO Wen, LIU Yong, BAO Jing-jing, GENG Jun-feng, YANG Lin-jun. Experimental Research on Fine Particles Removal from Flue Gas by Chemical Agglomeration[J]. Proc CSEE, 2013, 33(20): 52-58. http://d.wanfangdata.com.cn/Periodical/zgdjgcxb201320024 [19] 黄叶, 钱觉时, 王智, 张志伟.循环流化床锅炉固硫灰与煤粉锅炉粉煤灰的比较研究[J].粉煤灰综合利用, 2009, (3): 7-9. doi: 10.3969/j.issn.1005-8249.2009.03.002HUANG Ye, QIAN Jue-shi, WANG Zhi, ZHANG Zhi-wei. Comparative study of CFB ashes and PC ashes[J].Fly Ash Compr Util, 2009, (3): 7-9. doi: 10.3969/j.issn.1005-8249.2009.03.002 [20] WANG N, SUN X, ZHAO Q, YANG Y, WANG P. Leachability and adverse effects of coal fly ash: A review[J]. J Hazard Mater, 2020, 396: 122725. doi: 10.1016/j.jhazmat.2020.122725 [21] HU Bin, LIU Yong, YANG Chun-min, HOU Da-wei, YUAN Zhu-lin, YANG Lin-jun. Simultaneous control of PM2.5 and SO3 by chemical agglomeration collaborative electrostatic precipitation[J].J Chem Ind Eng (China), 2016, 67(9): 3902-3909. http://en.cnki.com.cn/Article_en/CJFDTotal-HGSZ201609047.htm [22] LANZERSTORFER C. Fly ash from coal combustion: Dependence of the concentration of various elements on the particle size[J]. Fuel, 2018, 228: 263-271. doi: 10.1016/j.fuel.2018.04.136 [23] GUO B, NAKAMA S, TIAN Q, PAHLEVI N D, HU Z, SASAKI K. Suppression processes of anionic pollutants released from fly ash by various Ca additives[J]. J Hazard Mater, 2019, 371: 474-483. doi: 10.1016/j.jhazmat.2019.03.036 [24] 李一鸣, 宋营营, 潘永萍, 宋慧凯, 杨斌, 包木太.黄原胶对水中铅离子吸附性能研究[J].环境科学与技术, 2011, 34(6G): 1-4. http://www.cqvip.com/QK/90776X/2011S1/1003575433.htmlLI Yi-ming, SONG Ying-ying, PAN Yong-ping, SONG Hui-kai, YANG Bin, BAO Mu-tai. Adsorption of Pb2+ by Xanthan Gum in Water[J]. Environ Sci Technol, 2011, 34(6G): 1-4. http://www.cqvip.com/QK/90776X/2011S1/1003575433.html [25] 傅丛, 白向飞, 连进京.燃煤灰渣中砷的连续柱淋滤特性及表生运移作用初探[J].煤质技术, 2016, (2): 53-59. doi: 10.3969/j.issn.1007-7677.2016.02.016FU Cong, BAI Xiang-fei, LIAN Jin-jing. Discussion on the leaching features of continuous column of arsenic in coal ash and the supergene migration[J]. Coal Qual Technol, 2016, (2): 53-59. doi: 10.3969/j.issn.1007-7677.2016.02.016 -

下载:

下载: