Change of sulfur and nitrogen compounds in the direct liquefaction oil from Shenfu coal upon the hydrofining process

-

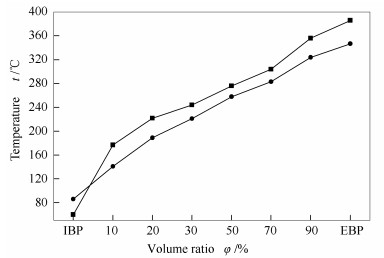

摘要: 采用实沸点蒸馏对神府煤液化油及其加氢精制油做了馏分切割, 并采用GC-PFPD与GC-NCD对液化油与精制油中的硫氮化合物类型进行了分析, 研究了液化油加氢精制过程中硫氮化合物分布的变化。结果表明, 液化油中硫含量随窄馏分的馏程由低到高呈现"U"型分布, 氮的分布基本上随窄馏分沸点温度的升高而增大, 氮的含量远高于硫的含量; 经过固定床加氢精制后, 97%的硫和98.9%的氮得到脱除。液化油中苯并噻吩和二苯并噻吩等二环和三环化合物占93.25%;经过加氢处理之后, 硫醇、硫醚、噻吩类等低沸点含硫化合物基本消失, 难脱除组分主要以苯并噻吩类、二苯并噻吩类为主。液化油中含氮化合物主要以五元杂环中性氮化物为主, 占54.96%;碱性氮化物主要以苯胺类为主, 占23.22%, 喹啉类相对较少; 经过加氢处理之后, 脂肪胺类含氮化合物被完全脱除, 精制油中残留的氮主要以碱性氮化物喹啉类与苯胺类含氮化合物存在。Abstract: The direct liquefaction oil from Shenfu coal and the refined oil through hydrofining were cut into different fractions by true boiling point distillation and the sulfur and nitrogen compounds in each fraction were analyzed by GC-PFPD and GC-NCD; the change in the sulfur and nitrogen compounds in the direct liquefaction oil upon the hydrofining process was then investigated. The results illustrated that the sulfur content in the direct liquefaction oil takes a 'U' type distribution with the distillation range from low to high boiling point, whereas the content of nitrogen is far higher than that of sulfur, which increases with the rising of the fraction boiling point. After hydrofining, the sulfur and nitrogen contents are removed by 97% and 98.9%, respectively. Bicyclic and tricyclic compounds such as benzothiophene and dibenzothiophene account for 93.25% of the sulfur compounds in the coal liquefaction oil; after the hydrofining, low boiling point sulfur compounds such as mercaptan, sulfoether and thiophene almost disappear, with benzothiophene and dibenzothiophene as the main sulfur compounds that are difficult to remove. In the coal liquefaction oil, five-membered heterocycle neutral compounds account for 54.96% nitrogen and the portion of basic nitrogen compounds, including mainly anilines with a relatively small amount of quinolones, is 23.22%. After hydrofining, fatty amines are removed completely and the residual nitrogen in the refined oil exists mainly as the basic nitrogen compounds such as quinolones and anilines.

-

Key words:

- direct coal liquefaction oil /

- sulfur compounds /

- nitrogen compounds /

- narrow fractions /

- hydrofining

-

表 1 煤液化油和精制油性质

Table 1 Properties of the direct coal liquefaction (DCL) oil and refined oil through hydrofining

Property DCL oil Refined oil Density /(g·cm-3) 0.948 0.867 H w/% 11.27 12.65 C w/% 87.23 86.44 O w/% 1.174 0.54 S w/(mg·kg-1) 780 23 N w/(mg·kg-1) 4 910 55 Alkane w/% 15.12 21.41 Cycloalkane w/% 7.02 75.16 Olefin w/% 2.32 - Aromatic w/% 73.48 5.43 Polar fraction w/% 3.1 - 表 2 加氢催化剂性质

Table 2 Properties of the hydrofining catalyst

Composition w/% Carrier Surface area A/(m2·g-1) Pore volume v/(mL·g-1) Mechanical strength /(N·cm-1) WO3 MoO3 NiO F 13.62 7.82 7.11 2.54 γ-Al2O3 >200 0.45-0.55 >155 表 3 液化油及精制油中类型硫含量

Table 3 Contents of sulfur compounds in the DCL oil and refined oil

Sulfur compound Contents w/(mg·kg-1) DCL oil refined oil MN 10.2 - SF 5.7 - T 7.8 <0.5 Ts 29.0 - BT 44.1 - BTs 259.5 9.6 DBT 146.6 5.3 DBTs 278.1 12.6 表 4 液化油及精制油中类型氮含量

Table 4 Contents of nitrogen compounds in the DCL oil and the refined oil

Nitrogen compound Contents w/(mg·kg-1) DCL oil refined oil Basic nitrogen compound AAs 179.0 - ANs 1 140.3 34.0 PDs 35.8 - Q 174.9 5.1 Qs 258.8 9.2 Neutral nitrogen compound ID 323.7 1.7 IDs 941.4 6.7 CZ 644.8 - CZs 788.5 3.1 -

[1] 朱继升, NORCIO L P, KUGLER E L, DADYBURJOR D B, 杨建丽, 刘振宇, 钟炳.两种烟煤的液化及液化油的组成特征研究[J].燃料化学学报, 2001, 29(3): 214-218. http://www.cnki.com.cn/Article/CJFDTOTAL-RLHX200103003.htmZHU Ji-sheng, NORCIO L P, KUGLER E L, DADYBURJOR D B, YANG Jian-li, LIU Zhen-yu, ZHONG Bing. Characterization of hexane soluble oils from liquefaction of two bituminous coals[J]. J Fuel Chem Technol, 2001, 29(3): 214-218. http://www.cnki.com.cn/Article/CJFDTOTAL-RLHX200103003.htm [2] 王永刚, 王彩红, 杨正伟, 董敏.典型中国煤直接液化油组成特征研究[J].中国矿业大学学报, 2009, 38(1): 96-100. http://www.cnki.com.cn/Article/CJFDTOTAL-ZGKD200901021.htmWANG Yong-gang, WANG Cai-hong, YANG Zheng-wei, DONG Min. Characterization of direct liquefied oils from three typical chinese coals[J]. J China Univ Min Technol, 2009, 38(1): 96-100. http://www.cnki.com.cn/Article/CJFDTOTAL-ZGKD200901021.htm [3] HUANG P, ZHANG X J, MAO X F. Research on the production of aromatic hydrocarbon via hydroreforming a light fraction in direct coal liquefaction oil[J]. Energy Fuels, 2015, 29(1): 86-90. doi: 10.1021/ef502146a [4] OMAIS B, COURTIADE M, CHARON N, ROULLET C, PONTHUS J, THIÉBAUT D. Using gas chromatography to characterize a direct coal liquefaction naphtha[J]. J Chromatogr A, 2012, 1226(4): 61-70. https://www.researchgate.net/publication/51547000_Using_gas_chromatography_to_characterize_a_direct_coal_liquefaction_naphtha [5] 王永刚, 周建明, 王彩红, 杨正伟.先锋煤和神华煤直接液化油的组成[J].煤炭学报, 2006, 31(1): 81-84. http://www.cnki.com.cn/Article/CJFDTOTAL-MTXB200601018.htmWANG Yong-gang, ZHOU Jian-ming, WANG Cai-hong, YANG Zheng-wei. Direct liquefaction oil products distribution of Xianfeng and Shenhua coals[J]. J China Coal Soc, 2006, 31(1): 81-84. http://www.cnki.com.cn/Article/CJFDTOTAL-MTXB200601018.htm [6] 殷长龙, 夏道宏.催化裂化汽油中类型硫含量分布[J].燃料化学学报, 2001, 29(3): 256-258. http://www.cnki.com.cn/Article/CJFDTOTAL-RLHX200103013.htmYIN Chang-long, XIA Dao-hong. Distribution of sulfur compounds in the full-range fcc and rfcc gasoline[J]. J Fuel Chem Technol, 2001, 29(3): 256-258. http://www.cnki.com.cn/Article/CJFDTOTAL-RLHX200103013.htm [7] 凌凤香, 姚银堂, 马波, 王少军.气相色谱-原子发射光谱联用技术测定柴油中硫化物[J].燃料化学学报, 2002, 30(6): 535-539. http://www.cnki.com.cn/Article/CJFDTOTAL-RLHX200206011.htmLING Feng-xiang, YAO Yin-tang, MA Bo, WANG Shao-jun. Study of sulfur compounds in diesel oil by GC-atomic emission detection[J]. J Fuel Chem Technol, 2002, 30(6): 535-539. http://www.cnki.com.cn/Article/CJFDTOTAL-RLHX200206011.htm [8] 王少军, 凌凤香, 王安杰.柴油非加氢脱硫技术研究中样品的选择[J].燃料化学学报, 2005, 33(2): 171-174. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract16537.shtmlWANG Shao-jun, LING Feng-xiang, WANG An-jie. Testing sample choice for non-hydrodesulfurization of diesels[J]. J Fuel Chem Technol, 2005, 33(2): 171-174. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract16537.shtml [9] 山红红, 李春义. FCC汽油中硫分布和催化脱硫研究[J].石油大学学报:自然科学版, 2001, 25(6): 78-80. http://www.cnki.com.cn/Article/CJFDTOTAL-SYDX200106025.htmSHAN Hong-hong, LI Chun-yi. Distribution of sulfur in FCC gasoline and desulfurization with catalytic cracking[J]. J China Univ Pet (Nat Sci), 2001, 25(6): 78-80. http://www.cnki.com.cn/Article/CJFDTOTAL-SYDX200106025.htm [10] 张月琴.直馏柴油和焦化柴油中含氮化合物类型分布[J].石油炼制与化工, 2013, 44(1): 41-45. http://www.cnki.com.cn/Article/CJFDTOTAL-SYLH201301023.htmZHANG Yue-qin. Characterizations of nitrogen compounds in coker gas oil and straight run diesel oil[J]. Petrol Process Petrochem, 2013, 44(1): 41-45. http://www.cnki.com.cn/Article/CJFDTOTAL-SYLH201301023.htm [11] 张月琴.催化裂化柴油中含氮化合物类型分布[J].石油炼制与化工, 2013, 44(5): 87-91. http://www.cnki.com.cn/Article/CJFDTOTAL-SYLH201305021.htmZHANG Yue-qin. Characterization of nitrogen compounds in fcc diesel fraction[J]. Petrol Process Petrochem, 2013, 44(1): 87-91. http://www.cnki.com.cn/Article/CJFDTOTAL-SYLH201305021.htm [12] MURTI S D S, SAKANISHI K, OKUMA O, KORAI Y, MOCHIDA I. Detailed characterization of heteroatom-containing molecules in light distillates derived from Tanito Harum coal and its hydrotreated oil[J]. Fuel, 2002, 81(17): 2241-2248. doi: 10.1016/S0016-2361(02)00159-X [13] MURTI S D S, CHOI K H, SAKANISHI K, OKUMA O, KORAI Y, MOCHIDA I. Analysis and removal of heteroatom containing species in coal liquid distillate over NiMo catalysts[J]. Fuel, 2005, 84(2): 135-142. https://www.researchgate.net/publication/244067949_Analysis_and_removal_of_heteroatom_containing_species_in_coal_liquid_distillate_over_NiMo_catalysts [14] GU X, MAO X F, ZHAO Y, LI W B, ZHANG X J. Study on the basic nitrogen compounds from coal-derived oil[J]. J Coal Sci Eng (China), 2013, 19(1): 83-89. doi: 10.1007/s12404-013-0114-7 [15] 谷小会, 黄澎, 李文博, 艾军.液化油中含氮化合物的研究进展[J].洁净煤技术, 2011, 17(4): 38-40. http://www.cnki.com.cn/Article/CJFDTOTAL-JJMS201104014.htmGU Xiao-hui, HUANG Peng, LI Wen-bo, AI Jun. Study on the nitrogen compounds in liquefaction oil[J]. Clean Coal Technol, 2011, 17(4): 38-40. http://www.cnki.com.cn/Article/CJFDTOTAL-JJMS201104014.htm [16] KIM K H. Performance characterization of the GC/PFPD for H2S, CH3SH, DMS, and DMDS in air[J]. Atmos Environ, 2005, 39(12): 2235-2242. doi: 10.1016/j.atmosenv.2004.12.039 [17] OA M A, FLORESB M, PARRAA S, QUIROZA W, MAXWELLC P, MESTERC Z. Chemometric optimization of an extraction procedure using tartaric acid for butyltin compounds from sediment samples by GC-PFPD[J]. J Chil Chem Soc, 2015, 60: 2803-2806. doi: 10.4067/S0717-97072015000100006 [18] WANG F C, ROBBINS WK, GREANEY MA. Speciation of nitrogen-containing compounds in diesel fuel by comprehensive two-dimensional gas chromatography[J]. J Sep Sci, 2004, 27(5/6): 468-472. https://www.researchgate.net/publication/8377507_Speciation_of_nitrogen-containing_compounds_in_diesel_fuel_by_comprehensive_two-dimensional_gas_chromatography [19] 向章敏, 商胜华, 蔡凯, 耿召良, 陈兴江.气相色谱-氮化学发光检测法测定烟草中的苦参碱及消解动态研究[J].农药学学报, 2012, 14(2): 198-202. http://www.cnki.com.cn/Article/CJFDTOTAL-NYXB201202018.htmXIANG Zhang-min, SHANG Sheng-hua, CAI Kai, GENG Zhao-liang, CHEN Xing-jiang. Determination and decline study of matrine residue in tobacco by gas chromatography-nitrogen chemiluminessence detector[J]. Chin J Pestic Sci, 2012, 14(2): 198-202. http://www.cnki.com.cn/Article/CJFDTOTAL-NYXB201202018.htm [20] 颜家保, 邹雄, 夏明桂.催化裂化柴油中碱性氮化物的脱除[J].石油炼制与化工, 2005, 36(3): 25-28. http://www.cnki.com.cn/Article/CJFDTOTAL-SYLH200503006.htmYAN Jia-bao, ZOU Xiong, XIA Ming-gui. Removing basic nitrogen compounds from fcc lco[J]. Petrol Process Petrochem, 2005, 36(3): 25-28. http://www.cnki.com.cn/Article/CJFDTOTAL-SYLH200503006.htm [21] 李立权.加氢裂化装置工艺计算与技术分析[M].北京:中国石化出版社, 2009.LI Li-quan. Process calculation and technical analysis of hydro cracking unit[M]. Beijing: China Petrochemical Press, 2009. [22] BEJ S K, MAITY S K, TURAGA U T. Search for an efficient 4, 6-DMDBT hydrodesulfurization catalyst: A review of recent studies[J]. Energy Fuels, 2004, 18(5): 1227-1237. doi: 10.1021/ef030179+ [23] GARCÍA-MARTÍNEZ J C, CASTILLO-ARAIZA C O, HEREDIA J A D L R, TREJO E, MONTESINOS A. Kinetics of HDS and of the inhibitory effect of quinoline on HDS of 4, 6-DMDBT over a Ni-Mo-P/Al2O3 catalyst: Part Ⅰ[J]. Chem Eng J, 2012, 210(6): 53-62. -

下载:

下载: