Structure evolution characteristics of Inner Mongolia coal char during CO2 gasification

-

摘要: 基于滴管炉制备内蒙褐煤快速热解焦,借助高频炉开展快速热解焦与CO2的气化实验,考察了煤焦气化过程的结构演变特性。结果表明,随着反应的进行,气化半焦的石墨化程度不断增加,但未达到天然石墨的有序化程度;比表面积先增大后减小,而平均孔径总体呈相反的变化趋势;气化半焦的粒径在反应前期逐渐减小,当转化率大于74%,半焦粒径逐渐增大,归因于气化后期部分颗粒的黏结。Abstract: The rapid pyrolysis chars of an Inner Mongolia (Neimeng) lignite were prepared in a drop tube furnace, and the coal char gasification experiments with CO2 were conducted using a high-frequency induction furnace. The characteristics of char structure evolution during gasification were studied. Results show that as the reaction proceeds, the graphitization degree of gasified chars increases, but it is far less than the degree of natural graphite. The specific surface area firstly increases and then decreases with char conversion, while the average pore size has an opposite trend overall. The particle size of gasified chars gradually increases with conversion in the early stage, and the particle size of gasified chars increases when the conversion exceeds 74%, which could be ascribed to the cohesion of some particles in the later stage of gasification.

-

Key words:

- rapid pyrolysis /

- coal char /

- CO2 gasification /

- structure evolution

-

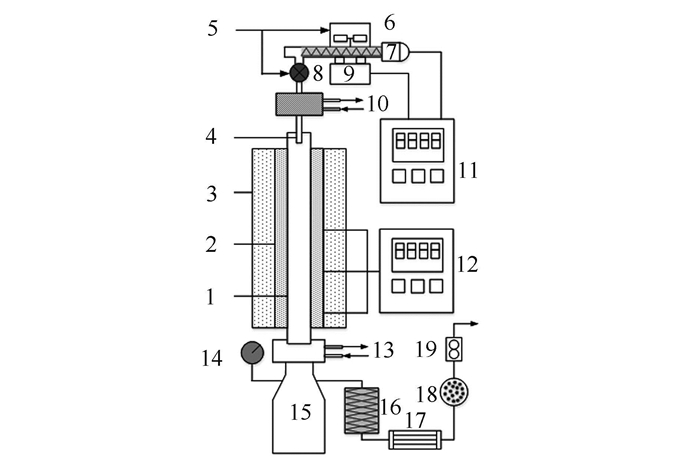

图 1 滴管炉实验装置流程示意图

Figure 1 Schematic diagram of drop tube furnace setup

1: corundum tube; 2: heater; 3: insulation; 4: feed nozzle; 5: N2 inlet; 6: hopper; 7: screw feeder; 8: air lock; 9: hopper weigher; 10, 13: cooling water; 11: weighing controller; 12: temperature controller; 14: pressure gage; 15: char collector; 16: filter; 17: cooler; 18: dry box; 19: gas flowmeter

图 2 高频炉实验装置流程示意图

Figure 2 Schematic diagram of high-frequency induction furnace setup

1: quartz tube; 2: feed tube; 3, 5: flowmeter; 4: N2 inlet; 6: CO2 inlet; 7: power controller; 8: molybdenum tube; 9: induction coil; 10: high-frequency current generator; 11: corundum tube; 12: emulsion pipe; 13: settling chamber; 14: gas washing bottle

表 1 煤样的工业分析和元素分析以及煤灰熔融特征温度

Table 1 Proximate and ultimate analysis and ash fusion temperatures of coal sample

Sample Proximate analysis wd/% Ultimate analysis wd/% Ash fusion temperature t/℃ V FC A C H N S O DT ST HT FT NM 42.09 43.60 14.31 61.18 2.35 1.21 0.64 20.31 1119 1169 1200 1218 note: d: dry basis; V: volatile matter; FC: fixed carbon; DT: deformation temperature; ST: softening temperature; HT: hemispherical temperature; FT: flow temperature 表 2 内蒙煤焦及其气化半焦的灰含量和转化率

Table 2 Ash contents and conversions of NM char and gasified chars

Sample Ad/% Conversion x/% NM-1200 51.75 NM-1230(g)-1 59.90 28 NM-1230(g)-2 69.28 52 NM-1230(g)-3 73.69 62 NM-1230(g)-4 80.28 74 NM-1230(g)-5 83.84 79 NM-1230(g)-6 88.15 86 NM-1230(g)-7 90.37 89 note:Ad: ash on dry basis; NM-1200: NM char obtained at 1200℃; NM-1230(g)-1: NM char gasified at 1230℃ for one time -

[1] 王辅臣.气流床煤气化炉内流动, 混合与反应过程的研究进展[J].燃料化学学报, 2013, 41(7):769-786. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract18210.shtmlWANG Fu-chen.Review for research of flow, mixing and reaction process in entrained flow coal gasifier[J].J Fuel Chem Technol, 2013, 41(7):769-786. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract18210.shtml [2] 丁路, 周志杰, 赵冰, 霍威, 于广锁.滴管炉内不同煤阶煤焦水蒸气气化反应特性[J].化工学报, 2014, 65(3):993-1002. http://www.cnki.com.cn/Article/CJFDTOTAL-HGSZ201403034.htmDING Lu, ZHOU Zhi-jie, ZHAO Bing, HUO Wei, YU Guang-suo.Characteristics of steam-gasification reaction of char with different coal rank in drop tube furnace[J].J Chem Ind Eng (China), 2014, 65(3):993-1002. http://www.cnki.com.cn/Article/CJFDTOTAL-HGSZ201403034.htm [3] KAJITANI S, HARA S, MATSUDA H.Gasification rate analysis of coal char with a pressurized drop tube furnace[J].Fuel, 2002, 81(5):539-546. doi: 10.1016/S0016-2361(01)00149-1 [4] LI S H, WHITTY K J.Physical phenomena of char-slag transition in pulverized coal gasification[J].Fuel Process Technol, 2012, 95:127-136. doi: 10.1016/j.fuproc.2011.12.006 [5] 陈路.滴管炉内煤和石油焦的快速热解及气化反应性研究[D].上海:华东理工大学, 2012.CHEN Lu.Study on characteristics of rapid pyrolysis and gasification reactivity of coal and petroleum coke in a DTF reactor[D].Shanghai:East China University of Science and Technology, 2012. [6] 吴磊, 周志杰, 王兴军, 于广锁, 王辅臣.神府烟煤水煤浆快速热解焦结构演化及其反应性的研究[J].燃料化学学报, 2013, 41(4):422-429. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract18161.shtmlWU Lei, ZHOU Zhi-jie, WANG Xing-jun, YU Guang-suo, WANG Fu-chen.Structure changes and gasification reactivity of CWS char from Shenfu coal rapid pyrolysis[J].J Fuel Chem Technol, 2013, 41(4):422-429. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract18161.shtml [7] 崔童敏, 李超, 周志杰, 常清华, 高瑞, 于广锁, 王辅臣.神府烟煤快速热解特性研究[J].燃料化学学报, 2015, 43(11):1287-1294. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract18721.shtmlCUI Tong-min, LI Chao, ZHOU Zhi-jie, CHANG Qing-hua, GAO Rui, YU Guang-suo, WANG Fu-chen.Rapid pyrolysis characteristic of Shenfu bituminous coal[J].J Fuel Chem Technol, 2015, 43(11):1287-1294. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract18721.shtml [8] 夏明星, 郑欣, 王峰, 刘辉, 蔡小梅, 白润.钼粉制备技术及研究现状[J].中国钨业, 2014, 29(4):45-48. http://www.cnki.com.cn/Article/CJFDTOTAL-ZGWU201404014.htmXIA ming-xing, ZHENG Xin, WANG Feng, LIU Hui, CAI Xiao-mei, BAI Run.Preparation Technology and research status of molybdenum powder[J].China Tungsten Ind, 2014, 29(4):45-48. http://www.cnki.com.cn/Article/CJFDTOTAL-ZGWU201404014.htm [9] 张双全.煤及煤化学[M].北京:化学工业出版社, 2013.ZHANG Shuang-quan.Coal and Coal Chemistry[M].Beijing:Chemical Industry Press, 2013. [10] TSAI C Y, SCARONI A W.The structural changes of bituminous coal particles during the initial stages of pulverized-coal combustion[J].Fuel, 1987, 66(2):200-206. doi: 10.1016/0016-2361(87)90241-9 [11] BADZIOCH S, HAWKSLEY P G W.Kinetics of thermal decomposition of pulverized coal particles[J].Ind Eng Chem Process Des Dev, 1970, 9(4):521-530. doi: 10.1021/i260036a005 [12] LU LIMING, SAHAJWALLA V, HARRIS D.Characteristics of chars prepared from various pulverized coals at different temperatures using drop-tube furnace[J].Energy Fuels, 2000, 14(4):869-876. doi: 10.1021/ef990236s [13] 常海洲, 蔡雪梅, 李改仙, 白官, 吕秀清.不同还原程度煤显微组分堆垛结构表征[J].山西大学学报 (自然科学版), 2008, 31(2):223-227. http://www.cnki.com.cn/Article/CJFDTOTAL-SXDR200802024.htmCHANG Hai-zhou, CAI Xue-mei, LI Gai-xian, BAI Guan, LÜ Xiu-qing.Characterization for the stacking structure of coal macerals with different type reductivity[J].J Shanxi Univ (Nat Sci Ed), 2008, 31(2):223-227. http://www.cnki.com.cn/Article/CJFDTOTAL-SXDR200802024.htm [14] LIU H, LUO C H, TOYOTA M, UEMIYA S, KOJIMA T.Kinetics of CO2/char gasification at elevated temperatures:Part Ⅱ:Clarification of mechanism through modelling and char characterization[J].Fuel Process Technol, 2006, 87(9):769-774. doi: 10.1016/j.fuproc.2006.02.007 [15] 王传格, 张妮, 陈燕.煤显微组分结构特征及其与热解行为的关系[J].煤炭转化, 2011, 34(3):11-16. http://www.cnki.com.cn/Article/CJFDTOTAL-MTZH201103004.htmWANG Chuan-ge, ZHANG Ni, CHEN Yan.Relationship between structural characterization of macerals and their thermal behavior[J].Coal Convers, 2011, 34(3):11-16. http://www.cnki.com.cn/Article/CJFDTOTAL-MTZH201103004.htm [16] 严继民, 张启元, 高敬琼.吸附与凝聚固体的表面与孔 (第2版)[M].北京:科学技术出版社, 1986.YAN Ji-min, ZHANG Qi-yuan, GAO Jing-qiong.Adsorption and Agglomeration Surface and Pore of Solid (2 ed.[M].Beijing:Science and Technology Press, 1986. [17] LIN S Y, HIRATO M, HORIO M.The characteristics of coal char gasification at around ash melting temperature[J].Energy Fuels, 1994, 8(3):598-606. doi: 10.1021/ef00045a014 -

下载:

下载: