Effects of Ba/Ce ratio on NOx storage performance of NSR catalyst

-

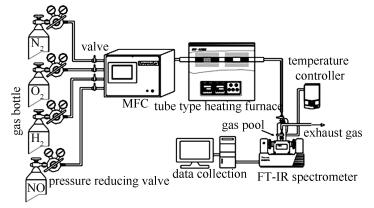

摘要: 通过改进的溶胶凝胶法结合浸渍法制备了一系列Pt/x Ba-(30-x)Ce/γ-Al2O3(x=10、15、20,x为质量分数)型NSR催化剂,并利用XRD、BET、H2-TPR和NO-TPD对其性能进行了表征。结果表明,Ba主要以BaCO3形式存在,CeO2晶粒粒径随着x值增大先减小后增大,且以无定型形式存在于催化剂中。随着Ce含量的增加,高温还原峰温度先降低后升高。NO-TPD结果表明,吸附于催化剂表面的NOx在低温时具有较好的热稳定性;通过NOx完全存储实验,探究了不同Ba/Ce比对催化剂NOx存储性能的影响。结果表明,当x=15时,催化剂的NOx存储量最大,NOx穿透时间达7 min,吸附稳定时NO2/NOx比为28%,NOx存储效率达47.1%,具有最佳的NOx存储性能。Abstract: In order to explore the effects of Ba/Ce ratio on the NOx storage performance of the catalyst, a series of Pt/xBa-(30-x)Ce/γ-Al2O3 (x=10, 15, 20, x is a mass fraction) NSR catalysts were prepared by a modified sol-gel method combined with an impregnation method, and their properties were characterized by means of X-ray diffraction (XRD), specific surface area analysis (BET), temperature programmed reduction of H2 (H2-TPR) and temperature programmed desorption of NO (NO-TPD). The results indicate that Ba mainly exists in the form of BaCO3, and CeO2 is present in the amorphous form. With the increase of x value, CeO2 grain size decreases firstly and then increases. With the increase of Ce content, the high temperature reduction peak has a similar tendency with that of CeO2 grain size. The NO-TPD results show that the NOx adsorbed on the surface of the catalyst has a better thermal stability with the temperature below 350℃. The effects of Ba/Ce ratio on the NOx storage performance were investigated by a simulated gas test platform. The results show that the NOx storage capacity of the Pt/15Ba-15Ce/γ-Al2O3 catalyst has a maximum value of 47.1%, and the NOx breakthrough time is 7 min. When the storage process completes, the NO2/NOx ratio of Pt/15Ba-15Ce/γ-Al2O3 catalyst is 28%. The NOx storage efficiency increases firstly and then decreases, and different Ba/Ce ratios have great influences on the storage path of the catalyst. The catalyst presents excellent NOx storage performance when the Ba/Ce ratio is 1.0. The experimental results provide a reference for the optimal design and application of NSR catalyst in the field of diesel exhaust after-treatment system.

-

Key words:

- sol-gel method /

- NOx storage and reduction /

- NOx storage performance /

- Ba/Ce ratio /

- breakthrough time

-

表 1 催化剂的比表面积以及孔容孔径

Table 1 BET and porous structure parameters of NSR catalysts

Catalyst ABET/(m2·g-1) Pore volume v/(cm3·g-1) Pore diameter d/ nm Pt/20Ba-10Ce/γ-Al2O3 65.7 0.143 3.7 Pt/15Ba-15Ce/γ-Al2O3 91.8 0.147 3.6 Pt/10Ba-20Ce/γ-Al2O3 85.4 0.165 3.7 γ-Al2O3 211.4 0.232 3.8 表 2 NSR催化剂的NOx存储相关参数

Table 2 storage performance related parameters of NSR catalysts

Catalyst NOx storage efficiency /% NOx storage capacity/(μmol·gcat-1) NO2/NOx Breakthrough time t/min Storage saturation time t/min Pt/20Ba-10Ce/γ-Al2O3 40.1 358.04 20.96 5 40 Pt/15Ba-15Ce/γ-Al2O3 47.1 567.72 28 7 54 Pt/10Ba-20Ce/γ-Al2O3 41.68 297.71 20.16 3 32 -

[1] INFANTES-MOLINA A, RIGHINI L, CASTOLDI L, LORICERA C. V, FIERRO J. L. G, SIN A, LIETTI L. Characterization and reactivity of Ce-promoted PtBa lean NOx trap catalysts[J]. Catal Today, 2012, 197(1):178-189. doi: 10.1016/j.cattod.2012.07.036 [2] 陈朝辉, 李志军, 高立波, 焦鹏昊, 张文斐, 刘磊. La2Cu(1-x)FexO4催化去除柴油机NOx和PM排放台架试验[J].农业机械学报, 2012, 43(9):11-15.CHEN Zhao-hui, LI Zhi-jun, GAO Li-bo, JIAO Peng-hao, ZHANG Wen-fei, LIU Lei. Simultaneous removal of diesel NOx and soot over La2Cu1-xFexO4 perovskite-type catalysts[J]. Trans Chin Soc of Agric Mach, 2012, 43(9):11-15. [3] 王攀, 谷文业, 雷利利, 乔冠军.催化剂存储还原柴油机NOx排放的试验[J].农业工程学报, 2015, 31(9):230-234. doi: 10.11975/j.issn.1002-6819.2015.09.035WANG Pan, GU Wen-ye, LEI Li-li, QIAO Guan-jun. Experiment of NOx storage and reduction from diesel engine with NSR catalysts[J]. Trans Chin Soc Agric Eng, 2015, 31(9):230-234. doi: 10.11975/j.issn.1002-6819.2015.09.035 [4] 谢颖, 金正来, 陈英, 马玉刚, 陈小平, 陈敏东. Pt/Ba/TiCeO催化剂上NOx的存储和抗硫性能研究[J].燃料化学学报, 2011, 39(4):300-306. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract17729.shtmlXIE Ying, JIN Zheng-lai, CHEN Ying, MA Yu-gang, CHEN Xiao-ping, CHEN Min-dong. Study on the properties of Pt/Ba/TiCeO catalyst for NOx storage and resistance to SO2[J]. J Fuel Chem Technol, 2011, 39(4):300-306. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract17729.shtml [5] EASTERLING V, JI Y, CROCKER M, URA J, THEIS J R, MCCABE R W. Effect of ceria on the desulfation characteristics of model lean NOx trap catalysts[J]. Catal Lett, 2009, 127(1):55-62. doi: 10.1007/s10562-007-9226-2 [6] ZOU Z Q, MENG M, TSUBAKI N, HE J J, WANG G, LI X G, ZHOU X Y. Influence of Co or Ce addition on the NOx storage and sulfur-resistance performance of the lean-burn NOx trap catalyst Pt/K/TiO2-ZrO2[J]. J Hazard Mater, 2009, 170(1):118-26. doi: 10.1016/j.jhazmat.2009.04.125 [7] YANG M, LI Y, WANG J, SHEN M Q. Effects of CO2 and steam on Ba/Ce-based NOx storage reduction catalysts during lean aging[J]. J Catal, 2010, 271(2):228-238. doi: 10.1016/j.jcat.2010.01.018 [8] DONGLIANG L WU, TSCHAMBER V, LIMOUSY L, KLEIN J, WESTERMANN A, AZAMBRE B, FECHETE I, GARIN F. Simultaneous effect of carbon and water on NOx adsorption on a stabilized Pt-Ba/Al2O3 catalyst[J]. CR Chim, 2014, 17(7/8):687-700. doi: 10.1021/jp044993p?src=recsys [9] 陈科, 李博, 吕刚, 朱彦涛, 宋崇林.铁改性水滑石基Pt/BaO/MgFeO催化剂焙烧温度对催化剂结构及NOx吸附-还原性能的影响[J].燃料化学学报, 2016, 44(12). doi: 10.3969/j.issn.0253-2409.2016.12.002 [10] KLEIN J, WU D, TSCHAMBER V, FECHETE I, GARIN F. Carbon-NSR catalyst interaction:Impact on catalyst structure and NOx storage efficiency[J]. Appl Catal B:Environ, 2013, 132/133(12):527-534. doi: 10.15541/jim20150100 [11] ZHANG Y X, YOU R, LIU D S, LIU C, LI X G, TIAN Y, JIANG Z, ZHANG S, HUANG Y Y, ZHA Y Q, MENG M. Carbonates-based noble metal-free lean NOx trap catalysts MOx-K2CO3/K2Ti8O17 (M=Ce, Fe, Cu, Co) with superior catalytic performance[J]. Appl Surf Sci, 2015, 357:2260-2276. doi: 10.1016/j.apsusc.2015.09.224 [12] GONZALEZ-VELASCO J R, GUTIERREZ -ORTIZ M A, MARC J L, BOTAS J A, GONZALEZ-MARCOS M P, BLANCHARD G. TWC Behaviour of platinum supported on high and Low surface area Cerium/Zirconium mixed oxides[J]. Top Catal, 2001, 16(1):101-106. [13] WANG X, YU Y, HE H. Effects of temperature and reductant type on the process of NOx storage reduction over Pt/Ba/CeO2 catalysts[J]. Appl Catal B:Environ, 2011, 104(1/2):151-160. doi: 10.1080/01614949308013915?scroll=top&needAccess=true [14] JI Y Y, FISK C, EASTERLING V, GRAHAM U, POOLE A, CROKER M, CHOI J S, PARTRIDGE W, WILSON K. NOx storage-reduction characteristics of Ba-based lean NOx trap catalysts subjected to simulated road aging[J]. Catal Today, 2010, 151(3/4):362-375. https://nepis.epa.gov/Exe/ZyPURL.cgi?Dockey=93000VJN.TXT [15] SHI C, JI Y, GRAHAM U M, ZHANG Z. NOx storage and reduction properties of model ceria-based lean NOx trap catalysts[J]. Appl Catal B:Environ, 2012, 119(21):183-196. https://ar.scribd.com/doc/154310011/Organic-Aldehyde-Isothiocyanate-Chemistry-1 [16] AYO B P, UNAI DE L T, GONZALEZ-MARCOS M. P, GONZALEZ-MARCOS J R. Influence of ceria loading on the NOx storage and reduction performance of model Pt-Ba/Al2O3, NSR catalyst[J]. Catal Today, 2014, 241:133-142. http://www.academia.edu/10628654/Evolved_Gas_Analysis_by_Mass_Spectrometry [17] LÜ L, WANG X, SHEN M, ZHANG Q, WANG J. The lean NOx traps behavior of (1-5%) BaO/CeO2 mixed with Pt/Al2O3 at low temperature (100-300℃):The effect of barium dispersion[J]. Chem Eng J, 2013, 222(222):401-410. https://es.scribd.com/doc/80638513/Extractive-Metallurgy-of-Rare-Earths [18] VOVK E I, TURKSOY A, BUKHTIYAROV V I, OZENSOY E. Interactive surface chemistry of CO2 and NO2 on metal oxide surfaces:Competition for catalytic adsorption sites and reactivity[J]. J Phys Chem C, 2013, 117(15):7713-7720. doi: 10.1021/jp400955g [19] 胡准, 孙科强, 徐柏庆. Pt-BaO催化剂的NOx储存-还原化学及结构-性能关系[J].催化学报, 2011, 32(1):17-26.HU ZHUN, SUN KEQIANG, XU BOQING, NOx storage-reduction catalysis and structure-performance relationship of Pt-BaO catalyst[J]. Chinese J Catal, 2011, 32(1):17-26. [20] VENKATASWAMY P, JAMPAIAH D, LIN F, ALXNEIT I, REDDY BM. Structural properties of alumina supported Ce-Mn solid solutions and their markedly enhanced catalytic activity for CO oxidation[J]. Appl Surf Sci, 2015, 349:299-309. doi: 10.1016/j.apsusc.2015.04.220 [21] ABBASI Z, HAGHIGHI M, FATEHIFAR E, SAEDY S. Synthesis and physicochemical characterizations of nanostructured Pt/Al2O3-CeO2, catalysts for total oxidation of VOCs[J]. J Hazard Mater, 2011, 186(2/3):1445-1454. doi: 10.1080/01614949308013910?scroll=top&needAccess=true [22] LIU G, GAO P X. A review of NOx storage/reduction catalysts:mechanism, materials and degradation studies[J]. Catal Sci Technol, 2011, 1(4):552-5. doi: 10.1039/c1cy00007a -

下载:

下载: