Study on ash fusion and viscosity temperature characteristics modification of Shanxi typical high aluminum coal

-

摘要: 以山西典型高铝煤为研究对象,研究了工业助熔剂石灰石、黏土以及两者的复合助熔剂对其灰熔融特性及黏温特性的影响。结果表明,随着助熔剂含量的增加,煤灰熔融流动温度下降;石灰石的助熔效果优于黏土,复合助熔剂效果优于单一助熔剂。添加石灰石使灰渣临界黏度温度tcv显著降低,添加黏土使其渣型向玻璃渣转变,复合助熔剂较单一助熔剂存在显著协同作用,即能同时实现tcv的降低和渣型的有利转变。对山西典型高铝煤两渡煤,在复合助熔剂添加量为4%(2%石灰石+2%黏土)时,不仅其渣型向玻璃渣转变,且tcv较单独添加石灰石(2%)降低133 ℃,较单独添加黏土(6%)降低222 ℃。矿物质分析结果证实了助熔剂的助熔原理。添加复合助熔剂改性的山西高铝煤可达到工业气流床气化对煤种的要求。Abstract: In this work, the influences of two industrial fluxes (i.e. limestone and clay) and their composite flux on ash fusion and viscosity temperature characteristics of Shanxi typical high-alumina coals were explored, respectively. The results indicated that flow temperature of coal ash decreased with increasing additive amount of flux. Moreover, limestone exhibited a better flux effect than clay, among which the flux effect of composite flux was more obvious than that of the single fluxes. It was also found that limestone could significantly reduce the tcv of coal ash slag and clay could promote the slag type transformation towards glassy slag. Compared with single fluxes, composite flux exhibited synergistic effect on both the significant reduction of tcv and the promotion of slag type transformation. For Shanxi typical high-alumina Liangdu coal, when total amount of composite flux was 4% (2% limestone+2% clay), not only the slag transformed into glassy slag, but also tcv of the slag decreased 133 and 222 ℃ compared with single flux limestone(2%) and clay (6%), respectively. Minerals analysis results confirmed the fluxing principle of different fluxes. After the addition of composite flux, Shanxi high-alumina coals could meet the requirements of industrial entrained-flow gasifier.

-

表 1 LD与GY煤的工业分析与元素分析

Table 1 Proximate and ultimate analysis of LD and GY coal

Sample Proximate analysis wad/% Ultimate analysis wad/% Calorific value /(MJ·kg-1, ad) M A V FC C H O N S LD 0.54 10.40 13.20 75.38 81.09 3.55 0.82 1.11 2.49 31.97 GY 0.46 8.42 16.51 74.19 83.90 3.54 0.08 1.27 2.33 32.87 表 2 LD与GY煤灰化学组成

Table 2 Ash chemical compositions of LD and GY coal

Sample Chemical compositions w/% SiO2 Al2O3 CaO Fe2O3 MgO K2O Na2O TiO2 P2O5 SO3 others S/A A/B LD 50.40 35.70 2.31 7.33 0.42 0.39 0.18 1.23 0.08 1.69 0.27 1.41 8.56 GY 49.49 39.33 2.80 3.96 0.26 0.32 0.31 1.52 0.38 1.20 0.43 1.26 12.65 表 3 助熔剂的化学组成

Table 3 Chemical compositions of flux

Sample Chemical compositions w/% SiO2 Al2O3 CaO Fe2O3 MgO K2O Na2O TiO2 P2O5 SO3 others S/A Clay 60.89 15.89 8.83 6.13 3.44 2.94 0.81 0.80 0.15 0.04 0.08 3.83 Limestone 2.90 0.85 91.03 0.93 3.13 0.45 0.12 - 0.42 - 0.17 3.41 表 4 煤灰熔融特征温度

Table 4 Ash melting characteristic temperatures

Sample Characteristic temperatures t/℃ DT HT ST FT LD 1 485 >1 550 >1 550 >1 550 GY >1 550 >1 550 >1 550 >1550 表 5 添加助熔剂后灰渣的特征温度

Table 5 Characteristic temperatures of ash slags with flux

Sample Characteristic temperatures t/℃ FT t25 tcv 2%limestone 1 379 1 380 1 381 6%clay 1 383 1 466 1 470 2%limestone+2%clay 1 364 1 245 1 248 -

[1] SAFRONOV D, FÖRSTER T, SCHWITALLA D, NIKRITYUK P, GUHL S, RICHTER A, MEYER B. Numerical study on entrained-flow gasification performance using combined slag model and experimental characterization of slag properties[J]. Fuel Process Technol, 2017, 161:62-75. doi: 10.1016/j.fuproc.2017.03.007 [2] 于广锁, 牛苗任, 王亦飞, 梁钦锋, 于遵宏.气流床煤气化的技术现状和发展趋势[J].现代化工, 2004, 24(5):23-26. http://d.wanfangdata.com.cn/Periodical/xdhg200405007YU Guang-suo, NIU Miao-ren, WANG Yi-fei, LIANG Qin-feng, YU Zun-hong. Application status and development tendency of coal entrained-bed gasification[J]. Mod Chem Ind, 2004, 24(5):23-26. http://d.wanfangdata.com.cn/Periodical/xdhg200405007 [3] 白进, 孔令学, 李怀柱, 郭振兴, 白宗庆, 尉迟唯, 李文.山西典型无烟煤灰流动性的调控[J].燃料化学学报, 2013, 41(7):805-813. http://manu60.magtech.com.cn/rlhxxb/CN/abstract/abstract18214.shtmlBAI Jin, KONG Ling-xue, LI Huai-zhu, GUO Zhen-xing, BAI Zong-qing, WEI Chi-wei, LI Wen. Adjustment in high temperature flow property of ash from Shanxi typical anthracite[J]. J Fuel Chem Technol, 2013, 41(7):805-813. http://manu60.magtech.com.cn/rlhxxb/CN/abstract/abstract18214.shtml [4] NINOMIYA Y, SATO A. Ash melting behavior under coal gasification conditions[J]. Energy Convers Manage, 1997, 38(10):1405-1412. http://d.wanfangdata.com.cn/NSTLQK/NSTL_QKJJ0211703111/ [5] KONDRATIEV A, JAK E. Predicting coal ash slag flow characteristics (viscosity model for the Al2O3-CaO-'FeO'-SiO2 system)[J]. Fuel, 2001, 80(14):1989-2000. doi: 10.1016/S0016-2361(01)00083-7 [6] JING N J, WANG Q H, YANG Y K, CHENG L M, LUO Z Y, CEN K F.Influence of ash composition on the sintering behavior during pressurized combustion and gasification process[J]. J Zhejiang Univ-Sci A, 2012, 13(3):230-238. doi: 10.1631/jzus.A1100206 [7] HURST H J, NOVAK F, PATTERSON J H. Phase diagram approach to the fluxing effect of additions of CaCO3 on Australian coal ashes[J]. Energy Fuels, 1996, 10(6):1215-1219. doi: 10.1021/ef950264k [8] 姚星一.煤灰熔点与化学成分的关系[J].燃料化学学报, 1965, 6(2):151-161. http://d.wanfangdata.com.cn/Thesis/Y2145614YAO Xing-yi. Relationship of coal ash fusibility to chemical composition[J]. J Fuel Chem Technol, 1965, 6(2):151-161. http://d.wanfangdata.com.cn/Thesis/Y2145614 [9] 代廷魁. 改善高铝煤灰熔融特性及助熔机理研究[D]. 淮南: 安徽理工大学, 2016.DAI Ting-kui. Study on improving ash fusibility and fluxing mechanism of high alumina coal[D]. Huainan:Anhui Univ Sci Technol, 2016. [10] XIAO H X, LI F H, LIU Q R, JI S H, FAN S H, FAN H L, XU M L, GUO Q Q, MA M J, MA X W. Modification of ash fusion behavior of coal with high ash fusion temperature by red mud addition[J]. Fuel, 2017, 192:121-127. doi: 10.1016/j.fuel.2016.12.012 [11] 李文, 白进.煤的灰化学[M].北京:科学出版社, 2013.LI Wen, BAI Jin. Chemistry of Ash from Coal[M]. Beijing:Science Press, 2013. [12] 黄千钧.以煤灰碱酸比与硅铝比的乘积作为动力用煤结渣指数的探讨[J].动力工程, 2004, 24(3):340-344. http://d.wanfangdata.com.cn/Periodical/dlgc200403008HUANG Qian-jun. The product of base/acid and silica/alumina of ash in steal coal-An index to ash slagging tendency[J]. Power Eng, 2004, 24(3):340-344. http://d.wanfangdata.com.cn/Periodical/dlgc200403008 [13] SONG W J, TANG L H, ZHU X D, WU Y Q, ZHU Z B, KOYAMA S.Effect of coal ash composition on ash fusion temperatures[J]. Energy Fuels, 2009, 24(1):182-189. http://d.wanfangdata.com.cn/OAPaper/oai_doaj-articles_8a5117724329f9a2cb94ab3bd6efc304 [14] 许洁, 刘霞, 张庆, 赵锋, 郭庆华, 于广锁, 王辅臣.高钙山鑫煤灰熔融及黏温特性分析[J].中国电机工程学报, 2013, 33(20):46-51. http://industry.wanfangdata.com.cn/yj/Detail/Periodical?id=Periodical_zgdjgcxb201320023XU Jie, LIU Xia, ZHANG Qing, ZHAO Feng, GUO Qing-hua, WANG Fu-chen. Research on ash fusibility and viscosity-temperature characteristic of high-calcium Shanxin coal ash[J]. Proc CSEE, 2013, 33(20):46-51. http://industry.wanfangdata.com.cn/yj/Detail/Periodical?id=Periodical_zgdjgcxb201320023 [15] LIU X, YU G, XU J, LIANG Q, LIU H. Viscosity fluctuation behaviors of coal ash slags with high content of calcium and low content of silicon[J]. Fuel Process Technol, 2017, 158:115-122. doi: 10.1016/j.fuproc.2016.12.013 [16] 刘霞, 梁钦锋, 刘海峰, 于广锁, 龚欣.煤灰黏温特性的测试条件[J].华东理工大学学报(自然科学版), 2015, 1:004. http://d.wanfangdata.com.cn/Periodical/hdlgdxxb201501004LIU Xia, LIANG Qin-feng, LIU Hai-feng, YU Guang-suo, GONG Xin. Measurement condition of coal ash viscosity-temperature characteristics[J]. J East China Univ Sci Technol:Nat Sci Ed, 2015, 1:004. http://d.wanfangdata.com.cn/Periodical/hdlgdxxb201501004 [17] 丁家海. SE-东方炉粉煤加压气化技术煤种适应性工业试验[J].大氮肥, 2016, 39(6):361-365. http://d.wanfangdata.com.cn/Periodical/ddf201606001DING Jia-hai. Coal adaptability experience in SE pulverized coal gasification[J]. Large Scale Nitrogenous Fertilizer Ind, 2016, 39(6):361-365. http://d.wanfangdata.com.cn/Periodical/ddf201606001 [18] TSURUDA A, ARMA L H, TAKEBE H. Viscosity measurement and prediction of gasified and synthesized coal slag melts[J]. Fuel, 2017, 200:521-528. doi: 10.1016/j.fuel.2017.03.094 [19] ILYUSHECHKIN A Y, HLA S S. Viscosity of high-iron slags from Australian coals[J]. Energy Fuels, 2013, 27(7):3736-3742. doi: 10.1021/ef400593k [20] WU G, YAZHENSKIKH E, HACK K, WOSCH E, MVLLER M. Viscosity model for oxide melts relevant to fuel slags. Part 1:Pure oxides and binary systems in the system SiO2-Al2O3-CaO-MgO-Na2O-K2O[J]. Fuel Process Technol, 2015, 137:93-103. doi: 10.1016/j.fuproc.2015.03.025 [21] 代百乾, 乌晓江, 陈玉爽, 张忠孝.煤灰熔融行为及其矿物质作用机制的量化研究[J].动力工程学报, 2014, 34(1):70-76. http://d.wanfangdata.com.cn/Periodical/dlgc201401012DAI Bai-qian, WU Xiao-jiang, CHEN Yu-shuang, ZHANG Zhong-xiao. Experimental study and quantum chemistry calculation on coal ash fusion behavior and related mineral evolution mechanism[J]. J Chin Soc Power Eng, 2014, 34(1):70-76. http://d.wanfangdata.com.cn/Periodical/dlgc201401012 -

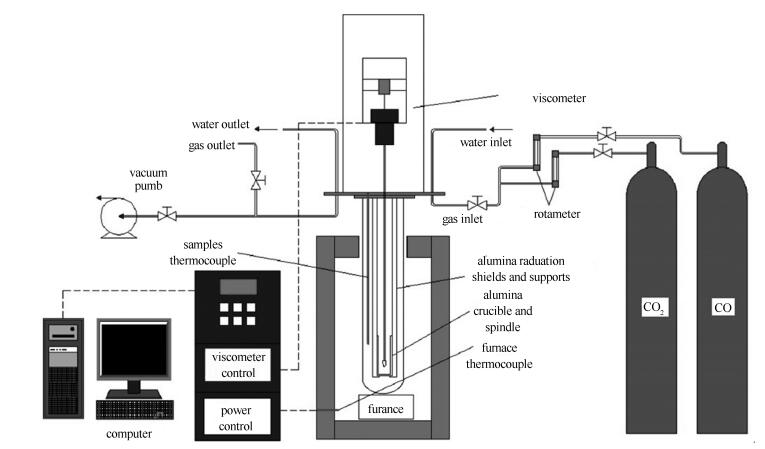

下载:

下载: