Effect of NaOH content for the properties of HZSM-5 zeolites and its catalytic performance on gas phase carbonylation of dimethoxymethane

-

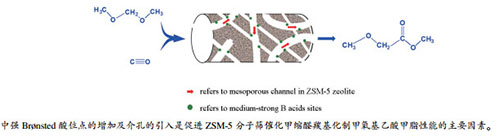

摘要: 通过调变合成过程中NaOH的含量,制备了一系列HZSM-5分子筛,并对其催化甲缩醛(DMM)气相羰基化合成甲氧基乙酸甲脂(MMAc)反应性能进行了详细考察。结果表明,本合成体系中,NaOH含量为0.8%(质量分数)时,ZSM-5分子筛表现出最佳的催化活性。BET、27Al NMR、NH3-TPD、Py-FTIR等多种表征结果证实NaOH含量的改变可有效调变分子筛孔道中介孔孔容及中强Brønsted酸(B酸)位点的分布,两者是影响分子筛催化活性的主要因素。中强B酸位点增加,原料DMM反应加剧,转化率提高;介孔孔容增大,产物扩散途径缩短,孔道限域效应减弱,副反应被抑制,MMAc选择性增加。进一步采用密度泛函理论对DMM与HZSM-5分子筛作用过程进行了初步探索,发现反应过程中将首先形成甲氧基甲基(ZOCH2OCH3)中间物种,在此基础上,提出了DMM羰基化生成MMAc的可能机制。Abstract: A series of ZSM-5 zeolites were prepared by changing the NaOH content, and their catalytic performance on the vapor-phase carbonylation of dimethoxymethane (DMM) to synthesize methyl methoxyacetate (MMAc) was investigated detailedly. The results indicate that the ZSM-5 zeolite prepared under the 0.81% NaOH content shows the best catalytic performance. Various characterization results, including BET, 27Al NMR, NH3-TPD and Py-FTIR, illustrate that medium-strong Brønsted acid sites and mesoporous volume are the chief factors in promoting carbonylation of DMM over ZSM-5 zeolite, which can be effectively regulated by changing NaOH content. The increase of medium-strong Brønsted acid sites can improve DMM conversion by providing more active acid sites; the introduction of mesoporous can increase MMAc selectivity by shortening the product diffusion path, weakening steric constraint of pore walls and suppressing parts of side reactions. Density functional theory was further carried out to study the interaction between DMM and ZSM-5 zeolite. The calculated results find that intermediate species ZOCH2OCH3 is formed firstly during DMM decomposition. Based on this, a possible formation mechanism of MMAc was then proposed.

-

Key words:

- dimethoxymethane /

- carbonylation /

- methyl methoxyacetate /

- NaOH /

- HZSM-5

-

表 1 不同NaOH含量合成HZSM-5分子筛的组成及织构性质

Table 1 Composition and textural properties of HZSM-5 catalysts prepared under different NaOH contents

Sample Si/Al molar ratioa ABETb/(m2·g-1) vmicroc/(cm3·g-1) vmeso/(cm3·g-1) Z-0.14 27 328 0.15 0.10 Z-0.27 25 351 0.13 0.16 Z-0.54 23 357 0.13 0.17 Z-0.81 20 362 0.12 0.21 Z-1.1 16 359 0.12 0.17 Z-1.3 15 344 0.12 0.12 note: a: determined by XRF; b: determined by the BET method; c: determined by the t-plot method 表 2 不同NaOH含量合成HZSM-5分子筛的酸性特征

Table 2 Acidic properties of HZSM-5 zeolites prepared under different NaOH contents

Sample Acidity by strengthd /(mmol·g-1) Acidity by typee /(mmol·g-1) weak medium-strong Brønsted Lewis Z-0.14 0.28 0.26 0.43 0.43 Z-0.27 0.33 0.42 0.52 0.29 Z-0.54 0.40 0.48 0.53 0.24 Z-0.81 0.44 0.48 0.59 0.27 Z-1.1 0.68 0.64 0.58 0.20 Z-1.3 0.82 0.66 0.56 0.24 表 3 不同NaOH含量合成ZSM-5分子筛的催化性能

Table 3 Catalytic performance of H-ZSM-5 zeolites prepared under different NaOH contents

Sample DMM conversion x/% Products selectivity s/% MMAc MF MeOH DME Z-0.14 2.5 35.3 35.9 3.1 25.7 Z-0.27 4.6 40.3 31.9 2.1 25.6 Z-0.54 9.9 61.3 18.6 1.4 18.6 Z-0.81 11.9 69.3 17.2 1.2 12.2 Z-1.1 9.3 56.8 24.6 1.5 17.2 Z-1.3 7.1 59.6 21.0 1.9 17.5 reaction conditions: 110 ℃, 0.6 MPa, DMM and CO rate of flow is 2.4×10-2 mol/h and 0.27 mol/h, 0.5 g catalysts -

[1] CELIK F E, KIM T J, MLINAR A N, BELL A T. An investigation into the mechanism and kinetics of dimethoxymethane carbonylation over FAU and MFI zeolites[J]. J Catal, 2010, 274(2):150-162. doi: 10.1016/j.jcat.2010.06.015 [2] 石磊, 姚杰, 朱文良, 刘中民.磺酸树脂催化甲缩醛一步羰化制高附加值甲氧基乙酸甲酯[J].化工学报, 2017, 68(10):3739-3746. http://d.old.wanfangdata.com.cn/Periodical/hgxb201710010SHI Lei, YAO Jie, ZHU Wen-liang, LIU Zhong-min. Efficient sulfonic acid resin catalysts for carbonylation of dimethoxymethane to value-added methyl methoxyacetate[J]. CIESC J, 2017, 68(10):3739-3746. http://d.old.wanfangdata.com.cn/Periodical/hgxb201710010 [3] 沈鑫权, 刘洪忠, 高志贤, 吾满江·艾力.甲缩醛与甲酸偶联合成甲氧基乙酸甲酯[J].天然气化工, 2012, 37(6):37-39. doi: 10.3969/j.issn.1001-9219.2012.06.009SHEN Xin-quan, LIU Hong-zhong, GAO Zhi-xian, WU Man-jiang Eli. Synthesis of methy methoxy acetate from methylal and formic acid[J]. Nat Gas Chem Ind, 2012, 37(6):37-39. doi: 10.3969/j.issn.1001-9219.2012.06.009 [4] 杜碧林, 储伟, 于作龙.甲酸甲酯与三聚甲醛偶联合成乙醇酸甲酯*Ⅱ.硫酸/金属羰基化合物对收率的影响[J].天然气化工, 1998, 23(3):34-36.DU Bi-lin, CHU Wei, YU Zuo-long. Synthesis of methyl glycolate by coupling of methyl formate with trioxane*Ⅱ. Effect of sulfuric acid and metal carbonyl compound on yield[J]. Nat Gas Chem Ind, 1998, 23(3):34-36. [5] 贺德华, 黄卫国, 刘金尧.同时合成羟基乙酸甲脂和甲氧基乙酸甲脂的方法: 中国, 1180067A[P]. 2001-01-10.HE De-hua, HUANG Wei-guo, LIU Jing-yao. Method for simultaneously synthesizing glycolic acid methyl ester and methoxyacetic acid methyl ester: CN, 1180067A[P]. 2001-01-10. [6] HE D H, HUANG W G, LIU J Y. The activity of H4SiW12O40 for the coupling of formaldehyde and methyl formate to methyl glycolate and methyl methoxy acetate[J]. J Mol Catal A:Chem, 1999, 145:335-338. doi: 10.1016/S1381-1169(99)00166-1 [7] LIU S P, ZHU W L, SHI L, LIU H C, LIU Y, NI Y M, LI L N, ZHOU H, XU S T, HE Y L, LIU Z M. A highly efficient Nafion-H catalyst for vapour phase carbonylation of dimethoxymethane[J]. RSC, 2014, 4(77):40999-41002. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=2891f5ef3bf10dfac561e33141ff6722 [8] LIU S P, ZHU W L, SHI L, LIU H C, LIU Y, NI Y M, LI L N, ZHOU H, XU S T, HE Y L, LIU Z M. Activity enhancement of Nafion resin:Vapor-phase carbonylation of dimethoxymethane over Nafion-silica composite[J]. Appl Catal A:Gen, 2015, 497:153-159. doi: 10.1016/j.apcata.2015.03.010 [9] BADMAEV S D, POTEMIN D I, PECHENKIN A A, VOLKOVA G G, SOBYANIN V A, PAMON A V N. Gas-phase carbonylation of dimethoxymethane to methyl methoxyacetate over the Cs2.5H0.5PW12O40 catalyst[J]. Dokl Phys Chem, 2016, 468(2):85-88. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=f9ac67e1cfd5c04f1010f03f17ed7078 [10] CELIK F E, KIM T J, BELL A T. Vapor-phase carbonylation of dimethoxymethane over H-Faujasite[J]. Angew Chem Int Ed, 2009, 48(26):4813-4815. doi: 10.1002/anie.200900464 [11] CELIK F E, KIM T J, BELL A T. Effect of zeolite framework type and Si/Al ratio on dimethoxymethane carbonylation[J]. J Catal, 2010, 270(1):185-195. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=2910f034e5d23050ca81aa68a7e03bfd [12] CHEUG P, BHAN A, SUNLEY G J, IGLESIA E. Selective carbonylation of dimethyl ether to methyl acetate catalyzed by acidic zeolites[J]. Angew Chem Int Ed, 2006, 45:1617-1620. doi: 10.1002/anie.200503898 [13] BARRI S A I, CHADWICK D. Carbonylation of formaldehyde with zeolite catalysts[J]. Catal Lett, 2011, 141:749-753. doi: 10.1007/s10562-011-0616-0 [14] REDDY J K, MOTOKURA K, KOYAMA T, MIYAJI A, BABA T. Effect of morphology and particle size of ZSM-5 on catalytic performance for ethylene conversion and heptane cracking[J]. J Catal, 2012, 289:53-61. doi: 10.1016/j.jcat.2012.01.014 [15] KIM J, CHOI M, RYONG R. Effect of mesoporosity against the deactivation of MFI zeolite catalyst during the methanol-to-hydrocarbon conversion process[J]. J Catal, 2010, 269(1):219-228. doi: 10.1016/j.jcat.2009.11.009 [16] YOKOI T, MOCHIZUKI H, NAMBA S, KONDO J K, TASUMI T. Control of the Al distribution in the framework of ZSM-5 zeolite and its evaluation by solid-state NMR technique and catalytic properties[J]. J Phys Chem C, 2015, 119:15303-15315. doi: 10.1021/acs.jpcc.5b03289 [17] LIANG T Y, CHEN J L, QIN Z F, LI J F, WANG P F, WANG S, WANG G F, DONG M, FAN W B, WANG J G. Conversion of methanol to olefins over H-ZSM-5 zeolite:Reaction pathway is related to the framework aluminum siting[J]. ACS Catal, 2016, 6(11):7311-7325. doi: 10.1021/acscatal.6b01771 [18] FRISCH M L, TRUCKS G W, SCHLEGEL H B, et al. Gaussian 09[CP]. Revision A.02, Gaussian Inc: allingford, CT, 2009. [19] RAVISHANKAR R, KIRSCHHOCKC, SCHOEMANB J, VANOPPENP, GROBETP J, STORCK S, MAIER W F, MARTENS J A, SCHRYVER F C D, JACOBS P A. Physicochemical characterization of silicalite-1 nanophase material[J]. J Phys Chem B, 1998, 102:2633-2639. doi: 10.1021/jp973147u [20] 潘文雅, 黄亮, 秦枫, 庄岩, 李雪梅, 马建学, 沈伟, 徐华龙.甘油脱水合成丙烯醛ZSM-5催化剂的孔结构和酸性调控[J].物理化学学报, 2015, 31(5):965-972. http://d.old.wanfangdata.com.cn/Periodical/wlhxxb201505021PAN Wen-ya, HUANG Liang, QIN Feng, ZHUANG Yan, LI Xue-mei, MA Jian-xue, SHEN Wei, XU Hua-long. Regulation of pore structure and acidity of a ZSM-5 catalyst for dehydration of glycerol to Acrolein[J]. Acta Phys-Chim Sin, 2015, 31(5):965-972. http://d.old.wanfangdata.com.cn/Periodical/wlhxxb201505021 [21] GROEN J C, ZHUW D, BROUWER S, HUYNINK S J, KAPTEIJIN F, MOULIJN J A, PEREZ-RAMIREZ J. Direct demonstration of enhanced diffusion in mesoporous ZSM-5 zeolite obtained via controlled desilication[J]. J Am Chem Soc, 2007, 129(2):355-360. doi: 10.1021/ja065737o [22] KLINOWSKI J. Solid-state NMR studies of molecular sieve catalysts[J]. Chem Rev, 1991, 91:1459-1479. doi: 10.1021/cr00007a010 [23] XU T, ZHANG Q H, SONG H, WANG Y. Fluoride-treated H-ZSM-5 as a highly selective and stable catalyst for the production of propylene from methyl halides[J]. J Catal, 2012, 295:232-241. doi: 10.1016/j.jcat.2012.08.014 [24] PONCELET G, DUBRU M L. An infrared study of surface acidity of germanic near-faujasite zeolite by pyridine adsorption[J]. J Catal, 1978, 52:321-331. doi: 10.1016/0021-9517(78)90146-X [25] ANDRES G T, AGUSTIN M. Direct synthesis of DME from syngas on hybrid Cu-Zn-Al/ZSM-5 catalysts:New insights into the role of zeolite acidity[J]. Appl Catal A:Gen, 2012, 411-412:170-179. doi: 10.1016/j.apcata.2011.10.036 [26] DING X, GENG S, LI C Y, YANG C H, WANG G H. Effect of acid density of HZSM-5 on the oligomerization of ethylene in FCC dry gas[J]. J Nat Gas Chem, 2009, 18:156-160. doi: 10.1016/S1003-9953(08)60100-0 [27] CHESTER A W, DEROUANE E G. Zeolites Characterization and Catalysis:A Tutorial[M]. Springer-Verlag New York Inc:New York, 2009:358-365. [28] LIETZ G, SCHNABEL K H, PEUKER C. GROSS T, STOREK W, VOLTER J. Modifications of H-ZSM-5 Catalysts by NaOH Treatment[J]. J Catal, 1994, 148:562-568. doi: 10.1006/jcat.1994.1242 -

下载:

下载: