Study of the relationship between the acidity of amorphous silica-alumina supports and diesel selectivity in Fischer-Tropsch wax hydrocracking

-

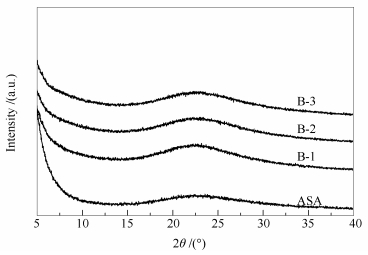

摘要: 利用逐梯度铵交换处理的方法合成了三个织构性质相似、酸性不同的无定形硅铝载体,并通过XRD、N2吸附-脱附、NH3-TPD、Py-FTIR和NMR等手段对载体的物化性质进行了研究。经等体积浸渍负载贵金属Pt,制成加氢裂化催化剂,以费托蜡加氢裂化生产柴油为探针反应,研究了无定形硅铝载体的酸性与柴油选择性之间的构效关系。结果表明,柴油选择性主要与载体的B酸性质有关,受L酸的影响很小;催化剂载体的强B酸含量与柴油选择性成相反关系,载体强B酸的含量越低,柴油选择性越高;催化剂Pt/B-1具有相对最高的柴油选择性,在反应压力7.0 MPa,H2/wax(volume ratio)=1 000:1,LHSV=1.0 h-1,温度为370℃的条件下,C22+转化率为62.52%时,对柴油的选择性达87.12%,具有比文献报道及商业化无定形硅铝载体ASA制备的催化剂Pt/ASA相对更高的活性和柴油选择性。Abstract: Three amorphous silica-alumina supports with similar textural properties and different amounts of acidity were successfully synthesized through ammonium exchange processing and their structures, acidity properties and the coordination of Si and Al in the as-synthesized supports were characterized using XRD, N2 adsorption-desorption, NH3-TPD, Py-FTIR and NMR. Amorphous silica-alumina was impregnated into a solution of H12N4PtCl2·XH2O to obtain hydrocracking catalysts. The relationship between acidic properties of supports and catalytic performance was studied by hydrocracking of Fischer-Tropsch (F-T) wax to diesel in a continuous-flow type fixed-bed reactor as a model reaction. The results illustrated that the diesel selectivity was mainly related to Brønsted acid properties of the supports while Lewis acid showed little correlation. The amount of strong Brønsted acid was reversely related to the selectivity of diesel:the smaller the amount, the higher the selectivity. The as-synthesized Pt/B-1 catalyst showed high selectivity of 87.12% to diesel at the conversion of F-T wax of about 62.52%, under the reaction conditions of 370℃, 7.0 MPa, LHSV of 1.0 h-1 and a hydrogen-to-wax ratio of 1 000:1. Pt/B-1 had better catalytic performance than Pt/ASA prepared by commercial amorphous silica-alumina (ASA).

-

Key words:

- hydrocracking /

- amorphous silica-alumina /

- Fischer-Tropsch wax /

- diesel /

- selectivity

-

表 1 无定形硅铝载体样品的物化性质

Table 1 Physical and chemical properties of different amorphous silica-alumina samples

Sample Content w/%a BET surface area A/(m2·g-1) b Pore volume v/(cm3·g-1) Average pore radius d/nm Na2O Si/Al micropore external total ASA 0.088 1.61 9 208 217 0.70 10.3 B-1 0.13 31.0 15 261 276 0.94 11.9 B-2 0.012 31.5 14 253 267 0.89 11.5 B-3 0.004 4 31.7 14 250 264 0.88 11.6 a: obtained from final solid product by XRF;

b: obtained by N2-adsorption at-196 ℃ using micromeritic ASAP2020表 2 无定形硅铝载体的B酸及L酸含量

Table 2 Concentration of Brønsted and Lewis acid sites of different samples

Sample Acidity /(μmolPy·g-1) Brønsted Lewis 200 ℃ 350 ℃ 200-350 ℃ 200 ℃ 350 ℃ 200-350 ℃ ASA 12.28 1.20 11.08 95.97 38.33 57.64 B-1 26.84 1.26 25.58 32.90 22.51 10.39 B-2 28.60 6.23 22.37 42.99 37.18 5.81 B-3 20.85 4.02 16.83 45.59 35.52 10.07 -

[1] 李大东.加氢处理工艺与工程[M].北京:中国石化出版社, 2004: 170-200.LI Da-dong. Hydrotreating Technology and Engineedng[M]. Beijing: China Petrochemical Press, 2004: 170-200. [2] MAXWEL L. Zeolte catalysis in hydroprocessing technology[J]. Catal Today, 1987, 1(4): 389-417. https://www.researchgate.net/publication/244320344_Zeolite_Catalysis_in_Hydroprocessing_Technology [3] WARD J W. Hydrocracking processes and catalysts[J]. Fuel Process Technol, 1993, 35(1/2): 55-85. http://www.sciencedirect.com/science/article/pii/037838209390085I [4] LECKEL D. Hydrocracking of iron-catalyzed fischer-tropsch waxes[J]. Energy Fuels, 2005, 19(5): 1795-1803. doi: 10.1021/ef050085v [5] 闫朋辉, 陶智超, 郝坤, 王煜丹, 杨勇, 李永旺.金属载体结合方式对镍钨催化剂费托合成蜡加氢裂化性能的影响[J].燃料化学学报, 2013, 41(6): 691-697. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract18196.shtmlYAN Peng-hui, TAO Zhi-chao, HAO Kun, WANG Yu-dan, YANG Yong, LI Yong-wang. Effect of impregnation methods on nickel-tungsten catalysts and its performance on hydrocracking of Fischer-Tropsch wax[J]. J Fuel Chem Technol, 2013, 41(6): 691-697. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract18196.shtml [6] GAMBA S, PELLEGRINI L A, CALEMMA V, GAMBARO C. Liquid fuels from Fischer-Tropsch wax hydrocracking: Isomer distribution[J]. Catal Today, 2010, 156: 58-64. doi: 10.1016/j.cattod.2010.01.009 [7] FLINN R A, LARSON O A, BEUTHER H. The mechanism of catalytic hydrocracking[J]. Ind Eng Chem, 1960, 52(2): 153-156. doi: 10.1021/ie50602a034 [8] COONRADT H L, GARWOOD W E. Mechanism of hydrocracking[J]. Ind Eng Chem, 1964, 3(1): 38-45. doi: 10.1021/i260009a010 [9] WANG Y D, TAO Z C, WU B S, CHEN H M, XU J, YANG Y, LI Y W. Shape-controlled synthesis of Pt particles and their catalytic performances in the n-hexadecane hydroconversion[J]. Catal Today, 2016, 259: 331-339. doi: 10.1016/j.cattod.2015.06.017 [10] WANG Y D, TAO Z C, WU B S, XU J, HUO C F, LI K, CHEN H M, YANG Y, LI Y W. Effect of metal precursors on the performance of Pt/ZSM-22 catalysts for n-hexadecane hydroisomerization[J]. J Catal, 2015, 322: 1-13. doi: 10.1016/j.jcat.2014.11.004 [11] CORMA A, GRANDE M S, GONZALEZ-ALFARO V, ORCHILLES A V. Cracking Activity and hydrothermal stability of MCM-41 and its comparison with amorphous silica-alumina and a USY Zeolite[J]. J Catal, 1996, 159: 375-382. doi: 10.1006/jcat.1996.0100 [12] JIANG J, YANG C, LU Z J, DING J, LI T, LU Y, CAO F H. Characterization and application of a Pt/ZSM-5/SSMF catalyst for hydrocracking of paraffin wax[J]. Catal Commun, 2015, 60: 1-4. doi: 10.1016/j.catcom.2014.10.025 [13] CUI Q Y, ZHOU Y S, WEI Q, TAO X J, YU G G, WANG Y, YANG J P. Role of the zeolite crystallite size on hydrocracking of vacuum gas oil over NiW/Y-ASA catalysts[J]. Energy Fuels, 2012, 26(8): 4664-4670. doi: 10.1021/ef300544c [14] CORMA A, MARTINEZ A, MARTINEZSORIA V, MONTON J B. Hydrocracking of vacuum gasoil on the novel mesoporous MCM-41 aluminosilicate catalyst[J]. J Catal, 1995, 153(11): 25-31. https://www.researchgate.net/publication/222073233_Hydrocracking_of_Vacuum_Gasoil_on_the_Novel_Mesoporous_MCM-41_Aluminosilicate_Catalyst [15] DONK S V, JANSSEN A H, BITTER J H, JONG K P D. Generation, characterization, and impact of mesopores in zeolite catalysts[J]. Cat Rev Sci Eng, 2003, 45(2): 297-319. doi: 10.1081/CR-120023908 [16] CORMA A, MARTINEZ A, PERGHER S, PERATELLO S, PEREGO C, BELLUSI G. Hydrocracking-hydroisomerization of n-decane on amorphous silica-alumina with uniform pore diameter[J]. Appl Catal A: Gen, 1997, 152(1): 107-125. doi: 10.1016/S0926-860X(96)00338-9 [17] ALI M.A, TAESUMI T, MASUDA T. Development of heavy oil hydrocracking catalysts using amorphous silica-alumina and zeolites as catalyst supports[J]. Appl Catal A: Gen, 2002, 233(1/2): 77-90. [18] 孟庆磊, 刘百军, 盖有东, 何琳琳. Y/ASA复合材料的制备及加氢裂化性能[J].燃料化学学报, 2012, 40(3): 354-358. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract17909.shtmlMENG Qing-lei, LIU Bai-jun, GAI You-dong, HE Lin-lin. Synthesis and hydrocracking performance of Y/ASA comopsite[J]. J Fuel Chem Technol, 2012, 40(3): 354-358. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract17909.shtml [19] LECKEL D. Selectivity effect of oxygenates in hydrocracking of Fischer-Tropsch waxes[J]. Energy Fuels, 2007, 21(2): 662-667. doi: 10.1021/ef060603h [20] LECKEL D, LIWANGA-EHUMBU M. Diesel-selective hydrocracking of an iron-based Fischer-Tropsch wax fraction (C15-C45) using a MoO3-modified noble metal catalyst[J]. Energy Fuels, 2006, 20(6): 2330-2336. doi: 10.1021/ef060319q [21] LI B, CALEMMA V, GAMBARO C, BARON G V, DENAYER J F M. Competitive adsorption of C20-C36 linear paraffins on the amorphous microporous silica-alumina ERS-8 in vapor phase and liquid phase[J]. Ind Eng Chem Res, 2010, 49(16): 7541-7549. doi: 10.1021/ie100728h [22] LIU S Y, REN J, ZHU S J, ZHANG H K, LV E, XU J, LI Y W. Synthesis and characterization of the Fe-substituted ZSM-22 zeolite catalyst with high n-dodecane isomerization performance[J]. J Catal, 2015, 330: 485-496. doi: 10.1016/j.jcat.2015.07.027 [23] 张学军, 王宗贤, 郭爱军, 袁宗胜, 王甫村.高中油型加氢裂化催化剂用Y型沸石的改性研究[J].燃料化学学报, 2008, 36(5): 606-609. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract17305.shtmlZHANG Xue-jun, WANG Zong-xian, GUO Ai-jun, YUAN Zong-sheng, WANG Fu-cun. Modification of zeolite Y for preparation of the maxinizing middle distillates htdrocracking catalyst[J]. J Fuel Chem Technol, 2008, 36(5): 606-609. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract17305.shtml [24] YU Z W, ZHENG A, WANG Q, CHEN L, XU J, AMOUREUX J P, DENG F. Insights into the dealumination of zeolite HY revealed by sensitivity-enhanced 27Al DQ-MAS NMR spectroscopy at high field[J]. Angew Chem Int Ed Eng, 2010, 49(46): 8657-61. doi: 10.1002/anie.201004007 [25] BOKHOVEN J A, KONINGSBERGER D C, KUNKELER P, BEKKUM H V, KENTGENS A P M. Stepwise dealumination of zeolite Beta at specific T-sites observed with 27Al MAS and 27Al MQ MAS NMR[J]. J Am Chem Soc, 2000, 122: 12842-12847. doi: 10.1021/ja002689d [26] IKUNO T, CHAIKITTISILP W, LIU Z, IIDA T, YANABA Y, YOSHIKAWA T, KOHARA S, WAKIHARA T, OKUBO T. Structure-directing behaviors of tetraethylammonium cations toward zeolite beta revealed by the evolution of aluminosilicate species formed during the crystallization process[J]. J Am Chem Soc, 2015, 137(45): 14533-14544. doi: 10.1021/jacs.5b11046 [27] LECKEL D. Noble metal wax hydrocracking catalysts supported on high-siliceous alumina[J]. Ind Eng Chem Res, 2007, 46(11): 3505-3512. doi: 10.1021/ie0700922 [28] ZECEVIC J, VANBUTSELE G, DE JONG K P, MARTENS J A. Nanoscale intimacy in bifunctional catalysts for selective conversion of hydrocarbons[J]. Nature, 2015, 528(7581): 245-252. doi: 10.1038/nature16173 -

下载:

下载: