Reaction kinetics of coal char gasification with CO2 and the effect of internal diffusion on the gasification

-

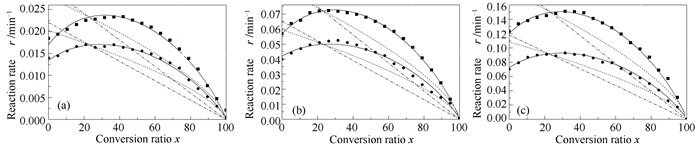

摘要: 采用热重分析仪考察了气化温度(850-1 150℃)和煤焦粒径(<60、505、950、1 515、2 000 μm)对常压下神木煤焦气化反应的影响。在此基础上,运用体积模型、缩核模型和随机孔模型研究了煤焦常压二氧化碳气化反应动力学,分析了内扩散对煤焦气化反应的影响。结果表明,随机孔模型能够准确预测反应速率随煤焦转化率的变化。基于本征动力学数据,通过对Thiele模数、内扩散效率因子的计算,并将其与实验效率因子相比较,发现计算效率因子能够评估内扩散对初始气化反应的影响,但不能准确评估整个气化过程中内扩散对气化反应的影响。Abstract: The effects of temperature (850-1 150℃) and particle size (<60, 505, 950, 1 515 and 2 000 μm) on the gasification of Shenmu coal char with CO2 were investigated by using thermogravimetric apparatus (TGA) under atmospheric pressure. Three kinetic models of volumetric, shrinking core and random pore were applied to validate the experimental results, which illustrates that the random pore model can accurately predict the conversion rate for coal char gasification. Thiele modulus and effectiveness factor were determined on the basis of the intrinsic kinetic rate at 850-1 000℃; a comparison between calculated and experimental effective factors suggests that the calculated effective factor can give a quantitative estimation of the effect of internal diffusion on the initial stage of gasification, but cannot describe the whole gasification process.

-

Key words:

- gasification /

- coal char /

- random pore model /

- intra-particle diffusion /

- effective factor

-

表 1 煤和煤焦的工业分析和元素分析

Table 1 Proximate and ultimate analyses of Shenmu (SM) coal and the residual char

Sample Proximate analysis wad /% Ultimate analysis wad /% V M A FC C H O* N St SM coal 32.46 1.56 6.73 59.25 75.78 4.65 10.12 1.01 0.15 SM char 1.40 0.57 10.31 87.72 86. 77 0.70 0.28 1.24 0.13 *: determined by difference -

[1] 向银花,王洋,张建民,黄戒介,赵建涛.煤气化动力学模型研究[J].燃料化学学报,2002,30(1):21-26. http://www.cnki.com.cn/Article/CJFDTOTAL-RLHX200201007.htmXIANG Yin-hua,WANG Yang,ZHANG Jian-min,HUANG Jie-jie,ZHAO Jian-tao.A study on kinetic models of char gasification[J].J Fuel Chem Technol,2002,30(1):21-26. http://www.cnki.com.cn/Article/CJFDTOTAL-RLHX200201007.htm [2] AHMED I I,GUPTA A K.Particle size,porosity and temperature effects on char conversion[J].Appl Energy,2011,88(12):4667-4677. doi: 10.1016/j.apenergy.2011.06.001 [3] MOLINA A,MONDRAGON F.Reactivity of coal gasification with steam and CO2[J].Fuel,1998,77(15):1831-18399. doi: 10.1016/S0016-2361(98)00123-9 [4] IRFAN MF,USMAN MR,KUSAKABE K.Coal gasification in CO2 atmosphere and its kinetics since 1948:A brief review[J].Energy,2011,36(1):12-40. doi: 10.1016/j.energy.2010.10.034 [5] 张林仙,黄戒介,房倚天,王洋.中国无烟煤焦气化活性的研究-水蒸气与二氧化碳气化活性的比较[J].燃料化学学报,2006,34(3):265-269. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract16992.shtmlZHNAG Lin-xian,HUANG Jie-jie,FANG Yi-tian,WANG Yang.Study on reactivity of Chinese anthracite chars gasification-comparison of reactivity between steam and CO2 gasification[J].J Fuel Chem Technol,2006,34(3):265-269. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract16992.shtml [6] KABIR K B,TAHMASEBI A,BHATTACHARYA S,YU J L.Intrinsic kinetics of CO2 gasification of a Victorian coal char[J].J Therm Anal Calorim,2016,123(2):1685-1694. doi: 10.1007/s10973-015-5060-8 [7] 林善俊,周志杰,霍威,丁路,于广锁.内扩散对煤和石油焦水蒸气气化反应性能的影响[J].燃料化学学报,2014,42(8):905-912. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract18464.shtmlLIN Shan-jun,ZHOU Zhi-jie,HUO Wei,DING Lu,YU Guang-suo.Effect of internal diffusion on steam gasification reactivity of coal and petroleum coke[J].J Fuel Chem Technol,2014,42(8):905-912. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract18464.shtml [8] OLLERO P,SERRERA A,ARJONA R,ALCANTARILLA S.Diffusional effects in TGA gasification experiments for kinetic determination[J].Fuel,2002,81(15):1989-2000. doi: 10.1016/S0016-2361(02)00126-6 [9] MANI T,MAHINPEY N,MURUGAN P.Reaction kinetics and mass transfer studies of biomass char gasification with CO2[J].Chem Eng Sci,2011,66(1):36-41. doi: 10.1016/j.ces.2010.09.033 [10] KIM R G,HWANG C-W,JEON C-H.Kinetics of coal char gasification with CO2:Impact of internal/external diffusion at high temperature and elevated pressure[J].App Energy,2014,129(1):299-307. https://www.researchgate.net/publication/262805883_Kinetics_of_coal_char_gasification_with_CO2_Impact_of_internalexternal_diffusion_at_high_temperature_and_elevated_pressure [11] HUO W,ZHOU Z J,WANG F C,YU G S.Mechanism analysis and experimental verification of pore diffusion on coke and coal char gasification with CO2[J].Chem Eng J,2014,244(15):227-233. https://www.researchgate.net/publication/260232936_Mechanism_analysis_and_experimental_verification_of_pore_diffusion_on_coke_and_coal_char_gasification_with_CO2 [12] VINCENT S S,MAHINPEY N,AQSHA A.Mass transfer studies during CO2 gasification of torrefied and pyrolyzed chars[J].Energy,2014,67(1):319-327. https://www.researchgate.net/publication/260006672_Mass_transfer_studies_during_CO2_gasification_of_torrefied_and_pyrolyzed_chars [13] ISHIDA M,WEN C Y.Comparison of zone-reaction model and unreacted-core shrinking model in solid-gas reactions-I Isothermal analysis[J].Chem Eng Sci,1971,26(7):1031-1041. doi: 10.1016/0009-2509(71)80017-9 [14] SZEKELY J,EVANS J W.A Structural model for gas-solid reactions with a moving boundary[J].Chem Eng Sci,1970,25(6):1091-1107. doi: 10.1016/0009-2509(70)85053-9 [15] BHATIA S K,PERMUTTER D D.A random pore model for fluid-solid reactions:1.Isothermal,kinetic control[J].AIChE J,1980,26(3):379-386. doi: 10.1002/(ISSN)1547-5905 [16] LIU G,WU H,GUPTA R P,LUCAS J A,TATE AG,WALL T F.Mathematical modeling of coal char reactivity with CO2 at high pressures and temperatures[J].Fuel,2000,79(10):627-633. https://www.researchgate.net/publication/223061558_Mathematical_modeling_of_coal_char_reactivity_with_CO2_at_high_pressures_and_temperatures [17] KAJITANI S,SUZUKI N,ASHIZAWA M,HARA S.CO2 gasification rate analysis of coal char in entrained flow coal gasifier[J].Fuel,2006,85(2):163-169. doi: 10.1016/j.fuel.2005.07.024 [18] LAURENDEAU N M.Heterogeneous kinetics of coal char gasification and combustion[J].Prog Energy Combust Sci,1978,4(4):221-270. doi: 10.1016/0360-1285(78)90008-4 -

下载:

下载: