Analysis of solid residues from the co-processing of different rank coals and oils

-

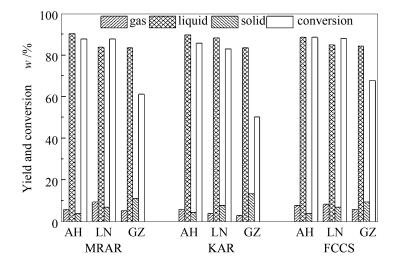

摘要: 选取安徽褐煤、辽宁褐煤和贵州烟煤三种煤为原料,以油溶性环烷酸钼为催化剂,分别与马瑞常渣(MRAR)、克炼常渣(KAR)以及催化裂化油浆(FCCS)在高压釜内模拟悬浮床加氢共炼反应。结果表明,不同的油体系下,两种褐煤都能达到83%以上的转化率,而对于贵州烟煤,转化率最高的FCCS体系与最低的KAR体系分别为67.75%和50.31%,相差很大。采用FT-IR和SEM分析反应后固体残渣,计算了固体残渣中脂肪族和芳香族中各个基团的相对含量,并对比了不同体系反应后固体残渣的微观形貌。结果表明,KAR体系的固体残渣脂肪链较长,支链化程度高,取代度较低。转化率较高的褐煤反应后固体残渣结构松散,分散度高;转化率较低的烟煤固体残渣随着转化率降低,残渣颗粒逐渐变大,表面更加光滑,板结程度加深。Abstract: Anhui lignite, Liaoning lignite and Guizhou bitumite were co-processed with Murray residue (MRAR), Karamay residue (KAR) and FCC slurry (FCCS) in an autoclave with molybdenum naphthenate as catalyst, simulating the slurry-phase hydrogenation co-processing. The results show that for two lignites under different oil systems, the conversion of coal exceeds 83%. However, for Guizhou bitumite, a great difference is observed in the coal conversion between FCCS (67.75%) and KAR (50.31%) for co-processing. The solid residues after co-processing were analyzed by FT-IR and SEM, to determine the relative content of aliphatic and aromatic groups and the micro morphology. It is found that the solid residue derived from the KAR system possesses a low content of CH2/CH3 and a low substitution degree. Moreover, the solid residues obtained from two lignites with high coal conversion exhibit a looser structure and a higher dispersion of solid particles than that from bitumite with a low coal conversion.

-

表 1 原料煤的工业分析和元素分析

Table 1 Proximate analysis and ultimate analysis of coals

Coal type Proximate analysis w/% Ultimate analysis wdaf/% Mad Aad Vdaf FCdaf C H N S Anhui lignite 0.75 3.97 56.24 43.76 58.70 5.15 0.51 0.35 Liaoning lignite 0.76 18.06 49.02 50.98 55.31 4.78 1.29 0.59 Guizhou bitumite 0.13 9.29 34.07 65.93 71.60 4.65 0.95 0.41 表 2 原料油的性质分析

Table 2 Properties of oils

Oil type Density (20 ℃) ρ/(g·mL-1) Viscosity (50 ℃) μ/(mm2·s-1) Carbon residue w/% Chemical composition w/% Ultimate analysis w/% saturates aromatics resins C7-asphaltenes C H S N MRAR 0.997 6 2 272.4 15.33 31.49 39.44 12.06 9.29 84.82 10.87 2.89 0.63 KAR 0.967 0 1 964.1 10.01 25.44 39.20 35.10 0.26 86.68 11.66 0.63 0.77 FCCS 1.093 6 12.41 5.84 12.69 84.28 2.11 0.09 88.38 7.34 3.96 0.25 表 3 反应后固体残渣不同基团的相对含量

Table 3 Relative contents of different groups in the solid residues

System CH3 CH2 CH Relative contents /% CH2/CH3 5 adjacent H deformation 4 adjacent H deformation 2 or 3 adjacent H deformation MRAR-AH 33.81 41.76 24.43 13.83 17.02 69.15 1.24 KAR-AH 23.85 50.18 25.97 15.34 13.07 71.59 2.10 FCCS-AH 29.76 47.06 23.18 29.89 12.64 57.47 1.58 MRAR-LN 27.00 42.00 31.00 15.37 19.26 65.37 1.56 KAR-LN 25.77 51.53 22.70 13.25 14.31 72.44 2.00 FCCS-LN 28.93 51.51 19.56 19.86 15.44 64.70 1.78 表 4 贵州煤反应后固体残渣不同基团的相对含量

Table 4 Relative contents of different groups in GZ solid residues

System CH3 CH2 CH Relative contents /% CH2/CH3 5 adjacent H deformation 4 adjacent H deformation 2 or 3 adjacent H deformation MRAR-GZ 20.27 39.86 39.86 52.86 15.00 62.14 1.97 KAR-GZ 23.79 50.80 25.40 47.97 14.86 66.89 2.14 FCCS-GZ 26.76 48.59 24.65 54.74 11.58 56.84 1.82 -

[1] 郝玉良, 杨建丽, 李允梅, 刘沐鑫, 杨勇.低阶煤温和液化特征分析[J].燃料化学学报, 2012, 40(10):1153-1160. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract18037.shtmlHAO Yu-liang, YANG Jian-li, LI Yun-mei, LIU Mu-xin, YANG Yong. Study on mild liquefaction of lower rank coal[J]. J Fuel Chem Technol, 2012, 40(10):1153-1160. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract18037.shtml [2] 商思玉, 凌开成, 王建平, 盛清涛, 申峻.神府煤与胜利减压渣油共处理反应特性的研究[J].燃料化学学报, 2005, 33(1):47-52. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract16507.shtmlSHANG Si-yu, LING Kai-cheng, WANG Jian-ping, SHENG Qing-tao, SHEN Jun. Reaction characteristics of coprocessing of Shenfu coal and Shengli vacuum resid[J]. J Fuel Chem Technol, 2005, 33(1):47-52. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract16507.shtml [3] 凌开成, 申峻, 邹纲明, 王志忠.杨村烟煤与石油渣油共处理反应特性的研究[J].燃料化学学报, 1997, 25(2):44-48. http://www.cnki.com.cn/Article/CJFDTOTAL-RLHX702.008.htmLING Kai-cheng, SHEN Jun, ZOU Gang-ming, WANG Zhi-zhong. Study on reaction property of coprocessing of Yangcun bituminous coal with petroleum residue[J]. J Fuel Chem Technol, 1997, 25(2):44-48. http://www.cnki.com.cn/Article/CJFDTOTAL-RLHX702.008.htm [4] 薛永兵, 凌开成, 邹纲明.钼酸胺催化剂对煤-油共处理反应性的影响[J].燃料化学学报, 2003, 31(3):225-229. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract16798.shtmlXUE Yong-bing, LING Kai-cheng, ZOU Gang-ming. Effect of ammonium molybdate catalyst on co-processing bituminous coal and residue[J]. J Fuel Chem Technol, 2003, 31(3):225-229. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract16798.shtml [5] MOLINER R, SUELVES I, LA ZARO M J. Synergetic effects in the copyrolysis of coal petroleum residue mixtures by pyrolysis gas chromatography influence of temperature, pressure, and coal nature[J]. Energy Fuels, 1998, 12(5):963-967. doi: 10.1021/ef980033o [6] 黄传峰, 李大鹏, 杨涛.煤油共炼技术现状及研究趋势讨论[J].现代化工, 2016, 36(8):8-13. http://www.cnki.com.cn/Article/CJFDTOTAL-XDHG201608004.htmHUANG Chuan-feng, LI Da-peng, YANG Tao. Status and research trends of co-processing of coal and oil[J]. Mod Chem Ind, 2016, 36(8):8-13. http://www.cnki.com.cn/Article/CJFDTOTAL-XDHG201608004.htm [7] 王国龙, 徐蓉, 张德祥, 鲁锡兰.煤液化残渣加氢性能[J].石油学报 (石油加工), 2009, 25(5):747-751. http://www.cnki.com.cn/Article/CJFDTOTAL-SXJG200905025.htmWANG Guo-long, XU Rong, ZHANG De-xiang, LU Xi-lan. The hydrogenation of coal liquefaction residue[J]. Acta Pet Sin (Pet Process Sect), 2009, 25(5):747-751. http://www.cnki.com.cn/Article/CJFDTOTAL-SXJG200905025.htm [8] 楚希杰, 李文, 白宗庆, 李保庆.神华煤直接液化残渣热解特性研究[J].燃料化学学报, 2009, 37(4):393-397. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract17462.shtmlCHU Xi-jie, LI Wen, BAI Zong-qing, LI Bao-qing. Pyrolysis characteristics of Shenhua direct liquefaction residue[J]. J Fuel Chem Technol, 2009, 37(4):393-397. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract17462.shtml [9] 李军, 杨建丽, 刘振宇.煤直接液化残渣的热解特性研究[J].燃料化学学报, 2010, 38(4):385-390. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract17595.shtmlLI Jun, YANG Jian-li, LIU Zhen-yu. Pyrolysis behavior of direct coal liquefaction residues[J]. J Fuel Chem Technol, 2010, 38(4):385-390. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract17595.shtml [10] 王光耀, 张晓静, 陈贵锋, 毛学锋, 颜丙峰.高温煤焦油用作煤油共处理溶剂反应性能研究[J].煤炭转化, 2015, 38(2):49-52. http://www.cnki.com.cn/Article/CJFDTOTAL-MTZH201502013.htmWANG Guang-yao, ZHANG Xiao-jing, CHEN Gui-feng, MAO Xue-feng, YAN Bing-feng. Study on reaction activity of high temperature coal tar using as coal-oil co-processing solvent[J]. Coal Convers, 2015, 38(2):49-52. http://www.cnki.com.cn/Article/CJFDTOTAL-MTZH201502013.htm [11] SHARMA B K, SHARMA C D, TYAGI O S, BHAGAT S D, ERHAN S Z. Structural characterization of asphaltenes and ethyl acetate insoluble fractions of petroleum vacuum residues[J]. Pet Sci Technol, 2007, 25(1/2):121-139. doi: 10.1080/10916460601054263 [12] 李冬, 刘鑫, 孙智慧, 李稳宏, 马伟.煤焦油中甲苯不溶物的性质和组成分析[J].石油学报 (石油加工), 2014, 30(1):76-82. http://www.cnki.com.cn/Article/CJFDTOTAL-SXJG201401015.htmLI Dong, LIU Xin, SUN Zhi-hui, LI Wen-hong, MA-Wei. Property and composition analysis of toluene insoluble materials in coal tar[J]. Acta Pet Sin (Pet Process Sect), 2014, 30(1):76-82. http://www.cnki.com.cn/Article/CJFDTOTAL-SXJG201401015.htm [13] YEN T F, WU W H, CHILINGAR G V. A study of the structure of petroleum asphaltenes and related substances by infrared spectroscopy[J]. Energy Source, 1984, 7(3):203-235. doi: 10.1080/00908318408908084 [14] PAINTER P, STARSINIC M, COLEMAN M. Determination of Functional Groups in Coal by Fourier Transform Interferometry[C]//Fourier Transform Infrared Spectra, 1985:169-241. [15] IBARRA J V, MUNOZ E, MOLINER R. FTIR study of the evolution of coal structure during the coalification process[J]. Org Geochem, 1996, 24(6):725-735. https://www.researchgate.net/publication/222789181_FTIR_Study_of_the_Evolution_of_Coal_Structure_during_the_Coalification_Process [16] LI K, KHANNA R, ZHANG J, BARATI M, LIU Z, XU T, YANG T, SAHAJWALLA V. Comprehensive investigation of various structural features of bituminous coals using advanced analytical techniques[J]. Energy Fuels, 2015, 29(11):7178-7189. doi: 10.1021/acs.energyfuels.5b02064 [17] ZHANG Y, KANG X, TAN J. Influence of calcination and acidification on structural characterization of Anyang anthracites[J]. Energy Fuels, 2013, 27(11):7191-7197. doi: 10.1021/ef401658p [18] 李刚, 凌开成.煤直接液化过程动力学阶段的划分与煤的高温快速液化[J].煤炭学报, 2007, 32(9):975-979. http://www.cnki.com.cn/Article/CJFDTOTAL-MTXB200709017.htmLI Gang, LING Kai-cheng. Division of kinetic stages in coal direct liquefaction process and coal quick liquefaction at high temperature[J]. J China Coal Soc, 2007, 32(9):975-979. http://www.cnki.com.cn/Article/CJFDTOTAL-MTXB200709017.htm [19] 吴乐乐, 李金璐, 邓文安, 张英红, 李传.煤焦油重组分甲苯不溶物结构组成及对悬浮床加氢裂化生焦的影响[J].燃料化学学报, 2015, 43(8):923-931. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract18672.shtmlWU Le-le, LI Jin-lu, DENG Wen-an, ZHANG Ying-hong, LI Chuan. Structure of toluene insoluble coal tar heavy fraction and its relevance to the coking be havior in slurry-bed hydrocracking[J]. J Fuel Chem Technol, 2015, 43(8):923-931. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract18672.shtml -

下载:

下载: