Influences of ammonium sulfate additive on Cl and N co-transformation during biomass/semi-coke oxy-fuel co-combustion

-

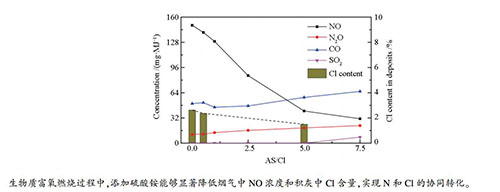

摘要: 在50 kW循环流化床燃烧实验台进行了O2/CO2气氛下硫酸铵添加剂对生物质和半焦混烧过程中K/S/Cl迁移和N2O/NO排放影响实验研究。结果表明,硫酸铵添加剂从提升管喷入后能够明显降低积灰中Cl含量,同时显著降低烟气中NO浓度。此外,硫酸铵添加剂还能够增强碱金属K向底渣和循环灰迁移转化,从而降低积灰中碱金属K含量。实验表明,硫酸铵添加剂的最佳喷入位置在提升管中上部。Abstract: To investigate the influences of ammonium sulfate(AS) on the K/S/Cl transformation and N2O/NO emission, the biomass and semi-coke were co-combusted in a 50 kW circulating fluidized bed under O2/CO2 atmosphere. The experimental results show that AS can reduce the Cl content in deposits obviously and decrease the NO concentration in flue gas significantly. Besides, AS can retain more K in bottom ash and circulating ash, thereby reducing the K content in deposits. In terms of reducing Cl in deposits, the top half of the riser is the optimal position to inject AS.

-

表 1 实验燃料的工业分析与元素分析

Table 1 Proximate and ultimate analyses of experimental fuels

Fuel Proximate analysis wad/% Ultimate analysis wad/% Qar, net /(MJ·kg-1) M A V FC C H O N S Cl CS 6.66 14.92 62.60 15.82 39.29 4.65 33.43 0.91 0.14 0.58 14.51 SC 5.75 12.28 12.10 69.87 73.18 1.29 6.45 0.73 0.32 - 25.34 表 2 燃料灰成分分析

Table 2 Ash compositions of experimental fuels

Fuel Content w/% SiO2 Al2O3 Fe2O3 CaO MgO TiO2 SO3 P2O5 K2O Na2O CS 54.40 7.46 3.01 7.47 5.40 0.50 2.10 1.52 11.47 1.89 SC 16.84 7.36 11.46 49.60 1.64 0.44 8.18 0.08 0.23 0.64 -

[1] 骆仲泱, 陈晨, 余春江.生物质直燃发电锅炉受热面沉积和高温腐蚀研究进展[J].燃烧科学与技术, 2014, 20(3):189-198. http://d.old.wanfangdata.com.cn/Periodical/rskxyjs201403001LUO Zhong-yang, CHEN Chen, YU Chun-jiang. Review of deposition and high-temperature corrosion in biomass-fired boilers[J]. J Combust Sci Technol, 2014, 20(3):189-198. http://d.old.wanfangdata.com.cn/Periodical/rskxyjs201403001 [2] GOUGH C, UPHAM P. Biomass energy with carbon capture and storage (BECCS or Bio-CCS)[J]. Greenhouse Gases:Sci Technol, 2011, 1(4):324-334. doi: 10.1002/ghg.34 [3] NIELSEN H P, FRANDSEN F J, DAM-JOHANSEN K, BAXTER L L. The implications of chlorine-associated corrosion on the operation of biomass-fired boilers[J]. Prog Energy Combust, 2000, 26(3):283-298. doi: 10.1016/S0360-1285(00)00003-4 [4] YU C, QIN J, NIE H, FANG M, LUO Z. Experimental research on agglomeration in straw-fired fluidized beds[J]. Appl Energy, 2011, 88(12):4534-4543. doi: 10.1016/j.apenergy.2011.05.046 [5] 别如山, 李炳熙, 陆慧林, 杨励丹.燃生物废料流化床锅炉[J].热能动力工程, 2000, 15(88):345-347. http://d.old.wanfangdata.com.cn/Periodical/rndlgc200004004BIE Ru-shan, LI Bing-xi, LU Hui-lin, YANG Li-dan. Biomass-fired fluidized bed boilers[J]. J Eng Therm Energy Power, 2000, 15(88):345-347. http://d.old.wanfangdata.com.cn/Periodical/rndlgc200004004 [6] DAYTON D C, JENKINS B M, TURN S Q, BAKKER R R, WILLIAMS R B, BELLE-OUDRY D, HILL L M. Release of inorganic constituents from leached biomass during thermal conversion[J]. Energy Fuels, 1999, 13(4):860-870. doi: 10.1021/ef980256e [7] DAVIDSSON K O, KORSGREN J G, PETTERSSON J B C, JALID U. The effects of fuel washing techniques on alkali release from biomass[J]. Fuel, 2002, 81(2):137-142. doi: 10.1016/S0016-2361(01)00132-6 [8] AHO M, VAINIKKA P, TAIPALE R, YRJAS P. Effective new chemicals to prevent corrosion due to chlorine in power plant superheaters[J]. Fuel, 2008, 87(6):647-654. doi: 10.1016/j.fuel.2007.05.033 [9] KASSMAN H, BAFVER L, ÅMAND L E. The importance of SO2 and SO3 for sulphation of gaseous KCl:An experimental investigation in a biomass fired CFB boiler[J]. Combust Flame, 2010, 157(9):1649-1657. doi: 10.1016/j.combustflame.2010.05.012 [10] KASSMAN H, PETTERSSON J, STEENARI B M, AMAND L E. Two strategies to reduce gaseous KCl and chlorine in deposits during biomass combustion-injection of ammonium sulphate and co-combustion with peat[J]. Fuel Process Technol, 2013, 105:170-180. doi: 10.1016/j.fuproc.2011.06.025 [11] KASSMAN H, BROSTROM M, BERG M, AMAND L E. Measures to reduce chlorine in deposits:Application in a large-scale circulating fluidized bed boiler firing biomass[J]. Fuel, 2011, 90(4):1325-1334. doi: 10.1016/j.fuel.2010.12.005 [12] NORLING R, NAFARI A, NYLUND A. Erosion-corrosion of Fe-and Ni-based tubes and coatings in a fluidized bed test rig during exposure to HCl- and SO2-containing atmospheres[J]. Wear, 2005, 258(9):1379-1383. doi: 10.1016/j.wear.2004.05.028 [13] MAYORAL M C, ANDRES J M, BELZUNCE J, HIGUERA V. Study of sulphidation and chlorination on oxidized SS310 and plasma-sprayed Ni-Cr coatings as simulation of hot corrosion in fouling and slagging in combustion[J]. Corros Sci, 2006, 48(6):1319-1336. doi: 10.1016/j.corsci.2005.06.004 [14] PHONGPHIPHAT A, RYU C, YANG Y B, FINNEY K N, LEYLAND A, SHARIFI V N, SWITHENBANK J. Investigation into high-temperature corrosion in a large-scale municipal waste-to-energy plant[J]. Corros Sci, 2010, 52(12):3861-3874. doi: 10.1016/j.corsci.2010.07.032 [15] 黄芳.秸秆燃烧过程中受热面沉积腐蚀问题研究[D].杭州: 浙江大学, 2013.HUANG Fang. Study on the deposit and corrosion problem on heating surface during straw combustion[D]. Hangzhou: Zhejiang Univeristy, 2013. [16] 何小明, 赵兵涛.藻类生物质与煤混烧过程氮硫污染物的排放与转化特性[J].动力工程学报, 2019, 39(6):474-477. http://d.old.wanfangdata.com.cn/Periodical/dlgc201906007HE Xiao-ming, ZHAO Bin-tao. Emission and conversion characteristics of NO and SO2 from Co-firing of algae biomass and coal[J]. J Chin Soc Power Eng, 2019, 39(6):474-477. http://d.old.wanfangdata.com.cn/Periodical/dlgc201906007 [17] JI X, BIE H, ZHANG Y, CHEN P, FANG W, BIE R. Release of K and Cl and emissions of NOx and SO2 during reed black liquor combustion in a fluidized bed[J]. Energy Fuels, 2017, 31(2):1631-1637. doi: 10.1021/acs.energyfuels.6b02701 [18] 陈安合.煤与生物质混烧过程氯、碱金属和氮氧化物排放行为研究[D].北京: 中国科学院过程工程研究所, 2007.CHEN An-he. Investigation of chlorine, alkalis, NOx and N2O emissions during coal-biomass Co-firing[D]. Beijing: Institute of Process Engineering, Chinese Academy of Sciences, 2007. [19] 谢敬思, 程世庆, 张慧敏, 张海瑞, 刘坤. O2/CO2气氛下生物质与煤混燃的NO排放特性研究[J].热力发电, 2012, 41(8):38-42. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=rlfd201208009XIE Jing-si, CHENG Shi-qing, ZHANG Hui-min, ZHANG Hai-rui, LIU Kun. Experimental study on no emission characteristic:of-firing of biomass and coal in O2/CO2 atmosphere[J]. Therm Power Gener, 2012, 41(8):38-42. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=rlfd201208009 [20] HANSEN L A, NIELSEN H P, FRANDSEN F J, DAM-JOHANSEN K, HORLYCK S, KARLSSON A. Influence of deposit formation on corrosion at a straw-fired boiler[J]. Fuel Process Technol, 2000, 64(1):189-209. doi: 10.1016-S0378-3820(00)00063-1/ [21] DAVIDSSON K O, AMAND L E, STEENARI B M, ELLED A L, ESKILSSON D, LECHNER B. Countermeasures against alkali-related problems during combustion of biomass in a circulating fluidized bed boiler[J]. Chem Eng Sci, 2008, 63(21):5314-5329. doi: 10.1016/j.ces.2008.07.012 [22] BROSTROM M, KASSMAN H, HELGESSON A, BERG M, ANDERSSON C, BACKMAN R, NORDIN A. Sulfation of corrosive alkali chlorides by ammonium sulfate in a biomass fired CFB boiler[J]. Fuel Process Technol, 2007, 88(11/12):1171-1177. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=7078671948d8d272e998f9c1f7ed964f [23] LIU D, LI W, LI S. Fundamental study of heterogeneous KCl sulfation under oxy-fuel combustion conditions[J]. Int J Energy Res, 2019, 43(9):4093-4103. doi: 10.1002/er.4501 -

下载:

下载: