-

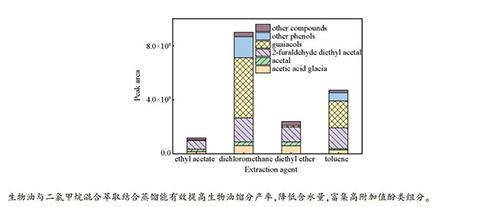

摘要: 选用乙酸乙酯、二氯甲烷、乙醚和甲苯四种溶剂,分别与生物油按一定质量比混合萃取。将萃取相蒸馏得到的四种油相层与原始生物油进行对比,研究不同萃取剂对生物油萃取-蒸馏后各馏分的产率、水分及高附加值酚类组分变化的影响。结果表明,经萃取-蒸馏后,生物油残渣比例减少,水分含量降低。在四种溶剂中,甲苯萃取率较低,蒸馏后酚类绝对峰面积较小;乙酸乙酯和乙醚萃取效率较高,但两者萃取相蒸馏后酚类含量低;二氯甲烷萃取酚类能力强,其馏分中愈创木酚及其衍生物相对含量为34.11%,比生物油高出15.52%,富集程度高,更有利于后续进一步提纯愈创木酚及其衍生物等高附加值化学品。Abstract: In order to separate and enrich the high value-added chemicals in bio-oil, solvent extraction and distillation methods were combined to separate and purify bio-oil. Ethyl-acetate, dichloromethane, diethyl ether and toluene were elected as extracting agents, which were mixed with bio-oil in a certain mass ratio. The 4 oil phases distilled from four extract phases were compared with bio-oil to study effects of different solvents on the yield, moisture and high value-added components of distillate. The results show that the distillate had higher yield and lower moisture content compared with that of bio-oil after the extraction and distillation. Among the 4 solvents, toluene had the poorest ability to extract high value-added components of bio-oil, achieving the lowest yield of phenols of distillate. The extraction efficiency of ethyl-acetate and diethyl ether was higher than that of toluene, but the contents of high value-added components in their oil phases were lower than those of others. The relative content of guaiacol and its derivatives was 34.11% in the oil phases of dichloromethane, which was 15.52% higher than that of bio-oil, and conducive to further extract for high value-added chemicals such as guaiacol and its derivatives.

-

Key words:

- bio-oil /

- extraction /

- distillation /

- separation /

- purification

-

表 1 生物油基本物性参数

Table 1 Basic physical properties of bio-oil

Sample Moisture /% pH value Calorific value /(J·g-1) Viscosity v/(mm2·s-1) Density ρ/(g·cm-3) Bio-oil 14.61 3.50 24561 39.39 1.03 表 2 四种试剂在25 ℃时的Hansen溶度参数

Table 2 Hansen solubility parameters of four reagents at 25 ℃

Extraction agent Nonpolar Polarity Hydrogen-bond Solubility parameter Ethyl acetate 15.8 5.3 7.2 18.2 Dichloromethane 18.1 1.4 2.1 18.2 Diethyl ether 18.2 6.3 6.1 20.2 Toluene 14.5 2.9 5.1 15.6 表 3 生物油及四种萃取相主要化合物的相对含量

Table 3 Relative content of compounds in bio-oil and four extraction phases

Compound Peak area/% bio-oil ethyl-acetate dichloro-methane diethyl-ether toluene Acetic acid glacia 4.68 1.34 3.45 3.54 1.94 Furfural 2.57 1.28 1.18 1.28 3.39 Guaiacol 5.95 6.78 7.07 6.63 5.61 2-methoxy-4-methylphenol 6.54 8.21 8.82 8.31 6.78 4-ethyl-2-methoxyphenol 4.43 5.16 5.56 5.18 4.80 4-hydroxy-3-methoxystyrene 1.67 1.64 1.61 1.71 1.44 Eugenol 2.88 2.71 2.86 2.70 3.12 Dihydroeugenol 1.29 1.48 1.71 1.59 1.43 Vanillin 1.29 1.38 1.03 1.39 1.14 Isoeugenol 12.23 12.42 12.63 12.13 14.81 Acetovanillone 1.27 1.27 1.39 1.29 1.12 4-hydroxy-3-methoxyphenylacetone 0.00 1.35 1.40 1.33 2.31 4-hydroxy-3-methoxycinnamaldehyde 2.47 2.32 2.15 2.36 1.35 5-tert-butylpyrogallol 2.37 1.92 1.83 1.85 2.33 4-allyl-2, 6-dimethoxyphenol 3.74 5.00 4.46 5.02 1.06 Syringaldehyde 0.00 1.04 1.04 0.81 0.93 2, 6-dimethoxyphenol 1.91 2.58 2.78 2.55 2.56 trans-13-octadecenoic acid 7.42 5.25 4.62 5.34 8.27 表 4 不同萃取剂下生物油蒸馏馏分基本性质

Table 4 Properties of distillation fractions of different crude extracts

Crude extracts Layer Color Fraction /% Moisture /% Organic /% Ethyl acetate upper yellowish 51.22 6.22 48.03 lower white 7.80 79.99 1.56 Dichloromethane upper white 11.56 76.33 1.63 lower back 52.64 1.78 51.70 Diethyl ether upper orange 49.24 4.83 46.86 lower white 12.10 77.33 1.54 Toluene upper yellow 67.85 0.91 67.23 lower white 6.58 68.92 1.49 表 5 各油相层成分分析

Table 5 Analysis of the composition of each oil phase

Compound Area /% ethyl acetate dichloromethane diethylether toluene Acetic acid glacia 7.27 4.59 16.29 4.20 Acetal 8.80 2.13 8.22 1.51 Propionaldehyde diethyl acetal 3.09 1.05 2.73 1.15 Ethyl 3-ethoxyacrylate 2.48 1.41 2.96 1.52 2-furaldehyde diethyl acetal 30.61 13.62 30.31 22.73 Hexaldehyde diethyl acetal 1.85 - 2.59 - Guaiacol - 14.46 3.20 11.93 2-methoxy-4-methylphenol 1.13 12.83 - 11.78 4-ethyl-2-methoxyphenol - 6.82 - 5.69 Eugenol - 2.25 - 3.02 Dihydroeugenol - 2.86 - 2.35 Isoeugenol - 4.47 - 3.70 2, 6-dimethoxyphenol - 1.29 - - 5-tert-butylpyrogallol - 1.12 - - note:“-” relative peak area<1.00% -

[1] 陈军昊, 卢亮, 王树荣.基于分子蒸馏的模拟生物油温和加氢研究[J].燃料化学学报, 2017, 45(9):1056-1063. doi: 10.3969/j.issn.0253-2409.2017.09.005CHEN Jun-hao, LU Liang, WANG Shu-rong.Mild hydrogenation of simulated bio-oil based on molecular distillation[J].J Fuel Chem Technol, 2017, 45(9):1056-1063. doi: 10.3969/j.issn.0253-2409.2017.09.005 [2] CHEN D Y, GAO A J, CEN K H, ZHANG J, CAO X B, MA Z Q. Investigation of biomass torrefaction based on three major components:Hemicellulose, cellulose, and lignin[J]. Energy Convers Manage, 2018, 169:228-237. doi: 10.1016/j.enconman.2018.05.063 [3] 徐善宝, 陕永杰.生物质热解油净化及其提纯处理研究[J].现代盐化工, 2018, (2):69-70. doi: 10.3969/j.issn.1005-880X.2018.02.033XU Shan-bao, SHAN Yong-jie. Research of purification and purification of biomass pyrolytic oil[J]. Mod Salt Chem Ind, 2018, (2):69-70. doi: 10.3969/j.issn.1005-880X.2018.02.033 [4] CHEN D Y, ZHOU J B, ZHANG Q S, ZHU X F. Evaluation methods and research progresses in bio-oil storage stability[J]. Renewable Sustainable Energy Rev, 2014, 40:69-79. doi: 10.1016/j.rser.2014.07.159 [5] CHEN D Y, ZHENG Z C, FU K X, ZENG Z, WANG J J, LU M T. Torrefaction of biomass stalk and its effect on the yield and quality of pyrolysis products[J]. Fuel, 2015, 159:27-32. doi: 10.1016/j.fuel.2015.06.078 [6] 张瑾, 李小华, 董良秀, 王嘉骏, 刘莎, 蔡忆昔, 邵珊珊, 张小雷, 胡超.碱处理HZSM-5分子筛在线催化提质生物油[J].燃料化学学报, 2017, 45(7):828-836. doi: 10.3969/j.issn.0253-2409.2017.07.007ZHANG Jin, LI Xiao-hua, DONG Liang-xiu, WANG Jia-jun, LIU Sha, CAI Yi-xi, SHAO Shan-shan, ZHANG Xiao-lei, HU Chao. Online upgrading of bio-oil with alkali-treated HZSM-5 zeolites[J]. J Fuel Chem Technol, 2017, 45(7):828-836. doi: 10.3969/j.issn.0253-2409.2017.07.007 [7] 方丽娜, 陈宇, 刘娅, 吴可荆, 吴玉龙, 杨明德.藻类水热液化产物生物油分离纯化及组分分析[J].化工学报, 2015, 66(9):3640-3648. http://d.old.wanfangdata.com.cn/Periodical/hgxb201509048FANG Li-na, CHEN Yu, LIU Ya, WU Ke-jing, WU Yu-long, YANG Ming-de. Separation, purification and composition analysis of bio-oil from hydrothermal liquefaction of microalgae[J]. J Chem Ind Eng, 2015, 66(9):3640-3648. http://d.old.wanfangdata.com.cn/Periodical/hgxb201509048 [8] KIM J S. Production, separation and applications of phenolic-rich bio-oil-A review[J]. Bioresour Technol, 2015, 178:90-98. doi: 10.1016/j.biortech.2014.08.121 [9] PEDERSEN T H, JENSEN C U, SANDSTRÖM L, ROSENDAHLA L A. Full characterization of compounds obtained from fractional distillation and upgrading of a HTL biocrude[J]. Appl Energy, 2017, 202:408-419. doi: 10.1016/j.apenergy.2017.05.167 [10] HASSAN E B, EL-GIAR E M, STEELE P. Evaluation of the antioxidant activities of different bio-oils and their phenolic distilled fractions for wood preservation[J]. Int Biodeterior Biodegrad, 2016, 110:121-128. doi: 10.1016/j.ibiod.2016.03.015 [11] WANG S R, WANG Y R, CAI Q J, WANG, X Y, JIN H, LUO Z Y. Multi-step separation of monophenols and pyrolytic lignins from the water-insoluble phase of bio-oil[J]. Sep Purif Technol, 2014, 122(3):248-255. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=54f9c757f130afde7a862466a23f2b2a [12] HU X, WANG Y, MOURANT D, GUNAWAN R, LIEVENS C, CHAIWAT W, GHOLIZADEH M, WU L P, LI X, LI C Z. Polymerization on heating up of bio-oil:A model compound study[J]. AIChE J, 2013, 59(3):888-900. doi: 10.1002/aic.v59.3 [13] ZHANG X S, YANG G X, JIANG H, LIU W J, DING H S. Mass production of chemicals from biomass-derived oil by directly atmospheric distillation coupled with co-pyrolysis[J]. Sci Rep, 2013, 3:1120. doi: 10.1038/srep01120 [14] 秦菲, 崔洪友, 王传波, 王丽红, 易维明.萃取耦合化学转化法提质生物油油溶相的研究[J].燃料化学学报, 2014, 42(7):805-812. http://www.ccspublishing.org.cn/article/id/100033162QIN Fei, CUI Hong-you, WANG Chuan-bo, WANG Li-hong, YI Wei-ming. Upgrading the oil-soluble fraction of bio-oil by solvent extraction coupling with chemical conversion[J]. J Fuel Chem Technol, 2014, 42(7):805-812. http://www.ccspublishing.org.cn/article/id/100033162 [15] WEI Y, LEI H W, WANG L, ZHU L, ZHANG X S, LIU Y P, CHEN S L, BIRGITTE A. Liquid-liquid extraction of biomass pyrolysis bio-oil[J]. Energy Fuels, 2014, 28(2):1207-1212. doi: 10.1021/ef402490s [16] 王誉蓉.基于水萃取和分子蒸馏的生物油分级分离研究[D].杭州: 浙江大学, 2016.WANG Yu-rong. Research on stepwise separation of bio-oil based on water extraction and molecular distillation[D]. Hangzhou: Zhejiang University, 2016. [17] 刘绍鹏.稻壳液化油的选择性分离、分析和酯化[D].徐州: 中国矿业大学, 2011.LIU Shao-peng. Selective isolation, analysis and esterification of the oil from rice husk pyrolysis[D]. Xuzhou: China University of Minning and Technology, 2011. [18] 杨潇.水热液化生物油的溶剂萃取与柱层析分离技术[D].上海: 复旦大学, 2014.YANG Xiao. Solvent extraction and column chromatography separation of bio-oil from hvdrothermal liquefaction of biomass residues[D]. Shanghai: Fudan University, 2014. [19] TANNERU S K, STEELE P H. Pretreating bio-oil to increase yield and reduce char during hydrodeoxygenation to produce hydrocarbons[J]. Fuel, 2014, 133(133):326-331. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=9328296d0012d9d628282576d0fb28b5 [20] 刘田元, 刘雄民, 马丽, 赖芳, 张闻扬.苯甲醚和苯乙醚氧化特性及其产物[J].应用化工, 2017, 46(8):1461-1465. doi: 10.3969/j.issn.1671-3206.2017.08.004LIU Tian-yuan, LIU Xiong-min, MA Li, LAI Fang, ZHANG Wen-yang. Oxidation characteristics and products of anisole and phenetole[J]. Appl Chem Ind, 2017, 46(8):1461-1465. doi: 10.3969/j.issn.1671-3206.2017.08.004 -

下载:

下载: