Influence of dolomite additive on the ash fusion and potassium fixation characteristics of rice straw

-

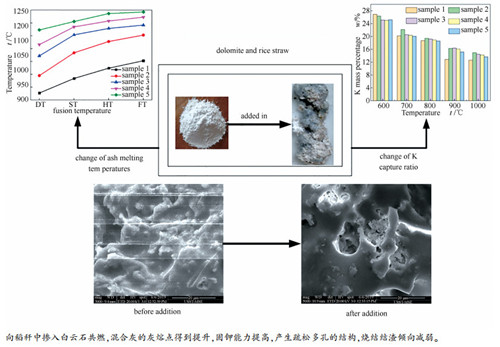

摘要: 在管式炉中研究了稻草秸秆的结渣特性与白云石作为添加剂对稻秆燃烧结渣的影响及其机理。采用电感耦合等离子体发射光谱(ICP-OES)和X射线衍射(XRD)表征了稻秆灰分与白云石之间的相互作用。结果表明,当白云石添加质量分数为5%时,对稻秆的结渣特性具有明显的改善。白云石具有较好的固钾能力,在900和1000℃下尤为明显。白云石中富含的Mg和Ca元素能够与稻秆灰分中的SiO2反应形成高熔点的硅酸盐矿物,包括透辉石、钙镁橄榄石和镁硅钙石。Abstract: The influence of dolomite as an additive on the slagging and potassium fixation characteristics of rice straw upon burning was investigated in a tube furnace; the slagging mechanism as well as the interaction between the rice straw ash and dolomite were explored by using the inductively coupled plasma optical emission spectrometry (ICP-OES) and X-ray diffraction (XRD). The results show that the slagging characteristics of rice straw are significantly influenced by adding 5% dolomite. Dolomite can greatly improve the potassium fixation ability, especially at 900-1000℃; moreover, the Mg and Ca elements rich in dolomite can react with SiO2 in the rice straw ash, forming high-melting silicate minerals including diopside, monticellite and merwinite.

-

Key words:

- rice straw /

- ash /

- slagging /

- dolomite /

- potassium fixation

-

图 6 不同温度下的稻秆灰中钾固定率

Figure 6 Potassium capture efficiency of various ash samples deposited at different temperatures

sample 1: pure rice straw ash;

sample 2: rice straw ash with 2.5% dolomite;

sample 3: rice straw ash with 5% dolomite;

sample 4: rice straw ash with 7.5% dolomite;

sample 5: rice straw ash with 10% dolomite表 1 稻草秸秆的工业分析与元素分析

Table 1 Proximate and ultimate analyses of rice straw

Sample Proximate analysis wad /% Ultimate analysis wd /% Qnet.ad/

(kJ·kg-1)M A V FC C H O N S Rice straw 6.57 10.52 72.42 10.49 44.65 6.93 35.75 0.89 0.34 15274.7 表 2 稻秆灰与白云石的成分分析

Table 2 Composition analysis of rice straw ash and dolomite

Samples SiO2 Al2O3 Fe2O3 Content w/% K2O Na2O CaO MgO SO3 Rice straw ash 29.66 2.66 1.16 10.80 7.25 1.06 32.18 2.34 Dolomite 2.13 0.23 0.15 29.08 19.27 1.45 0.13 0.23 表 3 样品内部元素原子百分比

Table 3 Atomic percentages of various elements in the ash

Sample Content w/% O Na K Al Si Mg Ca S Cl 1 35.63 0.80 10.95 8.12 40.23 2.06 1.11 0.24 0.31 3 28.15 1.14 2.40 0.49 37.46 16.28 12.89 0.17 0.19 表 4 不同温度下的样品成灰率

Table 4 Ash formation rates at different temperatures

Sample w/% 600℃ 700℃ 800℃ 900℃ 1000℃ Dolomite 95.84 68.76 66.11 53.43 52.31 Sample 1 15.82 13.44 11.45 11.40 10.86 Sample 2 16.51 16.45 15.87 16.19 16.27 Sample 3 17.16 15.96 15.10 15.40 15.35 Sample 4 17.97 15.05 13.94 15.01 14.72 Sample 5 18.80 14.00 13.33 14.80 14.62 -

[1] 赵海波, 宋蔷, 吴兴远, 姚强.稻秆焦炭热解和CO2气化过程中碱金属和碱土金属的迁移[J].燃料化学学报, 2018, 46(1):27-33. doi: 10.3969/j.issn.0253-2409.2018.01.004ZHAO Hai-bo, SONG Qiang, WU Xing-yuan, YAO Qiang. Transformation of alkali and alkaline earth metallic species during pyrolysis and CO2 gasification of rice straw char[J]. J Fuel Chem Technol, 2018, 46(1):27-33. doi: 10.3969/j.issn.0253-2409.2018.01.004 [2] 王茜, 韩奎华, 李辉, 齐建荟, 路春美. O2/CO2气氛下稻秆添加磷酸二氢铵对固钾及灰熔融特性的研究[J].燃料化学学报, 2015, 43(8):955-960. doi: 10.3969/j.issn.0253-2409.2015.08.008WANG Qian, HAN Kui-hua, LI Hui, QI Jian-hui, LU Chun-mei. Influence of ammonium dihydrogen phosphates additive on potassium fixation capacity and ash fusibility for rice straw combustion in an O2/CO2 atmosphere[J]. J Fuel Chem Technol, 2015, 43(8):955-960. doi: 10.3969/j.issn.0253-2409.2015.08.008 [3] MU L, ZHAO L, LIU L, YIN H. Elemental distribution and mineralogical composition of ash deposits in a large-scale wastewater incineration plant:A case study[J]. Ind Eng Chem Res, 2012, 51(25):8684-8694. doi: 10.1021/ie301074m [4] SANDBERG J, KARLSSON C, FDHILA B. A 7year long measurement period investigating the correlation of corrosion, deposit and fuel in a biomass fired circulated fluidized bed boiler[J]. Appl Energy, 2011, 88(1):99-110. https://www.researchgate.net/publication/223097194_A_7year_long_measurement_period_investigating_the_correlation_of_corrosion_deposit_and_fuel_in_a_biomass_fired_circulated_fluidized_bed_boiler [5] LI G, LI S, XU X, HUANG Q, YAO Q. Dynamic behavior of biomass ash deposition in a 25 kW one-dimensional down-fired combustor[J]. Energy Fuels, 2013, 28(1):219-227. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=e051c484f630c0edef1b382f294037f9 [6] NIU Y, ZHU Y, TAN H, HUI S, JING Z, XU W. Investigations on biomass slagging in utility boiler:Criterion numbers and slagging growth mechanisms[J]. Fuel Process Technol, 2014, 128:499-508. doi: 10.1016/j.fuproc.2014.07.038 [7] WANG L, HUSTAD E, SKREIBERG Ø, SKJEVRAK G, GRØNLI M. A critical review on additives to reduce ash related operation problems in biomass combustion applications[J]. Energy Procedia, 2012, 20:20-29. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=CC0213758168 [8] YANG M, XIE Q, WANG X, DONG H, ZHANG H, LI C. Lowering ash slagging and fouling tendency of high-alkali coal by hydrothermal pretreatment[J]. Int J Min Sci Technol, 2019, 29(3):521-525. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=zgkydxxb-e201903020 [9] NINOMIYA Y, ZHANG L, SAKANO T, KANAOKA C, MASUI M. Transformation of mineral and emission of particulate matters during co-combustion of coal with sewage sludge[J]. Fuel, 2004, 83(6):751-764. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=0c15b3ff02b7611027db161624e59ca1 [10] STRINGER J, WRIGHT G. Current limitations of high-temperature alloys in practical applications[J]. Oxid Met, 1995, 44(1/2):265-308. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=10.1177/004051755302300505 [11] WANG Q, CHEN N, YU Y, FENG C, NING Q, HU W. Chromium(Ⅵ) removal from aqueous solution using a new synthesized adsorbent[J]. Desalin Water Treat, 2016, 57(10):4537-4547. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=14c8ce66576d722d8e62d81846b5edd4 [12] 易其国, 张永光, 齐方杰, 肖波, 李方华.木质生物燃料与其半焦的混燃实验研究[J].环境科学学报, 2014, 34(9):2407-2412. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hjkxxb201409031YI Qi-guo, ZHANG Yong-guang, QI Fang-jie, XIAO bo, LI Fang-hua. Experimental studies on co-firing lignocellulosic biomass with biochar[J]. J Environ Sci-China, 2014, 34(9):2407-2412. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hjkxxb201409031 [13] 牛永红, 韩枫涛, 张雪峰, 王丽, 许嘉, 陈义胜.白云石催化松木燃料棒水蒸气气化试验[J].农业机械学报, 2016, 47(12):246-252. doi: 10.6041/j.issn.1000-1298.2016.12.030NIU Yong-hong, HAN Feng-tao, ZHANG Xue-feng, WANG Li, XU Jia, CHEN Yi-sheng. Transactions of the Chinese Society for Agricultural Machinery[J]. Trans Chin Soc Agric Mach, 2016, 47(12):246-252. doi: 10.6041/j.issn.1000-1298.2016.12.030 [14] LLORENTE F, AROCAS D, NEBOT G, GARCÍA C. The effect of the addition of chemical materials on the sintering of biomass ash[J]. Fuel, 2008, 87(12):2651-2658. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=69a08c332535b370090ff1b60dfc8987 [15] WANG L, BECIDAN M, SKREIBERG Ø. Sintering behavior of agricultural residues ashes and effects of additives[J]. Energy Fuels, 2012, 26(9):5917-5929. doi: 10.1021/ef3004366 [16] THY P, JENKINS M, GRUNDVIG S, SHIRAKI R, LESHER E. High temperature elemental losses and mineralogical changes in common biomass ashes[J]. Fuel, 2006, 85(5):783-795. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=8ee44008f72168d20b8202711a3609c9 [17] CHIN K, H'NG P, MAMINSKI M, GO W, LEE C, RAJA-NAZRIN R, KHOO P, ASHIKIN S, HALIMATUN I. Additional additives to reduce ash related operation problems of solid biofuel from oil palm biomass upon combustion[J]. Ind Crop Prod, 2018, 123:285-295. doi: 10.1016/j.indcrop.2018.06.081 [18] CHIN K, H'NG P, PARIDAH M, SZYMONA K, MAMINSKI M, LEE S, LUM W, NURLIYANA M, CHOW M, GO W. Reducing ash related operation problems of fast growing timber species and oil palm biomass for combustion applications using leaching techniques[J]. Energy, 2015, 90:622-630. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=52227577be43f5a114e31645756d072c [19] 周上坤, 王萌, 谭厚章, 熊小鹤, 吕钊敏, 杨富鑫.蛭石对高钠高钙准东煤结渣特性影响研究[J].燃料化学学报, 2019, 47(4):419-427. http://manu60.magtech.com.cn/rlhxxb/CN/abstract/abstract29373.shtmlZHOU Shang-kun, WANG Meng, TAN Hou-zhang, XIONG Xiao-he, LÜ Zhao-min, YANG Fu-xin. Effect of vermiculite on the slagging characteristics of high sodium and high calcium Zhundong coal[J]. J Fuel Chem Technol, 2019, 47(4):419-427. http://manu60.magtech.com.cn/rlhxxb/CN/abstract/abstract29373.shtml [20] SCHMITT E, KALTSCHMITT M. Effect of straw proportion and Ca-and Al-containing additives on ash composition and sintering of wood-straw pellets[J]. Fuel, 2013, 109:551-558. doi: 10.1016/j.fuel.2013.02.064 [21] WANG C, ZHAO L, HAN T, CHEN W, YAN Y, JIN X, CHE D. Release and transformation behaviors of sodium, calcium, and Iron during Oxy-fuel combustion of Zhundong coals[J]. Energy Fuels, 2018, 32(2):1242-1254. doi: 10.1021/acs.energyfuels.7b03200 [22] LI X, LI J, WU G, BAI Z, LI W. Clean and efficient utilization of sodium-rich Zhundong coals in China:Behaviors of sodium species during thermal conversion processes[J]. Fuel, 2018, 218:162-173. doi: 10.1016/j.fuel.2018.01.027 [23] KNUDSEN N, JENSEN A, LIN W, DAM-JOHANSEN K. Secondary capture of chlorine and sulfur during thermal conversion of biomass[J]. Energy Fuels, 2005, 19(2):606-617. doi: 10.1021/ef049874n [24] WU H, GLARBORG P, FRANDSEN J, DAM-JOHANSEN K, JENSEN A. Dust-firing of straw and additives:Ash chemistry and deposition behavior[J]. Energy Fuels, 2011, 25(7):2862-2873. doi: 10.1021/ef200452d -

下载:

下载: