Performance of activated carbon supported nickel catalysts in the pyrolysis of waste plastics to produce carbon nanotubes

-

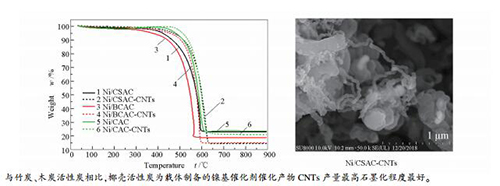

摘要: 以椰壳炭、竹炭和木炭三种活性炭为载体,采用浸渍法制备炭负载金属镍的催化剂,考察其在废塑料裂解制备碳纳米管过程中的催化反应性能;采用X射线衍射、扫描电镜、透射电镜、拉曼光谱仪、同步热分析仪、比表面积分析仪等手段分析了催化剂和产物碳纳米管的形貌和结构。结果表明,椰壳活性炭为载体制备的镍基催化剂上碳纳米管产量最高、石墨化程度最好。以椰壳活性炭为载体制备的镍基催化剂为例,研究了反应温度和镍负载量对其催化性能的影响。Abstract: A series of Ni based catalysts are prepared through impregnation method with coconut shell, bamboo charcoal and charcoal activated carbons as the support; their catalytic performance in the pyrolysis of waste plastics to produce carbon nanotubes was comparatively investigated. The structure and morphology of the catalyst and carbon nanotubes were characterized by X-ray diffraction, scanning electron microscope, transmission electron microscope, Raman spectroscopy, thermogravimetric analysis and nitrogen physisorption. The results show that carbon nanotubes with the highest yield and the best quality can be produced by using the nickel catalyst supported on coconut shell activated carbon (Ni/CSAC). In addition, the effect of reaction temperature and nickel loading on the catalytic performance of Ni/CSAC in the pyrolysis of waste plastics was considered.

-

表 1 不同催化剂的比表面积和孔结构特征

Table 1 Surface area and pore-structure characteristic of various catalysts

Sample ABET/ (m2·g-1) Amicro/ (m2·g-1) Ameso/ (m2·g-1) vtotal/ (m3·g-1) vmicro/ (m3·g-1) vmeso/ (m3·g-1) Amicro/ Ameso vmicro/ vmeso Ni/CSAC 545 288 257 0.389 0.149 0.240 1.121 0.621 Ni/BCAC 255 53 202 0.243 0.026 0.217 0.262 0.120 Ni/CAC 969 352 617 0.963 0.183 0.780 0.571 0.235 -

[1] 董欣.废弃塑料治理: 能源化利用或成突破口[N].中国能源报, 2018-06-11(19).DONG Xin. Waste plastics treatment: Energy utilization maybe become breakthrough[N]. China Energy Daily, 2018-06-11(19). [2] TRIPATHI P K, DURBACH S, COVILLE N J. Synthesis of multi-walled carbon nanotubes from plastic waste using a stainless-steel CVD reactor as catalyst[J]. Nanomaterials, 2017, 7(10):284-292. doi: 10.3390/nano7100284 [3] MOO J G S, VEKSHA A, OH W D, GIANNIS A, UDAYANGA W D C, LIN S X, GE L Y, LISAK G. Plastic derived carbon nanotubes for electrocatalytic oxygen reduction reaction:Effects of plastic feedstock and synthesis temperature[J]. Electrochem Commun, 2019, 101:11-18. doi: 10.1016/j.elecom.2019.02.014 [4] 张凌.碳纳米管薄膜的光学性质与应用[D].北京: 清华大学, 2017. http://cdmd.cnki.com.cn/Article/CDMD-10003-1018876558.htmZHANG Ling. The optical properties and applications of carbon nanotube film[D]. Beijing: University of Tsinghua, 2017. http://cdmd.cnki.com.cn/Article/CDMD-10003-1018876558.htm [5] LIU X T, SHEN B X, WU Z T, PARLETT C M A, HAN Z N, GEORGE A, YUAN P, PATEL D, WU C F. Producing carbon nanotubes from thermochemical conversion of waste plastics using Ni/ceramic based catalyst[J]. Chem Eng Sci, 2018, 192:882-891. doi: 10.1016/j.ces.2018.07.047 [6] HUH Y, GREEN M L H, KIM Y H, KIM Y H, LEE J Y, LEE C J. Control of carbon nanotube growth using cobalt nanoparticles as catalyst[J]. Appl Surf Sci, 2005, 249(1/4):145-150. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=d02df638cef52d9a5767caf2f131967e [7] MHLANGA S D, MONDAL K C, CARTER R, WITCOMB M J, COVILLE N J. The effect of synthesis parameters on the catalytic synthesis of multiwalled carbon nanotubes using Fe-Co/CaCO3 catalysts[J]. S Afr J Chem, 2009, 65(14):39-49. https://www.ajol.info/index.php/sajc/article/viewFile/123210/112750 [8] YAO D D, WU C F, YANG H P, ZHANG Y S, NAHIL M A, CHEN Y Q, WILLIAMS P T, CHEN H P. Co-production of hydrogen and carbon nanotubes from catalytic pyrolysis of waste plastics on Ni-Fe bimetallic catalyst[J]. Energy Convers Manage, 2017, 148:692-700. doi: 10.1016/j.enconman.2017.06.012 [9] LIU X T, ZHANG Y S, NAHIL M A, WILLIAMS P T, WU C F. Development of Ni-and Fe-based catalysts with different metal particle sizes for the production of carbon nanotubes and hydrogen from thermo-chemical conversion of waste plastics[J]. J Anal Appl Pyrolysis, 2017, 125:32-39. doi: 10.1016/j.jaap.2017.05.001 [10] SIVAKUMAR V M, ABDULLAH A Z, MOHAMED A R, CHAI S P. Optimized parameters for carbon nanotubes synthesis over Fe and Ni catalysts VIA methane CVD[J]. Rev Adv Mater Sci, 2011, 27(1):25-30. https://www.researchgate.net/publication/267404270_Optimized_parameters_for_carbon_nanotubes_synthesis_over_Fe_and_Ni_catalysts_VIA_methane_CVD [11] ACOMB J C, WU C, WILLIAMS P T. The use of different metal catalysts for the simultaneous production of carbon nanotubes and hydrogen from pyrolysis of plastic feedstocks[J]. Appl Catal B:Environ, 2016, 180(894):497-510. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=59c503b0daa6ee1842f8cb506310558f [12] 郑扬帆, 王军凯, 李赛赛, 宋健波, 张海军.高分子塑料催化裂解制备碳纳米管的研究进展[J].耐火材料, 2018, 52(4):304-309+314. doi: 10.3969/j.issn.1001-1935.2018.04.016ZHENG Yang-fan, WANG Jun-kai, LI Sai-sai, SONG Jian-bo, ZHANG Hai-jun. Research progress in preparaton of carbon nanotubes bu catalytic pyrolysis of polymer plastics[J]. Refractories, 2018, 52(4):304-309+314. doi: 10.3969/j.issn.1001-1935.2018.04.016 [13] JIANG Z W, SONG R J, BI W G, LU J, TANG T. Polypropylene as a carbon source for the synthesis of multi-walled carbon nanotubes via catalytic combustion[J]. Carbon, 2007, 45(2):449-458. doi: 10.1016/j.carbon.2006.08.012 [14] 张立剑.基于活性炭的高级还原体系构建及去除水中Cr(Ⅵ)污染效能研究[D].长春: 吉林大学, 2018. http://cdmd.cnki.com.cn/Article/CDMD-10183-1019001331.htmZHANG Li-jian. Expermental study on construction of advanced reduction system and removal of Cr(Ⅵ)from wastewater based on activated carbon[D]. Changchun: University of Jilin, 2018. http://cdmd.cnki.com.cn/Article/CDMD-10183-1019001331.htm [15] GONZÁLEZ Y S, COSTA C, MARQUEZ M C, RAMOS P. Thermal and catalytic degradation of polyethylene wastes in the presence of silica gel, 5A molecular sieve and activated carbon[J]. J Hazard Mater, 2011, 187(1/3):101-112. http://cn.bing.com/academic/profile?id=1b02404e36579753fa91d7b93b497680&encoded=0&v=paper_preview&mkt=zh-cn [16] GONG J, LIU J, JIANG Z W, WEN X, CHEN X C, MIJOWSKA E, WANG Y H, TANG T. Effect of the added amount of organically-modified montmorillonite on the catalytic carbonization of polypropylene into cup-stacked carbon nanotubes[J]. Chem Eng J, 2013, 225(6):798-808. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=b81c3b88564021f6c05b63b2fba67efc [17] GONG J, LIU J, WAN D, CHEN X C, WEN X, MIJOWSKA E, JIANG ZW, WANG Y H, TANG T. Catalytic carbonization of polypropylene by the combined catalysis of activated carbon with Ni2O3 into carbon nanotubes and its mechanism[J]. Appl Catal A:Gen, 2012, 449(1):112-120. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=a228c7dac18d7634f348543f545356c6 [18] FUERTES A B, ALVAREZ S. Graphitic mesoporous carbons synthesised through mesostructured silica templates[J]. Carbon, 2004, 42(15):3049-3055. doi: 10.1016/j.carbon.2004.06.020 [19] LIOU T H. Development of mesoporous structure and high adsorption capacity of biomass-based activated carbon by phosphoric acid and zinc chloride activation[J]. Chem Eng J, 2010, 158(2):129-142. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=3892d5252eb81d725b4c6137ac12c1b2 [20] WAN H Z, LI L, CHEN Y, GONG J L, DUAN M Q, LIU C, ZHANG J, WANG H. One pot synthesis of Ni12P5 hollow nanocapsules as efficient electrode materials for oxygen evolution reactions and supercapacitor applications[J]. Electrochim Acta, 2017, 229:380-386. doi: 10.1016/j.electacta.2017.01.169 [21] HUANG Z P, CHEN Z B, CHEN Z Z, LV C C, MENG H, ZHANG C. Ni12P5 Nanoparticles as an efficient catalyst for hydrogen generation via electrolysis and photoelectrolysis[J]. ACS Nano, 2014, 8(8):8121-8129. doi: 10.1021/nn5022204 [22] ABOUL-ENEIN A A, AWADALLAH A E. Production of nanostructured carbon materials using Fe-Mo/MgO catalysts via mild catalytic pyrolysis of polyethylene waste[J]. Chem Eng J, 2018, 354:802-816. doi: 10.1016/j.cej.2018.08.046 [23] GONG J, LIU J, WAN D, CHEN X C, WEN X, MIJOWSKA E, JIANG Z W, WANG Y H, TANG T. Catalytic carbonization of polypropylene by the combined catalysis of activated carbon with Ni2O3 into carbon nanotubes and its mechanism[J]. Appl Catal A:Gen, 2012, 449:112-20. doi: 10.1016/j.apcata.2012.09.028 [24] LIU X T, SUN H M, WU C F, PATEL D, HUANG J. Thermal chemical conversion of high-density polyethylene for the production of valuable carbon nanotubes using Ni/AAO membrane catalyst[J]. Energy Fuels, 2018, 32(4):4511-4520. doi: 10.1021/acs.energyfuels.7b03160 [25] DANAFAR F, FAKHRU'L-RAZI A, SALLEH M A M, BIAK D R A. Fluidized bed catalytic chemical vapor deposition synthesis of carbon nanotubes-A review[J]. Chem Eng J, 2009, 155(1/2):37-48. http://cn.bing.com/academic/profile?id=5d157aba80fa132f0df1384aecc617c9&encoded=0&v=paper_preview&mkt=zh-cn -

下载:

下载: