Influence of carbonization degree of walnut shell char on pore structure and combustion characteristics

-

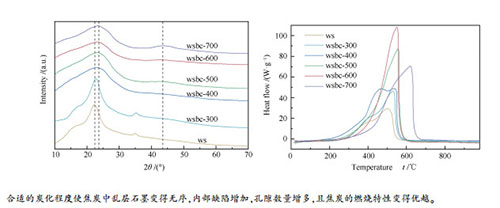

摘要: 利用傅里叶变换红外光谱仪(FT-IR)、扫描电子显微镜(SEM)和X射线衍射仪(XRD)研究了炭化程度对核桃壳焦孔隙及微晶结构的影响,并使用热重-差示扫描量热仪(TG-DSC)对核桃壳焦及其原料的燃烧特性进行了分析。结果表明,合适的炭化程度(焦炭挥发分含量为6%-15%)使焦炭内乱层石墨变得无序,碳质微晶结构中缺陷增多,导致焦炭内孔隙结构相对发达;热解温度为500 ℃时,核桃壳焦的比表面积最大,为374.60 m2/g;热解温度为600 ℃时,核桃壳焦的燃烧特性最优,其燃烧特性指数为7.16×106;合适的炭化程度可使焦炭内的挥发分含量减少,从而使得核桃壳焦的高位热值升高,且由于相对发达的孔隙使焦炭在燃烧时与空气的接触面积增大,导致焦炭的燃烧速率加快。Abstract: The effect of carbonization degree on pore structure and microstructure of walnut shell chars was studied by Fourier transform infrared spectroscopy (FT-IR), scanning electron microscopy (SEM) and X-ray diffraction (XRD). The combustion characteristics of raw material and walnut shell chars were analyzed using a thermogravimetry coupled with differential scanning calorimeter (TG-DSC). The results show that the appropriate degree of carbonization (volatile content is 6%-15%) leads to the disorderly crystallization of turbostratic and the increase of defects in the carbonaceous microcrystalline structure, which causes a relatively flourishing pore structure and an increase of specific surface. Pyrolysis char at temperature of 500℃ has the maximum specific surface area of 374.60 m2/g, while walnut shell char prepared at 600℃ has the optimal combustion characteristics with the combustion characteristics index of 7.16×106, which indicate that the appropriate carbonization degree of char could reduce the volatile content and increase the higher calorific value of char during combustion process. Moreover, the developed pore structure can increase the contact area between char and air, leading to the accelerated combustion rate of char.

-

表 1 核桃壳的工业分析和元素分析

Table 1 Proximate and ultimate analyses of walnut shell

Proximate analysis war/% Ultimate analysis war/% QHHV/(MJ·kg-1) M V A FCa C H Ob N S 3.73 74.32 0.97 20.98 50.54 5.84 43.02 0.34 0.26 19.20 a, b: calculated by difference 表 2 核桃壳焦的工业分析和元素分析

Table 2 Proximate and ultimate analyses of walnut shell char

Sample Proximate analysis wd/% Ultimate analysis wd/% O/C H/C QHHV/(MJ·kg-1) w/% V A FCa C H Ob N S wsbc-300 65.14 0.94 39.92 59.97 5.32 34.41 0.05 0.25 0.57 0.09 23.18 84.62 wsbc-400 39.25 1.97 58.78 79.00 4.10 16.54 0.08 0.28 0.21 0.05 29.92 33.31 wsbc-500 14.87 2.44 82.69 85.35 3.61 10.69 0.09 0.26 0.13 0.04 32.55 27.20 wsbc-600 6.59 2.72 90.69 90.57 3.10 5.98 0.11 0.24 0.07 0.03 33.53 24.55 wsbc-700 5.11 3.64 91.25 92.37 2.64 4.66 0.11 0.22 0.05 0.03 33.46 22.83 a, b: calculated by difference 表 3 核桃壳焦的燃烧特性指数

Table 3 Combustion characteristic index of walnut shell chars

Sample wsbc-300 wsbc-400 wsbc-500 wsbc-600 wsbc-700 Temperature range Δt/℃ 326-537 378-548 430-562 444-556 469-633 Wavg/(%·min-1) 22.64 19.18 27.56 31.75 20.03 Wmax/(%·min-1) 10.96 15.88 24.24 24.71 15.85 S/×106 4.35 3.89 6.43 7.16 2.28 表 4 核桃壳焦的燃烧效率参数

Table 4 Combustion efficiency parameters of walnut shell chars

Sample wsbc-300 wsbc-400 wsbc-500 wsbc-600 wsbc-700 ΔQ/(MJ·kg-1) 16.70 21.23 26.15 27.75 25.22 η/% 72.04 70.96 80.34 80.69 75.37 -

[1] LIU Z, HAN G. Production of solid fuel biochar from waste biomass by low temperature pyrolysis[J]. Fuel, 2015, 158: 159-165. doi: 10.1016/j.fuel.2015.05.032 [2] TAN X, LIU S, LIU Y, GU Y, ZENG G, HU X, WANG X, LIU S. Biochar as potential sustainable precursors for activated carbon production: multiple applications in environmental protection and energy storage[J]. Bioresour Technol, 2017, 227: 359-372. doi: 10.1016/j.biortech.2016.12.083 [3] 李文跃, 吴诗勇, 吴幼青, 黄胜, 高晋生.微孔椰壳焦孔结构表征[J].燃料化学学报, 2019, 47(3): 297-305. http://www.cnki.com.cn/Article/CJFDTotal-RLHX201903006.htmLI Wen-yue, WU Shi-yong, WU You-qing, HUANG Sheng, GAO Jin-sheng. Pore structure characterization of coconut shell char with narrow microporosity[J]. J Fuel Chem Technol, 2019, 47(3): 297-305. http://www.cnki.com.cn/Article/CJFDTotal-RLHX201903006.htm [4] 耿毅德, 梁卫国, 刘剑, 康志勤, 武鹏飞, 姜玉龙.不同温压条件下油页岩孔裂隙结构演化试验研究[J].岩石力学与工程学报, 2018, 37(11): 2510-2519. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=yslxygcxb201811010GENG Yi-de, LIANG Wei-guo, LIU Jian, KANG Zhi-qin, WU Peng-fei, JIANG Yu-long. Experimental study on the variation of pore and fracture structure of oil shale under different temperatures and pressures[J]. Chin J Rock Mech Eng, 2017, 227: 359-372. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=yslxygcxb201811010 [5] 丘倩媛, 陈倩阳, 刘志军, 刘江.以椰壳生物质炭为燃料的直接炭固体氧化物燃料电池[J].燃料化学学报, 2019, 47(3): 352-360. http://www.ccspublishing.org.cn/article/id/606b92ca-0005-4c6e-a088-28e5a23f07f3QIU Qian-yuan, CHEN Qian-yang, LIU Zhi-jun, LIU Jiang. Biochar derived from coconut as fuel for the direct carbon solid oxide fuel cell. J Fuel Chem Technol, 2019, 47(3): 352-360. http://www.ccspublishing.org.cn/article/id/606b92ca-0005-4c6e-a088-28e5a23f07f3 [6] 汪岸, 骆仲泱, 方梦祥, 岑建梦, 姚鹏.煤热解沥青炭化程度对KOH活化制备活性炭孔隙结构的影响[J].浙江大学学报(工学版), 2018, 52(8): 1551-1557. http://d.old.wanfangdata.com.cn/Periodical/zjdxxb-gx201808015WANG An, LUO Zhong-yang, FANG Meng-xiang, CEN Jian-meng, YAO Peng. Influence of carbonization degree of coal pyrolytic pitch on the pore structure of carbon activated with KOH[J]. J Zhejiang Univ, 2018, 52(8): 1551-1557. http://d.old.wanfangdata.com.cn/Periodical/zjdxxb-gx201808015 [7] 周芳磊, 胡雨燕, 陈德珍.不同种类生物质热解残焦的CO2气化研究[J].太阳能学报, 2017, 38(5): 1440-1446. http://d.old.wanfangdata.com.cn/Periodical/tynxb201705038ZHOU Fang-lei, HU Yu-yan, CHEN De-zhen. Production of CO by CO2 gasification of biomass-derived char[J]. Acta Energ Sol Sin, 2017, 38(5): 1440-1446. http://d.old.wanfangdata.com.cn/Periodical/tynxb201705038 [8] CHEN T, CAI J, LIU R. Combustion kinetics of biochar from fast pyrolysis of pine sawdust: isoconversional analysis[J]. Energy Sin, 2015, 37(20): 2208-2217. http://cn.bing.com/academic/profile?id=08c27a67503f64d6bf49bcdca477e6b4&encoded=0&v=paper_preview&mkt=zh-cn [9] YOUSAF B, LIU G, ABBAS Q, WANG R, ALI M U, ULLAH H, LIU R, ZHOU C. Systematic investigation on combustion characteristics and emission-reduction mechanism of potentially toxic elements in biomass-and biochar-coal co-combustion systems[J]. Appl Energy, 2017, 208: 142-157. doi: 10.1016/j.apenergy.2017.10.059 [10] DUNNIGAN L, ASHMAN P J, ZHANG X, KWONG C. Production of biochar from rice husk: Particulate emissions from the combustion of raw pyrolysis volatiles[J]. J Clean Prod, 2018, 172: 1639-1645. doi: 10.1016/j.jclepro.2016.11.107 [11] BRASSARD P, GODBOUT S, RAGHAVAN V, PALACIOS H J, GRENIER M, DAN Z. The production of engineered biochars in a vertical auger pyrolysis reactor for carbon sequestration[J]. Energies, 2017, 10(3): 288. doi: 10.3390/en10030288 [12] 白云坡, 杨勇, 王珏, 郑林, 廉鹏飞, 青明, 王有良, 王洪, 张广积.炭化过程对铁基费托合成催化剂强度和结构的影响[J].燃料化学学报, 2018, 46(2): 204-210. doi: 10.3969/j.issn.0253-2409.2018.02.010BAI Yun-po, YANG Yong, WANG Jue, ZHENG Lin, LIAN Peng-fei, QING Ming, WANG You-liang, WANG Hong, ZHANG Guang-ji. Effect of carbonization process on the strength and structure of Fe-based Fischer-Tropsch synthesis catalyst[J]. J Fuel Chem Technol, 2018, 46(2): 204-210. doi: 10.3969/j.issn.0253-2409.2018.02.010 [13] LI K, ZHU C, ZHANG L, ZHU X. Study on pyrolysis characteristics of lignocellulosic biomass impregnated with ammonia source[J]. Bioresour Technol, 2016, 209: 142-147. doi: 10.1016/j.biortech.2016.02.136 [14] CHEN D, ZHENG Y, ZHU X. In-depth investigation on the pyrolysis kinetics of raw biomass. Part Ⅰ: Kinetic analysis for the drying and devolatilization stages[J]. Bioresour Technol, 2013, 131: 40-46. doi: 10.1016/j.biortech.2012.12.136 [15] 朱谢飞, 李凯, 马善为, 朱锡锋.生物油蒸馏残渣理化性质及热失重研究[J].燃料化学学报, 2017, 45(1): 29-33. doi: 10.3969/j.issn.0253-2409.2017.01.005ZHU Xie-fei, LI Kai, MA Shan-wei, ZHU Xi-feng. Physicochemical characteristics and TGA of distillation residues from bio-oil[J]. J Fuel Chem Technol, 2017, 45(1): 29-33. doi: 10.3969/j.issn.0253-2409.2017.01.005 [16] 李晓辉.活性炭纤维在热处理过程中的结构变化及电化学性能[D].上海: 华东理工大学, 2018.LI Xiao-hui. Structure changes and electrochemical performance of activated carbon fibers during heat-treatment[D]. Shanghai: East China University of Science and Technology, 2018. [17] 王爽, 姜秀民, 王谦, 吉恒松.海藻生物质颗粒流化床燃烧试验研究[J].化工学报, 2013, 64(5): 1592-1600. doi: 10.3969/j.issn.0438-1157.2013.05.013WANG Shuang, JIANG Xiu-min, WANG Qian, JI Heng-song. Fluidized bed combustion of seaweed biomass particles[J]. J Chem Ind Eng, 2013, 64(5): 1592-1600. doi: 10.3969/j.issn.0438-1157.2013.05.013 [18] KRÓI M, GRYGLEWICAZ G, MACHNIKOWSKI J. KOH activation of pitch-derived carbonaceous materials-Effect of carbonization degree[J]. Fuel Process Technol, 2011, 92(1): 158-165. doi: 10.1016/j.fuproc.2010.09.019 [19] 林淑萍, 徐浩, 罗诗渊, 马志超, 林起浪.新型沥青基高比表面积活性炭的制备及性能[J].化工新型材料, 2015, 43(12): 137-139. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hgxxcl201512046LIN Shu-ping, XU Hao, LUO Shi-yuan, MA Zhi-chao, LIN Qi-liang. Preparation and property of pitch-based activated carbons with high surface area[J]. New Chem Mater, 2015, 43(12): 137-139. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hgxxcl201512046 [20] KANEKO K, ISHII C, RUIKE M. Origin of superhigh surface area and microcrystalline graphitic structures of activated carbons[J]. Carbon, 1992, 30(7): 1075-1088. doi: 10.1016/0008-6223(92)90139-N [21] WANG G, YANG J, PARK J, GOU X, WANG B, LIU H, YAO J. Facile synthesis and characterization of graphene nanosheets[J]. J Phys Chem C, 2008, 112(22): 8192-8195 doi: 10.1021/jp710931h [22] ZHANG L, LI S, LI K, ZHU X. Two-step pyrolysis of corncob for value-added chemicals and high quality bio-oil: Effects of pyrolysis temperature and residence time[J]. Energy Convers Manage, 2018, 166: 260-267. doi: 10.1016/j.enconman.2018.04.002 [23] 陈鸿, 孙学信, 韩才元, 崔和平.煤粉孔隙结构对燃烧过程的影响[J].化工学报, 1994, 4(3): 327-333. http://www.cqvip.com/Main/Detail.aspx?id=1383194CHEN Hong, SUN Xue-xin, HAN Cai-yuan, CUI He-ping. Effects of porous structure on coal particle reactivity of combustion[J]. J Chem Ind Eng, 1994, 4(3): 327-333. http://www.cqvip.com/Main/Detail.aspx?id=1383194 [24] 熊邵武, 张守玉, 吴巧美, 郭熙, 董爱霞, 陈川, 郑红俊, 邓文祥, 刘大海, 唐文蛟.生物质炭燃烧特性与动力学分析[J].燃料化学学报, 2013, 41(8): 958-965. doi: 10.3969/j.issn.0253-2409.2013.08.009XIONG Shao-wu, ZHANG Shou-yu, WU Qiao-mei, GUO Xi, DONG Ai-xia, CHEN Chuan, ZHENG Hong-jun, DENG Wen-xiang, LIU Da-hai, TANG Wen-jiao. Investigation on combustion characterisitcs and kinetics of bio-char[J]. J Fuel Chem Technol, 2013, 64(8): 958-965. doi: 10.3969/j.issn.0253-2409.2013.08.009 [25] 邹冲, 温良英, 张生富, 白晨光, 吕学伟, 王昆, 谭秀琴.过氧化钙对煤粉燃烧效率的影响[J].中国电机工程学报, 2012, 32(5): 15-20. http://d.old.wanfangdata.com.cn/Periodical/zgdjgcxb201205004ZOU Chong, WEN Liang-ying, ZHANG Sheng-fu, BAI Chen-guang, LV Xue-wei, WANG Kun, TAN Xiu-qin. Effect of calcium peroxide on combustion efficiency of pulverized coal[J]. Proc CSEE, 2012, 32(5): 15-20. http://d.old.wanfangdata.com.cn/Periodical/zgdjgcxb201205004 -

下载:

下载: