Effect of hydrothermal treatment on Na and Ca migration behavior during pyrolysis of Baishihu coal

-

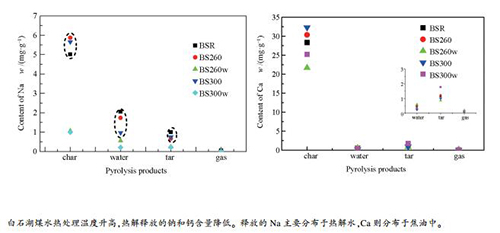

摘要: 采用高压釜对富镜质组白石湖煤进行了水热处理,通过傅里叶红外光谱(FT-IR)分峰拟合方法分析了煤中含氧官能团变化。在固定床中开展分离废液和未分离废液水热处理煤样的热解实验,利用原子吸收分光光度计(AAS)测定了热解产物中钠钙含量。结果表明,白石湖煤经水热处理后水分、挥发分、氧含量以及Cl、Na和Ca等无机元素含量明显降低。水热处理过程中芳香醚水解和羧酸盐发生离子交换反应使得氢含量和H/C原子比增加,促进固定床热解焦油产率升高。300℃下水热处理脱除了部分有机形式Ca后随水废液被分离;废液中钠钙等无机元素的催化作用导致未分离废液较分离废液的样品具有更高热解气产率和更低焦油产率。白石湖原煤及其水热处理样品热解产物中Na含量和分布由高到低顺序均为:热解焦>热解水>焦油>热解气,Ca含量和分布顺序为:热解焦>焦油>热解水>热解气。水热处理温度越高,热解过程钠和钙释放率越低,释放的Na主要进入热解水,其次焦油;而释放的Ca则主要分布于焦油中,其次热解水。Abstract: Vitrinite-rich Baishihu coal (BSR) was hydrothermally treated in an autoclave. FT-IR spectra peak fitting was used to investigate change of oxygen functional groups. Fixed bed was applied to pyrolysis of hydrothermal treated samples with and without separation of liquid waste, then contents of Na and Ca in these pyrolysis products were determined by atomic absorption spectrophotometer (AAS).The results show that moisture and chlorine content in Baishihu coal and Na2O content in ash decrease significantly after hydrothermal treatment. The hydrolysis of aryl ethers of Baishihu coal and the ion exchange reaction of carboxylate lead to increase of hydrogen content and H/C atomic ratio, promoting increase of tar yield during pyrolysis. The organic Ca can be removed by hydrothermal treatment at 300℃ and is separated with the hydrothermal liquid waste. Because of catalysis of inorganic elements such as sodium and calcium in hydrothermal liquid on coal pyrolysis, the hydrothermal treated samples without separation of liquid waste has higher gas yield and lower tar yield than those with separation of liquid waste. Na content and distribution in pyrolysis products of BSR and treated samples decease as:char > water > tar > gas, while the order of Ca is:char > tar > water > gas. As the hydrothermally treated temperature increases, the released content of sodium and calcium during pyrolysis process decreases. The released Na during pyrolysis mainly distributes in water, followed by tar, while Ca is just opposite.

-

表 1 白石湖煤水热处理前后工业分析和元素分析

Table 1 Proximate and ultimate analyses of coal samples before and after hydrothermal treatment

Sample Proximate analysis w/% Ultimate analysis wdaf/% St, d

w/%Cld

w/%H/Cb O/Cb Mad Ad Vdaf FCda C H N Oa BSR 13.42 15.07 52.97 39.94 72.81 4.82 0.82 21.13 0.34 0.412 0.79 0.22 BS260w 5.33 16.15 50.78 41.27 74.44 5.25 0.88 19.02 0.34 0.026 0.85 0.19 BS300w 5.20 16.84 48.41 42.90 77.14 5.23 0.95 16.28 0.34 0.023 0.81 0.16 BS260 5.42 17.21 50.63 42.35 74.35 5.17 0.83 19.21 0.37 0.353 0.83 0.19 BS300 5.18 17.66 48.77 43.83 77.39 5.10 0.89 16.25 0.36 0.319 0.79 0.16 note: a: by difference; b: atomic molar ratio 表 2 白石湖煤水热处理前后煤灰成分分析

Table 2 Ash composition of coal samples

Sample Ash composition w/% SiO2 Al2O3 Fe2O3 TiO2 CaO MgO K2O Na2O MnO2 SO3 P2O5 BSR 46.42 21.99 7.91 0.75 14.34 0.63 0.34 3.10 0.17 3.87 0.05 BS260w 45.77 22.38 9.02 0.72 13.80 0.74 0.29 0.39 0.23 5.27 0.03 BS300w 46.54 22.40 8.45 0.72 13.52 0.70 0.30 0.49 0.23 4.80 0.03 BS260 42.75 21.10 8.06 0.66 14.04 0.72 0.32 2.84 0.22 5.59 0.03 BS300 43.69 21.96 8.16 0.68 14.92 0.70 0.31 2.54 0.22 5.00 0.03 表 3 白石湖煤中不同形态钠钙的含量

Table 3 Contents of different kinds of sodium and calcium in BSR

Element Content w/(mg·g-1) water soluble ammonium acetate soluble hydrochloric acid soluble insoluble total Na 3.82(85.4) 0.36(8.1) 0.07(1.5) 0.22(5.0) 4.47 Ca 1.03(5.7) 8.45(46.8) 6.49(36.0) 2.07(11.5) 18.04 amount in the bracket is the percentage of each corresponding element 表 4 含氧官能团位置及分峰拟合的峰面积百分比

Table 4 Main assignment of oxygen functionally groups and area percentage of fitted curves

Position/cm-1 Assignment BSR w/% BS260 w/% BS300 w/% 1005 clay minerals 6.34 13.91 6.83 1035 alkyl ethers 7.03 14.47 18.21 1100 aryl ethers 5.85 4.91 3.91 1167 C-O phenol 2.43 8.63 4.01 1207 C-O phenol 1.37 0.81 4.19 1269 C-O phenol 1.45 0.49 1.36 1310 C-O phenol 0.88 0.45 1.04 1376 CH3-Ar 2.56 1.77 2.47 1442 -CH3, -CH2 6.82 4.02 5.28 1556 aromatic C=C 8.02 7.70 8.63 1588 aromatic C=C 13.92 10.67 12.23 1620 conjugated C=O 18.39 13.88 15.95 1656 conjugated C=O 14.55 10.71 10.64 1696 carboxyl acids 10.39 7.56 5.23 -

[1] 张守玉, 陈川, 施大钟, 吕俊复, 王健, 郭熙, 董爱霞, 熊绍武.高钠煤燃烧利用现状[J].中国电机工程学报, 2013, 33(5):1-12. http://d.old.wanfangdata.com.cn/Periodical/zgdjgcxb201305001ZHANG Shou-yu, CHEN Chuan, SHI Da-zhong, LÜ Jun-fu, WANG Jian, GUO Xi, DONG Ai-xia, XIONG Shao-wu.Situation of combustion utilization of high sodium coal[J]. Proc CSEE, 2013, 33(5):1-12. http://d.old.wanfangdata.com.cn/Periodical/zgdjgcxb201305001 [2] ZHOU H, ZHOU B, ZHANG H, LI L. Behavior of fouling deposits formed on a probe with different surface temperatures[J]. Energy Fuels, 2014, 28:7701-7711. doi: 10.1021/ef502141x [3] 杨涛, 李文广, 吴莎, 王学斌, 谭厚章.新疆高钙钠煤燃烧设备结焦机理研究[J].燃料化学学报, 2015, 43(11):1320-1326. http://www.cnki.com.cn/Article/CJFDTotal-RLHX201511006.htmYANG Tao, LI Wen-guang, WU Sha, ZHANG Lan, WANG Xue-bin, TAN Hou-zhang. Study on fouling mechanism in a boiler burning Xinjiang coal with high content of calcium and sodium[J]. J Fuel Chem Technol, 2015, 43(11):1320-1326. http://www.cnki.com.cn/Article/CJFDTotal-RLHX201511006.htm [4] GAO Q, LI S, YUAN Y, ZHANG Y, YAO Q. Ultrafine particulate matter formation in the early stage of pulverized coal combustion of high-sodium lignite[J]. Fuel, 2015, 158:224-231. doi: 10.1016/j.fuel.2015.05.028 [5] ILYUSHECHKIN A Y, ROBERTS D.Slagging behaviour of Australian brown coals and implications for their use in gasification technologies[J]. Fuel Process Technol, 2016, 147:47-56. doi: 10.1016/j.fuproc.2015.10.028 [6] ZHANG L, TAN H, YANG T, MIKULČIĆ H, DUIĆ N. The ash deposition mechanism in boilers burning Zhundong coal with high contents of sodium and calcium:A study from ash evaporating to condensing[J]. Appl Therm Eng, 2015, 80:150-159. doi: 10.1016/j.applthermaleng.2015.01.051 [7] ZHAO Y, HU H, JIN L, HE X, WU B. Pyrolysis behavior of vitrinite and inertinite from Chinese Pingshuo coal by TG-MS and in a fixed bed reactor[J]. Fuel Process Technol, 2011, 92:780-786. doi: 10.1016/j.fuproc.2010.09.005 [8] 朱川, 曲思建, 张凝凝, 邵徇, 蔡志丹, 张宇宏, 王越, 解强.新疆白石湖富镜质组高碱煤热解特性[J].煤炭学报, 2017, 42(10):2725-2732. http://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201710029.htmZHU Chuan, QU Si-jian, ZHANG Ning-ning, SHAO Xun, CAI Zhi-dan, ZHANG Yu-hong, WANG Yue, XIE Qiang. Pyrolysis characteristics of Xinjiang Baishihuvitrinite-rich coal with high alkali content[J]. J China Coal Soc, 2017, 42(10):2725-2732. http://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201710029.htm [9] 巩志坚.褐煤水热提质研究进展[J].洁净煤技术, 2015, 21(1):41-44+49. http://d.old.wanfangdata.com.cn/Periodical/jjmjs201501011GONG Zhi-jian. Research progress of lignite hydrothermal upgrading technology[J]. Clean Coal Technol, 2015, 21(1):41-44+49. http://d.old.wanfangdata.com.cn/Periodical/jjmjs201501011 [10] XIANG F, HE Y, KUMAR S, WANG Z, LIU L, HUANG Z, LIU J, CEN K. Influence of hydrothermal dewatering on trace element transfer in Yimincoal[J]. Appl Therm Eng, 2017, 117:675-681. doi: 10.1016/j.applthermaleng.2016.12.100 [11] 赵冰, 王嘉瑞, 陈凡敏, 王小悦, 李小江.高钠煤水热脱钠处理及其对燃烧特性的影响[J].燃料化学学报, 2014, 42(12):1416-1422. doi: 10.3969/j.issn.0253-2409.2014.12.002ZHAO Bing, WANG Jia-rui, CHEN Fan-min, WANG Xiao-yue, LI Xiao-jiang. Hydrothermal treatment to remove sodium from highsodium coal anditsinfluence on combustion characteristics[J]. J Fuel Chem Technol, 2014, 42(12):1416-1422. doi: 10.3969/j.issn.0253-2409.2014.12.002 [12] LI G Y, DING J X, ZHANG H, HOU C X, WANG F, LI Y Y, LIANG Y H. ReaxFF simulations of hydrothermal treatment of lignite and its impaction chemical structures[J]. Fuel, 2015, 154:243-251. doi: 10.1016/j.fuel.2015.03.082 [13] ZHANG D, LIU P, LU X, WANG L, PAN T. Upgrading of low rank coal by hydrothermal treatment:Coal tar yield during pyrolysis[J]. Fuel Process Technol, 2016, 141:117-122. doi: 10.1016/j.fuproc.2015.06.037 [14] LI C Z.维多利亚褐煤科学进展[M].余江龙, 常丽萍译.北京: 化学工艺出版社, 2009.LI C Z. Advances in the Victorian Brown Coal[M].YU Jiang-long, CHANG Li-ping translate. Beijing: Chemical Technology Press, 2009. [15] HAYASHI J, MORI T, AMAMOTO S, KUSAKABE A K, MOROOKA S. Flash pyrolysis of brown coal modified by alcohol-vapor explosion treatment[J]. Energy Fuels, 1996, 10(5):1099-1107. doi: 10.1021/ef950118e [16] 杨燕梅, 张扬, 张海, 吴玉新, 刘青, 吕俊复.惰性气氛下准东煤Na/Ca释放特性的研究[J].燃料化学学报, 2018, 46(4):385-390. doi: 10.3969/j.issn.0253-2409.2018.04.001YANG Yan-mei, ZHANG Yang, ZHANG Hai, WU Yu-xin, LIU Qing, LÜ Jun-fu. Release characteristics of Na/Ca in Zhundong coal under inert atmosphere[J]. J Fuel Chem Technol, 2018, 46(4):385-390. doi: 10.3969/j.issn.0253-2409.2018.04.001 [17] 骆安琪, 朱平, 张建树, 曲旋, 张荣, 毕继诚, 张金利.二氧化碳和水气氛对高钠煤转化过程中钠迁移的影响[J].燃料化学学报, 2018, 46(5):513-520. doi: 10.3969/j.issn.0253-2409.2018.05.001LUO An-qi, ZHU Ping, ZHANG Jian-shu, QU Xuan, ZHANG Rong, BI Ji-cheng, ZHANG Jin-li. Effect of atmosphere on sodium migration during conversion of high sodium coals[J]. J Fuel Chem Technol, 2018, 46(5):513-520. doi: 10.3969/j.issn.0253-2409.2018.05.001 [18] 豆斌林, 鲁军, 申文琴, 高晋生, 沙兴中.高温煤气中氯化氢和碱金属蒸气的脱除[J].华东理工大学学报, 2001, 3:273-276. doi: 10.3969/j.issn.1006-3080.2001.03.014DOU Bin-lin, LU Jun, SHEN Wen-qin, GAO Jin-sheng, SHA Xing-zhong. Removal of HCl and Alkali Metal Vapor in High-temperature Coal Gas[J]. J East China Uni Sci Technol, 2001, 3:273-276. doi: 10.3969/j.issn.1006-3080.2001.03.014 [19] 王文慧, 贾宝玉, 姚洪, 李显.准东煤热解过程中钠的迁移规律研究[J].工程热物理学报, 2015, 36(12):2733-2737. http://cdmd.cnki.com.cn/Article/CDMD-10487-1016920069.htmWANG Wen-hui, JIA Bao-yu, YAO Hong, LI Xian. An investigation of sodium transformation in Zhundong coal during pyrolysis[J]. J Eng Thermophysics, 2015, 36(12):2733-2737. http://cdmd.cnki.com.cn/Article/CDMD-10487-1016920069.htm [20] 宋维健, 宋国良, 张海霞, 范金龙, 吕清刚.准东高钠煤热解过程中钠的迁移特性实验研究[J].燃料化学学报, 2015, 43(1):16-21. doi: 10.3969/j.issn.0253-2409.2015.01.003SONG Wei-jian, SONG Guo-liang, ZHANG Hai-xia, FAN Jin-long, LÜ Qing-gang. Experimental study on alkali metal transformation during high-sodium Zhundong coal pyrolysis[J].J Fuel Chem Technol, 2015, 43(1):16-21. doi: 10.3969/j.issn.0253-2409.2015.01.003 [21] WANG Z, LIU Y, WHIDDON R, WAN K, HE Y, XIA J, CEN K. Measurement of atomic sodium release during pyrolysis and combustion of sodium-enriched Zhundong coal pellet[J]. Combust Flame, 2017, 176:429-438. doi: 10.1016/j.combustflame.2016.10.020 [22] 邱朋华, 赵岩, 陈希叶, 徐健健, 杜亚文, 方来熙, 孙绍增.碱及碱土金属对准东煤热解特性及动力学影响分析[J].燃料化学学报, 2014, 42(10):1178-1189. doi: 10.3969/j.issn.0253-2409.2014.10.005QIU Peng-hua, ZHAO Yan, CHEN Xi-ye, XU Jian-jian, DU Ya-wen, FANG Lai-xi, SUN Shao-zeng. Effects of alkali and alkaline earth metallic species on pyrolysis characteristics and kinetics of Zhundongcoal[J]. J Fuel Chem Technol, 2014, 42(10):1178-1189. doi: 10.3969/j.issn.0253-2409.2014.10.005 [23] 刘炎泉, 程乐鸣, 季杰强, 张维国, 王勤辉, 周棋, 聂立.准东煤燃烧碱金属析出气、固相分布特性[J].燃料化学学报, 2016, 44(3):314-320. doi: 10.3969/j.issn.0253-2409.2016.03.008LIU Yan-quan, CHEN Le-ming, JI Jie-qiang, ZHANG Wei-guo, WANG Qin-hui, ZHOU Qi, NIE Li. Distribution characteristics of alkali emission between gas and solid phase during Zhundong coal combustion[J]. J Fuel Chem Technol, 2016, 44(3):314-320. doi: 10.3969/j.issn.0253-2409.2016.03.008 [24] YANG Y, WU Y, ZHANG H, ZHANG M, LIU Q, YANG H, LU J. Improved sequential extraction method for determination of alkali andalkaline earth metals in Zhundongcoals[J]. Fuel, 2016, 181:951-957. doi: 10.1016/j.fuel.2016.05.014 [25] WU J H, WANG J, LIU J Z, YANG Y M, CHENG J, WANG Z H, ZHOU J H. Moisture removal mechanism of low-rank coal by hydrothermal dewatering:Physicochemical property analysis and DFT calculation[J]. Fuel, 2017, 187:242-249. [26] WU J H, WANG J, LIU J Z, YANG Y M, CHENG J, WANG Z H. Moisture removal mechanism of low-rank coal by hydrothermal dewatering:Physicochemical property analysis and DFT calculation[J]. Fuel, 2017, 187:242-249. doi: 10.1016/j.fuel.2016.09.071 [27] 李祥, 秦志宏, 良辉, 杨状, 沈辰阳.炼焦煤的官能团结构分析及其黏结性产生机理[J].燃料化学学报, 2016, 44(4):385-393. doi: 10.3969/j.issn.0253-2409.2016.04.001LI Xiang, QIN Zhi-hong, BU Liang-hui, YANG Zhuang, SHEN Chen-yang. Structural analysis of functional group and mechanism investigation of caking property of coking coal[J]. J Fuel Chem Technol, 2016, 44(4):385-393. doi: 10.3969/j.issn.0253-2409.2016.04.001 [28] GE L C, ZHANG Y W, XU C, WANG Z H, ZHOU J H, CEN K F. Influence of the hydrothermal dewatering on the combustion characteristics of Chinese low-rank coals[J]. Appl Therm Eng, 2015, 90:174-181. doi: 10.1016/j.applthermaleng.2015.07.015 [29] LIU P, LE J, ZHANG D, WANG S, PAN T. Free radical reaction mechanism on improving tar yield and quality derived from lignite after hydrothermal treatment[J]. Fuel, 2017, 207:244-252. doi: 10.1016/j.fuel.2017.06.081 [30] QUYN D M, WU H, BHATTACHARYA S P, LI C Z. Volatilisation and catalytic effects of alkali and alkaline earth metallic species during the pyrolysis and gasification of Victorian brown coal. Part Ⅱ. Effects of chemical form and valence[J]. Fuel, 2002, 81(2):151-158. doi: 10.1016/S0016-2361(01)00128-4 [31] GB/T 1574, 煤灰成分分析方法[S].GB/T 1574, Stand test method for major and minor elements in coal ash[S]. [32] WU X, ZHANG Z, CHEN Y, ZHOU T, FAN J, PIAO G, KOBAYASHI N, MORI S, YOSHINORI I. Main mineral melting behavior and mineral reaction mechanism at molecular level of blended coal ash under gasification condition[J]. Fuel Proces Technol, 2010, 91:1591-1600. doi: 10.1016/j.fuproc.2010.06.007 [33] 范建勇, 周永刚, 李培, 孔艳丽, 王炳辉, 赵虹.准东煤灰熔融温度表征结渣特性的试验研究[J].煤炭学报, 2013, 38(S2):478-482. http://d.old.wanfangdata.com.cn/Periodical/mtxb2013z2036FAN Jian-yong, ZHOU Yong-gang, LI Pei, KONG Yan-li, WANG Bin-hui, ZHAO Hong. Research on Zhundong coal's ash melting temperature characterizing its slagging characteristics[J]. J China Coal Soc, 2013, 38(S2):478-482. http://d.old.wanfangdata.com.cn/Periodical/mtxb2013z2036 [34] 宋维健, 宋国良, 齐晓宾, 吕清刚.不同预处理方法对准东高碱煤中碱金属含量测定的影响[J].燃料化学学报, 2016, 44(2):162-167. doi: 10.3969/j.issn.0253-2409.2016.02.005SONG Wei-jian, SONG Guo-liang, QI Xiao-bin, LÜ Qing-gang. Effect of pretreatment methods on the determination of alkali metal content in high alkali metal Zhundong coal[J]. J Fuel Chem Technol, 2016, 44(2):162-167. doi: 10.3969/j.issn.0253-2409.2016.02.005 [35] LIU Z, GUO X, SHI LEI, HE W, WU J, LIU Q, LIU J. Reaction of volatiles-A crucial step in pyrolysis of coals[J]. Fuel, 2015, 154:361-369. doi: 10.1016/j.fuel.2015.04.006 [36] ROBERTS M J, EVERSON R C, WJPNEOMAGUS H, OKOLO G N, VAN NIEKERK D, MATHEWS J P. The characterisation of slow-heated inertinite-and vitrinite-rich coals from the South African coalfields[J]. Fuel, 2015, 158:591-601. doi: 10.1016/j.fuel.2015.06.006 [37] LU K M, LEE W J, CHEN W H, LIN T C. Thermogravimetric analysis and kinetics of co-pyrolysis of raw/torrefied wood and coal blends[J]. Appl Energy, 2013, 105:57-65. doi: 10.1016/j.apenergy.2012.12.050 -

下载:

下载: