Effect of moisture content on gas release and pore structure development of wetted Shenfu coal during rapid pyrolysis

-

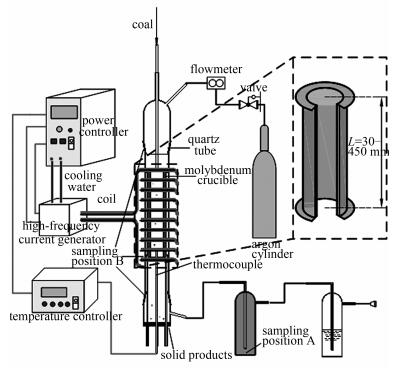

摘要: 通过外添加水分改变神府煤含水量,利用高频加热炉进行快速热解,研究了含水量对神府煤快速热解过程的影响,考察了四种含水量神府煤快速热解气相产物分布及变化规律,利用孔/表面分析仪表征了固相产物的结构变化。结果表明,随着煤中含水量升高,热解气总体积和最大释放速率减小;热解焦的比表面积和孔容随含水量升高而增大,与原煤煤焦相比,含水煤制得热解焦中保留了较多小孔,孔隙结构更加发达;水分有利于抑制热解过程孔的阻塞与塌陷,提高煤焦表面的粗糙程度和多孔结构的复杂程度。Abstract: The rapid pyrolysis experiments of Shenfu coal with various moisture content prepared by adding water were conducted in a high-frequency furnace to study the influence of moisture content on the thermal behavior. The gas composition and the structure properties of char were analyzed. The result shows that the gas yield and the maximal release rate decrease when the moisture content of coal increases. After pyrolysis, both BET surface and pore volume increase with increasing moisture. Compared to the char from dry coal pyrolysis, the char from pyrolysis of coal with high moisture content has more developed pore structure with more micropores. Furthermore, the moisture can inhabit the occurrence of pore obstruction and collapse during rapid pyrolysis, and also contribute to the enhancement of the surface roughness and the pore structure complexity.

-

Key words:

- wet coal /

- rapid pyrolysis /

- gas release /

- pore structure

-

表 1 干燥后神府烟煤的工业分析和元素分析

Table 1 Proximate and ultimate analysis of Shenfu bituminous coal

Coal sample Proximate analysis wd/% Ultimate analysis wd/% V FC A C H N S O* SF-coal 35.48 59.06 5.46 72.87 3.88 1.01 0.17 16.61 *: by difference 表 2 神府煤及煤焦颗粒粒径平均值

Table 2 Average particle size of Shenfu coal wetted and chars

Moisture content Particle size d/μm 0 9% 17% 23% Coal 127.1 128.4 129.9 131.6 Char 109.1 109.0 109.2 109.0 Average 118.1 118.7 119.6 120.3 表 3 煤颗粒在不同长度恒温区中停留时间

Table 3 Residence time of the coal particles at different length of hot zones

Moisture content Residence time at different length of hot zones t/ms (T=1 573 K) 30 mm 60 mm 120 mm 150 mm 180 mm 210 mm 270 mm 300 mm 330 mm 360 mm 450 mm 0 147 293 587 733 880 1 027 1 320 1 466 1 613 1 760 2 200 9% 145 290 581 726 871 1 017 1 307 1 452 1 598 1 743 2 179 17% 143 286 573 716 859 1 002 1 289 1 432 1 575 1 718 2 148 23% 141 283 566 707 849 990 1 273 1 414 1 556 1 697 2 121 表 4 含水量神府煤及部分热解焦的水分形态

Table 4 Moisture form of Shenfu coal wetted and chars

Sample Mf, ar/% Minh, ar/% Mar/% Sample Mf, ar/% Minh, ar/% Mar /% SF-coal (9%) 7.07 1.97 9.04 SF-180-17% 1.57 0.93 2.50 SF-coal (17%) 15.09 1.93 17.02 SF-450-17% 0 0.01 0.01 SF-coal (23%) 21.01 1.87 22.88 SF-270-23% 3.73 1.81 5.54 SF-450-9% 0 0.01 0.01 SF-300-23% 1.42 0.89 2.31 SF-150-17% 3.96 1.84 5.80 SF-450-23% 0 0.02 0.02 -

[1] 王辅臣, 于广锁, 龚欣, 刘海峰, 王亦飞, 梁钦峰.大型煤气化技术的研究与发展[J].化工进展, 2009, 28(2):173-180. http://www.cnki.com.cn/Article/CJFDTOTAL-HGJZ200902002.htmWANG Fu-chen, YU Guang-suo, GONG Xin, LIU Hai-feng, WANG Yi-fei, LIANG Qin-feng. Research and development of large-scale coal gasification technology[J]. Chem Ind Eng Prog, 2009, 28(2):173-180. http://www.cnki.com.cn/Article/CJFDTOTAL-HGJZ200902002.htm [2] RAMIN A, LESLIE L. ISAACS. Drying kinetics of lignite, subbituminous coals, and high-volatile bituminous coals[J]. Energy Fuels, 1990, 4(5):448-452. doi: 10.1021/ef00023a007 [3] LI X C, SONG H, WANG Q, MEESRI C, WALL T, YU J L. Experimental study on drying and moisture re-adsorption kinetics of an Indonesian low rank coal[J]. J Environ Sci, 2009, 21(s1):127-130. http://www.sciencedirect.com/science/article/pii/S1001074209600553 [4] WANG H H. Kinetic analysis of dehydration of a bituminous coal using the TGA technique[J]. Energy Fuels, 2007, 21(6):3070-3075. doi: 10.1021/ef070170y [5] PATISSON F, ETIENNE L, HANROT F, ABLITZER D, HOUZELOT J L. Coal pyrolysis in a rotary kiln:Part I. Model of the pyrolysis of a single grain[J]. Metall Mater Trans B, 2000, 31(2):381-390. doi: 10.1007/s11663-000-0056-5 [6] DING L, ZHOU Z J, DAI Z H, YU G S. Effects of coal drying on the pyrolysis and in-situ gasification characteristics of lignite coals[J]. Appl Energy, 2015, 155:660-670. doi: 10.1016/j.apenergy.2015.06.062 [7] ZHOU Z J, DING L, WU L, LIN S J, CUI T M, YU G S. Comparison of structure and gasification reactivity of rapid pyrolysis chars of coal water slurries and parent coals[J]. Energy Technol, 2014, 2(3):284-291. doi: 10.1002/ente.v2.3 [8] HAYASHI J, NORINAGA K, YAMASHITA T, TADATOSHI C. Effect of sorbed water on conversion of coal by rapid pyrolysis[J]. Energy Fuels, 1999, 13(3):611-616. doi: 10.1021/ef980186b [9] YIP K, WU H W, ZHANG D K. Effect of inherent moisture in collie coal during pyrolysis due to in-situ steam gasification[J]. Energy Fuels, 2007, 21(5):2883-2891. doi: 10.1021/ef7002443 [10] CAI Z, CLAYTON S, WU H W, HAYASHI J, LI C Z. Effects of dewatering on the pyrolysis and gasification reactivity of Victorian brown coal[J]. Energy Fuels, 2007, 21(2):399-404. doi: 10.1021/ef060404y [11] 吴磊, 周志杰, 王兴军, 于广锁, 王辅臣.神府烟煤水煤浆快速热解焦结构演化及其反应性的研究[J].燃料化学学报, 2013, 41(4):422-429. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract18161.shtmlWU Lei, ZHOU Zhi-jie, WANG Xin-jun, YU Guang-suo, WANG Fu-chen. Structure changes and gasification reactivity of CWS char from Shenfu coal rapid pyrolysis[J]. J Fuel Chem Technol, 2013, 41(4):422-429. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract18161.shtml [12] 崔童敏, 李超, 周志杰, 常清华, 高瑞, 于广锁, 王辅臣.神府烟煤快速热解特性研究[J].燃料化学学报, 2015, 43(11):1287-1294. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract18721.shtmlCUI Tong-min, LI Chao, ZHOU Zhi-jie, CHANG Qing-hua, GAO Rui, YU Guang-suo, WANG Fu-chen. Rapid pyrolysis characteristic of Shenfu bituminous coal[J]. J Fuel Chem Technol, 2015, 43(11):1287-1294. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract18721.shtml [13] BUTUZOVA L, MARIA R, KRZTON A, MINKOVA V. The effect of water on the yield and structure of the products of brown coal pyrolysis and hydrogenation[J]. Fuel, 1998, 77(6):639-643. doi: 10.1016/S0016-2361(97)00212-3 [14] 胡二峰, 张纯, 武荣成, 付晓恒, 许光文.内构件固定床反应器中不同水分煤的热解特性[J].化工学报, 2015, 66(7):2656-2663. http://www.cnki.com.cn/Article/CJFDTOTAL-HGSZ201507040.htmHU Er-feng, ZHANG chun, WU Rong-cheng, FU Xiao-heng, XU Guang-wen. Pyrolysis of coal with different moisture contents in fixed-bed reactor with internals[J]. CIESC J, 2015, 66(7):2656-2663. http://www.cnki.com.cn/Article/CJFDTOTAL-HGSZ201507040.htm [15] PRATIONOA W, ZHANG J, CUI J F, WANG Y T, ZHANG L. Influence of inherent moisture on the ignition and combustion of wet Victorian brown coal in air-firing and oxy-fuel modes:Part 1:The volatile ignition and flame propagation[J]. Fuel Process Technol, 2015, 138:670-679. doi: 10.1016/j.fuproc.2015.07.008 [16] 刘辉, 吴少华, 孙锐, 徐睿, 邱朋华, 李可夫, 秦裕琨.快速热解褐煤焦的比表面积及孔隙结构[J].中国电机工程学报, 2005, 25(12):86-90. http://www.cnki.com.cn/Article/CJFDTOTAL-ZGDC200512015.htmLIU Hui, WU Shao-hua, SUN Rui, XU Rui, QIU Peng-hua, LI Ke-fu, QIN Yu-kun. Specific area and pore structure of lignite char under the condition of fast pyrolysis[J]. Proc CSEE, 2005, 25(12):86-90. http://www.cnki.com.cn/Article/CJFDTOTAL-ZGDC200512015.htm [17] 谢克昌.煤的结构与反应性[M].北京:科学出版社, 2002.XIE Ke-chang. Coal Structure and Its Reactivity[M]. Beijing:Science Press, 2002. [18] YAO Y, LIU D, TANG D, TANG S, HUANG W. Fractal characterization of adsorption-pores of coals from North China:An investigation on CH4 adsorption capacity of coals[J]. Int J Coal Geol, 2008, 73(1):27-42. doi: 10.1016/j.coal.2007.07.003 [19] PYUN S I, RHEE C K. An investigation of fractal characteristics of mesoporous carbon electrodes with various pore structures[J]. Electrochim Acta, 2004, 49(24):4171-4780. doi: 10.1016/j.electacta.2004.04.012 [20] PFEIFER P, AVNIR D. Chemistry nonintegral dimensions between two and three[J]. Chem Phys, 1983, 79(7):3369-3558. https://www.researchgate.net/publication/285323109_Chemistry_non-integral_dimensions_between_two_and_threeJ [21] 许慎启. 煤气化反应动力学及渣中残碳反应活性研究[D]. 上海: 华东理工大学, 2010.XU Shen-qi. Gasification kinetics study of coal char and unburned carbon in slag[D]. Shanghia:East China University of Science and Technology, 2010. -

下载:

下载: