Investigation on catalytic gasification reaction characteristics of coal char with Na2CO3

-

摘要: 基于热重分析仪开展负载碳酸钠神府烟煤/遵义无烟煤煤焦气化实验,并借助扫描电子显微镜和孔结构及比表面积分析仪表征焦样孔结构及表观结构变化,考察了反应温度(650-800℃)、气化剂(水蒸气、二氧化碳)及碳酸钠负载量(钠离子负载量2.2%、4.4%、6.6%,质量分数)对神府烟煤/遵义无烟煤焦样气化反应活性的影响。结果表明,碳酸钠有利于促进神府/遵义煤热解过程孔隙结构的发展。在二氧化碳气氛下,适宜催化剂负载量使神府烟煤反应活性提高,过多负载催化剂堵塞煤焦内部孔隙结构,使得气化反应活性降低,遵义无烟煤反应活性随负载量增加而提高,两者反应活性均随温度升高而提高。在水蒸气气氛下,神府烟煤/遵义无烟煤在一定条件下反应活性随催化剂负载量增大、温度升高而提高。碳酸钠的添加能够在保证气化反应性的前提下降低气化反应温度和活化能。Abstract: The coal char gasification experiments with Na2CO3 as catalyst was investigated on TGA. The pore structure and apparent structure evolution characteristics of char were studied by scanning electron microscopy and pore structure and specific surface area analyzer. The influence of temperature (650-800℃), gasification agent (steam, CO2) and sodium carbonate loadings (Na+ loading amounts 2.2%, 4.4%, 6.6%) on the gasification reactivity of Shenfu bituminous coal (SF) and Zunyi anthracite (ZY) were investigated. The results show that the loading of Na2CO3 stimulates the development of pore structure in pyrolysis process. In the atmosphere of CO2, there was a saturated catalyst capacity for SF and excessive catalyst loading could block internal pore structure of coal, leading to the decrease of gasification reactivity. ZY gasification reactivity increases with catalyst loading, and both SF and ZY gasification reactivity increase with the increase of temperature. In the atmosphere of steam, both SF and ZY gasification reactivity increase with the rise of catalyst loading and temperature. Na2CO3 is favorable for the decrease of reaction temperature and activation energy under the desired gasification rate.

-

Key words:

- Na2CO3 /

- catalytic gasification /

- pore structure /

- reactivity

-

图 2 神府/遵义样品催化和非催化气化反应性比较

Figure 2 Gasification reactivity comparison of SF/ZY coal with and without Na2CO3

(a): 650℃-CO2 gasification; (b): 700℃-CO2 gasification; (c): 750℃-CO2 gasification; (d): 800℃-CO2 gasification ■: SF-raw-800P; □: SF-2.2Na-800P; ▲: SF-4.4Na-800P; △: SF-6.6Na-800P; ▼: ZY-raw-800P; ▽: ZY-2.2Na-800P; ●: ZY-4.4Na-800P; ○: ZY-6.6Na-800P

图 3 神府/遵义样品催化和非催化气化反应性比较

Figure 3 Gasification reactivity comparison of SF and ZY coal with and without Na2CO3

(a): 650℃-H2O gasification; (b): 700℃-H2O gasification; (c): 750℃-H2O gasification; (d): 800℃-H2O gasification ■: SF-raw-800P; □: SF-2.2Na-800P; ▲: SF-4.4Na-800P; △: SF-6.6Na-800P; ▼: ZY-raw-800P; ▽: ZY-2.2Na-800P; ●: ZY-4.4Na-800P; ○: ZY-6.6Na-800P

表 1 样品的煤质分析

Table 1 Characteristic data of tested coal samples

Sample Proximate analysis wd /% Ultimate analysis wd/% Ash fusion temperature t/℃ V FC A C H N S O DT ST HT FT SF 35.42 58.29 6.29 79.14 2.32 1.12 0.77 10.36 1152 1167 1175 1179 ZY 7.59 73.46 18.95 76.57 2.13 1.10 0.83 0.42 1345 1370 1395 1463 表 2 原料的主要灰组分

Table 2 The main ash compositions of raw materials

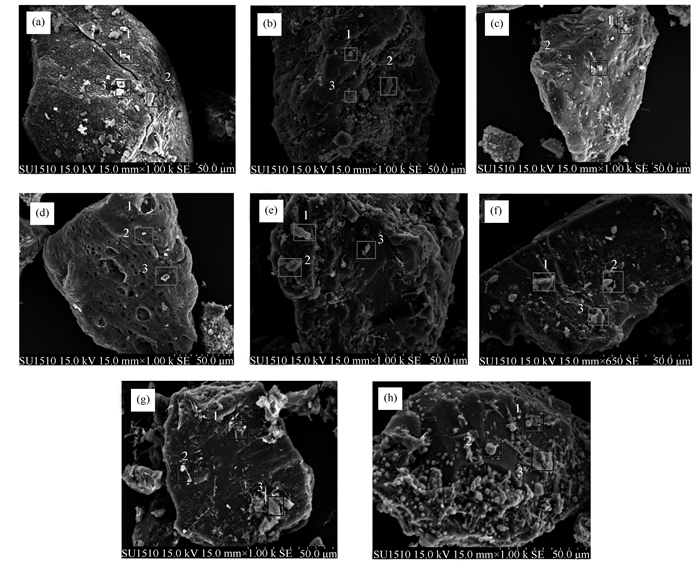

Sample Composition w/% SiO2 Al2O3 Fe2O3 CaO Na2O K2O MgO SF 33.36 12.44 9.11 27.78 1.73 0.67 1.34 ZY 43.05 20.78 21.43 7.42 0.86 0.52 2.90 表 3 负载碳酸钠煤/煤焦表面的元素组成

Table 3 Elemental composition of coal/char with or without Na2CO3

Contact surface Composition w/% Contact surface Composition w/% C O Na C O Na SF-raw-4.4Na-1 29.5 30.3 22.5 ZY-raw-4.4Na-1 33.2 40.5 8.5 SF-raw-4.4Na-2 48.5 25.2 7.0 ZY-raw-4.4Na-2 37.5 18.2 18.0 SF-raw-4.4Na-3 46.3 26.6 8.0 ZY-raw-4.4Na-3 38.2 34.5 18.1 SF-4.4Na-800P-1 51.3 24.5 7.3 ZY-4.4Na-800P-1 10.3 41.6 23.8 SF-4.4Na-800P-2 25.3 25.6 32.3 ZY-4.4Na-800P-2 18.3 4.6 12.9 SF-4.4Na-800P-3 7.5 3.9 8.1 ZY-4.4Na-800P-3 7.8 43.2 25.2 SF-raw-6.6Na-1 28.6 27.6 30.5 ZY-raw-6.6Na-1 30.7 41.6 5.7 SF-raw-6.6Na-2 32.5 24.8 20.7 ZY-raw-6.6Na-2 30.6 19.5 20.3 SF-raw-6.6Na-3 28.0 13.7 17.9 ZY-raw-6.6Na-3 35.7 17.3 19.6 SF-6.6Na-800P-1 6.9 5.4 20.5 ZY-6.6Na-800P-1 11.5 30.5 24.9 SF-6.6Na-800P-2 14.5 13.8 6.7 ZY-6.6Na-800P-2 16.8 26.8 20.6 SF-6.6Na-800P-3 20.7 28.9 12.6 ZY-6.6Na-800P-3 19.5 30.8 16.9 note: SF-raw-4.4Na-1 is the surface area of 1# in SF-raw-4.4Na 表 4 氮气吸附法测定的样品孔结构参数

Table 4 Pore structure parameters of samples measured by N2 gas adsorption analysis

Sample ABET

/(m2·g-1)Pore volume

v/ (cm3·g-1)SF-raw-800P 2.2070 0.0014 SF-4.4Na-800P 17.2330 0.0195 SF-6.6Na-800P 2.9011 0.0064 ZY-raw-800P 1.6845 0.0052 ZY-4.4Na-800P 1.8891 0.0076 ZY-6.6Na-800P 1.7665 0.0067 表 5 煤/煤焦的水溶性和离子交换型钠元素含量

Table 5 Water-soluble and ion-exchanged Na contents in coal/char

Coal/char Actual loading of

sodium w/%Theoretical loading of

sodium w/%SF-raw-2.2Na 1.9 2.2 SF-raw-4.4Na 4.3 4.4 SF-raw-6.6Na 6.3 6.6 SF-2.2Na-800P 1.3 2.2 SF-4.4Na-800P 3.7 4.4 SF-6.6Na-800P 5.7 6.6 ZY-raw-2.2Na 2.1 2.2 ZY-raw-4.4Na 4.3 4.4 ZY-raw-6.6Na 6.4 6.6 ZY-2.2Na-800P 1.1 2.2 ZY-4.4Na-800P 2.1 4.4 ZY-6.6Na-800P 4.3 6.6 表 6 神府和遵义样品的动力学参数

Table 6 Kinetic parameters of SF and ZY samples

Sample Ea/(kJ·mol-1) lnA SF-2.2Na-800P-CO2 142.8 14.5623 SF-4.4Na-800P-CO2 106.1 10.4127 SF-6.6Na-800P-CO2 120.3 12.7232 ZY-2.2Na-800P-CO2 150.1 15.4361 ZY-4.4Na-800P-CO2 133.1 11.9361 ZY-6.6Na-800P-CO2 104.7 7.4310 SF-2.2Na-800P-H2O 126.3 12.7423 SF-4.4Na-800P-H2O 111.2 11.5243 SF-6.6Na-800P-H2O 95.3 9.4760 ZY-2.2Na-800P-H2O 121.2 12.4653 ZY-4.4Na-800P-H2O 102.3 10.7434 ZY-6.6Na-800P-H2O 86.4 8.5263 -

[1] 李珊.煤催化气化催化剂发展现状及研究展望[J].化学工业与工程技术, 2013, 34(5):10-15. http://www.cnki.com.cn/Article/CJFDTOTAL-HXGJ201305003.htmLI Shan.Developing status and research prospect of catalysts for coal catalytic gasification[J].J Chem Ind Eng, 2013, 34(5):10-15. http://www.cnki.com.cn/Article/CJFDTOTAL-HXGJ201305003.htm [2] 高旭霞, 郭晓镭, 龚欣.气流床煤气化渣的特征[J].华东理工大学学报 (自然科学版), 2009, 35(5):677-683. http://www.cnki.com.cn/Article/CJFDTOTAL-HLDX200905004.htmGAO Xu-xia, GUO Xiao-lei, GONG Xin.Characterization of slag from entrained-flow coal gasification[J].J East China Univ Sci Technol (Nat Sci Ed), 2009, 35(5):677-683. http://www.cnki.com.cn/Article/CJFDTOTAL-HLDX200905004.htm [3] 孟磊, 周敏, 王芬.煤催化气化催化剂研究进展[J].煤气与热力, 2010, 30(4):B18-B22. http://www.cnki.com.cn/Article/CJFDTOTAL-MQRL201004029.htmMENG Lei, ZHOU Min, WANG Fen.Progress of research on catalyst for catalytic gasification of coal[J].Gas Heat, 2010, 30(4):B18-B22. http://www.cnki.com.cn/Article/CJFDTOTAL-MQRL201004029.htm [4] POPA T, FAN M H, ARGYLE M D, SLIMANE R B, BELL D A, TOWLER B F.Catalytic gasification of a Powder River Basin coal[J].Fuel, 2013, 103:161-170. doi: 10.1016/j.fuel.2012.08.049 [5] MONTERROSO R, FAN M H, ZHANG F, GAO Y, POPA T, ARGYLE M D, TOELER B, SUN Q Y.Effects of an environmentally-friendly, inexpensive composite iron-sodium catalyst on coal gasification[J].Fuel, 2014, 116:341-349. doi: 10.1016/j.fuel.2013.08.003 [6] KARIMI A, GRAY M R.Effectiveness and mobility of catalysts for gasification of bitumen coke[J].Fuel, 2011, 90(1):120-125. doi: 10.1016/j.fuel.2010.07.032 [7] WANG Y, WANG Z, HUANG J, FANG Y.Catalytic gasification activity of Na2CO3 and comparison with K2CO3 for a high-aluminum coal char[J].Energy Fuels, 2015, 29(11):6988-6998. doi: 10.1021/acs.energyfuels.5b01537 [8] 陈彦, 张济宇.Na2CO3催化剂对福建高变质无烟煤比表面及气化反应特性的影响[J].化工学报, 2011, 62(10):2768-2775.CHEN Yan, ZHANG Ji-yu.Effects of catalyst loading of Na2CO3 on specific surface area and gasification characteristics of Fujian high-metamorphous anthracite[J].CIESC J, 2011, 62(10):2768-2775. [9] SAMS D A, SHADMAN F.Catalytic effect of potassium on the rate of char-CO2 gasification[J].Fuel, 1983, 62(8):880-882. doi: 10.1016/0016-2361(83)90153-9 [10] 陈彦, 张济宇.福建无烟煤Na2CO3催化气化过程的比表面变化特性[J].化工学报, 2012, 63(8):2443-2452.CHEN Yan, ZHANG Ji-yu.Variation of specific surface area in catalytic gasification process of Fujian anthracite with Na2CO3 catalyst[J].CIESC J, 2012, 63(8):2443-2452. [11] 王西明, 王兴军, 陈凡敏, 刘海峰, 于广锁, 王辅臣.水蒸气气氛煤中温催化气化动力学研究[J].燃料化学学报, 2013, 41(10):1166-1172. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract18270.shtmlWANG Xi-ming, WANG Xing-jun, CHEN Fan-min, LIU Hai-feng, YU Guang-suo, WANG Fu-chen.Catalytic gasification kinetics of coal with steam at mid-temperature[J].J Fuel Chem Technol, 2013, 41(10):1166-1172. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract18270.shtml [12] PANETH H R.The mechanism of self-diffusion in alkali metals[J].Phys Rev, 1950, 80(4):708-711. doi: 10.1103/PhysRev.80.708 [13] GODAVARTY A, AGARWAL A.Distribution and catalytic activity of eutectic salts in steam gasification of coal[J].Energy Fuels, 2000, 14(3):558-565. doi: 10.1021/ef990156o [14] WEI X F, HUANG J J, LIU T F, FANG Y T, WANG Y.Transformation of alkali metals during pyrolysis and gasification of a lignite[J].Energy Fuels, 2008, 22(3):1840-1844. doi: 10.1021/ef7007858 [15] 康守国.K2CO3催化煤焦-水蒸气气化的研究[D].天津:河北工业大学, 2011.KANG Shou-guo.Study on catalytic gasification reactivity of coal char supported with K2CO3[D].Tianjin:Hebei University of Technology, 2011. [16] GIL M V, RIAZA J, ÁLVAREZ L, PEVIDA C, RUBIERA F.Biomass devolatilization at high temperature under N2 and CO2:Char morphology and reactivity[J].Energy, 2015, 91:655-662. doi: 10.1016/j.energy.2015.08.074 [17] LIU H, LUO C, KANEKO M, KATO S, KOJIMA T.Unification of gasification kinetics of char in CO2 at elevated temperatures with a modified random pore model[J].Energy Fuels, 2003, 17(4):961-97. doi: 10.1021/ef020231m -

下载:

下载: