-

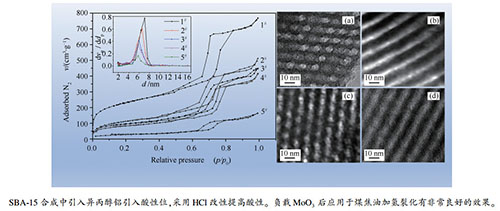

摘要: 利用蒸发诱导法制备了HCl改性的MoO3/Al-SBA-15系列催化剂,采用XRD、BET、TEM、NH3-TPD进行了表征。结果表明,改性后的催化剂保留着SBA-15的六角结构,孔道结构保持有序状态,改性后样品的孔径8 nm左右,壁厚4 nm左右,属于典型的介孔分子筛,活性组分在载体中分布良好。以预加氢后的中低温煤焦油为原料,采用固定床加氢裂化对催化剂进行了评价,结果表明,经过预硫化之后,负载了MoO3的Al-SBA-15具有良好的加氢裂化活性,MoO3负载量14.9%的情况下,65-145℃石脑油和145-280℃航煤馏分两种较轻组分合计收率为79.21%,其中,石脑油具备很高的芳潜值,最高可达72.4,是优良的重整制取芳烃的原料,裂化后的尾油BMCI值过高,不适宜作为裂化乙烯的原料。Abstract: A series MoO3/Al-SBA-15 catalysts modified by HCl were prepared by evaporation induction method. The catalysts were characterized by XRD, BET, TEM and NH3-TPD. The results showed that the modification of the catalyst retained the hexagonal structure of SBA-15 with ordered pore structure. The pore size of the modified samples was about 8 nm with wall thickness of about 4 nm. The catalysts were typical mesoporous molecular sieves over which the active components were well distributed. The Al-SBA-15 loaded with MoO3 had good hydrocracking activity after prevulcanization. Under the condition of 14.9% MoO3 loading, the total yield of naphtha and aviation kerosene fraction was 79.21%. The naphtha had the highest aromatic potential of 72.4, which was an excellent feedstock for reforming to produce aromatics. The high BMCI value of the cracked tail oil was not suitable for ethylene production by cracking.

-

Key words:

- coal tar /

- SBA-15 /

- hydrocracking /

- aromatic potential

-

表 1 MoO3/Al-SBA-15样品一览表

Table 1 Elements contents of MoO3/Al-SBA-15 samples

Sample Si/Mo (mol ratio) Al/Mo (mol ratio) MoO3 w/% Mow/% 1# - - 0 0 2# 43.5 2.18 5.1 3.4 3# 22.4 1.12 9.9 6.5 4# 14.9 0.75 14.9 9.8 5# 11.0 0.55 20.1 13.3 表 2 煤焦油预加氢油性质

Table 2 Properties of the coal tar after pre-hydrogenation

Elemental analysis ρ20c/ (kg· m-3) Hydrocarbon group composition w/% Hw/% Cw/% Oaw/% Sb/(mg·kg-1) Nb/(mg·kg-1) alkane naphthene aromatics polar fraction monocyclic bicyclic tricyclic 10.73 88.32 0.86 349 557 0.9751 24.9 28.68 22.83 16.29 5.15 2.13 Fraction distribution v/% IBP 5 10 20 30 40 50 60 70 80 90 99.5 t/℃ 97.2 158.4 181.3 241.2 270.6 283.6 318.6 328.3 350.1 370.2 388.8 423.1 a: by difference; b: detected by micro sulfur and nitrogen analyzer; c: density at 20 ℃ 表 3 催化剂样品的孔结构参数

Table 3 Physico-chemical properties of the catalysts

Sample MoO3w/% SBETa/(m2·g-1) vPb/(cm3·g-1) d cBJH/nm 1# 0 854 1.17 7.7 2# 5.1 434 0.74 6.1 3# 9.9 335 0.69 5.9 4# 14.9 295 0.64 5.8 5# 20.1 99 0.28 4.7 a:specific surface area determined by Brunauer-Emmett-Teller (BET) method;b:total pore volume recorded at p/p0 = 0.99;c:pore diameter calculated by Barrett-Joyner-Halenda (BJH) method 表 4 加氢裂化物料平衡

Table 4 Mass balance of hydro-cracking processing

Sample 1# 2# 3# 4# 5# Input w/% Coal tar 100 100 100 100 100 DMDS 0.25 0.25 0.25 0.25 0.25 H2 4.14 5.07 5.63 5.92 5.31 Total 104.39 105.32 105.88 106.17 105.56 Output w/% H2S 0.20 0.22 0.22 0.22 0.22 NH3 0.05 0.06 0.07 0.07 0.06 CO 0.08 0.07 0.04 0.03 0.04 CO2 0.05 0.03 0.03 0.02 0.03 <65℃* 7.49 4.53 4.71 5.07 4.25 65-145℃ 26.23 40.12 45.28 47.42 40.33 145-280 ℃ 20.72 25.61 29.59 31.89 33.8 280-370 ℃ 30.17 20.25 15.89 12.88 14.67 >370 ℃ 18.31 13.62 9.17 7.67 11.26 H2O 0.73 0.81 0.88 0.90 0.90 Total 104.39 105.32 105.88 106.17 105.56 *:<65 ℃: C1-5 表 5 加氢裂化产物性质

Table 5 Properties of hydrocracking products

Sample 1# 2# 3# 4# 5# 65-145 ℃ ρ20c/(kg·m-3) 777.9 765.8 758.3 749.4 750.1 H/C 1.98 2.04 2.07 2.11 2.09 Aromatic potential 69.4 70.6 72.4 71.1 68.7 145-280 ℃ ρ20c/(kg·m-3) 853.2 847.1 843.3 838.5 841.1 H/C 1.94 1.96 1.97 1.98 2.02 Freezing point /℃ <-60 <-60 <-60 <-60 <-60 280-370 ℃ ρ20c/(kg·m-3) 907.6 905.5 903.2 899.6 901.1 H/C 1.71 1.77 1.79 1.83 1.82 Condensation point -33 -39 -42 -43 -46 Cetane index 41 39 38 37 39 >370 ℃ ρ20c/(kg·m-3) 972.3 968.6 965.4 963.8 964.1 H/C 1.39 1.40 1.43 1.42 1.44 BMCI 74.4 70.1 68.6 65.7 69.3 -

[1] 李立权.加氢裂化装置工艺计算与技术分析[M].北京:中国石化出版社, 2009.LI Li-quan. Process Calculation and Technical Analysis of Hydro Cracking Unit[M]. Beijing:China Petrochemical Press, 2009. [2] 徐洁, 吴韬, 陈胜利, 袁桂梅.催化柴油加氢裂化生产BTX研究现状[J].工业催化, 2018, 26(2):15-22. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gych201802002XU Jie, WU Tao, CHEN Sheng-li, YUAN Gui-mei. Research progress of hydrocracking of diesel to produce BTX[J]. Ind Catal, 2018, 26(2):15-22. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gych201802002 [3] PENG C, FANG X C, ZENG R H, GUO R, HAO W Y. Commercial analysis of catalytic hydroprocessing technologies in producing diesel and gasoline by light cycle oil[J]. Catal Today, 2016, 276(1):11-18. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=9e7cce41876587237be592edb75d620c [4] HUANG P, ZHANG X J, MAO X F. Research on the production of aromatic hydrocarbon via hydroreforming a light fraction in direct coal liquefaction oil[J]. Energy Fuels, 2015, 29(1):86-90. doi: 10.1021/ef502146a [5] HATA Y, HAYASHIZAKI H, TAKAFUMI T, KANEHASHI K. Structural analysis of primary coal Tar by FD-MS[J]. J Iron Steel Inst, 2019, 105(6):601-609. doi: 10.2355/tetsutohagane.TETSU-2018-134 [6] 黄澎, 李文博, 毛学锋, 马博文.热解重油加氢裂化制取高芳潜石脑油的研究[J].燃料化学学报, 2019, 47(11):1329-1336. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=rlhxxb201911007HUANG Peng, LI Wen-bo, MAO Xue-feng, MA Bo-wen. Study on preparation of high aromatic potential naphtha from pyrolysis heavy oil via hydrocracking[J]. J Fuel Chem Technol, 2019, 47(11):1329-1336. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=rlhxxb201911007 [7] 王泽洋, 王龙延.煤基燃料油品特性与煤制油产业发展分析[J].化工进展, 2019, 38(7):3079-3088. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hgjz201907008WANG Ze-yang, WANG Long-yan. Analysis on characteristics of coal-based vehicle fuels and development of coal-to-liquids industry[J]. Chem Ind Eng Prog, 2019, 38(7):3079-3088. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hgjz201907008 [8] 曹宏伟, 李月婷, 王腾达, 张香文, 李国柱.煤直接液化油制备航空航天燃料的工艺研究[J].含能材料, 2020, (5):376-381. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hncl202005006CAO Hong-wei, LI Yue-ting, WANG Teng-da, ZHANG Xiang-wen, LI Guo-zhu. Process of upgrading diret coal liquefaction oil to aerospace fuel[J]. Chin J Energ Mater, 2020, (5):376-381. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hncl202005006 [9] INAMURAL K, KAGAMI N, SHIRAKAWA T, EURA S, WATABE M. Improvement in hydrocracking activity of heavy oil upgrading catalyst by modifications to some specific properties of Y-zeolite[J]. Res Chem Intermed, 2015, 41(12):1-11. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=c32f7dff7c6685724aa5c4d24f21ccc6 [10] 韩宝斋.加氢裂化催化剂裂化组分Y分子筛改性研究[D].北京: 中国石油大学, 2017. http://cdmd.cnki.com.cn/Article/CDMD-10425-1019837162.htmHAN Bao-zhai. Study on the modification of Y zeolite for hydrocracking catalysts[D]. Beijing: China University of Petroleum, 2017. http://cdmd.cnki.com.cn/Article/CDMD-10425-1019837162.htm [11] DIDI D A, LUQMAN B, GIVENI C S, RESTI N U. Preparation, characterization, and activation of Co-Mo/Y zeolite catalyst for coal tar conversion to liquid fuel[J]. Bull Chem React Eng Catal, 2017, 12(2):219-226. doi: 10.9767/bcrec.12.2.768.219-226 [12] MARAKATTI V S, PETER S C. Nickel-antimony nanoparticles confined in SBA-15 as highly efficient catalysts for the hydrogenation of nitroarenes[J]. New J Chem, 2016, 40(6):5448-5457. doi: 10.1039/C5NJ03479E [13] LEI Z P, GAO L J, SHUI H F, CHEN W L, WANG Z C, REN S B. Hydrotreatment of heavy oil from a direct coal liquefaction process on sulfided Ni-W/SBA-15 catalysts[J]. Fuel Process Technol, 2011, 92(10):2055-2060. doi: 10.1016/j.fuproc.2011.06.007 [14] WANG L, LI J, WANG L, CHU S, YANG L. Synthesis of core-shell HZSM-5@SBA-15 composite and its performance in the conversion of methanol to aromatics[J]. China Pet Process Petrochem Technol, 2018, 20(1):16-24. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=zgsyjgysyhgjs201801004 [15] 盖媛媛, 李海涛, 李建法, 孙瑞霞. Zr-MCM-41与Zr-SBA-15催化剂肉桂醛MPV转移加氢性能[J].工业催化, 2018, 26(12):61-66. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gych201812009GAI Yuan-yuan, LI Hai-tao, LI Jian-fa, SUN Rui-xia. Catalytic performance of Zr-MCM-41 and Zr-SBA-15 catalysts for cinnamaldehyde MPV transfer hydrogenation[J]. Ind Catal, 2018, 26(12):61-66. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gych201812009 [16] 李祥珍, 王晓钟, 刘瑜, 陈伟, 黄璐.介孔材料Al-SBA-15的合成研究进展[J].化工进展, 2013, 32(7):1555-1563. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hgjz201307018LI Xiang-zhen, WANG Xiao-zhong, LIU Yu, CHEN Wei, HUANG Lu. Research progress in the synthesis of mesoporous Al-SBA-15 material[J]. Chem Ind Eng Prog, 2013, 32(7):1555-1563. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hgjz201307018 [17] SAUL P B, PERLA B B, GUSTAVO E, RAMIREZ C. Surface structure and acidity properties of mesoporous silica SBA-15 modified with aluminum and titanium:First-principles calculations[J]. J Phys Chem C, 2016, 120(32):18105-18114. doi: 10.1021/acs.jpcc.6b05630 [18] LUZ G E, LIMA F C A, NETO C O C, PAZ G L, SILVA E F B, BARBOSA M N. Determination of SBA-15 acidity through n-butyl amine TPD:A theoretical and experimental study[J]. J Mater Sci, 2013, 48(20):6885-6890. doi: 10.1007/s10853-013-7492-5 [19] 田志茗.介酸改性SBA-15介孔材料制备、表征及催化性能[D].大连: 大连理工大学, 2008. http://cdmd.cnki.com.cn/article/cdmd-10141-2009041173.htmTian Zhi-ming. Preparation, characterization and catalytic performance of acid-modified SBA-15 mesoporous materials[D]. Dalian: Dalian University of Technology, 2008. http://cdmd.cnki.com.cn/article/cdmd-10141-2009041173.htm [20] 丁志杰, 陈君华, 公旭中, 程年寿.酸的种类及浓度对SBA-15有序介孔分子筛结构与形貌的影响[J].硅酸盐学报, 2008, (7):978-984. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gsyxb200807018DING Zhi-jie, CHEN Jun-hua, GONG Xu-zhong, CHENG Nian-shou. Effect of different kinds of acid and their concentration on mesostructure and morphology of ordered mesoporous molucular sieve SBA-15[J]. J Chin Silic Soc, 2008, (7):978-984. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gsyxb200807018 [21] 曹正凯, 霍海峰, 吴子明.掺炼催化裂化柴油对加氢裂化产品性质的影响[J].炼油技术与工程, 2018, 48(5):26-31. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=lysj201805006CAO Zheng-kai, HUO Hai-feng, WU Zi-ming. Study on the impact of mixing FCC diesel on the performance of hydrocracking unit[J]. Pet Refin Eng, 2018, 48(5):26-31. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=lysj201805006 [22] MARK S, STEPHEN O B, STEPHAN S, GALEN D S. Hydrothermal and postsynthesis surface modification of cubic, MCM-48, and ultralarge pore SBA-15 mesoporous silica with titanium[J]. Chem Mater, 2000, 12(4):898-911. doi: 10.1021/cm9901663 [23] ZHAO D Y FENG J L, HUO Q S, NICHOLAS M, GLENN H, FREDRICKSON, BRADLEY F C, GALEN D S. Triblock copolymer syntheses of mesoporous silica with periodic 50 to 300 angstrom pores[J]. Science, 1998, 279(5350):548-552. doi: 10.1126/science.279.5350.548 [24] ZHAO D S, HUO Q S, FENG J L, BRADLEY F C, GALEN D S. Nonionic triblock and star diblock copolymer and oligomeric surfactant syntheses of highly ordered, hydrothermally stable, mesoporous silica structures[J]. J Am Chem Soc, 1998, 120(24):6024-6036. doi: 10.1021/ja974025i [25] SRINIVAS D, SRIVASTAVA R, RATNASAMY P. Transesterification over titanosilicate molecular sieves[J]. Catal Today, 2004, 96(3):127-133. doi: 10.1016/j.cattod.2004.06.113 [26] LIU C H, GAO X H, ZhANG Z D, ZHANG H T, SUN S H, DENG Y Q. Surface modification of zeolite Y and mechanism for reducing naphtha olefin formation in catalytic cracking reaction[J]. Appl Catal A:Gen, 2004, 264(2):225-228. doi: 10.1016/j.apcata.2003.12.048 [27] YORI J C, KRASNOGOR L M, CASTRO A A. Correlation between acid Strength(H0) and ammonia desorption temperature for aluminas and silica-aluminas[J]. React Kinet Catal Lett, 1986, 32(1):27-32. doi: 10.1007/BF02063445 [28] 程俊杰, 李振荣, 赵亮富. Hβ/Al-SBA-15介微孔复合分子筛负载Ni-W催化剂对萘加氢裂化制BTX的催化性能[J].燃料化学学报, 2017, 45(1):93-99. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=rlhxxb201701013CHENG Jun-jie, LI Zhen-rong, ZHAO Liang-fu. Catalytic performance of Ni-W supported on micro-mesoporous Hβ/Al-SBA-15 composite molecular sieves in the hydrocracking of naphthalene to BTX[J]. J Fuel Chem Technol, 2017, 45(1):93-99. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=rlhxxb201701013 [29] LI X P, ZHANG J G, LIU B, LIU J P, WANG C B, CHEN G Y. Hydrodeoxygenation of lignin-derived phenols to produce hydrocarbons over Ni/Al-SBA-15 prepared with different impregnants[J]. Fuel, 2018, 20(1):16-24. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=8eb9726acd37d8d8d12322af2813c231 [30] 王峰.炼油产乙烯裂解原料的优化利用及经济分析[J].当代化工, 2014, (2):243-245. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=ddhg201402031WANG Feng. Optimization and economic analysis of ethylene cracking feedstock produced in refinery[J]. Contemp Chem Ind, 2014, (2):243-245. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=ddhg201402031 [31] 王汉松.乙烯工艺与技术[M].北京:中国石化出版社, 2012.WANG Han-song. Ethylene Process and Technology[M]. Beijing:China Petrochemical Press, 2012. -

下载:

下载: