Effect of impregnation sequence of Ce on the performance of Cu/Zn-Al catalysts derived from hydrotalcite precursor in methanol steam reforming

-

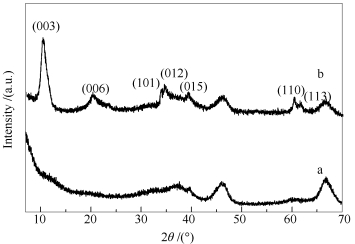

摘要: 采用原位合成法在γ-Al2O3载体上合成了锌铝水滑石,再经浸渍法制备了Cu/Zn-Al、Ce/Cu/Zn-Al、Cu/Ce/Zn-Al和Cu-Ce/Zn-Al催化材料,使用XRD、XRF、SEM、氮吸附,XPS、H2-TPR和N2O滴定等手段对其进行了表征,探讨了Ce的浸渍顺序对Cu/Zn-Al水滑石衍生材料甲醇水蒸气重整制氢反应催化性能的影响。结果表明,Ce的浸渍顺序主要影响催化剂的还原性质,进而影响了其催化性能。其中,Ce/Cu/Zn-Al催化剂的催化性能最佳,在250℃、水醇物质的量比为1.2、甲醇气体空速为800 h-1的条件下,甲醇转化率达到100%;与Cu/Zn-Al催化剂相比,甲醇转化率提高了近40%。Abstract: ZnAl-LDHs was prepared by in-situ synthesis method on γ-Al2O3 and the Cu/Zn-Al, Ce/Cu/Zn-Al, Cu/Ce/Zn-Al and Cu-Ce/Zn-Al catalysts were then obtained by wet impregnation method for methanol steam reforming. The catalysts were characterized by XRD, XRF, SEM, N2 sorption, XPS, H2-TPR and N2O titration; the effect of impregnation sequence of Ce on the performance of the Cu/Zn-Al catalysts in methanol steam reforming to produce hydrogen was investigated. The results showed that the impregnation sequence of Ce has a significant influence on the reducibility of resultant catalyst, which subsequently affects the catalytic performance. The Ce/Cu/Zn-Al catalyst exhibits the highest activity; over it, the methanol conversion reaches 100% under 250℃ and with a water/methanol molar ratio of 1.2 and gas hourly space velocity of 800 h-1, which is almost 40% higher than that achieved on the Cu/Zn-Al catalyst.

-

Key words:

- impregnation sequence /

- hydrotalcite /

- ceria /

- methanol steam reforming /

- hydrogen

-

表 1 不同浸渍顺序催化剂的元素含量

Table 1 Components of the catalysts prepared with different impregnation sequences

Catalyst Element content w/% Cu Zn Al Ce O Cu/Zn-Al 9.66 14.60 36.90 - 38.84 Ce/Cu/Zn-Al 9.19 13.88 35.42 3.50 38.01 Cu-Ce/Zn-Al 8.68 13.59 35.80 3.74 38.19 Cu/Ce/Zn-Al 8.98 13.44 35.70 3.73 38.15 表 2 催化剂的物化性质及其催化甲醇水蒸气重整反应中氢气产率

Table 2 Physical characteristics of the prepared catalysts and and their hydrogen production rate in methanol steam reforming

Catalyst ABET

/(m2·g-1)Pore volume

v/(cm3·g-1)dCuO

/nmCu dispersiona

/%Cu surface areaa

A/(m2·g-1)H2 production rateb

/(cm3·kg-1·s-1)Cu/Zn-Al 147.0 0.47 34 10.3 5.9 446.2 Ce/Cu/Zn-Al 109.6 0.41 23 11.5 6.3 810.7 Cu-Ce/Zn-Al 96.4 0.46 24 11.1 6.1 673.1 Cu/Ce/Zn-Al 101.5 0.43 24 11.3 6.2 723.3 a: Cu dispersion and Cu surface area are determined by N2O sorption;

b: the reactions are carried out under atmospheric pressure, 240 ℃, water/methanol ratio of 1.2, GHSV of 800 h-1; no carrier gas was used表 3 高斯拟合后还原峰位置

Table 3 Positions of the reduction peaks by a Gauss fit of the H2-TPR profiles

Catalyst Peak position t/℃ peak 1 peak 2 peak 3 Cu/Zn-Al 266 324 - Ce/Cu/Zn-Al 242 266 281 Cu-Ce/Zn-Al 276 288 - Cu/Ce/Zn-Al 254 294 306 表 4 甲醇转换率大致相同时CO浓度和选择性

Table 4 Comparison of CO molar concentration and selectivity at similar methanol conversion

Catalyst Conversion x/% CO molar concentration/% CO selectivity s/% Temperature t/℃ Cu/Zn-Al 93 0.60 2.4 280 Ce/Cu/Zn-Al 92 0.22 0.9 240 Cu-Ce/Zn-Al 85 0.44 1.8 260 Cu/Ce/Zn-Al 88 0.92 3.6 250 -

[1] SA S, SILVA H, BRANDAO L, SOUSA J M, MENDES A. Catalysts for methanol steam reforming-A review[J]. Appl Catal B:Environ, 2010, 99(1/2):43-57. https://www.sciencedirect.com/science/article/pii/S0926337310002584 [2] LYTKINA A A, ZHILYAEVA N A, ERMILOVA M M, OREKHOVA N V, YAROSLAVTSEV A B. Influence of the support structure and composition of Ni-Cu-based catalysts on hydrogen production by methanol steam reforming[J]. Int J Hydrogen Energy, 2015, 40(31):9677-9684. doi: 10.1016/j.ijhydene.2015.05.094 [3] 张磊, 雷俊腾, 田园, 胡鑫, 白金, 刘丹, 杨义, 潘立卫.前驱体和沉淀剂浓度对CuO/ZnO/CeO2-ZrO2甲醇水蒸气重整制氢催化剂性能的影响[J].燃料化学学报, 2015, 43(11):1366-1374. doi: 10.3969/j.issn.0253-2409.2015.11.012ZHANG Lei, LEI Jun-teng, TIAN Yuan, HU Xin, BAI Jin, LIU Dan, YANG Yi, PAN Li-wei. Effect of precursor and precipitant concentration on the performance of CuO/ZnO/CeO2-ZrO2 catalyst for methanol steam reforming[J]. J Fuel Chem Technol, 2015, 43(11):1366-1374. doi: 10.3969/j.issn.0253-2409.2015.11.012 [4] BASILE A, PARMALIANA A, TOSTI S, LULIANELLI A, GALLUCCI F, ESPRO C, SPOOREN J. Hydrogen production by methanol steam reforming carried out in membrane reactor on Cu/Zn/Mg-based catalyst[J]. Catal Today, 2008, 137(1):17-22. doi: 10.1016/j.cattod.2008.03.015 [5] MA Y F, GUAN G Q, PHANTHONG P, LI X M, CAO J, HAO X G, WANG Z D, ABUDULA A. Steam reforming of methanol for hydrogen production over nanostructured wire-like molybdenum carbide catalyst[J]. Int J Hydrogen Energy, 2014, 39(33):18803-18811. doi: 10.1016/j.ijhydene.2014.09.062 [6] KUC J, NEUMANN M, ARMBRUSTER M, YOON S, ZHANG Y C, ERNI R, WEIDENKAFF A, MATAM S K. Methanol steam reforming catalysts derived by reduction of perovskite-type oxides LaCo1-x-yPdxZnyO3±δ[J]. Catal Sci Technol, 2016, 6(5):1455-1468. doi: 10.1039/C5CY01410G [7] AGRELL J, GERMANI G, JARAS S G, BOUTONNET M. Production of hydrogen by partial oxidation of methanol over ZnO-supported palladium catalysts prepared by microemulsion technique[J]. Appl Catal A:Gen, 2003, 242(2):233-245. doi: 10.1016/S0926-860X(02)00517-3 [8] LIU N, YUAN Z S, WANG C W, WANG S D, ZHANG C X, WANG S J. The role of CeO2-ZrO2 as support in the ZnO-ZnCr2O4 catalysts for autothermal reforming of methanol[J]. Fuel Process Technol, 2008, 89(6):574-581. doi: 10.1016/j.fuproc.2007.11.029 [9] HUANG G, LIAW B J, JHANG C J, CHEN Y Z. Steam reforming of methanol over CuO/ZnO/CeO2/ZrO2/Al2O3 catalysts[J]. Appl Catal A:Gen, 2009, 358(1):7-12. doi: 10.1016/j.apcata.2009.01.031 [10] LI Y F, DONG X F, LIN W M. Effects of ZrO2-promoter on catalytic performance of CuZnAlO catalysts for production of hydrogen by steam reforming of methanol[J]. Int J Hydrogen Energy, 2004, 29(15):1617-1621. doi: 10.1016/j.ijhydene.2004.03.001 [11] 蒋元力, 黄强, 王福安, HYUN K D, SOOK L M.在Cu/ZnO/Al2O3催化剂上进行甲醇蒸气重整的动力学研究[J].燃料化学学报, 2001, 29(4):347-350. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=rlhx200104012&dbname=CJFD&dbcode=CJFQJIANG Yuan-li, HUANG Qiang, WANG Fu-an, HYUN K D, SOOK L M. Kinetic study of methanol steam reforming over Cu/ZnO/Al2O3 catalysts[J]. J Fuel Chem Technol, 2001, 29(4):347-350. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=rlhx200104012&dbname=CJFD&dbcode=CJFQ [12] FIERRO G, JACONO M L, INVERSI M, PORTA P, CIOCI F, LAVECCHIA R. Study of the reducibility of copper in CuO/ZnO catalysts by temperature-programmed reduction[J]. Appl Catal A:Gen, 1996, 137(2):327-348. doi: 10.1016/0926-860X(95)00311-8 [13] CHOI Y, FUTAGAMI K, FUTAGAMI K, FUJITANI T, NAKAMURA J. The role of ZnO in Cu/ZnO methanol synthesis catalysts-morphology effect or active site model[J]. Appl Catal A:Gen, 2001, 208(1/2):163-167. https://www.sciencedirect.com/science/article/pii/S0926860X00007122 [14] KIM W, MOHAIDEEN K K, SEO D J, YOON W L. Methanol-steam reforming reaction over Cu-Al-based catalysts derived from layered double hydroxides[J]. Int J Hydrogen Energy, 2017, 42(4):2081-2087. doi: 10.1016/j.ijhydene.2016.11.014 [15] 巢磊, 武丹丹, 李工. Cu-Fe-MgO/AlPO4-5对甲醇水蒸气重整制氢的催化性能研究[J].燃料化学学报, 2017, 45(9):1105-1113. http://manu60.magtech.com.cn/rlhxxb/CN/abstract/abstract19091.shtmlCHAO Lei, WU Dan-dan, LI Gong. Study on catalytic properties of Cu-Fe-MgO/AlPO4-5 for hydrogen production from steam reforming of methanol[J]. J Fuel Chem Technol, 2017, 45(9):1105-1113. http://manu60.magtech.com.cn/rlhxxb/CN/abstract/abstract19091.shtml [16] DAS D, LLORCA J, DOMINGUEZ M, COLUSSI S, TROVARELLI A, GAYEN A. Methanol steam reforming behavior of copper impregnated over CeO2-ZrO2 derived from a surfactant assisted coprecipitation route[J]. Int J Hydrogen Energy, 2015, 40(33):10463-10479. doi: 10.1016/j.ijhydene.2015.06.130 [17] HAMMOUD D, GENNEQUIN C, ABOUKAIS A, AAD E A. Steam reforming of methanol over x% Cu/Zn-Al 400500 based catalysts for production of hydrogen:Preparation by adopting memory effect of hydrotalcite and behavior evaluation[J]. Int J Hydrogen Energy, 2015, 40(2):1283-1297. doi: 10.1016/j.ijhydene.2014.09.080 [18] LIN K S, CHOWDHURY S, YEH H P, HONG W T, YEH C T. Preparation and characterization of CuO/ZnO-Al2O3 catalyst washcoats with CeO2 sols for autothermal reforming of methanol in a microreactor[J]. Catal Today, 2011, 164(1):251-256. doi: 10.1016/j.cattod.2010.11.038 [19] UDANI P P C, GUNAWARDANA P V D S, LEE H C, KIM D H. Steam reforming and oxidative steam reforming of methanol over CuO-CeO2 catalysts[J].Int J Hydrogen Energy, 2009, 34(18):7648-7655. doi: 10.1016/j.ijhydene.2009.07.035 [20] PATEL S, PANT K K. Hydrogen production by oxidative steam reforming of methanol using ceria promoted copper-alumina catalysts[J]. Fuel Process Technol, 2007, 88(8):825-832. doi: 10.1016/j.fuproc.2007.04.004 [21] 张新荣, 史鹏飞. CeO2改性Cu/Al2O3催化剂上甲醇水蒸气重整制氢[J].物理化学学报, 2003, 19(1):85-89. http://www.whxb.pku.edu.cn/EN/abstract/abstract25994.shtmlZHANG Xin-rong, SHI Peng-fei. Catalytic production of hydrogen form steam reforming of methanol on CeO2 promoted Cu/Al2O3 catalysts[J]. Acta Phys-Chim Sin, 2003, 19(1):85-89. http://www.whxb.pku.edu.cn/EN/abstract/abstract25994.shtml [22] SHIM J O, NA H S, JHA A, JANG W J, JEONG D W, NAH I W, JEON B H, ROH H S. Effect of preparation method on the oxygen vacancy concentration of CeO2-promoted Cu/γ-Al2O3 catalysts for HTS reactions[J]. Chem Eng J, 2016, 306:908-915. doi: 10.1016/j.cej.2016.08.030 [23] HE J P, YANG Z X, ZHANG L, LI Y, PAN L W. Cu supported on ZnAl-LDHs precursor prepared by in-situ synthesis method on γ-Al2O3 as catalytic material with high catalytic activity for methanol steam reforming[J]. Int J Hydrogen Energy, 2017, 42(15):9930-9937. doi: 10.1016/j.ijhydene.2017.01.229 [24] XIE R F, FAN G L, YANG L, LI F. Solvent-free oxidation of ethylbenzene over hierarchical flower-like core-shell structured Co-based mixed metal oxides with significantly enhanced catalytic performance[J]. Catal Sci Technol, 2015, 5(1):540-548. doi: 10.1039/C4CY00744A [25] AGARWAL V, PATEL S, PANT K K. H2 production by steam reforming of methanol over Cu/ZnO/Al2O3 catalysts:Transient deactivation kinetics modeling[J]. Appl Catal A:Gen, 2005, 279(1/2):155-164. [26] ZHANG L, PAN L W, NI C J, SUN T J, ZHAO S S, WANG S D, WANG A J, HU Y K. CeO2-ZrO2-promoted CuO/ZnO catalyst for methanol steam reforming[J]. Int J Hydrogen Energy, 2013, 38(11):4397-4406. doi: 10.1016/j.ijhydene.2013.01.053 [27] ZHANG L PAN L W, SUN T J, WANG S D, HU Y K, WANG A J, ZHAO S S.Effects of precipitation aging time on the performance of CuO/ZnO/CeO2-ZrO2 for methanol steam reforming[J]. J Fuel Chem Technol, 2013, 41(7):883-888. doi: 10.1016/S1872-5813(13)60038-9 [28] HURST N W, GENTRY S J, JONES A, MCNICOL B D. Temperature programmed reduction[J]. Catal Rev Sci Eng, 1982, 24(2):233-309. doi: 10.1080/03602458208079654 [29] WANG C, CHENG Q P, WANG X L, MA K, BAI X Q, TAN S R, TIAN Y, TONG D, ZHENG L R, ZHANG J, LI X G. Enhanced catalytic performance for CO preferential oxidation over CuO catalysts supported on highly defective CeO2 nanocrystals[J]. Appl Surf Sci, 2017, 422:932-943. doi: 10.1016/j.apsusc.2017.06.017 [30] JONES S D, NEAL L M, HAGELIN WEAVER H E. Steam reforming of methanol using Cu-ZnO catalysts supported on nanoparticle alumina[J]. Appl Catal B:Environ, 2008, 84(3/4):631-642. https://www.sciencedirect.com/science/article/pii/S0926337308001999 [31] 张国强, 郭天玉, 郑华艳, 李忠.焙烧温度对CuCe/Ac催化剂甲醇氧化羰基化性能的影响[J].燃料化学学报, 2016, 44(6):674-679. http://manu60.magtech.com.cn/rlhxxb/CN/abstract/abstract18844.shtmlZHANG Guo-qiang, GUO Tian-yu, ZHNEG Hua-yan, LI Zhong. Effect of calcination temperature on catalytic performance of CuCe/Ac catalysts for oxidative carbonylation of methanol[J]. J Fuel Chem Technol, 2016, 44(6):674-679. http://manu60.magtech.com.cn/rlhxxb/CN/abstract/abstract18844.shtml [32] YAO X J, GAO F, YU Q, QI L, TANG C J, DONG L, CHEN Y. NO reduction by CO over CuO-CeO2 catalysts:Effect of preparation methods[J]. Catal Sci Technol, 2013, 3(5):1355-1366. doi: 10.1039/c3cy20805b [33] XIAO S, ZHANG Y F, GAO P, ZHONG L S, LI X P, ZHANG Z Z, WANG H, WEI W, SUN Y H. Highly efficient cu-based catalysts via hydrotalcite-like precursors for CO2 hydrogenation to methanol[J]. Catal Today, 2017, 281:327-336. doi: 10.1016/j.cattod.2016.02.004 [34] LIU L J, YAO Z J, DENG Y, GAO F, LIU B, DONG L. Morphology and crystal plane effects of nanoscale ceria on the activity of CuO/CeO2 for NO reduction by CO[J]. ChemCatChem, 2011, 3(6):978-989. doi: 10.1002/cctc.v3.6 [35] LIANG F L, YU Y, ZHOU W, XU X Y, ZHU Z H. Highly defective CeO2 as a promoter for efficient and stable water oxidation[J]. J Mater Chem A, 2015, 3(2):634-640. doi: 10.1039/C4TA05770H [36] 苏石龙, 张磊, 张艳, 雷俊腾, 桂建州, 刘丹, 刘道胜, 潘立卫.千瓦级PEMFC甲醇水蒸气重整制氢过程热力学模拟[J].石油化工高等学校学报, 2015, 28(2):19-25. doi: 10.3969/j.issn.1006-396X.2015.02.004SU Shi-long, ZHANG Lei, ZHANG Yan, LEI Jun-teng, GUI Jian-zhou, LIU Dan, LIU Dao-sheng, PAN Li-wei. Thermodynamic simulation for hydrogen production in the methanol steam reforming system of kilowatt PEMFC[J]. Journal of Petrochemical Universities, 2015, 28(2):19-25. doi: 10.3969/j.issn.1006-396X.2015.02.004 -

下载:

下载: