Effects of multiple agglomeration technology on the removal of particulate matters and particulate heavy metals: A pilot study

-

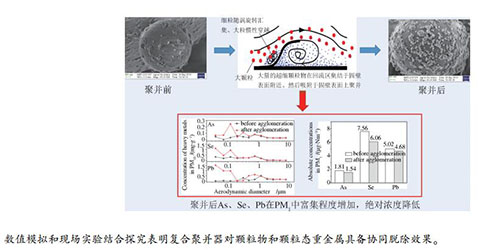

摘要: 燃煤颗粒物和其上富集的As、Se、Pb等重金属排入大气后危害环境和人体健康。本研究开发以湍流聚并、壁面回流吸附为原理的复合聚并器,研究了聚并前后对颗粒物和颗粒态重金属的聚并效果。首先采用数值模拟方法综合考虑压力损失、速度均匀性和颗粒物聚并效果,优选了折叶片作为复合聚并器的叶片类型。随后进行了不同流量的颗粒物聚并中试研究,发现复合聚并器对PM1的聚并率可达32.84%,随着流量从11.1 m/s增加到17.6 m/s,PM2.5聚并率呈现一定下降趋势,说明了流量增加导致颗粒停留时间缩短和颗粒物聚并率的下降。通过对比聚并前后颗粒物中As、Se、Pb的浓度变化,发现聚并过程增强了对气态重金属的吸附,也会聚集富含重金属的纳米级颗粒物,从而造成PM1中重金属浓度的增加。聚并后PM1内的As、Se、Pb绝对浓度的降低,显示了复合聚并器对颗粒物和颗粒态重金属的协同脱除效果。Abstract: The emmision of particulate matters and heavy metals such as As, Se and Pb from coal combustion into the atmosphere would cause a serious environmental and human health hazard. Therefore, a multiple agglomeration based on the principle of turbulent coalescence and wall surface adsorption was developed to investigate the agglomeration effects on the removal of particulate matter and particulate heavy metals. Firstly, a numerical simulation method was adopted to comprehensively study the pressure loss, the velocity uniformity and the particle agglomeration effect, and a folded blade was selected for the multiple agglomeration device. Subsequently, a pilot study at a coal-fired plant on the particle agglomeration at different flue gas velocities was carried out. It is found that the agglomeration rate of PM1 in the multiple agglomeration device is up to 32.84%. As the gas velocity is increased from 11.1 to 17.6 m/s, the agglomeration rate of PM2.5 shows a certain decline, indicating that an increase in gas velocity would lead to a shorter residence time of particles and thus a decrease in agglomeration rate of particles. By comparing the concentration changes of As, Se and Pb in the particles before and after agglomeration, it is found that the agglomeration process can enhance the adsorption to gaseous heavy metals and also aggregate the nano-particles rich in heavy metals, thus resulting in an increase in the concentration of heavy metals in PM1. The decrease of the absolute concentrations of As, Se and Pb in PM1 after coalescence shows a cooperative removal effect in the multiple agglomeration device on the particulate matter and particulate heavy metals.

-

表 1 机组燃用煤种的元素分析和工业分析

Table 1 Proximate and ultimate analysis of coal

Ultimate analysis wdaf/% Proximate analysis wad/% C H N S O* M V A FC 59.9 3.8 1.1 0.6 34.6 4.4 41.6 22.6 31.3 *: by difference 表 2 不同烟气流量下复合聚并器对颗粒物的聚并效率

Table 2 Agglomeration rates of PM1 and PM2.5 at different flue gas velocities

Pilot study 11.1 m/s 13.4 m/s 17.6 m/s Agglomeration rate of PM1/% 28.40 32.84 13.56 Agglomeration rate of PM2.5/% 26.06 20.66 18.79 Simulation 10 m/s 14 m/s 18 m/s Agglomeration rate of PM1/% 32.29 26.41 24.59 Agglomeration rate of PM2.5/% 8.14 6.43 5.29 -

[1] WEN C, YU D, WANG J, WU J, YAO H, XU M. Effect of the devolatilization process on PM10 formation during oxy-fuel combustion of a typical bituminous coal[J]. Energy Fuels, 2014, 28(9): 5682-5689. doi: 10.1021/ef501264v [2] WEN C, XU M, ZHOU K, YU D, ZHAN Z, MO X. The melting potential of various ash components generated from coal combustion: Indicated by the circularity of individual particles using CCSEM technology[J]. Fuel Process Technol, 2015, 133, 128-136. doi: 10.1016/j.fuproc.2015.01.012 [3] 李振.典型燃煤电厂烟气系统中PM2.5变化规律及排放特征研究[D].北京: 清华大学, 2017.LI Zhen. Characterization of PM2.5 emissions from conventional coal fired power plants during flue gas cleaning processes[D]. Beijing: Tsinghua University, 2017. [4] YU D, XU M, YAO H, LIU X. Size distributions of major elements in residual ash particles from coal combustion[J]. Chin Sci Bull, 2009, 54: 958-964. doi: 10.1007/s11434-009-0122-6 [5] 王超, 刘小伟, 徐义书, 吴建群, 王建培, 徐明厚, 林显敏, 李海山, 夏永俊. 660MW燃煤锅炉细微颗粒物中次量与痕量元素的分布特性[J].化工学报, 2013, 8: 2975-2981. http://d.wanfangdata.com.cn/Periodical/hgxb201308039WANG Chao, LIU Xiao-wei, XU Yi-shu, WU Jian-qun, WANG Jian-pei, XU Ming-hou, LIN Xian-min, LI Hai-shan, XIA Yong-jun. Distribution characteristics of minor and trace elements in fine particulate matters from a 660 MW coal-fired boiler[J]. CIESC J, 2013, 8: 2975-2981. http://d.wanfangdata.com.cn/Periodical/hgxb201308039 [6] 徐明厚, 王文煜, 温昶, 于敦喜, 刘小伟.燃煤电厂细微颗粒物脱除技术研究新进展[J].中国电机工程学报, 2019, 39(22): 6627-6640. http://d.wanfangdata.com.cn/periodical/zgdjgcxb201922014XU Ming-hou, WANG Wen-yu, WEN Chang, YU Dun-xi, LIU Xiao-wei. Research development of precipitation technology to accomplish the ultra-low emission from coal-fired power plants[J]. Proc CSEE, 2019, 39(22): 6627-6640. http://d.wanfangdata.com.cn/periodical/zgdjgcxb201922014 [7] XU F, LUO Z, BO W, ZHAO L, GAO X, FANG M, CEN K. Experimental investigation on charging characteristics and penetration efficiency of PM2.5 emitted from coal combustion enhanced by positive corona pulsed ESP[J]. J Electrost, 2009, 67(5): 799-806. doi: 10.1016/j.elstat.2009.06.002 [8] HUANG Q, LI S, SHAO Y, ZHAO Y, YAO Q. Dynamic evolution of impaction and sticking behaviors of fly ash particle in pulverized coal combustion[J].Proc Combust Inst, 2019, 37(4): 4419-4426. doi: 10.1016/j.proci.2018.06.035 [9] 刘含笑, 郦建国, 姚宇平, 郭峰, 余顺利, 陈招妹. PM2.5湍流聚并方法研究进展[J].中国环保产业, 2013, 4: 27-30. http://www.cnki.com.cn/Article/CJFDTotal-ZHBY201304023.htmLIU Han-xiao, LI Jian-guo, YAO Yu-ping, GUO Feng, YU Shun-li, CHEN Zhao-mei. Research Progress on PM2.5 turbulent flows and assembling method[J]. Chin Environ Prot Ind, 2013, 4: 27-30. http://www.cnki.com.cn/Article/CJFDTotal-ZHBY201304023.htm [10] 章鹏飞, 米建春, 潘祖明.烟气流速和装置元件角度对细颗粒湍流聚并的影响[J].中国电机工程学报, 2016, 36(10): 2714-2720. http://qikan.cqvip.com/Qikan/Article/Detail?id=668888582ZHANG Peng-fei, MI Jian-chun, PAN Zu-ming. Influences of flue-gas velocity and device-element angle on fine particle amalgamation[J]. Proc CSEE, 2016, 36(10): 2714-2720. http://qikan.cqvip.com/Qikan/Article/Detail?id=668888582 [11] 章鹏飞, 米建春, 潘祖明.装置元件排列间距和颗粒浓度对细颗粒湍流聚并的影响[J].中国电机工程学报, 2016, 36(6): 1625-1632. http://www.cqvip.com/QK/90021X/201606/668311503.htmlZHANG Peng-fei, MI Jian-chun, PAN Zu-ming. Influences of elemental arrangement and particle concentration on fine particle amalgamation[J]. Proc CSEE, 2016, 36(6): 1625-1632. http://www.cqvip.com/QK/90021X/201606/668311503.html [12] 杨陈好.湍流聚并器中细颗粒聚并特性的数值模拟及实验研究[D].长沙: 长沙理工大学, 2017.YANG Chen-hao. Numerical modelling and experimental investigation of agglomeration characteristics of fine particles in a turbulent agglomerator[D]. Changsha: Changsha University of Science & Technology, 2017. [13] CHEN D, WU K, MI J. Experimental investigation of aerodynamic agglomeration of fine ash particles from a 330 MW PC-fired boiler[J]. Fuel, 2016, 165: 86-93. doi: 10.1016/j.fuel.2015.10.036 [14] 陈冬林, 吴康, 米建春, 唐斌, 冯伟, 贺善军. 300 MW燃煤锅炉机组超细颗粒聚并器的实验研究[J].环境工程学报, 2015, 9(4): 1926-1930. http://d.wanfangdata.com.cn/Periodical_hjwrzljsysb201504066.aspxCHEN Dong-lin, WU Kang, MI Jian-chun, TANG Bin, FENG Wei, HE Shan-jun. Experimental study of ultrafine particle agglomerator installed on a 300 MW PC-fired boiler[J]. Chin J Environ Eng, 2015, 9(4): 1926-1930. http://d.wanfangdata.com.cn/Periodical_hjwrzljsysb201504066.aspx [15] 陈冬林, 杨陈好, 吴康, 刘经.烟气参数对细颗粒湍流聚并的影响[J].环境工程学报, 2017, 11(9): 5084-5090. http://www.cqvip.com/QK/90325X/201709/673050212.htmlCHEN Dong-lin, YANG Chen-hao, WU Kang, LIU Jing. Influences of turbulent agglomeration of fine particles under flue gas parameters[J]. Chin J Environ Eng, 2017, 11(9): 5084-5090. http://www.cqvip.com/QK/90325X/201709/673050212.html [16] XU Y, LIU X, ZHANG P, GUO J, HAN J, ZHOU Z, XU M. Role of chlorine in ultrafine particulate matter formation during the combustion of a blend of high-Cl coal and low-Cl coal[J]. Fuel, 2016, 184: 185-191. doi: 10.1016/j.fuel.2016.07.015 [17] WANG C, LIU X, LI D, SI J, ZHAO B, XU M. Measurement of particulate matter and trace elements from a coal-fired power plant with electrostatic precipitators equipped the low temperature economizer[J]. Proc. Combust. Inst., 2015, 35(3): 2793-2800. doi: 10.1016/j.proci.2014.07.004 [18] JOHNSON K L, KENDALL K, ROBERTS A D. Surface energy and the contact of elastic solids[C]. Proceedings of the Royal Society of London A Mathematical and Physical Sciences, 1971, 324(1558): 301-313. -

下载:

下载: