Hydrogen-rich gas production from catalytic steam gasification of biomass in a decoupled dual loop gasification system

-

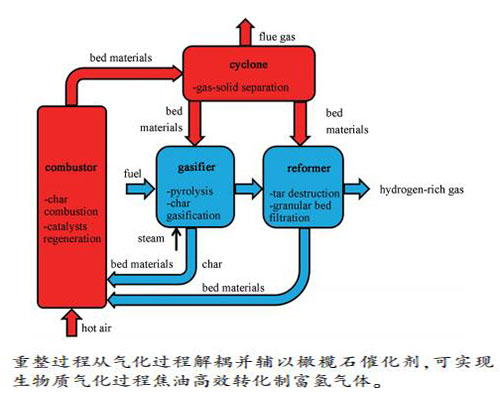

摘要: 为强化生物质气化过程中焦油转化和氢气富集,提出了一种新型解耦双回路气化系统(DDLG)。该气化系统将气化过程解耦为燃料气化、焦油重整和半焦燃烧三个子过程,分别发生于三个独立的反应器,即气化反应器、重整反应器和燃烧反应器。其中,气化反应器和重整反应器并行布置,分别与燃烧反应器相连,形成两个平行的且可独立控制的双循环回路。以松木屑为原料及兼作为原位焦油重整催化剂的煅烧橄榄石为循环固体热载体,考察了反应条件对DDLG中松木屑气化性能的影响。结果表明,重整反应器从气化反应器中解耦,并辅以橄榄石催化剂,可实现焦油高效转化脱除。如气化反应器700 ℃、重整反应器850 ℃和水蒸气与原料中碳的质量比(S/C)1.2反应条件下,产品气中焦油含量降低至13.9 g/m3,气体产率和H2分别达到1.0 m3/kg,和38.8%。Abstract: In order to strengthen tar destruction and hydrogen-rich gas production in the biomass gasification, a novel decoupled dual loop gasification (DDLG) system was proposed. The system decouples gasification process into fuel gasification, tar reforming and residual char combustion, which occur in three independent reactors, i.e. gasifier, reformer and combustor. Both the gasifier and the reformer are separately interconnected with the combustor, forming two circulation loops in parallel. With pine sawdust as feedstock, and calcined olivine as both solid heat carriers and in-situ tar destruction catalyst, the performance of biomass gasification was investigated. The results indicate that the reforming after the gasifier and the presence of olivine catalyst greatly improve the tar destruction. Specifically, at the gasifier temperature of 700 ℃, the reformer temperature of 850 ℃ and the steam to carbon mass ratio (S/C) of 1.2, the tar content in product gas decreases to 13.9 g/m3, and the dry gas yield and H2 concentration reach 1.0 m3/kg, and 38.8%, respectively.

-

Key words:

- biomass gasification /

- decouple /

- tar removal /

- hydrogen-rich gas

-

图 2 解耦双回路气化系统实验室规模装置示意图

Figure 2 Schematic diagram of DDLG facility

1: air compressor; 2: gas flow meter; 3: air pre-heater; 4: pre-fluidizer; 5: riser combustor; 6: cyclone; 7: screw conveyor; 8: gasifier; 9: reformer; 10: pipe bundle condenser; 11: condenser; 12: cotton wool filter; 13: needle valve; 14: surge flask; 15: vacuum pump; 16: gas meter; 17: three way valve; 18: silica gel filter; 19: gas holder; 20: venturi gas scrubber; 21: water tank; 22: circulating water pump; 23: rotary valve

表 1 松木屑的工业分析和元素分析

Table 1 Proximate and ultimate analyses of pine sawdust

Proximate analysis wad/% Ultimate analysis wdaf/% QLHV/(MJ·kg-1) M A V FC C H Oa N S 9.0 0.6 77.8 12.6 47.8 7.0 44.7 0.1 0.4 18.7 a: by difference 表 2 橄榄石XRF化学组成分析

Table 2 Chemical composition of olivine analyzed by XRF

Composition w/% MgO SiO2 Fe2O3 Al2O3 Cr2O3 CaO NiO 51.80 36.50 9.14 0.88 0.60 0.37 0.36 表 3 解耦双回路气化系统操作参数

Table 3 Operating conditions of the DDLG

Gasificaton or reforming circulation ratio (C/F) 10 Bed height in the gasifier /mm 100 Residence time of solid in the gasifier t /min 20 Residence time of solid in the reformer t /min 40 Biomass feeding rate /(kg·h-1) 0.2 Gasifier temperature t /℃ 650-850 Reformer temperature t /℃ 750-850 Combustor temperature t /℃ 850 Gauge pressure in the gasifier p /Pa 0 Gauge pressure in the reformer p /Pa (-100)-(-50) 表 4 床料对松木屑气化性能的影响

Table 4 Effect of bed materials on gasification performance of pine sawdust

Bed materials Silica sand Olivine Gasifier temperature t/℃ 700 700 Reformer temperature t/℃ 850 850 C/F 10 10 S/C 1.2 1.2 Dry gas composition /% H2 34.5 38.8 CO 20.8 15.8 CO2 26.3 31.3 CH4 13.4 11.1 C2H4 3.9 2.3 C2H6 0.8 0.6 C3H6 0.3 0.2 C3H8 < 0.1 < 0.1 H2/CO ratio 1.7 2.5 Dry gas yield w/(m3·kg-1) 0.8 1.0 Tar yield w/% 5.7 1.3 Tar content w/(g·m-3) 77.1 13.9 Carbon conversion /% 59.6 70.3 Water conversion /% 0.1 6.0 Cold gas efficiency /% 64.5 70.5 -

[1] 吴创之, 阴秀丽, 刘华财, 陈勇.生物质能分布式利用发展趋势分析[J].中国科学院院刊, 2016, (2):191-198. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=zgkxyyk201602006WU Chuang-zhi, YIN Xiu-li, LIU Hua-cai, CHEN Yong. Perspective on development of distributed bioenergy utilization[J]. Bull Chin Aca Sci, 2016, (2):191-198. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=zgkxyyk201602006 [2] DOU B, ZHANG H, SONG Y, ZHAO L, JIANG B, HE M, RRAN C, CHEN H, XU Y. Hydrogen production from the thermochemical conversion of biomass:Issues and challenges[J]. Sustainable Energy Fuels, 2019, 3:314-342. doi: 10.1039/C8SE00535D [3] 贾爽, 应浩, 孙云娟, 孙宁, 徐卫, 许玉, 宁思云.生物质水蒸气气化制取富氢合成气及其应用的研究进展[J].化工进展, 2018, 37(2):497-504. http://d.old.wanfangdata.com.cn/Periodical/hgjz201802011JIA Shuang, YING Hao, SUN Yun-juan, SUN Ning, XU Wei, XU Yu, NING Si-yun. Research advance in biomass steam gasification for hydrogen-rich syngas and its application[J]. Chem Ind Eng Prog, 2018, 37(2):497-504. http://d.old.wanfangdata.com.cn/Periodical/hgjz201802011 [4] SANSANIWAL S K, PAL K, ROSEN M A, TYAGI S K. Recent advances in the development of biomass gasification technology:A comprehensive review[J]. Renewable Sustainable Energy Rev, 2017, 72:363-384. doi: 10.1016/j.rser.2017.01.038 [5] MA X, ZHAO X, GU J, SHI J. Co-gasification of coal and biomass blends using dolomite and olivine as catalysts[J]. Renewable Energy, 2019, 132:509-514. doi: 10.1016/j.renene.2018.07.077 [6] GUAN G, KAEWPANHA M, HAO X, ABUDULA A. Catalytic steam reforming of biomass tar:Prospects and challenges[J]. Renewable Sustainable Energy Rev, 2016, 58:450-461. doi: 10.1016/j.rser.2015.12.316 [7] KIRNBAUER F, HOFBAUER H. Investigations on bed material changes in a dual fluidized bed steam gasification plant in Güssing, Austria[J]. Energy Fuels, 2011, 25:3793-3798. doi: 10.1021/ef200746c [8] NAQVI M, YAN J, DANISH M, FAROOQ U, LU S G. An experimental study on hydrogen enriched gas with reduced tar formation using pre-treated olivine in dual bed steam gasification of mixed biomass compost[J]. Int J Hydrogen Energy, 2016, 41(25):10608-10618. doi: 10.1016/j.ijhydene.2016.04.206 [9] XIAO Y, XU S, TURSUN Y, WANG C, WANG G. Catalytic steam gasification of lignite for hydrogen-rich gas production in a decoupled triple bed reaction system[J]. Fuel, 2017, 189:57-65. doi: 10.1016/j.fuel.2016.10.078 [10] 肖亚辉.生物质和煤解耦催化气化制富氢气体工艺研究[D].大连: 大连理工大学, 2017. http://cdmd.cnki.com.cn/Article/CDMD-10141-1018038212.htmXIAO Ya-hui. Decoupled catalytic gasification of biomass and coal for hydrogen-rich gas production[D]. Dalian: Dalian University of Technology, 2017. http://cdmd.cnki.com.cn/Article/CDMD-10141-1018038212.htm [11] 许光文, 董利, 刘新华, 汪印, 王宝群, 高士秋.解耦热化学转化: 方法、技术与研发现状[C]//中国颗粒学会第六届学术年会暨海峡两岸颗粒技术研讨会论文集.上海, 2008: 949-952. http://cpfd.cnki.com.cn/Article/CPFDTOTAL-ZGKL200812002094.htmXU Guang-wen, DONG Li, LIU Xin-hua, WANG Yin, WANG Bao-qun, GAO Shi-qiu. Decoupling thermochemical conversion: Method, technique and research status[C]//Proceedings of 6th annual conference of China society of particuology cum symposium on particle technology across Taiwan straits. Shanghai, 2008: 949-952. http://cpfd.cnki.com.cn/Article/CPFDTOTAL-ZGKL200812002094.htm [12] ZHANG J, WANG Y, DONG L, GAO S, XU G. Decoupling gasification:Approach principle and technology justification[J]. Energy Fuels, 2010, 24:6223-6232. doi: 10.1021/ef101036c [13] ZHANG J, WU R, ZHANG G, YU J, YAO C, WANG Y, GAO S, XU G. Technical review on thermochemical conversion based on decoupling for solid carbonaceous fuels[J]. Energy Fuels, 2013, 27(4):1951-1966. doi: 10.1021/ef400118b [14] LI C Z, XU G W. Decoupled thermochemical conversion-Preface[J]. Fuel, 2013, 112:607-608. doi: 10.1016/j.fuel.2013.06.027 [15] 王晓明, 肖显斌, 刘吉, 陈旭娇, 覃吴, 董长青, 李文艳.双流化床生物质气化炉研究进展[J].化工进展, 2015, 34(1):26-31. http://d.old.wanfangdata.com.cn/Periodical/hgjz201501007WANG Xiao-ming, XIAO Xian-bin, LIU Ji, CHEN Xu-jiao, QIN Wu, DONG Chang-qing, LI Wen-yan. Research progress of dual fluidized bed biomass gasifier[J]. Chem Ind Eng Prog, 2015, 34(1):26-31. http://d.old.wanfangdata.com.cn/Periodical/hgjz201501007 [16] 孙延林, 曾玺, 王芳, 崔彦斌, 许光文.低阶碎煤流化床两段气化中试试验[J].煤炭学报, 2017, 42(5):1297-1303. http://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201705028.htmSUN Yan-lin, ZENG Xi, WANG Fang, CUI Yan-bin, XU Guang-wen.Pilot test of low-rank crushed coal gasification in two-stage fluidized bed reactor[J]. J China Coal Soc, 2017, 42(5):1297-1303. http://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201705028.htm [17] 曾骥敏, 肖睿, 衡丽君, 曾德望, 邵珊珊.生物质化学链气化制备高H2/CO物质的量比的合成气[J].燃烧科学与技术, 2016, 22(3):229-235. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=rskxyjs201603007ZENG Ji-min, XIAO Rui, HENG Li-jun, ZENG De-wang, SHAO Shan-shan. Chemical looping gasification of biomass for high H2/CO-ratio syngas[J]. J Combust Sci Technol, 2016, 22(3):229-235. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=rskxyjs201603007 [18] 郭万军, 葛晖骏, 沈来宏, 宋涛, 顾海明, 蒋守席.基于铁矿石载氧体25kWth串行流化床生物质化学链气化实验研究[J].热科学与技术, 2017, 16(1):78-86. http://d.old.wanfangdata.com.cn/Periodical/rkxyjs201701013GUO Wan-jun, GE Hui-jun, SHEN Lai-hong, SONG Tao, GU Hai-ming, JIANG Shou-xi. Experimental study on chemical looping gasification of biomass with hematite base on 25 kWth fluidized beds[J]. J Therm Sci Technol, 2017, 16(1):78-86. http://d.old.wanfangdata.com.cn/Periodical/rkxyjs201701013 [19] ZHANG Z, PANG S. Experimental investigation of tar formation and producer gas composition in biomass steam gasification in a 100kW dual fluidised bed gasifier[J]. Renewable Energy, 2018, 132:416-424. http://cn.bing.com/academic/profile?id=8cc490a1616ae68d67813565729ab428&encoded=0&v=paper_preview&mkt=zh-cn [20] MAUERHOFER A M, FUCHS J, MÜLLER S, BENEDIKT F, SCHMID J C, HOFBAUER H. CO2 gasification in a dual fluidized bed reactor system:Impact on the product gas composition[J]. Fuel, 2019, 253:1605-1616. doi: 10.1016/j.fuel.2019.04.168 [21] XIAO Y, XU S, SONG Y, WANG C, OUYANG S. Gasification of low-rank coal for hydrogen-rich gas production in a dual loop gasification system[J]. Fuel Process Technol, 2018, 171:110-116. doi: 10.1016/j.fuproc.2017.11.014 [22] XIAO Y, XU S, SONG Y, SHAN Y, WANG C, WANG G. Biomass steam gasification for hydrogen-rich gas production in a decoupled dual loop gasification system[J]. Fuel Process Technol, 2017, 165:54-61. doi: 10.1016/j.fuproc.2017.05.013 [23] DEVI L, PTASINSKI K J, JANSSEN F J J G. Pretreated olivine as tar removal catalyst for biomass gasifiers:Investigation using naphthalene as model biomass tar[J]. Fuel Process Technol, 2005, 86(6):707-730. doi: 10.1016/j.fuproc.2004.07.001 [24] VIRGINIE M, ADÁNEZ J, COURSON C, DE DIEGO L F, GARCIA-LABIANO F, NIZNANSKY D, KIENNEMANN A, GAYÁN P, ABAD A. Effect of Fe-olivine on the tar content during biomass gasification in a dual fluidized bed[J]. Appl Catal B:Environ, 2012, 121/122:214-222. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=3d9a3deba33c98648062eee2f6917a7e [25] LANCEE R J, DUGULAN A I, THÜNE P C, VERINGA H J, NIEMANTSVERDRIET J W, FREDRIKSSON H O A. Chemical looping capabilities of olivine, used as a catalyst in indirect biomass gasification[J]. Appl Catal B:Environ, 2014, 145:216-222. doi: 10.1016/j.apcatb.2013.01.041 [26] WOLFESBERGER U, AIGNER I, HOFBAUER H. Tar content and composition in producer gas of fluidized bed gasification of wood-Influence of temperature and pressure[J]. Environ Prog Sustainable Energy, 2009, 28:372-379. doi: 10.1002/ep.10387 [27] DEVI L, PTASINSKI K J, JANSSEN F J J G, VAN PAASEN S V B, BERGMAN P C A, KIEL J H A. Catalytic decomposition of biomass tars:use of dolomite and untreated olivine[J]. Renewable Energy, 2005, 30(4):565-587. doi: 10.1016/j.renene.2004.07.014 [28] ISRAELSSON M, THUNMAN H. Gasification reaction pathways of condensable hydrocarbons[J]. Energy Fuels, 2016, 30:4951-4959. doi: 10.1021/acs.energyfuels.6b00515 [29] KOPPATZ S, PFEIFER C, HOFBAUER H. Comparison of the performance behaviour of silica sand and olivine in a dual fluidized bed reactor system for steam gasification of biomass at pilot plant scale[J]. Chem Eng J, 2011, 175:468-483. doi: 10.1016/j.cej.2011.09.071 -

下载:

下载: