Effect of combustion heat on release and transformation of the sodium during Zhundong coal ash-forming process

-

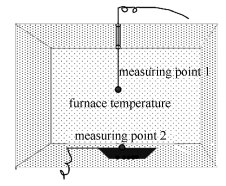

摘要: 选取典型的准东煤五彩湾煤为研究对象,在马弗炉内制备400-1200℃的燃烧灰和再热灰,采用K型热电偶测量燃烧过程中样品表面温度,通过XRF、XRD分析获得灰的成分和结晶形式,取部分灰样逐级萃取,通过微波消解及电感耦合等离子体质谱仪(ICP-MS),获得灰中钠的赋存特性。结果表明,燃烧和再热灰在成分和晶体形式上差异显著,再热灰钠含量明显高于燃烧灰且灰熔点偏低;随着温度升高灰中钠盐总量明显减少,其中,水溶钠、醋酸铵溶钠迅速减少,而盐酸溶钠含量先增加后减少,不可溶钠增加,释放的钠以可溶钠为主;加热温度和时间影响钠的释放,燃烧反应放热导致煤粉表面温度超过环境温度200℃以上,是钠盐过多释放的主要原因。Abstract: As a typical Zhundong coal, Wucaiwan coal was chosen as the object of the investigation. The combustion ash with coal sample and the reheated ash with ashing sample at 400℃ were prepared in a muffle furnace. K-type thermocouple was used to measure the temperature, XRF and XRD were used to investigate the composition of ash, and the sequential chemical extraction was used to examine the modes of occurrence of Sodium. The results show that the combustion ash and the reheated ash have marked differences in composition and melting points, sodium content in the reheated ash is higher than that in the combustion ash and the melting temperature of the reheated ash is lower than that in the combustion ash. With the increase of temperature, the total content of sodium decreases obviously, the water-soluble and ammonia-soluble sodium decreases rapidly, while the HCl soluble sodium increases first and then decreases and the insoluble sodium increases. The sodium released is mainly soluble. Heating temperature and time have an influence on the releasing of sodium, and the combustion reaction leads to the temperature on particle surface higher than surrounding temperature by 200℃, which is the main cause of releasing more sodium.

-

Key words:

- Zhundong coal /

- sodium release /

- ash composition /

- combustion reaction

-

图 7 不同温度下燃烧灰的XRD谱图

Figure 7 XRD patterns of combustion ash at different temperatures

A: albite (NaAlSi3O8); An: anhydrite(CaSO4); C: calcite(CaCO3); Ca: merwinite (Ca3Mg(SiO4)2) F: forsterite(Mg2SiO4); G: gehlenite(Ca2Al2SiO7); Gl: glauberite(Na2Ca(SO4)2); H: halite(NaCl); He: hedenbergite(CaFe(Si2O6)); M: merwinite(Ca3Mg(SiO4)2); N: nitratine(NaNO3); P: pyrite(FeS2); Q: quartz(SiO2); S: msylvine(KCl)

图 8 不同温度下再热灰的XRD谱图

Figure 8 XRD patterns of reheated ash at different temperatures

A: albite (NaAlSi3O8); An: anhydrite(CaSO4); C: calcite(CaCO3); Ca: merwinite (Ca3Mg(SiO4)2) F: forsterite(Mg2SiO4); G: gehlenite(Ca2Al2SiO7); Gl: glauberite(Na2Ca(SO4)2); H: halite(NaCl); He: hedenbergite(CaFe(Si2O6)); M: merwinite(Ca3Mg(SiO4)2); N: nitratine(NaNO3); P: pyrite(FeS2); Q: quartz(SiO2); S: msylvine(KCl)

表 1 五彩湾煤样的工业分析和元素分析

Table 1 Proximate and ultimate analysis of Wcw sample

Sample Proximate analysis w/% Ultimate analysis w/% Qd, net

/(MJ·kg-1)Ad Vd FCd Cdaf Hdaf Ndaf Sdaf Odaf* Wcw-Raw 5.65 32.13 62.22 73.96 3.96 0.54 0.64 20.90 25.52 O*: by difference 表 2 燃烧和再热灰的成分及熔点分析

Table 2 Composition and melting points of combustion and reheated ash

Sample Content w/% Temperature t/℃ Al2O3 SiO2 SO3 K2O CaO Na2O MgO Fe2O3 DT ST FT L-ash 10.33 17.64 20.51 0.19 29.17 4.64 7.68 4.03 1186 1258 1290 C-800 10.35 18.30 26.35 0.07 29.74 2.49 7.13 4.19 1224 1293 1316 R-800 10.02 18.08 24.74 0.15 29.08 4.10 7.27 4.15 1206 1280 1298 表 3 灰样中金属离子含量

Table 3 Content of metal ions in ash samples

Sample Content w/(mg·g-1) Na Ca Mg Fe Al L-ash 70.25 238.29 22.40 74.22 46.72 C-600 33.06 284.64 28.89 80.20 52.57 C-800 25.99 278.63 30.70 96.76 55.88 C-1000 21.77 291.77 26.14 99.13 56.42 C-1200 14.00 296.10 28.80 89.59 64.40 R-600 54.23 276.30 28.54 74.29 46.44 R-800 41.08 278.47 27.59 78.58 49.97 R-1000 32.82 284.70 28.35 83.83 50.57 R-1200 24.50 297.11 31.46 89.07 48.58 -

[1] 陈川, 张守玉, 刘大海, 郭熙, 董爱霞, 熊绍武, 施大钟, 吕俊复.新疆高钠煤中钠的赋存形态及其对燃烧过程的影响[J].燃料化学学报, 2013, 41(7):832-838. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract18218.shtmlCHEN Chuan, ZHANG Shou-yu, LIU Da-hai, GUO Xi, DONG Ai-xia, XIONG Shao-wu, SHI Da-zhong, LÜ Jun-fu. Existence form of sodium in high sodium coals from Xinjiang and its effect on combustion process[J]. J Fuel Chem Technol, 2013, 41(7):832-838. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract18218.shtml [2] 郭帅, 蒋云峰, 熊青安, 宋双双, 赵建涛, 房倚天.准东煤热解过程中不同赋存形态钠变迁规律的研究[J].燃料化学学报, 2017, 45(3):1-8. http://rlhxxb.sxicc.ac.cn/CN/Y2017/V45/I03/257GUO Shuai, JIANG Yun-feng, XIONG Qing-an, SONG Shuang-shuang, ZHAO Jian-tao, FANG Yi-tian. Release and transformation behaviors of sodium species with different occurrence modes during pyrolysis of Zhundong coal[J]. J Fuel Chem Technol, 2017, 45(3):1-8. http://rlhxxb.sxicc.ac.cn/CN/Y2017/V45/I03/257 [3] 张小培, 张成, 余圣辉, 李鑫, 冯小飞, 马亚飞, 陈刚.准东煤水热提质过程中煤质特性变化对CO2气化影响[J].燃料化学学报, 2017, 45(10):1185-1190. doi: 10.3969/j.issn.0253-2409.2017.10.005ZHANG Xiao-pei, ZHANG Cheng, YU Sheng-hui, LI Xin, FENG Xiao-fei, MA Ya-fei, CHEN Gang. Changes of Zhundong coal properties by hydrothermal upgrading and its impacts on CO2 gasification[J]. J Fuel Chem Technol, 2017, 45(10):1185-1190. doi: 10.3969/j.issn.0253-2409.2017.10.005 [4] 孙鑫, 赵斌, 王子兵, 梁精龙, 李慧. SO2和H2O(g)对新疆高钠煤中钠挥发和形态迁移的研究[J].燃料化学学报, 2017, 45(10):1178-1184. doi: 10.3969/j.issn.0253-2409.2017.10.004SUN Xin, ZHAO Bin, WANG Zi-bing, LIANG Jing-long, LI Hui. Effect of H2O(g) and SO2(g) on the volatilization and transformation of sodium during Xinjiang high-sodium coal combustion[J]. J Fuel Chem Technol, 2017, 45(10):1178-1184. doi: 10.3969/j.issn.0253-2409.2017.10.004 [5] 齐晓宾, 宋国良, 宋维健, 吕清刚.准东煤循环流化床气化过程中的矿物质转化行为特性[J].燃烧科学与技术, 2017, 23(1):29-35. http://journals.tju.edu.cn/rs/oa/pdfdow.aspx?Sid=R201603028QI Xiao-bin, SONG Guo-liang, SONG Wei-jian, LÜ Qing-gang. Mineral transformation behavior of Zhundong coal during circulating fludized bed gasification[J]. J Combust Sci Technol, 2017, 23(1):29-35. http://journals.tju.edu.cn/rs/oa/pdfdow.aspx?Sid=R201603028 [6] 王智化, 李谦, 刘敬, 黄镇宇, 周志军, 周俊虎, 岑可法.准东煤中碱金属的赋存形态及其在热解过程中的迁移规律[J].中国电机工程学报, 2014, 34(S1):130-135. http://www.cnki.com.cn/Article/CJFDTotal-ZGDC2014S1018.htmWANG Zhi-hua, LI Qian, LIU Jing, HUANG Zhen-yu, ZHOU Zhi-jun, ZHOU Jun-hu, CEN Ke-fa. Occurrence of alkali metals in Zhundong coal and its migration during pyrolysis process[J]. Proc CSEE, 2014, 34(S1):130-135. http://www.cnki.com.cn/Article/CJFDTotal-ZGDC2014S1018.htm [7] CHAKRAVARTY S, MOHANTY A, BANERJEE A, TRIPATHY R, MANDAL G K, BASARIYA M R, SHARMA M. Composition, mineral matter characteristics and ash fusion behavior of some Indian coals[J]. Fuel, 2015, 150:96-101. doi: 10.1016/j.fuel.2015.02.015 [8] 陈冠益, 王钦, 颜蓓蓓.煤中痕量元素在循环流化床锅炉中的迁移行为与富集特性[J].燃料化学学报, 2013, 41(9):1050-1055. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract18250.shtmlCHEN Guan-yi, WANG Qin, YAN Bei-bei. Mobility and enrichment of trace elements in a coal-fired circulating fluidized bed boiler[J]. J Fuel Chem Technol, 2013, 41(9):1050-1055. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract18250.shtml [9] CHEN H, PAN P, JIAO J, WANG Y, ZHAO Q. Low-temperature ash deposition and dewpoint corrosion of a coal-fired travelling grate boiler[J]. Appl Therm Eng, 2017, 117:752-761. doi: 10.1016/j.applthermaleng.2017.02.052 [10] 莫鑫, 蔡润夏, 吕俊复.基于返料灰温偏差的600MW(e)循环流化床锅炉内气固不均匀分布[J].中国电机工程学报, 2016, 36(8):2175-2180. http://www.doc88.com/p-5837657514689.htmlMO Xin, CAI Run-xia, LU Jun-fu. Analysis of non-uniform distribution of gas-solid flow in the 600MW(e) CFB boiler based on the non-uniform distribution of returning ash temperature[J]. Proc CSEE, 2016, 36(8):2175-2180. http://www.doc88.com/p-5837657514689.html [11] MODLINSKI N, HARDY T. Development of high-temperature corrosion risk monitoring system in pulverized coal boilers based on reducing conditions identification and CFD simulations[J]. Appl Energ, 2017, 204:1124-1137. doi: 10.1016/j.apenergy.2017.04.084 [12] 张传美, 金晶, 张号, 蒋杰, 高文静, 董振.干煤粉加压气化炉对流废热锅炉内多相流场和温度场的数值模拟[J].动力工程学报, 2013, 33(6):424-429. http://www.cnki.com.cn/Article/CJFDTotal-HGJX201502030.htmZHANG Chuan-mei, JIN Jing, ZHANG Hao, JIANG Jie, GAO Wen-jing, DONG Zhen. Numerical simulation on flow and temperature field of multi-phase flow in convective waste heat boiler of pressurized coal gasifiers[J]. J Power Eng, 2013, 33(6):424-429. http://www.cnki.com.cn/Article/CJFDTotal-HGJX201502030.htm [13] 刘敬, 王智化, 项飞鹏, 黄镇宇, 刘建忠, 周俊虎, 岑可法.准东煤中碱金属的赋存形式及其在燃烧过程中的迁移规律实验研究[J].燃料化学学报, 2014, 42(3):316-322. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract18373.shtmlLIU Jing, WANG Zhi-hua, XIANG Fei-peng, HUANG Zhen-yu, LIU Jian-zhong, ZHOU Jun-hu, CEN Ke-fa. Modes of occurrence and transformation of alkali metals in Zhundong coal during combustion[J]. J Fuel Chem Technol, 2014, 42(3):316-322. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract18373.shtml [14] 何金桥, 陈冬林, 鄢晓忠.低碱酸比煤灰在碳化硅质耐火板上的煅烧结渣特性[J].煤炭学报, 2011, 36(6):1022-1026. http://www.cqvip.com/QK/96550X/201106/38395779.htmlHE Jin-qiao, CHEN Dong-lin, YAN Xiao-zhong. Slagging characteristics of low alkailine-aild ratio coal ash on carborundumbased refractory liner under high temperature calcination[J]. J China Coal Soc, 2011, 36(6):1022-1026. http://www.cqvip.com/QK/96550X/201106/38395779.html [15] 田思达, 禚玉群, 康志忠, 方永旭.低比重分煤中结渣相关矿物质分布的实验研究[J].工程热物理学报, 2016, 37(8):1796-1801. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hgxb201408051TIAN Si-da, ZHUO Yu-qun, KANG Zhi-zhong, FANG Yong-xu. Experimental study on distribution of mineral matter relating to slagging in light coal fractions[J]. J Eng Therm, 2016, 37(8):1796-1801. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hgxb201408051 [16] 王东旭, 祁超, 王洋, 李文艳, 肖海平, 康志忠. CaO含量对高钠煤灰熔融特性的影响[J].燃料化学学报, 2017, 45(9):1025-1034. http://rlhxxb.sxicc.ac.cn/CN/Y2017/V09/I45/1025WANG Dong-xu, QI Chao, WANG Yang, LI Wen-yan, XIAO Hai-ping, KANG Zhi-zhong. Effect of CaO content on the ash fusibility of high sodium coal[J]. J Fuel Chem Technol, 2017, 45(9):1025-1034. http://rlhxxb.sxicc.ac.cn/CN/Y2017/V09/I45/1025 [17] 林雄超, 杨远平, 徐荣声, 李首毅, 岳文菲, 王永刚.新疆高碱煤分选组分中碱性矿物赋存及差异演化研究[J].燃料化学学报, 2017, 45(2):157-164. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract18974.shtmlLIN Xiong-chao, YANG Yuan-ping, XU Rong-sheng, LI Shou-yi, YUE Wen-fei, WANG Yong-gang. Occurrence and transformation behavior of AAEMs in the flotation fraction of a typical Xinjiang coal[J]. J Fuel Chem Technol, 2017, 45(2):157-164. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract18974.shtml [18] LI G, WANG C, YAN Y, JIN X, LIU Y, CHE D. Release and transformation of sodium during combustion of Zhundong coals[J]. J Energy Inst, 2016, 89(1):48-56. doi: 10.1016/j.joei.2015.01.011 [19] CHEN X, KONG L, BAI J, BAI Z, LI W. Effect of Na2O on mineral transformation of coal ash under high temperature gasification condition[J]. J Fuel Chem Technol, 2016, 44(3):263-272. doi: 10.1016/S1872-5813(16)30015-9 [20] SHEN J, HU H, XU M, LIU H, XU K, ZHANG X, YAO H, NARUSE I. Interactions between molten salts and ash components during Zhundong coal gasification in eutectic carbonates[J]. Fuel, 2017, 207:365-372. doi: 10.1016/j.fuel.2017.06.079 [21] MISHRA V, BHOWMICK T, CHAKRAVARTY S, VARMA A K, SHARMA M. Influence of coal quality on combustion behaviour and mineral phases transformations[J]. Fuel, 2016, 186:443-455. doi: 10.1016/j.fuel.2016.08.092 [22] JORDAN C A, AKAY G. Speciation and distribution of alkali, alkali earth metals and major ash forming elements during gasification of fuel cane bagasse[J]. Fuel, 2012, 91(1):253-263. doi: 10.1016/j.fuel.2011.05.031 [23] ZHOU C, LIU G, YAN Z, FANG T, WANG R. Transformation behavior of mineral composition and trace elements during coal gangue combustion[J]. Fuel, 2012, 97:644-650. doi: 10.1016/j.fuel.2012.02.027 [24] ZHANG H, GUO X, ZHU Z. Effect of temperature on gasification performance and sodium transformation of Zhundong coal[J]. Fuel, 2017, 189:301-311. doi: 10.1016/j.fuel.2016.10.097 [25] LIU S, QIAO Y, LU Z, GUI B, WEI M, YU Y, XU M. Release and transformation of sodium in kitchen waste during torrefaction[J]. Energy Fuels, 2014, 28(3):1911-1917. doi: 10.1021/ef500066b [26] KUMARI G, VAIRAKANNU P. Laboratory scale studies on CO2 oxy-fuel combustion in the context of underground coal gasification[J]. J CO2 Util, 2017, 21:177-190. doi: 10.1016/j.jcou.2017.06.021 [27] 宋维健, 宋国良, 齐晓宾, 吕清刚.准东高钠煤气化过程中Na的迁移转化规律[J].煤炭学报, 2016, 41(2):490-496. http://www.cqvip.com/QK/96550X/201602/668316482.htmlSONG Wei-jian, SONG Guo-liang, QI Xiao-bin, LU Qing-gang. Sodium transformation law of Zhundong coal during gasification[J]. J China Coal Soc, 2016, 41(2):490-496. http://www.cqvip.com/QK/96550X/201602/668316482.html [28] ZHANG J, HAN C-L, YAN Z, LIU K, XU Y, SHENG C D, PAN W P. The varying characterization of alkali metals (Na, K) from coal during the initial stage of coal combustion[J]. Energy Fuels, 2001, 15(4):786-793. doi: 10.1021/ef000140u -

下载:

下载: