Fluxing mechanism of rice straw for Jincheng anthracite under weak reducing atmosphere

-

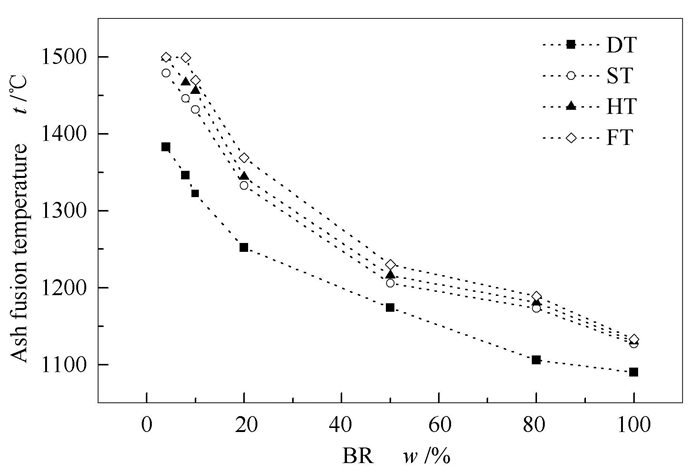

摘要: 以高灰熔点的晋城无烟煤和水稻秸秆为研究对象,通过CaO-Al2O3-SiO2三元相图、X射线衍射分析(XRD)和扫描电镜耦合X射线能谱分析(SEM-EDX)研究了弱还原气氛下水稻秸秆对晋城无烟煤的助熔机理。随着水稻秸秆添加比例的增加,灰熔融特征温度呈下降趋势,灰中碱性氧化物CaO、Na2O和K2O含量增多,结渣指数Rb/a值在0.20-0.69;当水稻秸秆添加量为20%(质量分数)时,流动温度(FT)降低至1 369℃,可满足气化炉液态排渣的要求;水稻秸秆的添加降低了灰中液相出现的温度,增加了液相物质出现的比例和几率,使灰更易发生熔融;混合灰中所形成的钠长石等低熔点矿物质以及钙长石、石英和莫来石所形成的低温共熔物导致灰熔点降低。

-

关键词:

- 晋城无烟煤 /

- 水稻秸秆 /

- CaO-Al2O3-SiO2相图 /

- 矿物质 /

- 助熔机理

Abstract: The fluxing mechanism of rice straw for Jincheng anthracite with high ash fusion temperatures was investigated under weak reducing atmosphere by CaO-Al2O3-SiO2 ternary phase diagram, X-ray diffraction (XRD) and scanning electron microscopy coupled with energy dispersive X-ray spectrometry (SEM-EDX). The fusion temperatures of blended ash decrease, and the content of basic oxide CaO, Na2O and K2O increases with increment of rice straw addition. The slagging index Rb/a is between 0.20 and 0.69. The fluid temperature (FT) declines to 1 369℃ by adding 20% rice straw, which could satisfy requirement of liquid slag discharge for gasifier. The addition of rice straw reduces the initial temperature and increases the occurrences proportion and probability of liquid phase in the ash. The formation of crystal albite with low melting point and eutectics formed from anorthite, quartz and mullite lead the decrease of ash fusion temperatures. -

图 4 灰样在不同热处理温度下的XRD谱图

Figure 4 XRD patterns of ashes at different heat-treatment temperatures

(a): Jincheng coal ash (CA); (b): rice straw ash (BA); (c): mixed ash (MA) Q: quartz (SiO2); I: illite (K1.5Al4(Si6.5Al1.5) O20(OH)4); H: hematite (Fe2O3); M: mullite (3Al2O3·2SiO2); He: hercynite (FeO·Al2O3); A: anhydrite (CaSO4); K: kaliophilite (KAlSiO4); Au: augite (Ca (Mg, Fe) Si2O6); W: wollastonite (CaO·SiO2); Al: albite (NaAlSi3O8); An: anorthite (CaAl2Si2O8)

表 1 晋城无烟煤和水稻秸秆的工业分析和元素分析

Table 1 Proximate and ultimate analysis of Jincheng anthracite and rice straw

Feedstock Proximate analysis w/% Ultimate analysis wdaf/% Mad Ad FCdaf Vdaf C H O* N S Jincheng coal 0.95 21.40 89.79 10.21 87.94 3.22 5.32 1.10 2.42 Rice straw 5.83 15.79 14.65 85.35 45.91 2.88 48.50 0.93 1.78 *: by difference 表 2 晋城无烟煤灰与水稻秸秆灰的化学组成及灰熔融特征温度

Table 2 Chemical compositions and fusion temperatures of ash from Jincheng anthracite and rice straw

Sample Chemical composition w/% Ash fusion temperature t/°C SiO2 Al2O3 TiO2 Fe2O3 CaO MgO K2O Na2O SO3 DT ST HT FT Jincheng ash 49.37 31.94 1.46 11.10 2.91 1.12 0.80 0.57 0.73 >1500 Rice straw ash 42.68 5.03 1.56 2.74 13.37 6.76 11.45 5.52 10.89 1090 1127 1130 1133 DT:deformation temperature;ST:soften temperature;HT:hemispherical temperature;FT:fusion temperature 表 3 不同水稻秸秆添加比例下混合原料灰产率的实验值与计算值

Table 3 Experimental and calculated value of ash yield from blended Jincheng coal with different BRs of rice straw

Ash yield w/% 0% 2% 4% 8% 10% 20% 50% 80% 100% Experimental 24.14 23.60 23.57 23.38 22.91 22.79 20.36 17.92 15.82 Calculated - 24.01 23.81 23.47 22.89 22.84 19.98 17.48 - -

[1] 乌晓江, 张忠孝, 朴桂林, 小林信介, 森滋勝, 板古羲纪.高灰熔点煤加压气流床气化特性[J].燃烧科学与技术, 2009, 15(2):182-186. http://www.cnki.com.cn/Article/CJFDTOTAL-RSKX200902016.htmWU Xiao-jiang, ZHANG Zhong-xiao, PIAO Gui-lin, KOBAYASHI Nobusuke, MORI Shigekatsu, ITATYA Yoshinori.Gasifiction characteristics of coal with high ash fusion temperature in lab-scale down-flow gasifier[J].J Combust Sci Technol, 2009, 15(2):182-186. http://www.cnki.com.cn/Article/CJFDTOTAL-RSKX200902016.htm [2] KIRUBAKARAN V, SIVARAMAKRISHNAN V, NALINI R, SEKAR T, PREMALATHA M, SUBRAMANIAN P.A review on gasification of biomass[J].Renewable Sustainable Energy Rev, 2009, 13:179-186. doi: 10.1016/j.rser.2007.07.001 [3] CHEN X L, TANG J Y, TIAN X J, WANG L.Influence of biomass addition on Jincheng coal ash fusion temperatures[J].Fuel, 2015, 160:614-620. doi: 10.1016/j.fuel.2015.08.024 [4] ZHANG G J, REINMÖLLER M, KLINGER M, MEYER B.Ash melting behavior and slag infiltration into alumina refractory simulating co-gasification of coal and biomass[J].Fuel, 2015, 139:457-465. doi: 10.1016/j.fuel.2014.09.029 [5] PRIYANTO D E, UENO S, SATO N, KASAI H, TANOUE T.Ash transformation by co-firing of coal with high ratios of woody biomass and effect on slagging propensity[J].Fuel, 2016, 174:172-179. doi: 10.1016/j.fuel.2016.01.072 [6] KUPKA T, MANCINI M, IRMER M, WEBER R.Investigation of ash deposit formation during co-firing of coal with sewage sludge, saw-dust and refuse derived fuel[J].Fuel, 2008, 87(12):2824-2837. doi: 10.1016/j.fuel.2008.01.024 [7] VASSILEV S V, BAXTER D, ANDERSEN L K, VASSILEVA C G.An overview of the composition and application of biomass ash.Part 1.Phase-mineral and chemical composition and classification[J].Fuel, 2015, 105:40-76. https://www.researchgate.net/publication/256712205_An_overview_of_the_composition_and_application_of_biomass_ash_Part_1_Phase-mineral_and_chemical_composition_and_classification [8] 姚润生, 李小红, 左永飞, 李凡.钠基助熔剂对灵石煤灰熔融特性温度的影响[J].煤炭学报, 2011, 36(6):1027-1031. http://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201106027.htmYAO Run-sheng, LI Xiao-hong, ZUO Yong-fei, LI Fan.Effect of sodium based flux on the ash melting characteristics temperature of Lingshi coal[J].J China Coal Soc, 2011, 36(6):1027-1031. http://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201106027.htm [9] VAN DYK J C.Understanding the influence of acidic components (Si, Al, and Ti) on ash flow temperature of South African coal sources[J].Miner Eng, 2006, 19(3):280-286. doi: 10.1016/j.mineng.2005.06.018 [10] 李文, 白进.煤的灰化学[M].北京:科学出版社, 2013.LI Wen, BAI Jin.Chemistry of Ash from Coal[M].Beijing:Science Press, 2013. [11] 李振珠, 李风海, 马名杰, 黄戒介, 房倚天.高灰熔点煤灰熔融特性的可控调整研究进展[J].化学工程, 2015, 43(3):60-63. http://www.cnki.com.cn/Article/CJFDTOTAL-IMIY201503015.htmLI Zhen-zhu, LI Feng-hai, MA Ming-jie, HUANG Jie-jie, FANG Yi-tian.Review on controllable adjustment of coal ash melting characteristic with high ash melting point[J].Chem Eng, 2015, 43(3):60-63. http://www.cnki.com.cn/Article/CJFDTOTAL-IMIY201503015.htm [12] LIU B, HE Q H, JIANG Z H, XU R F, HU B X.Relationship between coal ash composition and ash fusion temperatures[J].Fuel, 2013, 105:293-300. doi: 10.1016/j.fuel.2012.06.046 [13] 王勤辉, 景妮洁, 骆仲泱, 李小敏, 揭涛.灰成分影响煤灰烧结温度的实验研究[J].煤炭学报, 2010, 35(6):1015-1020. http://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201006035.htmWANG Qin-hui, JING Ni-jie, LUO Zhong-yang, LI Xiao-min, JIE Tao.Experiments on the effect of chemical components of coalash on the sintering temperature[J].J China Coal Soc, 2010, 35(6):1015-1020. http://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201006035.htm [14] DU S L, YANG H P, QIAN K Z, WANG X H, CHEN H P.Fusion and transformation properties of the inorganic components in biomass ash[J].Fuel, 2014, 117:1281-1287. doi: 10.1016/j.fuel.2013.07.085 [15] 陈树江, 田凤仁, 李国华, 张云.相图分析与应用[M].北京:冶金工业出版社, 2007.CHEN Shu-jiang, TIAN Feng-ren, LI Guo-hua, ZHANG Yun.Analysis and Application of Phase Diagram[M].Beijing:Metallurgical Industry Press, 2007. [16] DENG C Y, ZHANG C, TAN P, FANG Q Y, CHEN G.The melting and transformation characteristics of minerals during co-combustion of coal with different sludges[J].Energy Fuels, 2015, 29(10):6758-6767. doi: 10.1021/acs.energyfuels.5b01201 [17] 乌晓江, 张忠孝, 朴桂林, 森滋勝, 板谷羲纪, 陈龙.配煤对降低高灰熔融性煤的三元相图分析[J].洁净煤技术, 2007, 13(3):64-67. http://www.cnki.com.cn/Article/CJFDTOTAL-JJMS200703019.htmWU Xiao-jiang, ZHANG Zhong-xiao, PIAO Gui-ling, MORI Shigekatsu, ITATYA Yoshinori, CHEN Long.Analysis of coal ash fusion characteristics of high fusibility coal blending with low's with ternarr phase diagram[J].Clean Coal Technol, 2007, 13(3):64-67. http://www.cnki.com.cn/Article/CJFDTOTAL-JJMS200703019.htm [18] WU X J, ZHANG Z X, CHEN Y S, ZHOU T, FAN J J, PIAO G L, KOBAYASHI N, MORI S, ITAYA Y.Main mineral melting behavior and mineral reaction mechanism at molecular level of blended coal ash under gasification condition[J].Fuel Process Technol, 2010, 91(11):1591-1600. doi: 10.1016/j.fuproc.2010.06.007 [19] WANG H G, QIU P H, WU S J, ZHU Y, LI Y Q, ZHAO G B.Melting behavior of typical ash particles in reducing atmosphere[J].Energy Fuels, 2012, 26(6):3527-3541. doi: 10.1021/ef300247y [20] LI F H, LI Z Z, HUANG J J, FANG Y T.Understanding mineral behaviors during anthracite fluidized-bed gasification based on slag characteristics[J].Appl Energy, 2014, 131:279-287. doi: 10.1016/j.apenergy.2014.06.051 [21] WANG L, SKREIBERGØ, BECIDAN M, LI H.Investigation of rye straw ash sintering characteristics and the effect of additives[J].Appl Energy, 2016, 162:1195-1204. doi: 10.1016/j.apenergy.2015.05.027 [22] NAMKUNG H, XU L, KIM C, YUAN X Z, KANG T J, KIM H T.Effect of mineral components on sintering of ash particles at low temperature fouling conditions[J].Fuel Process Technol, 2016, 141:82-92. doi: 10.1016/j.fuproc.2015.06.004 [23] MATJIE R H, FRENCH D, WARD C R, PISTORIUS P C, LI Z S.Behaviour of coal mineral matter in sintering and slagging of ash during the gasification process[J].Fuel Process Technol, 2011, 92(8):1426-1433. doi: 10.1016/j.fuproc.2011.03.002 -

下载:

下载: