Form and distribution of sulfur in pulverized Jincheng coal and their influence on its ash fusibility

-

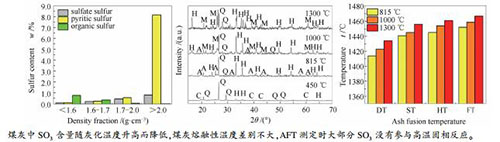

摘要: 选取山西晋城煤研究煤粉中硫存在形态、分布规律及其对煤灰熔融性的影响。采用浮沉法将煤粉分选成 < 1.6、1.6-1.7、1.7-2.0和>2.0 g/cm3四个密度级别子样,分析各子样的硫含量、赋存形态及分布规律;测定了不同密度子样煤灰熔融性,并将>2.0 g/cm3密度级别子样加热到450、815、1000和1300℃,研究煤粉中硫受热挥发及其对灰熔融温度的影响规律,并通过XRD和XRF分析进行机理研究。结果表明,晋城煤粉中硫在各密度子样中分布不均匀,在>2.0 g/cm3密度级中含量最高;随密度提高,各子样中有机硫含量快速下降,而硫酸盐硫、硫铁矿硫含量均显著上升。随灰化温度提高,原煤及各密度级别子样硫含量均下降,其中,450℃挥发87%,1300℃基本挥发完全。不同密度子样熔融温度不同,>2.0 g/cm3样品灰熔融温度最低;随灰化温度提高煤灰熔融温度升高。机理研究表明,不同密度子样灰熔融温度发生分化主要是其化学组成不同造成的,而>2.0 g/cm3子样熔融温度随灰化温度变化规律主要是灰中残留SO3造成的。Abstract: Forms and distribution of sulfur in pulverzied Jincheng coal were analyzed, and their influence on ash fusion temperature (AFT) was studied. With the float-sink method, the whole coal was separated into four density fractions, i.e. < 1.6, 1.6-1.7, 1.7-2.0 and >2.0 g/cm3. The distribution of sulfur content and their forms were analyzed. SO3 content and AFT of the coal samples ashed at 450, 815, 1000, and 1300℃ were determined. XRF and XRD were used to reveal the mechanism. The results show that sulfur in pulverized Jincheng coal is not evenly distributed in different density fractions, mainly concentrated in >2.0 g/cm3. With increase of the density, content of organic sulfur decreases rapidly, while those of sulphate sulfur and pyrite increase significantly. With increasing ashing temperature, sulfur contents in the whole coal and density fractions decrease. At 450℃, 87% sulfur is vaporized and at 1300℃ almost all sulfur is vaporized. Different density fraction shows different AFT, with >2.0 g/cm3 having the lowest AFT. Besides, AFT of >2.0 g/cm3 increases with rising ashing temperature. Mechanism study shows that the differentiation of AFT in different density fraction can be attributed to their chemical composition. The increase of AFT of >2.0 g/cm3 with ashing temperature is mainly due to sulfur SO3 content in the ash residual.

-

Key words:

- Jincheng coal /

- forms of sulfur /

- density fraction /

- ash fusibility

-

表 1 晋城原煤的工业分析和元素分析

Table 1 Proximate and ultimate analyses of Jincheng coal

Proximate analysis w/% Ultimate analysis w/% Mad Ad Vd FCd Cdaf Hdaf Ndaf Odaf* St,d 4.49 19.24 7.78 68.49 88.60 3.24 1.11 3.20 3.11 *: by difference 表 2 晋城原煤的熔融温度

Table 2 Ash fusion temperatures of Jincheng coal

Temperature t/℃ DT ST HT FT 1525 1547 1562 1581 表 3 晋城煤灰中SO3含量随灰化温度变化规律

Table 3 SO3 content in Jincheng coal ash at different temperatures

Temperature t /℃ 450 815 1000 1300 SO3 w /% 2.18 2.03 0.31 0.07 表 4 晋城不同密度级子样的熔融温度

Table 4 AFT of the density fractions in pulverized Jincheng coal

Sample Temperature t/℃ DT ST HT FT JC1 >1500 >1500 >1500 >1500 JC2 >1500 >1500 >1500 >1500 JC3 >1500 >1500 >1500 >1500 JC4 1414 1441 1445 1452 表 5 不同密度晋城煤粉815℃下煤灰的化学组成

Table 5 Chemical composition of Jincheng coal ash with different densities at 815℃

Sample Composition w/% B/A* SiO2 Al2O3 Fe2O3 CaO MgO SO3 TiO2 K2O Na2O P2O5 JC1 48.94 37.53 4.58 3.29 0.65 0.50 1.34 0.96 0.43 0.09 0.11 JC2 49.76 36.86 5.41 2.71 0.50 0.64 1.22 1.03 0.61 0.08 0.11 JC3 50.68 34.99 5.41 2.96 0.53 0.65 1.16 1.12 0.50 0.08 0.12 JC4 45.81 25.78 17.28 4.25 0.42 3.51 1.03 0.82 0.44 0.06 0.32 *: B/A=(Fe2O3 +K2O +Na2O+ CaO+ MgO)/(SiO2+ Al2O3 +TiO2) 表 6 晋城煤粉>2.0g/cm3子样不同灰化温度下灰的化学组成

Table 6 composition of > 2.0g/cm3 ash in Jincheng coal at different ashing temperatures

Temp.

t/℃Composition w/% B/A SiO2 Al2O3 Fe2O3 CaO MgO SO3 TiO2 K2O Na2O P2O5 450 45.02 24.93 17.21 4.32 0.41 3.82 1.03 0.95 0.48 0.06 0.33 815 45.21 25.78 17.28 4.25 0.42 3.51 1.03 0.92 0.54 0.08 0.33 1000 45.00 25.85 18.15 4.47 0.30 3.17 1.02 0.74 0.24 0.06 0.33 1300 47.16 27.51 18.92 4.18 0.33 0.01 1.09 0.78 0.31 0.06 0.32 -

[1] 张鹏启, 杨琪琪, 屠卡滨, 王月伦, 王祖威, 刘林林.晋城粉煤煤灰不均匀熔融规律研究[J].燃料化学学报, 2018, 46(1):8-14. doi: 10.3969/j.issn.0253-2409.2018.01.002ZHANG Peng-qi, YANG Qi-qi, TU Ka-bin, WANG Yue-lun, WANG Zu-wei, LIU Lin-lin. Study on the uneven melting law of coal ash in Jincheng[J]. J Fuel Chem Technol, 2018, 46(1):8-14. doi: 10.3969/j.issn.0253-2409.2018.01.002 [2] ZHANG H, WU S, YANG Y, CHENG J, LUN F, WANG Q. Mineral distribution in pulverized blended Zhundong coal and its influence on ash deposition propensity in a real modern boiler situation[J]. ACS Omega, 2020, 5:4386-4394. doi: 10.1021/acsomega.9b02928 [3] 唐黎, 李仲根, 刘鸿雁, 陈吉.贵州省煤中硫形态分布特征及与汞的相关性[J].吉林大学学报(地球科学版), 2015:45(增刊1). http://d.old.wanfangdata.com.cn/Conference/9244431TANG Li, LI Zhong-gen, LIU Hong-yan, CHEN Ji. Distribution characteristics of sulfur in coal and its correlation with mercury in Guizhou Province[J]. J Jilin Univ (Earth Sci), 2015:45(S1). http://d.old.wanfangdata.com.cn/Conference/9244431 [4] 陈文敏, 姜宁.煤灰成分和煤灰熔融性的关系[J].洁净煤技术, 1996, 2(2):34-37. http://d.old.wanfangdata.com.cn/Periodical/shanxhg201604013CHEN Wen-min, JIANG Ning. The relationship between coal ash composition and coal ash fusion[J]. Clean coal Technol, 1996, 2(2):34-37. http://d.old.wanfangdata.com.cn/Periodical/shanxhg201604013 [5] KLEINHANS U, WIELAND C, FRANDSEN F J, SPLIETHOFF H. Ash formation and deposition in coal and biomass fired combustion systems:Progress and challenges in the field of ash particle sticking and rebound behavior[J]. Prog Energy Combust Sci, 2018, 68:65-168. doi: 10.1016/j.pecs.2018.02.001 [6] 张德祥, 龙永华, 高晋生, 郑斌.煤灰中矿物的化学组成与灰熔融性的关系[J].华东理工大学学报, 2003, 12(6):590-594. doi: 10.3969/j.issn.1006-3080.2003.06.012ZHANG De-xiang, LONG Yong-hua, GAO Jin-sheng, ZHENG Bing. Relationship between the coal ash fusibility and its chemical composition[J]. East China Univ Sci Technol, 2003, 12(6):590-594. doi: 10.3969/j.issn.1006-3080.2003.06.012 [7] CHENG J, ZHOU J H, LIU J Z, ZHOU Z J. Sulfur removal at high temperature during coal combustion in furnaces:A review[J]. Prog Energy Combust Sci, 2003, 29(5):381-405. doi: 10.1016/S0360-1285(03)00030-3 [8] 谢峻林, 肖飞燕, 狄东仁, 朱战岭.高硫煤对水泥熟料矿物形成及显微结构的影响[J].武汉理工大学学报, 2010, 32(15):1-4. doi: 10.3963/j.issn.1671-4431.2010.15.001XIE Jun-lin, XIAO Fei-yan, DI Dong-ren, ZHU Zhan-ling.Effect of high-sulfur coal on mineral formation and petrographic structure of cement clinker[J]. J Wuhan Univ Technol, 2010, 32(15):1-4. doi: 10.3963/j.issn.1671-4431.2010.15.001 [9] ZHANG H, MO Y, SUN M, WEI X. Determination of the mineral distribution in pulverized coal using densitometry and laser particle sizing[J]. Energy Fuels, 2005, 19(6):2261-2267. doi: 10.1021/ef050201u [10] REINMÖLLER M, SCHREINER M, GUHL S, NEUROTH M. Formation and transformation of mineral phases in various fuels studied by different ashing methods[J]. Fuel, 2017, 202:641-649. doi: 10.1016/j.fuel.2017.04.115 [11] 张渤, 张洪, 杨云飞, 胡光洲, 张鹏启, 伦飞.晋城煤粒度变化对灰熔融性影响规律研究[J].燃料化学学报, 2018, 46(12):1430-1436. doi: 10.3969/j.issn.0253-2409.2018.12.003ZHANG Bo, ZHANG Hong, YANG Yun-fei, HU Guang-zhou, ZHANG Peng-qi, LUN Fei. Study on the influence of particle size on the ash melting behavior of Jincheng coal[J]. J Fuel Chem Technol, 2018, 46(12):1430-1436. doi: 10.3969/j.issn.0253-2409.2018.12.003 [12] 陈国芳.沁水煤田晋城矿区成煤环境分析[J].华北国土资源, 2016, (3):18-19. doi: 10.3969/j.issn.1672-7487.2016.03.009CHEN Guo-fang.Analysis of coal-forming environment in Jincheng mining area of Qinshui coalfield[J]. North China Land Res, 2016, (3):18-19. doi: 10.3969/j.issn.1672-7487.2016.03.009 [13] 李文, 白进.煤的灰化学[M].北京, 科学出版社, 2013.LI Wen, BAI Jin. Ash Chemistry of Coal[M]. Beijing:Science Press, 2013. -

下载:

下载: