-

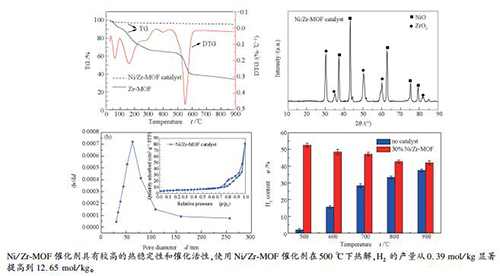

摘要: 通过均匀沉淀法制备了以锆-金属有机骨架化合物(Zr-metal organic framework,Zr-MOF)为载体的Ni/Zr-MOF催化剂,并用于湿污泥和秸秆混合催化热解实验。采用元素分析、X射线荧光光谱(XRF)、热重分析(TG)、X射线衍射(XRD)、扫描电镜(SEM)和N2吸附-脱附等温(BET)对载体和催化剂进行表征分析,通过一系列实验来探讨热解温度、秸秆添加量和Ni负载量对于湿污泥和秸秆混合催化热解制备富氢合成气的影响。结果表明,Zr-MOF载体颗粒均匀呈八面体,比表面积高达805.93 m2/g,平均孔径为20.14 nm,为介孔结构。Ni/Zr-MOF催化剂具有较高的热稳定性和催化活性。与不添加催化剂相比,使用Ni/Zr-MOF催化剂在500 ℃下热解,H2的产量从0.39 mol/kg显著提高到12.65 mol/kg。随着热解温度的升高,催化剂出现团聚现象,同时在反复使用之后其表面产生了少量的积炭,导致催化剂催化活性逐渐降低。因此,Ni/Zr-MOF催化剂适用于生物质低温催化热解。Abstract: The catalytic co-pyrolysis of wet sewage sludge and wheat straw for hydrogen-rich gas production was experimentally investigated in a fixed bed reactor with Ni/Zr-MOF catalyst. The Ni/Zr-MOF catalyst was characterized by ultimate analysis, XRF, TG, XRD, SEM and BET. The effects of reactor temperature, straw content and Ni loading on the composition and yield of gasification gases were explored. The experimental results indicate that the mesoporous Zr-MOF support particles are octahedral with a specific surface area of 805.93 m2/g and an average pore diameter of 20.14 nm. The Ni/Zr-MOF catalyst has high thermal stability and catalytic activity. Compared with the pyrolysis without catalyst, the H2 yield increases significantly from 0.39 mol/kg to 12.65 mol/kg using Ni/Zr-MOF catalyst at 500 ℃. After reuse, the carbon deposits are formed on the surface of catalyst. With the increase in reactor temperature, the catalytic activity decreases gradually due to the agglomeration of the catalyst. Therefore, the Ni/Zr-MOF catalyst is suitable for catalytic pyrolysis of biomass at lower temperature.

-

表 1 干污泥和小麦秸秆的工业分析和元素分析

Table 1 Proximate and ultimate analysis of dry sludge and wheat straw

Sample Proximate analysis wad/% Ultimate analysis w/% M A V FC C H N S O* Sludge 4.15 50.69 35.33 9.83 25.20 5.62 3.82 0.15 14.52 Wheat straw 10.88 6.91 67.11 15.10 31.04 4.22 0.40 0.06 57.37 *: by difference 表 2 样品的元素分析和XRF分析

Table 2 Ultimate analysis and XRF analysis of samples

Sample Main composition and content w/% C H N ZrO2 NiO K2O Zr-MOF 33.16 3.57 3.29 58.34 - - Ni/Zr-MOF 0.13 - - 29.63 65.89 3.01 Waste Ni/Zr-MOF 5.47 - - 26.73 63.89 2.54 表 3 Zr-MOF载体、Ni/Zr-MOF催化剂和废Ni/Zr-MOF催化剂的结构参数

Table 3 Textural parameters of Zr-MOF, Ni/Zr-MOF and waste Ni/Zr-MOF

Sample BET surface area A/(m2·g-1) Total pore volume v/(cm3·g-1) Average pore diameter d/nm Zr-MOF 805.93 0.47 20.14 Ni/Zr-MOF 17.96 0.13 102.11 Waste Ni/Zr-MOF 4.01 0.02 132.58 表 4 催化剂对于气体组成和特性的影响

Table 4 Influence of catalyst on gas composition and gas characterization

Catalyst No catalyst 30%Ni/Zr- MOF catalyst Pyrolysis temperature t/℃ 500 500 Catalytic temperature t/℃ 500 500 H2 content φ/% 1.94 52.48 CO content φ/% 55.07 12.03 CH4 content φ/% 20.03 5.74 CO2 content φ/% 21.12 29.38 CnHm content φ/% 1.83 0.37 Dry gas yield /(m3·kg-1) 0.45 0.54 H2 yield /(mol·kg-1) 0.39 12.65 QLHV/(MJ·m-3) 15.51 9.87 -

[1] SAXENA R C, ADHIKARI D K, GOYAL H B. Biomass-based energy fuel through biochemical routes:A review[J]. Renewable Sustainable Energy Rev, 2009, 13(1):167-178. doi: 10.1016/j.rser.2007.07.011 [2] ZHAO Z Y, YAN H. Assessment of the biomass power generation industry in China[J]. Renew Energy, 2012, 37(1):53-60. [3] ISMAIL T M, EL-SALAM M A. Parametric studies on biomass gasification process on updraft gasifier high temperature air gasification[J]. Appl Therm Eng, 2017, 112:1460-1473. doi: 10.1016/j.applthermaleng.2016.10.026 [4] XU X, ZHAO B, SUN M, CHEN X, ZHANG M, LI H, XU S. Co-pyrolysis characteristics of municipal sewage sludge and hazelnut shell by TG-DTG-MS and residue analysis[J]. Waste Management, 2017, 62:91-100. doi: 10.1016/j.wasman.2017.02.012 [5] HAN J, KIM H. The reduction and control technology of tar during biomass gasification/pyrolysis:An overview[J]. Renewable Sustainable Energy Rev, 2008, 12(2):397-416. doi: 10.1016/j.rser.2006.07.015 [6] ZHOU Y, WANG W, SUN J, FU L, SONG Z, ZHAO X, MAO Y. Microwave-induced electrical discharge of metal strips for the degradation of biomass tar[J]. Energy, 2017, 126:42-52. doi: 10.1016/j.energy.2017.03.008 [7] 杨泽, 李挺, 王美君, 常丽萍, 任秀蓉. Ni基生物质焦油重整催化剂的研究进展[J].化工进展, 2016, 35(10):3155-3163. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hgjz201610020YANG Ze, LI Ting, WANG Mei-jun, CHANG Li-ping, REN Xiu-rong. Research progress on Ni-based catalyst for tar reforming in biomass gasification[J]. Chem Ind Eng Prog, 2016, 35(10):3155-3163. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hgjz201610020 [8] LI J, LIU J, LIAO S, YAN R. Hydrogen-rich gas production by air-steam gasification of rice husk using supported nano-NiO/γ-Al2O3 catalyst[J]. Int J Hydrog Energy, 2010, 35(14):7399-7404. doi: 10.1016/j.ijhydene.2010.04.108 [9] 纪婷婷, 杨晓萱, 王亚晶, 王玉和.不同方法制备的介孔Ni/MgO催化剂上水蒸气重整苯酚制氢[J].燃料化学学报, 2016, 44(9):1131-1137. doi: 10.3969/j.issn.0253-2409.2016.09.015JI Ting-ting, YANG Xiao-xuan, WANG Ya-jing, WANG Yu-he. Steam reforming of phenol for producing hydrogen over nickel support on MgO prepared by different methods[J]. J Fuel Chem Technol, 2016, 44(9):1131-1137. doi: 10.3969/j.issn.0253-2409.2016.09.015 [10] SHI X W, XIN X, LIU Z, YAO L U, HONG-XIA L I, JIAN-FEN L I, CHEN Q P. Preparation and characterization of Ni/TPC catalyst and applied in straw pyrolysis gas reforming[J]. J Fuel Chem Technol, 2018, 46(6):659-665. doi: 10.1016/S1872-5813(18)30028-8 [11] 史训旺, 李建芬, 辛馨, 李红霞, 路遥, 刘照, 程群鹏. NiO-Fe2O3/PG-γ-Al2O3催化剂的制备及其在秸秆热解中的应用[J].燃料化学学报, 2017, 45(12):1434-1440. doi: 10.3969/j.issn.0253-2409.2017.12.004SHI Xun-wang, LI Jian-fen, XIN Xin, LI Hong-xia, LU Yao, LIU Zhao, CHENG Qun-peng. Preparation of NiO-Fe2O3/PG-γ-Al2O3 catalysts and its application in pyrolysis of biomass straw[J]. J Fuel Chem Technol, 2017, 45(12):1434-1440. doi: 10.3969/j.issn.0253-2409.2017.12.004 [12] REN J, LANGMI H W, NORTH B C, MATHE M, BESSARABOV D. Modulated synthesis of zirconium-metal organic framework (Zr-MOF) for hydrogen storage applications[J]. Int J Hydrog Energy, 2014, 39(2):890-895. doi: 10.1016/j.ijhydene.2013.10.087 [13] LV P M, XIONG Z H, CHANG J, WU C Z, CHEN Y, ZHU J X. An experimental study on biomass air-steam gasification in a fluidized bed[J]. Bioresour Technol, 2004, 95(1):95-101. doi: 10.1016/j.biortech.2004.02.003 [14] QIAN K, KUMAR A. Catalytic reforming of toluene and naphthalene (model tar) by char supported nickel catalyst[J]. Fuel, 2017, 187:128-136. doi: 10.1016/j.fuel.2016.09.043 [15] HU M, LAGHARI M, CUI B, XIAO B, ZHANG B, GUO D. Catalytic cracking of biomass tar over char supported nickel catalyst[J]. Energy, 2018, 145:228-237. doi: 10.1016/j.energy.2017.12.096 [16] XIAO X, CAO J, MENG X, LE D D, LI L, OGAWA Y, SATO K, TAKARADA T. Synthesis gas production from catalytic gasification of waste biomass using nickel-loaded brown coal char[J]. Fuel, 2013, 103:135-140. doi: 10.1016/j.fuel.2011.06.077 [17] SHEN W, MOMOI H, KOMATSUBARA K, SAITO T, YOSHIDA A, NAITO S. Marked role of mesopores for the prevention of sintering and carbon deposition in dry reforming of methane over ordered mesoporous Ni-Mg-Al oxides[J]. Catal Today, 2011, 171(1):150-155. doi: 10.1016/j.cattod.2011.04.003 [18] YANG Y, ZHU J, ZHU G, YANG L, ZHU Y. The effect of high temperature on syngas production by immediate pyrolysis of wet sewage sludge with sawdust[J]. J Therm Anal Calorim, 2018, 132(3):1783-1794. doi: 10.1007/s10973-018-7143-9 [19] HU M, GAO L, CHEN Z, MA C, ZHOU Y, CHEN J, MA S, LAGHARI M, XIAO B, ZHANG B, GUO D. Syngas production by catalytic in-situ steam co-gasification of wet sewage sludge and pine sawdust[J]. Energy Convers Manage, 2016, 111:409-416. doi: 10.1016/j.enconman.2015.12.064 [20] 王晨光, 王铁军, 吕鹏梅, 常杰, 徐莹.整体式催化剂催化重整净化生物质粗燃气性能研究[J].燃料化学学报, 2007, 35(3):285-288. doi: 10.3969/j.issn.0253-2409.2007.03.006WANG Chen-guang, WANG Tie-jun, LÜ Peng-mei, CHANG Jie, XU Ying. Reforming of raw biomass fuel gas over monolithic catalyst[J]. J Fuel Chem Technol, 2007, 35(3):285-288. doi: 10.3969/j.issn.0253-2409.2007.03.006 [21] XU L, SONG H, CHOU L. Carbon dioxide reforming of methane over ordered mesoporous NiO-MgO-Al2O3 composite oxides[J]. Appl Catal B:Environ, 2011, 108/109:177-190. doi: 10.1016/j.apcatb.2011.08.028 -

下载:

下载: