-

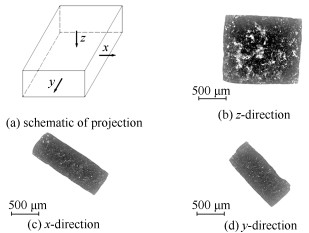

摘要: 采用高温热台显微镜观测了片状煤焦颗粒CO2气化过程中的形态演变,并通过拉曼光谱分析了气化半焦的碳微晶结构,同时研究了气化温度(1000-1200℃)和煤焦初始当量直径(1.00-1.60 mm)对其CO2气化过程中的形态及结构演变的影响规律。结果表明,与反应前期相比,反应后期的颗粒收缩(面积、体积、当量直径)更加剧烈。在所研究的气化温度范围内,随着气化温度的升高,煤焦颗粒的面积收缩率和体积收缩率逐渐减小。煤焦初始粒径显著影响颗粒收缩,1100℃气化温度下,颗粒的收缩趋势在初始粒径1.30 mm处出现转折。煤焦气化过程中碳消耗主导着表观密度的变化,在所研究的温度和粒径范围内,当碳转化率达到80%时,表观密度比线性减小到0.4以下。在相同气化温度下,随着碳转化率的增加,煤焦的石墨化程度先减小后增加,无定形碳含量先增加再减小。Abstract: High temperature stage microscope was applied to observe morphology evolution of flaky char particles during gasification. Raman spectroscopy was used to analyze crystalline structures of gasification semicoke. Effect of gasification temperature (1000-1200℃) and initial equivalent diameter (1.00-1.60 mm) on morphology and structure evolution were examined. The results show that particle shrinkage in later stage of gasification is more intense than that in early stage. Within tested gasification temperature, the particle ASR (area shrinkage ratio) and VSR (volumetric shrinkage ratio) decrease with increasing temperature. The initial particle size of char has a significant effect on particle shrinkage. At 1100℃ the shrinkage trend of particle marks a turning point at initial diameter of 1.30 mm. The variation of char apparent density is dominated by carbon consumption. When the carbon conversion reaches 80%, the apparent density ratio linearly decreases below 0.4. At the same gasification temperature, with increasing carbon conversion the graphitization of char reduces first and then increases, while the amorphous carbon is opposite.

-

表 1 原煤和热解焦的工业分析和元素分析

Table 1 Proximate, ultimate analysis of raw coal and pyrolysis char

Sample Proximate analysis wd/% Ultimate analysis wd/% A V FC C H O* N S SM 5.90 34.78 59.32 79.35 5.00 8.19 1.00 0.56 SMC 8.40 1.64 89.96 89.10 0.42 0.28 1.27 0.53 表 2 片状煤焦颗粒长、宽、高的尺寸

Table 2 Specific dimension of length, width and height for flaky char particles

Initial equivalent diameter /mm Length /mm Width /mm Height /mm 1.00 1.08-1.14 0.98-1.12 0.52-0.54 1.15 1.27-1.30 1.05-1.19 0.58-0.60 1.30 1.49-1.53 1.26-1.35 0.58-0.62 1.60 1.74-1.80 1.61-1.62 0.72-0.74 表 3 1100 ℃气化温度下反应前期和反应后期的比表面积对比

Table 3 Comparison of specific surface area at the early stage and later stage of reaction

Sample 1100 ℃-0.3 1100 ℃-0.5 1100 ℃-0.7 ABET/(m2·g-1) 237.2 280.9 442.6 表 4 不同气化温度下碳转化率为50%的气化半焦的BET比表面积

Table 4 BET specific surface area of gasification semi-coke with carbon conversion of 50 % at different gasification temperatures

Sample 1000 ℃-0.5 1100 ℃-0.5 1200 ℃-0.5 ABET /(m2·g-1) 649.2 280.9 78.3 -

[1] AHMED I I, GUPTA A K. Particle size, porosity and temperature effects on char conversion[J]. Appl Energy, 2011, 88(12):4667-4677. doi: 10.1016/j.apenergy.2011.06.001 [2] 李绍锋, 吴诗勇.高温下煤焦的碳微晶及孔结构的演变行为[J].燃料化学学报, 2010, 38(5):513-517. http://www.oalib.com/paper/4272639LI Shao-feng, WU Shi-yong. Evolvement behavior of carbon minicrystal and pore structure of coal chars at high temperatures[J]. J Fuel Chem Technol, 2010, 38(5):513-517. http://www.oalib.com/paper/4272639 [3] 林善俊, 李献宇, 丁路, 周志杰, 于广锁.内蒙煤焦CO2气化过程的结构演变特性[J].燃料化学学报, 2016, 44(12):1409-1415. doi: 10.3969/j.issn.0253-2409.2016.12.001LIN Shan-jun, LI Xian-yu, DING Lu, ZHOU Zhi-jie, YU Guang-suo. Structure evolution characteristics of Inner Mongolia coal char during CO2 gasification[J]. J Fuel Chem Technol, 2016, 44(12):1409-1415. doi: 10.3969/j.issn.0253-2409.2016.12.001 [4] DAI P, DENNIS J S, SCOTT S A. Using an experimentally-determined model of the evolution of pore structure for the gasification of chars by CO2[J]. Fuel, 2016, 171:29-43. doi: 10.1016/j.fuel.2015.12.041 [5] COETZEE G H, SAKUROVS R, NEOMAGUS H W J P, MORPETH L, EVERSON R C, MATHEWS J P, BUNT J R. Pore development during gasification of South African inertinite-rich chars evaluated using small angle X-ray scattering[J]. Carbon, 2015, 95:250-260. doi: 10.1016/j.carbon.2015.08.030 [6] COETZEE G H, SAKUROVS R, NEOMAGUS H W J P, MORPETH L, EVERSON R C, MATHEWS J P, BUNT J R. Particle size influence on the pore development of nanopores in coal gasification chars:from micron to millimeter particles[J]. Carbon, 2017, 112:37-46. doi: 10.1016/j.carbon.2016.10.088 [7] LI S, WHITTY K J. Physical phenomena of char-slag transition in pulverized coal gasification[J]. Fuel Process Technol, 2012, 95:127-136. doi: 10.1016/j.fuproc.2011.12.006 [8] LI T, ZHANG L, DONG L, ZHANG S, QIU P, WANG S, LI C Z. Effects of gasification temperature and atmosphere on char structural evolution and AAEM retention during the gasification of Loy Yang brown coal[J]. Fuel Process Technol, 2017, 159:48-54. doi: 10.1016/j.fuproc.2017.01.022 [9] BAI Y, WANG Y, ZHU S, LI F, XIE K. Structural features and gasification reactivity of coal chars formed in Ar and CO2 atmospheres at elevated pressures[J]. Energy, 2014, 74:464-470. doi: 10.1016/j.energy.2014.07.012 [10] MERMOUD F, GOLFIER F, SALVADOR S, STEENE L V, DIRION J L. Experimental and numerical study of steam gasification of a single charcoal particle[J]. Combust Flame, 2006, 145(1):59-79. [11] MOLINTAS H, GUPTA A K. Combustion of spherically shaped large wood char particles[J]. Fuel Process Technol, 2016, 148:332-340. doi: 10.1016/j.fuproc.2016.02.029 [12] HAUGEN N E L, TILGHMAN M B, MITCHELL R E. The conversion mode of a porous carbon particle during oxidation and gasification[J]. Combust Flame, 2014, 161(2):612-619. doi: 10.1016/j.combustflame.2013.09.012 [13] TILGHMAN M B, HAUGEN N E L, MITCHELL R E. A comprehensive char-particle gasification model adequate for entrained-flow and fluidized-bed gasifiers[J]. Energy Fuels, 2017, 31:2652-2662. doi: 10.1021/acs.energyfuels.6b03241 [14] 赵英杰, 陈雪莉, 陈汉鼎, 刘海峰.稻草固定床热解过程中不同赋存状态钾的迁移转化行为[J].燃料化学学报, 2014, 42(4):427-433. http://www.ccspublishing.org.cn/article/id/100033107ZHAO Ying-jie, CHEN Xue-li, CHEN Han-ding, LIU Hai-feng. Transfer of potassium in different forms during pyrolysis of rice straw in a fixed bed reactor[J]. J Fuel Chem Technol, 2014, 42(4):427-433. http://www.ccspublishing.org.cn/article/id/100033107 [15] SHEN Z, LIANG Q, XU J, ZHANG B, LIU H. In-situ experimental study of CO2 gasification of char particles on molten slag surface[J]. Fuel, 2015, 160:560-567. doi: 10.1016/j.fuel.2015.08.010 [16] SHEN Z, LIANG Q, XU J, ZHANG B, HAN D, LIU H. In situ experimental study on the combustion characteristics of captured chars on the molten slag surface[J]. Combust Flame, 2016, 166:333-342. doi: 10.1016/j.combustflame.2016.02.002 [17] SADEZKY A, MUCKENHUBER H, GROTHE H, NIESSNER R, PÖSCHL U. Raman microspectroscopy of soot and related carbonaceous materials:spectral analysis and structural information[J]. Carbon, 2005, 43(8):1731-1742. doi: 10.1016/j.carbon.2005.02.018 [18] BOURAOUI Z, JEGUIRIM M, GUIZANI C, LIMOUSY L, DUPONT C, GADIOU R. Thermogravimetric study on the influence of structural, textural and chemical properties of biomass chars on CO2 gasification reactivity[J]. Energy, 2015, 88:703-710. doi: 10.1016/j.energy.2015.05.100 [19] GUIZANI C, JEGUIRIM M, GADIOU R, SANZ F J E, SALVADOR S. Biomass char gasification by H2O, CO2 and their mixture:Evolution of chemical, textural and structural properties of the chars[J]. Energy, 2016, 112:133-145. doi: 10.1016/j.energy.2016.06.065 [20] ESSENHIGH R H. Influence of initial particle density on the reaction mode of porous carbon particles[J]. Combust Flame, 1994, 99(2):269-279. doi: 10.1016/0010-2180(94)90131-7 [21] HURT R H, DUDEK D R, LONGWELL J P, SAROFIM A F. The phenomenon of gasification-induced carbon densification and its influence on pore structure evolution[J]. Carbon, 1988, 26(4):433-449. doi: 10.1016/0008-6223(88)90142-X [22] ESSENHIGH R H, KLIMESH H E, FÖRTSCH D. Combustion characteristics of carbon:Dependence of the zone Ⅰ-zone Ⅱ transition temperature (Tc) on particle radius[J]. Energy Fuels, 1999, 13(4):826-831. doi: 10.1021/ef980241g [23] ALVARADO P N, CADAVID F J, SANTAMARÍA A, RUIZ W. Reactivity and structural changes of coal during its combustion in a low-oxygen environment[J]. Energy Fuels, 2016, 30(11):9891-9899. doi: 10.1021/acs.energyfuels.6b01913 [24] CHABALALA V P, WAGNER N, POTGIETER-VERMAAK S. Investigation into the evolution of char structure using Raman spectroscopy in conjunction with coal petrography; Part 1[J]. Fuel Process Technol, 2011, 92(4):750-756. doi: 10.1016/j.fuproc.2010.09.006 [25] ZHU X, SHENG C. Influences of carbon structure on the reactivities of lignite char reacting with CO2 and NO[J]. Fuel Process Technol, 2010, 91(8):837-842. doi: 10.1016/j.fuproc.2009.10.015 [26] SHENG C. Char structure characterised by Raman spectroscopy and its correlations with combustion reactivity[J]. Fuel, 2007, 86(15):2316-2324. doi: 10.1016/j.fuel.2007.01.029 [27] LIU X, ZHENG Y, LIU Z, DING H, HUANG X, ZHENG C. Study on the evolution of the char structure during hydrogasification process using Raman spectroscopy[J]. Fuel, 2015, 157:97-106. doi: 10.1016/j.fuel.2015.04.025 -

下载:

下载: