-

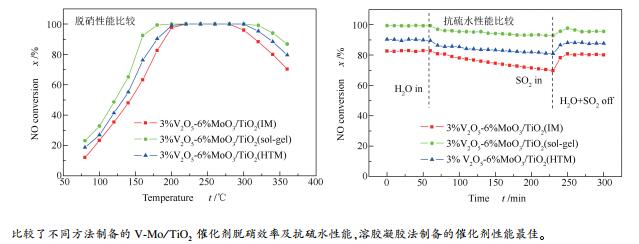

摘要: 采用浸渍法、溶胶凝胶法和水热法制备了一系列V-Mo/TiO2催化剂,考察了制备方法对催化剂脱硝性能及抗SO2/H2O性能的研究。并运用XRD、BET、NH3-TPD、H2-TPR、XPS等方法对催化剂的理化性能进行了表征,结果表明,溶胶凝胶法制备的催化剂具有较小的晶粒粒径,较大的比表面积和孔容,较多的表面酸量,较强的氧化还原能力以及较高的V4+和表面活性氧,因此,3% V2O5-6% MoO3/TiO2(sol-gel)催化剂在80-360℃,表现出最佳的脱硝效率;引入10% H2O和0.03% SO2后,NO转化率仅下降7个百分点,表现出最佳的抗SO2/H2O性能。

-

关键词:

- 催化剂 /

- V2O5-MoO3/TiO2 /

- 制备方法 /

- 脱硝效率

Abstract: A series of V-Mo/TiO2 catalysts were prepared by impregnation method, sol-gel method and hydrothermal method. The denitrification performance and anti-SO2/H2O performance of the catalysts were investigated.The physical and chemical properties of the catalyst were characterized by XRD, BET, NH3-TPD, H2-TPR and XPS.The results showed that the catalyst prepared by sol-gel method had smaller grain size, larger specific area and pore volume, more surface acidity, stronger redox ability and higher V4+ and surface active oxygen.Therefore, the 3% V2O5-6% MoO3/TiO2 (sol-gel) catalyst exhibited the best denitration efficiency in the temperature range of 80-360℃. After introducing 10% H2O and 0.03% SO2, the NO conversion of 3% V2O5-6% MoO3/TiO2 (sol-gel) catalyst decreased by only 7 percentage points, showing the best resistance to SO2/H2O.-

Key words:

- catalyst /

- V2O5-MoO3/TiO2 /

- preparation method /

- denitration efficiency

-

表 1 催化剂的结构和晶胞参数

Table 1 Structure and unit cell parameters of the catalyst

Sample Crystal parameters /nm D/nm v/nm3 a b c IM 0.378116 0.378116 0.949616 29.53 0.13577 Sol-gel 0.377498 0.377498 0.950567 13.07 0.13546 HTM 0.376812 0.376812 0.946093 30.29 0.13433 表 2 催化剂的物理化学性质

Table 2 Physicochemical properties of the catalyst

Sample Specific surface area

A/(m2·g-1)Average pore volume

v/(cm3·g-1)Average aperture

d/nmH2 consumption

/(μmol·g-1)IM 61.7 0.124 7.27 224 Sol-gel 65.4 0.172 7.13 599 HTM 63.7 0.158 7.02 315 表 3 催化剂的酸量分布

Table 3 Acid distribution of catalyst

Sample Weak acid /

total acid(%)Total acid

(normalized calculation)IM 0.48 1 Sol-gel 0.68 10.94 HTM 0.60 1.46 表 4 催化剂的表面原子浓度

Table 4 Surface atomic concentration of the catalyst

Sample O 1s E/eV V 2p E/eV Mo 3d E/eV Oα/

(Oα+Oβ)V4+/

(V4++V5+)Mo4+/

(Mo4++Mo6+)Oα Oβ V4+ V5+ 3d5/2 3d3/2 Mo4+ Mo6+ Mo4+ Mo6+ IM 530.4 531.8 516.8 517.5 232.6 233.1 235.9 236.3 0.32 0.36 0.21 Sol-gel 530.4 531.8 516.7 517.5 232.7 233.2 235.9 236.3 0.36 0.39 0.17 HTM 530.3 531.3 516.9 517.5 232.6 233.0 235.7 236.2 0.34 0.31 0.20 -

[1] 孙凤霞, 谢燊坤, 崔艳丽, 周德凤. Sr2+掺杂非化学计量LaFeO3的溶剂热制备及光催化性能[J].复合材料学报, 2016, 33(8):1755-1761. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=fhclxb201608021SUN Feng-xia, XIE Shen-kun, CUI Yan-li, ZHOU De-feng. Solvothermal of Sr2+ doped and nonstoichiometric LaFeO3 and their photocatalytic activity[J]. Acta Mater Compositae Sin, 2016, 33(8):1755-1761. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=fhclxb201608021 [2] 王亮亮, 王明洪, 费兆阳, 张竹修, 陈献, 汤吉海, 崔咪芬, 乔旭.非晶态MnOx/TiO2催化剂的制备及其低温NH3-SCR性能[J].燃料化学学报, 2017, 45(8):993-1000. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=rlhxxb201708013WANG Liang-liang, WANG Ming-hong, FEI Zhao-yang, ZHANG Zhu-xiu, CHEN Xian, TANG Ji-hai, CUI Mi-fen, QIAO Xu. Preparation of amorphous MnOx/TiO2 catalyst and its performance in low temperature NH3-SCR[J]. J Fuel Chem Technol, 2017, 45(8):993-1000. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=rlhxxb201708013 [3] 唐南, 黄妍, 李元元, 赵永谦, 周婷, 张俊丰, 杨柳春.水热法制备铁锰催化剂脱硝性能及抗水抗硫性能研究[J].分子催化, 2018, 32(3):240-248. http://d.old.wanfangdata.com.cn/Periodical/fzch201803006TANG Nan, HUANG Yan, LI Yuan-yuan, ZHAO Yong-qian, ZHOU Ting, ZHANG Jun-feng, YANG Liu-chun. Low temperature selective catalytic reduction of NO with NH3 over Fe-Mn catalysts prepared by hydrothermal method[J]. J Mol Catal, 2018, 32(3):240-248. http://d.old.wanfangdata.com.cn/Periodical/fzch201803006 [4] 赵梦梦, 陈梦寅, 张鹏举, 赵辉, 唐富顺, 阮乐, 杨宏斌.共沉淀法掺杂SiO2对V2O5-WO3/TiO2催化剂SCR性能的影响[J].分子催化, 2017, 31(3):223-235. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=fzch201703004ZHAO Meng-meng, CHEN Meng-yin, ZHANG Peng-ju, ZHAO Hui, TANG Fu-shun, RUAN Le, YANG Hong-bin. Influence of SiO2-doped V2O5-WO3/TiO2 catalysts by Co-precipitation method[J]. J Mol Catal, 2017, 31(3):223-235. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=fzch201703004 [5] 吴彦霞, 梁海龙, 赵春林, 陈鑫, 陈琛, 戴长友, 唐婕.载体对Mn-Ce催化剂低温选择性催化还原脱硝性能的影响[J].石油炼制与化工, 2019, 50(4):44-48. http://d.old.wanfangdata.com.cn/Periodical/sylzyhg201904010WU Yan-xia, LIANG Hai-long, ZHAO Chun-lin, CHEN Xin, CHEN Chen, DAI Chang-you, TANG Jie. Effect of support on low temperature denitrification performance of Mn-Ce catalysts[J]. Pet Process Petrochem, 2019, 50(4):44-48. http://d.old.wanfangdata.com.cn/Periodical/sylzyhg201904010 [6] LIN Zhuo-wei. Research on the middle-low temperature denitration properties of V2O5-MoO3 SCR catalysts[J]. Beijing:North China Electric Power University, 2017. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=rlhxxb201701016 [7] 贾勇, 张松, 戴波, 顾明言, 史德明, 夏勇军, 胡笳.负载型磷酸氧钒低温脱硝催化剂的制备及其抗硫抗水性能[J].环境工程学报, 2019, 13(1):125-133. http://d.old.wanfangdata.com.cn/Periodical/hjwrzljsysb201901015JIA Yong, ZHANG Song, DAI Bo, GU Ming-yan, SHI De-ming, XIA Yong-jun, HU Jia. Preparation of low-temperature DeNOx catalyst of supported vanadium phosphate and its resistance to sulfur dioxide and water vapor[J]. Chin J Environ Eng, 2019, 13(1):125-133. http://d.old.wanfangdata.com.cn/Periodical/hjwrzljsysb201901015 [8] 王敏, 刘琼, 孙亚杰, 车寅生, 姜承志.溶胶-凝胶法制备Eu3+掺杂BiVO4及其可见光光催化性能[J].无机材料学报, 2013, 28(2):153-158. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=wjclxb201302006WANG Min, LIU Qiong, ZHANG Ya-jie, CHE Yin-sheng, JIANG Cheng-zhi. Photocatalytic property of Eu/BiVO4 photocatalyst by citric acid sol-gel method[J]. J Inorg Mater, 2013, 28(2):153-158. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=wjclxb201302006 [9] 朱少文, 沈伯雄, 池桂龙, 张笑.铁钴共掺杂的Mn-Ce/TiO2催化剂低温SCR脱硝[J].环境工程学报, 2017, 11(6):3633-3639. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hjwrzljsysb201706043ZHU Shao-wen, SHEN Bo-xiong, CHI Gui-long, ZHANG Xiao. Low-temperature SCR of NO over Fe and Co co-doped Mn-Ce/TiO2 catalyst[J]. Chin J Environ Eng, 2017, 11(6):3633-3639. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hjwrzljsysb201706043 [10] 曲瑞阳.新型宽温度窗口催化剂选择性催化还原NOx的机理研究[D].杭州: 浙江大学, 2017. http://cdmd.cnki.com.cn/Article/CDMD-10335-1017045798.htmQU Rui-yang. A mechanistic study on the rational design of SCR catalyst with wide operation temperature window[D]. Hangzhou: Zhejiang University, 2017. http://cdmd.cnki.com.cn/Article/CDMD-10335-1017045798.htm -

下载:

下载: