Effect of H-ZSM-5 zeolite morphology on the performance of bifunctional ZnCr2O4/H-ZSM-5 catalysts in the direct conversion of syngas into aromatics

-

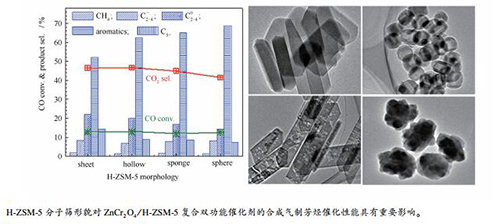

摘要: 采用水热法,通过改变合成条件选择性制备出具有球状堆积、薄片状、中空和海绵条状结构的四种不同形貌的H-ZSM-5分子筛,并采用XRD、SEM、Py-FTIR、NH3-TPD、ICP和N2物理吸附等手段对其结构性质进行了表征。将具有尖晶石结构的ZnCr2O4复合氧化物与不同形貌的H-ZSM-5分子筛组成ZnCr2O4/H-ZSM-5双功能催化剂,应用于合成气直接制芳烃(STA)的反应过程,研究了H-ZSM-5分子筛形貌对该双功能催化剂STA性能的影响。结果表明,H-ZSM-5分子筛形貌对ZnCr2O4/H-ZSM-5的合成气制芳烃催化性能具有重要影响;不同形貌H-ZSM-5分子筛的芳烃选择性由高到低顺序依次为球状堆积>海绵条状>中空结构>薄片状结构。其中,ZnCr2O4氧化物与具有球状堆积结构的H-ZSM-5分子筛组成的ZnCr2O4/H-ZSM-5(sphere)双功能催化剂在STA反应过程中表现出最佳的催化性能:在350℃和3.0 MPa条件下,CO转化率为12.6%,芳烃选择性高达68.8%,而甲烷、C2-40烷烃和CO2选择性分别降低至1.3%、14.3%和41.4%。这是由于球状堆积H-ZSM-5分子筛粒径适中(约350 nm),孔道长度适宜,适合芳烃产物的扩散但又能避免低碳烃类过早扩散出酸性分子筛孔道,从而有利于合成气转化中间产物的芳构化,提高芳烃产物的选择性。

-

关键词:

- 合成气制芳烃 /

- ZSM-5分子筛 /

- 形貌 /

- ZnCr2O4尖晶石 /

- 双功能催化剂

Abstract: A series of H-ZSM-5 zeolites with different morphologies including spherical, hollow, sheet and sponge-strip forms were hydrothermally synthesized through elaborately controlling the synthesis conditions and their crystal structural, textural and acidic properties were characterized by XRD, SEM, Py-FTIR, NH3-TPD, ICP and N2-sorption. The H-ZSM-5 zeolites of different morphologies and a spinel ZnCr2O4 oxide were then used to compose the bifunctional ZnCr2O4/H-ZSM-5 catalysts for the direct conversion of syngas into aromatics (STA). The effect of H-ZSM-5 morphology on the catalytic performance of ZnCr2O4/H-ZSM-5 in STA was then investigated. The results indicate that the morphology of H-ZSM-5 zeolites has significant influences on the catalytic performance of ZnCr2O4/H-ZSM-5 in STA.The selectivity to aromatics over the bifunctional catalysts with different H-ZSM-5 morphologies follows the order of sphere > sponge-strip > hollow > sheet. In particular, the ZnCr2O4/H-ZSM-5(sphere) catalyst composed of ZnCr2O4 and spherical H-ZSM-5 exhibits excellent performance in STA; under 350℃ and 3.0 MPa, a high selectivity of 68.8% to aromatics is achieved, with a CO conversion of 12.6%, whereas the selectivities to CH4, C2-40 alkanes and CO2 decrease to 1.3%, 14.3% and 41.4%, respectively. The isotropic and moderate particle size (about 350 nm) with appropriate pore length of spherical H-ZSM-5 zeolite are capable of avoiding the formation of lower hydrocarbons from early diffusion out of the acid zeolite channels and meanwhile yet conducive to the diffusion of aromatics, which can promote the aromatization of intermediates in STA and enhance the selectivity to aromatic products.-

Key words:

- syngas to aromatics /

- ZSM-5 zeolite /

- morphology /

- ZnCr2O4 spinel /

- bifunctional catalyst

-

表 1 不同形貌H-ZSM-5分子筛的织构性质和相对结晶度

Table 1 Textural properties and relative crystallinity of H-ZSM-5 zeolites with the different morphologies

Zeolite Surface area A/(m2·g-1) Pore volume v/(cm3·g-1) Relative crystallinity /% total micro external total micro H-ZSM-5(sphere) 376 314 62 0.22 0.12 100 H-ZSM-5(hollow) 377 303 73 0.28 0.12 99 H-ZSM-5(sheet) 368 287 81 0.25 0.13 99 H-ZSM-5(sponge) 393 333 60 0.26 0.13 92 表 2 不同形貌H-ZSM-5分子筛的硅铝比及酸性质

Table 2 Si/Al ratio and acid properties of the H-ZSM-5 zeolites of different morphologies

Zeolite Si/Al by ICP Acidity by NH3-TPD / (μmol·g-1) Acidity by Py-FTIR /(μmol·g-1) weak strong total Brönsted Lewis H-ZSM-5(sphere) 129 36 104 140 37 13 H-ZSM-5(hollow) 90 54 147 201 52 13 H-ZSM-5(sheet) 130 34 120 154 52 43 H-ZSM-5(sponge) 104 48 137 185 56 8 表 3 不同ZnCr2O4/H-ZSM-5双功能催化剂上合成气制芳烃产物分布

Table 3 Detailed product distribution for the STA over various ZnCr2O4/H-ZSM-5 bifunctional catalysts, reported at a time on stream of 30 h

Catalyst CO conv. x/% Hydrocarbons distribution /% CO2 sel. s/% CH4 C2-4= C2-40 non-arom. C5+ aromatics H-ZSM-5(sphere) 12.6 1.3 8.0 14.3 7.2 68.8 41.4 H-ZSM-5(hollow) 13.0 1.4 6.8 19.9 8.9 62.5 46.6 H-ZSM-5(sheet) 12.9 1.9 8.4 22.1 14.3 52.2 46.4 H-ZSM-5(sponge) 11.9 1.5 7.7 16.8 8.5 65.0 44.8 -

[1] XU Y, LIU D, LIU X. Conversion of syngas toward aromatics over hybrid Fe-based Fischer-Tropsch catalysts and H-ZSM-5 zeolites[J]. Appl Catal A:Gen, 2018, 552:168-183. doi: 10.1016/j.apcata.2018.01.012 [2] SETTLE A E, BERSTIS L, RORRER N A, ROMAN-LESHKOV Y, BECKHAM G T, RICHARDS R M, VARDON D R. Heterogeneous Diels-Alder catalysis for biomass-derived aromatic compounds[J]. Green Chem, 2017, 19(15):3468-3492. doi: 10.1039/C7GC00992E [3] 丁明.略论我国芳烃工业的现状及进展趋势[J].广东化工, 2015, 42(7):78-80. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gdhg201507037DING Ming, Recent progress of aromatics industry and development trend[J]. Guangdong Chem Ind, 2015, 42(7):78-80. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gdhg201507037 [4] YUNG M M, JABLONSKI W S, MAGRINI-BAIR K A. Review of catalytic conditioning of biomass-derived syngas[J]. Energy Fuels, 2009, 23(3/4):1874-1887. http://cn.bing.com/academic/profile?id=b7cc8b335e6b199d8939409c3936f05c&encoded=0&v=paper_preview&mkt=zh-cn [5] CHANG C D, LANG W H, SILVESTRI A J. Synthesis gas conversion to aromatic-hydrocarbons[J]. J Catal, 1979, 56(2):268-273. doi: 10.1016/0021-9517(79)90113-1 [6] YANG J H, PAN X L, JIAO F, LI J, BAO X H. Direct conversion of syngas to aromatics[J]. Chem Commun, 2017, 53(81):11146-11149. doi: 10.1039/C7CC04768A [7] CHENG K, ZHOU W, KANG J C, HE S, SHI S L, ZHANG Q H, PAN Y, WEN W, WANG Y. Bifunctional catalysts for one-step conversion of syngas into aromatics with excellent selectivity and stability[J]. Chem, 2017, 3(2):334-347. doi: 10.1016/j.chempr.2017.05.007 [8] 罗耀亚, 王森, 郭淑佳, 原凯, 王浩, 董梅, 秦张峰, 樊卫斌, 王建国.不同合成方法制备ZnxCe2-yZryO4/SAPO-34催化剂及其合成气制低碳烯烃催化性能的研究[J].燃料化学学报, 2020, 48(05):594-600. http://www.ccspublishing.org.cn/article/id/1315c011-d49c-4dd5-b670-5d8cb45e02d6LUO Yao-ya, WANG Sen, GUO Shu-jia, YUAN Kai, WANG Hao, DONG Mei, QIN Zhang-feng, FAN Wei-bin, WANG Jian-guo. Study on different synthesis methods of ZnxCe2-yZryO4/SAPO-34 catalyst and its catalytic performance in syngas to low-carbon olefins[J]. J Fuel Chem Technol, 2020, 48(05):594-600. http://www.ccspublishing.org.cn/article/id/1315c011-d49c-4dd5-b670-5d8cb45e02d6 [9] 杨成, 张成华, 许健, 吴宝山, 杨勇, 李永旺.氧化锆催化合成气直接转化制芳烃[J].燃料化学学报, 2016, 44(7):837-844. http://www.ccspublishing.org.cn/article/id/21906165-027d-430c-be3f-af2bd81f3ae1YANG Cheng, ZHANG Cheng-hua, XU Jian, Wu Bao-shan, YANG Yong, LI Yong-wang. One-step catalytic conversion of syngas to aromatics over ZrO2 catalyst[J]. J Fuel Chem Technol, 2016, 44(7):837-844. http://www.ccspublishing.org.cn/article/id/21906165-027d-430c-be3f-af2bd81f3ae1 [10] LIU J G, HE Y R, YAN L L, LI K, ZHANG C H, XIANG H W, WEN X D, LI Y W. Nano-sized ZrO2 derived from metal-organic frameworks and their catalytic performance for aromatic synthesis from syngas[J]. Catal Sci Technol, 2019, 9(11):2982-2992. doi: 10.1039/C9CY00453J [11] ZHOU W, SHI S, WANG Y, ZHANG L, WANG Y, ZHANG G, MIN X, CHENG K, ZHANG Q, KANG J, WANG Y. Selective conversion of syngas to aromatics over a Mo-ZrO2/H-ZSM-5 bifunctional catalyst[J]. ChemCatChem, 2019, 11(6):1681-1688. doi: 10.1002/cctc.201801937 [12] LIU C, LIU S, ZHOU H B, SU J J, JIAO W Q, ZHANG L, WANG Y D, HE H Y, XIE Z K. Selective conversion of syngas to aromatics over metal oxide/HZSM-5 catalyst by matching the activity between CO hydrogenation and aromatization[J]. Appl Catal A:Gen, 2019, 585:117206-117215. doi: 10.1016/j.apcata.2019.117206 [13] YANG X L, SUN T, MA J G, SU X, WANG R F, ZHANG Y R, DUAN H M, HUANG Y Q, ZHANG T. The influence of intimacy on the 'iterative reactions' during OX-ZEO process for aromatic production[J]. J Energy Chem, 2019, 35:60-65. doi: 10.1016/j.jechem.2018.11.003 [14] GILANI S Z A, LU L, ARSLAN M T, ALI B, WANG Q, WEI F. Two-way desorption coupling to enhance the conversion of syngas into aromatics by MnO/H-ZSM-5[J]. Catal Sci Technol, 2020, 10(10):3366-3375. doi: 10.1039/D0CY00275E [15] ZHOU W, ZHOU C, YIN H R, SHI J Q, ZHANG G Q, ZHENG X L, MIN X J, ZHANG Z Q, CHENG K, KANG J C, ZHANG Q H, WANG Y. Direct conversion of syngas into aromatics over a bifunctional catalyst:Inhibiting net CO2 release[J]. Chem Commun, 2020, 56(39):5239-5242. doi: 10.1039/D0CC00608D [16] FIROOZI M, BAGHALHA M, ASADI M. The effect of micro and nano particle sizes of H-ZSM-5 on the selectivity of MTP reaction[J]. Catal Commun, 2009, 10(12):1582-1585. doi: 10.1016/j.catcom.2009.04.021 [17] CHOI M, NA K, KIM J, SAKAMOTO Y, TERASAKI O, RYOO R. Stable single-unit-cell nanosheets of zeolite MFI as active and long-lived catalysts[J]. Nature, 2009, 461:246-249. doi: 10.1038/nature08288 [18] WANG K, DONG M, LI J, LIU P, ZHANG K, WANG J, FAN W. Facile fabrication of ZSM-5 zeolite hollow spheres for catalytic conversion of methanol to aromatics[J]. Catal Sci Technol, 2017, 7(3):560-564. doi: 10.1039/C6CY02476A [19] YANG J H, GONG K, MIAO D Y, JIAO F, PAN X L, MENG X J, XIAO F S, BAO X H. Enhanced aromatic selectivity by the sheet-like ZSM-5 in syngas conversion[J]. J Energy Chem, 2019, 35, 44-48. doi: 10.1016/j.jechem.2018.10.008 [20] XU Y, LIU J, WANG J, MA G, LIN J, YANG Y, LI Y, ZHANG C, DING M. Selective conversion of syngas to aromatics over Fe3O4@MnO2 and hollow HZSM-5 bifunctional catalysts[J]. ACS Catal, 2019, 9(6):5147-5156. doi: 10.1021/acscatal.9b01045 [21] LI Q H, HEDLUND J, STERTE J, CREASER D, BONS A J. Synthesis and characterization of zoned MFI films by seeded growth[J]. Microporous Mesoporous Mater, 2002, 56(3):291-302. doi: 10.1016/S1387-1811(02)00503-6 [22] NA J, LIU G, ZHOU T, DING G, HU S, WANG L. Synthesis and catalytic performance of ZSM-5/MCM-41 zeolites with varying mesopore size by surfactant-directed recrystallization[J]. Catal Lett, 2013, 143(3):267-275. doi: 10.1007/s10562-013-0963-0 [23] WEI Z H, XIA T F, LIU M H, CAO Q S, XU Y R, ZHU K, ZHU X D. Alkaline modification of ZSM-5 catalysts for methanol aromatization:The effect of the alkaline concentration[J]. Front Chem Sci Eng, 2015, 9(4):450-460. doi: 10.1007/s11705-015-1542-2 [24] 王玉杰, 付廷俊, 马哲, 邵娟, 马倩, 李晗, 郭宇航, 崔丽萍, 李忠.甲醇制烃反应ZSM-5催化剂微孔孔道控制的最新研究进展[J].化工进展, 2019, 38(10):4554-4563. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hgjz201910020WANG Yu-jie, FU Ting-jun, MA Zhe, SHAO Juan, MA Qian, LI Han, GUO Yu-hang, CUI Li-ping, LI Zhong. Recent progress on the control of microporous channel for ZSM-5 catalyst in methanol to hydrocarbon[J]. Chem Ind Eng Prog 2019, 38(10):4554-4563. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hgjz201910020 [25] JANG H G, MIN H K, LEE J K, HONG S B, SEO G. SAPO-34 and ZSM-5 nanocrystals' size effects on their catalysis of methanol-to-olefin reactions[J]. Appl Catal A:Gen, 2012, 437:120-130. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=7e286d172f322002dbaabcd6b5c9607f -

下载:

下载: