Effects of modified olivine on the CO2 reforming of toluene

-

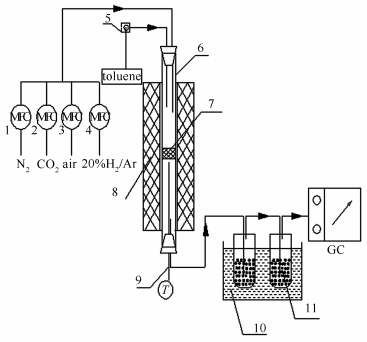

摘要: 在固定床反应器中,以甲苯作为生物质气化焦油模型化合物,橄榄石作为甲苯裂解催化剂,结合XRD、SEM、BET、H2-TPR等表征手段,考察了不同重整反应温度、CO2浓度、橄榄石煅烧温度以及载镍量对甲苯催化重整性能的影响。结果表明,甲苯转化率随着重整反应温度的升高而增加,橄榄石对甲苯具有较高的催化活性,经900℃煅烧后的橄榄石活性最高。相比于橄榄石直接催化裂解甲苯,CO2的加入能够显著降低催化剂表面的积炭率,当CO2/C7H8物质的量比为4时,橄榄石催化剂表面的积炭率降低至17.0%。橄榄石载镍后,对C7H8/CO2的催化重整性能进一步提高,甲苯转化率最高达到99.4%,但是积炭率也会随之增加。Abstract: An olivine catalyst was tested in a fixed bed reactor in CO2 reforming of the toluene as a tar model molecule produced during biomass gasification. The olivine catalyst was characterized by XRD, SEM, BET, H2-TPR; and the effects of the operating parameters (reforming reaction temperature and CO2 concentration) and catalyst preparation parameters (calcination temperature and nickel content) on the activity and selectivity for toluene conversion were examined. The results show that the olivine catalyst can increase the toluene conversion and lower the carbon formation. The toluene conversion also increases with the reforming temperature rise. The calcined olivine reaches the highest activity when the calcination temperature is 900℃. The CO2 addition can reduce the carbon formation obviously by 17.0% when the CO2/C7H8 molar ratio is 4. Moreover, the Ni/olivine catalyst has a better performance and the toluene conversation is up to 99.4%, while the carbon formation increases a little bit.

-

Key words:

- modified olivine /

- toluene /

- CO2 /

- catalytic reforming

-

图 5 甲苯裂解反应路径示意图[15]

Figure 5 Schematic diagram of toluene pyrolysis reaction paths

表 1 橄榄石原矿的化学组成

Table 1 Chemical compositions of natural olivine

Content w/% Fe Mg Ni Al Si O Ca Cr Mn 5.52 23.39 0.22 1.91 17.72 49.43 1.17 0.28 0.11 表 2 不同煅烧温度下橄榄石的比表面积和平均孔径

Table 2 Surface area and average pore diameter of natural olivine and the olivine calcined at different temperatures

Sample Surface area A/(m2·g-1) Average pore diameter d/nm Raw ore 11.84 7.51 Olivine-700 ℃ 39.86 7.99 Olivine-900 ℃ 16.81 17.96 Olivine-1 100 ℃ 4.56 25.73 Olivine-1 400 ℃ 1.67 10.63 -

[1] ABDOULMOUMINE N, ADHIKARI S, KULKARMI A, CHATTANATHAN S. A review on biomass gasification syngas cleanup[J]. Appl Energy, 2015, 155:294-307. doi: 10.1016/j.apenergy.2015.05.095 [2] 张书, 陈宗定, 徐敏, 许德平, 王永刚.煤气化焦油脱除/催化重整技术研究进展[J].煤炭科学技术, 2014, 42(1):106-111. http://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ201401028.htmZHANG Shu, CHEN Zong-ding, XU Min, XU De-ping, WANG Yong-gang. Review on technology development for tar removal/catalytical reforming during coal gasification[J]. Coal Sci Technol, 2014, 42(1):106-111. http://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ201401028.htm [3] YUNG M M, JABLONSKI W S, MAGRINI-BAIR K A. Review of catalytic conditioning of biomass-derived syngas[J]. Energy Fuels, 2009, 23(4):1874-1887. doi: 10.1021/ef800830n [4] 吴悠, 赵立欣, 孟海波, 丛宏斌, 姚宗路, 侯书林.生物质热解焦油脱除方法研究进展[J].化工环保, 2016, 36(1):17-21. http://www.cnki.com.cn/Article/CJFDTOTAL-HGHB201601005.htmWU You, ZHAO Li-xin, MENG Hai-bo, CONG Hong-bin, YAO Zong-lu, HOU Shu-lin. Research progresses on removal of tar in biomass pyrolysis[J]. Environ Prot Chem Ind, 2016, 36(1):17-21. http://www.cnki.com.cn/Article/CJFDTOTAL-HGHB201601005.htm [5] DEVI L, CRAJE M, THÜNE P, PTASINSKI K J, JANSSEN F J J G. Olivine as tar removal catalyst for biomass gasifiers:Catalyst characterization[J]. Appl Catal A:Gen, 2005, 294:68-79. doi: 10.1016/j.apcata.2005.07.044 [6] VIRGINIE M, ADANEZ J, COURSON C, DIEGO L F, LABIANO F G, NIZNANSKY D, KIENNEMANN A, GAYAN P, ABAD A. Effect of Fe-olivine on the tar content during biomass gasification in a dual fluidized bed[J]. Appl Catal B:Environ, 2012, 121:214-222. [7] 岳宝华, 卜宪昵, 汪学广, 丁伟中.焙烧温度对橄榄石催化甲苯裂解性能的影响[J].化工学报, 2009, 60(2):378-383. http://www.cnki.com.cn/Article/CJFDTOTAL-HGSZ200902017.htmYUE Bao-hua, BU Xian-ni, WANG Xue-guang, DING Wei-zhong. Effect of calcination temperature on catalytic performance of olivine for toluene cracking[J]. CIESC J, 2009, 60(2):378-383. http://www.cnki.com.cn/Article/CJFDTOTAL-HGSZ200902017.htm [8] 魏立纲, 徐绍平, 刘长厚, 刘淑芹.预煅烧对橄榄石生物质气化催化性能的影响[J].燃料化学学报, 2008, 36(4):426-430. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract17325.shtmlWEI Li-gang, XU Shao-ping, LIU Chang-hou, LIU Shu-qin. Effects of precalcination on catalytic activity of olivine in biomass gasification[J]. J Fuel Chem Technol, 2008, 36(4):426-430. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract17325.shtml [9] VIRGINIE M, COURSON C, KIENNEMANN A. Toluene steam reforming as tar model molecule produced during biomass gasification with an iron/olivine catalyst[J]. Comptes Rendus Chimie, 2010, 13(10):1319-1325. doi: 10.1016/j.crci.2010.03.022 [10] CHEAH S, GAGTON K R, PARENT Y O, JARVIS M W, VINZANT T B, SMITH K M, THORNBURG N E, NIMLOS M R, MAGRINI-BAIR K A. Nickel cerium olivine catalyst for catalytic gasification of biomass[J]. Appl Catal B:Environ, 2013, 134:34-45. https://www.researchgate.net/publication/255813032_Nickel_Cerium_Olivine_Catalyst_for_Catalytic_Gasification_of_Biomass [11] 杨小芹, 徐绍平, 胡冠, 刘长厚.不同矿源橄榄石对催化苯水蒸气重整的影响[J].催化学报, 2009, 30(6):497-502. http://www.cnki.com.cn/Article/CJFDTOTAL-CHUA200906006.htmYANG Xiao-qin, XU Shao-ping, HU Guan, LIU Chang-hou. Effects of olivines from different quarries on the steam reforming of benzene[J]. Chin J Catal, 2009, 30(6):497-502. http://www.cnki.com.cn/Article/CJFDTOTAL-CHUA200906006.htm [12] RAUCH R, BOSCH K, SWIERCZYNSKI D, COURSON C, KIENNEMANN A. Comparison of different olivines for biomass steam gasification[M]. na, 2004. [13] SWIERCZYNSKI D, COURSON C, BEDEL L, KIENNEMANN A, VILMINOT S. Oxidation reduction behavior of iron-bearing olivines (Fex Mg1-x) 2SiO4 used as catalysts for biomass gasification[J]. Chem Mater, 2006, 18(4):897-905. doi: 10.1021/cm051433+ [14] CHRISTODOULOU C, GRIMEKIS D, PANOPOULOS K D, PACHATOURIDOU E P, ILIOPOULOU E F, KAKARAS E. Comparing calcined and un-treated olivine as bed materials for tar reduction in fluidized bed gasification[J]. Fuel Process Technol, 2014, 124:275-285. doi: 10.1016/j.fuproc.2014.03.012 [15] 王惠, 杨海峰, 冉新权, 文振翼, 史启祯.甲苯热解机理的AM1研究Ⅰ热力学分析[J].无机化学学报, 2001, 17(4):538-544. http://www.cnki.com.cn/Article/CJFDTOTAL-WJHX200104013.htmWANG Hui, YANG Hai-feng, RAN Xin-quan, WEN Zhen-yi, SHI Qi-zhen. AM1 thermodynamic research of the pyrolysis mechanism of toluene (Ⅰ)[J]. Chin J Inorg Chem, 2001, 17(4):538-544. http://www.cnki.com.cn/Article/CJFDTOTAL-WJHX200104013.htm [16] 孔猛.基于生物质合成气的焦油模型组分甲苯二氧化碳催化重整转化研究[D].杭州:浙江大学, 2012.KONG Meng. Carbon dioxide reforming of tolueneas a model compound of tar from biomass-derived syngas over Ni catalyst[D]. Hangzhou:Zhejiang Univisity, 2012. [17] KONG M, YANG Q, FEI J H, ZHENG X M. Experimental study of Ni/MgO catalyst in carbon dioxide reforming of toluene, a model compound of tar from biomass gasification[J]. Int J Hydrogen Energy, 2012, 37(18):13355-13364. doi: 10.1016/j.ijhydene.2012.06.108 [18] 李兰兰, 郑安庆, 冯宜鹏, 孟俊光, 赵增立, 李海滨.橄榄石对甲苯催化重整反应的影响[J].燃料化学学报, 2015, 43(7):806-815. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract18657.shtmlLI Lan-lan, ZHENG An-qing, FENG Yi-peng, MENG Jun-guang, ZHAO Zeng-li, LI Hai-bin. Effects of olivine on the catalytic reforming of toluene[J]. J Fuel Chem Technol, 2015, 43(7):806-815. http://rlhxxb.sxicc.ac.cn/CN/abstract/abstract18657.shtml [19] YANG X X, XU S P, XU H L, LIU X D, LIU C H. Nickel supported on modified olivine catalysts for steam reforming of biomass gasification tar[J]. Catal Commun, 2010, 11(5):383-386. doi: 10.1016/j.catcom.2009.11.006 [20] 施培超, 陈天虎, 张先龙, 陈冬, 宋磊, 李金虎.生物质焦油组分甲苯在镍/凹凸棒石上的二氧化碳催化重整[J].催化学报, 2010, 31(10):1281-1285. http://www.cnki.com.cn/Article/CJFDTOTAL-CHUA201010018.htmSHI Pei-chao, CHEN Tian-hu, ZHANG Xian-long, CHEN Dong, SONG Lei, LI Zong-hu. CO2 reforming of toluene from biomass tar over Ni/palygorskite catalast[J]. Chin J Catal, 2010, 31(10):1281-1285. http://www.cnki.com.cn/Article/CJFDTOTAL-CHUA201010018.htm -

下载:

下载: