Study on the influence of particle size on the ash melting behavior of Jincheng coal

-

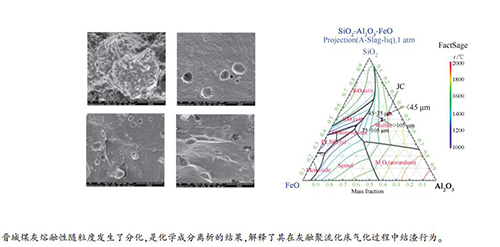

摘要: 探索山西晋城煤在灰熔聚流化床气化过程中的结渣机理。采用山西晋城无烟煤,将其破碎到不同粒径,采用XRF、XRD、AFT、SEM和FactSageTM研究了煤的灰分、煤灰化学组成、矿物组成和熔融性随煤样粒径变化规律。结果发现,对于破碎到6 mm以下的晋城煤样,不同粒径子样煤灰化学组成和熔融温度差异不大;对于粉磨到0.2 mm以下的晋城煤粉样品,不同粒径子样化学组成和矿物组成存在较大差异,其中,铁含量差异最明显。AFT和SEM结果都证明, < 45 μm粒径煤粉子样煤灰熔融温度明显高于其他三种样品。FactSageTM计算得到的液相量变化规律和AFT、SEM观察结果一致,说明煤灰熔融性随粒径变化是煤灰化学成分离析造成的,而SiO2-Al2O3-Fe2O3三元相图较好地解释了晋城煤煤灰熔融性随粒径变化机理。Abstract: The slagging mechanism of the Jincheng coal in the ash-agglomerate fluidized bed gasification was explored. A typical Jincheng coal sampled from Shanxi, China was prepared into different particle size and the XRF, XRD, AFT, SEM and FactSageTM were employed to study the influence of particle size on the ash content, chemical and mineral composition and ash fusibility. The results indicate that the ash chemical composition and AFTs vary little with size below 6 mm. For the pulverized samples below 0.2 mm, there are apparent differences in the chemical composition and mineral composition, especially in Fe2O3. Both AFT results and SEM observations show that the sample with particle size less than 45 μm has a significantly higher melting temperature than the other three samples. The slag contents calculated with FactSageTM are consistent with the AFT results and SEM observations, which indicates that the change of ash melting behavior with particle size results from the change in chemical composition. The ternary phase diagram of SiO2-Al2O3-Fe2O3 can be used successfully to explain the mechanism of the change of ash melting behavior with particle size for Jincheng coal.

-

Key words:

- Jincheng coal /

- ash-agglomerate fluidized bed /

- ash fusion temperature /

- slagging

-

表 1 晋城原煤的工业分析和元素分析

Table 1 Proximate analysis and ultimate analysis of Jincheng raw coal

Proximate analysis w/% Ultimate analysis w/% Mad Ad Vd FCd Cdaf Hdaf Ndaf Odaf* St, d 4.49 19.24 7.78 72.98 88.60 3.24 1.11 3.94 3.11 *:by difference 表 2 晋城原煤煤灰化学组成含量

Table 2 Chemical composition of Jincheng raw coal ash

Content w/% SiO2 Al2O3 CaO Fe2O3 MgO TiO2 P2O5 K2O Na2O SO3 47.50 33.05 3.07 8.39 1.12 1.17 0.06 0.96 0.18 2.20 表 3 晋城煤粉不同粒径煤灰化学组成

Table 3 Ash chemical composition of size fractions in pulverized Jincheng coal sample

d/μm Content w/% SiO2 Al2O3 CaO Fe2O3 MgO TiO2 P2O5 K2O Na2O SO3 <45 59.37 33.78 3.20 6.55 1.06 1.06 0.06 1.00 0.18 1.52 45-75 55.18 30.56 3.20 13.77 1.59 1.32 0.06 0.60 0.12 2.65 75-105 55.21 31.83 2.75 15.67 1.01 1.10 0.06 0.58 0.10 2.10 >105 55.29 33.58 2.16 13.00 1.05 1.16 0.06 0.65 0.09 1.50 -

[1] 陈鹏.中国煤炭性质、分类和用[M].北京:化学工业出版社, 2007.CHEN Peng. Nature, Classification and Utilization of Coal in China[M]. Beijing:Chemical Industry Press, 2007. [2] 房倚天, 王洋, 马小云, 黄戎介, 吴晋沪, 程中虎, 陈寒石.灰熔聚流化床粉煤气化技术加压大型化研发新进展[J].煤化工, 2007, 35(1):11-15. doi: 10.3969/j.issn.1005-9598.2007.01.003FANG Yi-tian, WANG Yang, MA Xiao-yun, HUANG Jie-jie, WU Jin-hu, CHENG Zhong-hu, CHEN Han-shi. New progress in research and development of pressurized large-scale coal gasification technology for ash fusion fluidized bed coal gasification technology[J]. Coal Chem, 2007, 35(1):11-15. doi: 10.3969/j.issn.1005-9598.2007.01.003 [3] 李风海, 黄戒介, 房倚天, 王洋.晋城无烟煤流化床气化结渣机理的探索[J].太原理工大学学报, 2010, 41(5):666-669. http://d.old.wanfangdata.com.cn/Periodical/tylgdxxb201005048LI Feng-hai, HUANG Jie-jie, FANG Yi-tian, WANG Yang. Exploration on slagging mechanism of Jincheng anthracite during fluidized-bed gasification[J]. J Taiyuan Univ Technol, 2010, 41(5):666-669. http://d.old.wanfangdata.com.cn/Periodical/tylgdxxb201005048 [4] NARUSE I, KAMIHASHIRA D, KHAINIL, MIYAUCHI Y, KATO Y, YAMASHITA Y, TOMINAGA H. Fundamental ash deposition characteristics in pulverized coal reaction under high temperature conditions[J]. Fuel, 2005, 84(4):405-410. doi: 10.1016/j.fuel.2004.09.007 [5] WU X, ZHANG Z, PIAO G, HEX, CHEN Y, KOBAYASHI N, MORI S, ITAYA Y. Behavior of mineral matters in chinese coal ash melting during char-CO2/H2O gasification reaction[J]. Energy Fuels, 2009, 23(5):2420-2428. doi: 10.1021/ef801002n [6] MATJIE RH, LI Z, WARD C R, FRENCH D. Chemical composition of glass and crystalline phases in coarse coal gasification ash[J]. Fuel, 2008, 87(6):857-869. doi: 10.1016/j.fuel.2007.05.050 [7] WALL T F, CREELMAN R A, GUPTA R P, GUPTA S K, COIN C, LOWE A. Coal ash fusion temperatures-New characterization techniques, and implications for slagging and fouling[J]. Prog Energy Combust Sci, 1998, 24(4):345-353. doi: 10.1016/S0360-1285(98)00010-0 [8] BARTELS M, LIN W, NIJENHUIS J. Agglomeration in fluidized beds at high temperatures:Mechanisms, detection and prevention[J]. Prog Energy Combust Sci, 2008, 34(5):633-666. doi: 10.1016/j.pecs.2008.04.002 [9] 张洪, 胡光洲, 范佳鑫, 蒲文秀, 莫言学, 哈斯, 李迎.矿物在煤粉中的分布规律研究[J].工程热物理学报, 2008, 29(7):1231-1235. doi: 10.3321/j.issn:0253-231X.2008.07.041ZHANG Hong, HU Guang-zhou, FANG Jia-xin, PU Wen-xiu, MO Yan-xue, HA Si, LI Ying. Study on the distribution of minerals in pulverized coals[J]. J Eng Therm, 2008, 29(7):1231-1235. doi: 10.3321/j.issn:0253-231X.2008.07.041 [10] ZHANG, H, MO Y, SUN M. Determination of the mineral distribution in pulverized coal using densitometry and laser particle sizing[J]. Energy Fuels, 2005, 19(6):2261-2267. doi: 10.1021/ef050201u [11] 张鹏启, 杨琪琪, 屠卡滨, 王月伦, 王祖威, 刘林林.晋城粉煤煤灰不均匀熔融规律研究[J].燃料化学学报, 2018, 46(1):8-14. doi: 10.3969/j.issn.0253-2409.2018.01.002ZHANG Peng-qi, YANG Qi-qi, TU Ka-bin, WANG Yue-lun, WANG Zu-wei, LIU Lin-lin. Study on the uneven melting law of coal ash in Jincheng[J]. J Fuel Chem T echnol, 2018, 46(1):8-14. doi: 10.3969/j.issn.0253-2409.2018.01.002 [12] 毕可军.灰融聚流化床粉煤气化装置煤气洗涤水处理改进方案探讨[J].化肥设计, 2011, 49(2):26-28. doi: 10.3969/j.issn.1004-8901.2011.02.005BI Ke-jun. Discussion on improvement scheme of gas washing water treatment in ash fusion fluidized bed coal gasification unit[J]. Chem Fert Des, 2011, 49(2):26-28. doi: 10.3969/j.issn.1004-8901.2011.02.005 [13] REINMÖLLER M, SCHREINER M, GUHL S, NEUROTH M, MEYER B. Formation and transformation of mineral phases in various fuels studied by different ashing methods[J]. Fuel, 2017, 202:641-649. doi: 10.1016/j.fuel.2017.04.115 [14] CHAKRAVARTY S, MOHANTY A, BANERJEE A, TRIPATHY R, MANDAL G K, BASARIYA M R, SHARMA M. Composition, mineral matter characteristics and ash fusion behavior of some Indian coals[J]. Fuel, 2015, 150:96-101. doi: 10.1016/j.fuel.2015.02.015 [15] REINMÖLLER M, KLINGER M, SCHREINER M. Relationship between ash fusion temperatures of ashes from hard coal, brown coal, and biomass and mineral phases under different atmospheres:A combined FactSageTM computational and network theoretical approach[J]. Fuel, 2015, 151:118-123. doi: 10.1016/j.fuel.2015.01.036 [16] LI F, LI Z, HUANG J, FANG Y. Understanding mineral behaviors during anthracite fluidized-bed gasification based on slag characteristics[J]. Appl Energy, 2014, 131:279-287. doi: 10.1016/j.apenergy.2014.06.051 [17] 赵斌, 王庆功, 么强, 屈婷婷, 吕俊复, 岳光溪.流化床煤颗粒分级试验研究[J].中国矿业大学学报, 2014, 43(4):678-683. http://d.old.wanfangdata.com.cn/Periodical/zgkydxxb201404017ZHAO Bin, WANG Qing-gong, MO Qiang, QU Ting-ting, LU Jun-fu, YUE Guang-xi. Study on classification of coal particles in fluidized bed[J]. J China Univ Min Technol, 2014, 43(4):678-683. http://d.old.wanfangdata.com.cn/Periodical/zgkydxxb201404017 -

下载:

下载: