Macroporous alumina with three-dimensionally interconnected pore structure: Synthesis, characterization and transformation mechanism

-

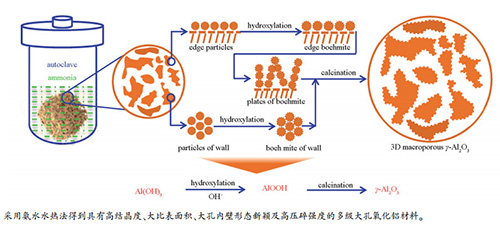

摘要: 利用相分离技术制备了非晶三维贯穿大孔氧化铝初始材料,然后通过氨水水热改性处理,使其大孔形态发生了显著改变,孔壁边缘生长有尺寸为50-300 nm的片状聚集体,大孔尺寸由430 nm下降到250 nm,但仍然保持蠕虫状三维贯穿且空间分布均匀的特性。改性后的氧化铝材料经550℃焙烧转化为高结晶度γ氧化铝,比表面积达到331 m2/g,具有8.9 nm及250 nm两种集中的孔径分布,L酸度及抗压强度均有所提高。研究表明,无定形水合羟基铝离子聚合物与氨水发生再水合反应生成薄水铝石中间物,因此,可在较低的焙烧温度下转晶为γ态;大孔孔壁边缘的AlOOH晶粒受NH4+模板诱导作用从里向外重排形成片状聚集体,从而改变了大孔的形态。Abstract: Amorphous macroporous alumina with three-dimensionally interconnected pore structure was prepared by phase separation technique. The macroporous morphology was modified significantly by hydrothermal treatment with ammonia. There are many plate-like aggregates of alumina with a size of 50-300 nm at the edge of wall; the product is still characterized by the worm-like three-dimensional penetration and uniform spatial distribution, whereas the size of macropores decreases from 430 to 250 nm. The modified alumina material was converted into high crystallinity gamma alumina by calcination at 550℃, which displays a specific surface area of up to 331 m2/g and pore size distributions con-centrated at 8.9 and 250 nm; meanwhile, the Lewis acidity and crushing strength are also improved. It was speculated that the amorphous hydrated hydroxyaluminium ion polymer rehydrated to form boehmite intermediate and transformed into gamma state at low calcination temperature; the AlOOH particles at the edge of macropore wall were then rearranged from inside to outside with NH4+ as template, fabricated into plate-like aggregates.

-

Key words:

- 3D-interconnected penetration /

- macropore /

- ammonia /

- hydrothermal treatment /

- γ-alumina

-

表 1 大孔氧化铝的抗压强度

Table 1 Crushing strength of the as-synthesized products

Sample Crushing strength /(N·mm-1) 550℃ 600℃ 650℃ 700℃ 750℃ 800℃ Primary sample 18.8 19.4 20.3 21.4 21.9 23.4 Modified sample 18.5 19.6 20.9 21.7 22.3 24.2 表 2 氨水处理前后样品的L酸分布

Table 2 Distribution of Lewis acidity on the primary and modified samples via ammonia treatment

Sample Acidity /(mmol·g-1) 160℃ 250℃ 350℃ Primary sample 0.409 0.276 0.128 Modified sample 0.413 0.189 0.089 -

[1] CENTENO G, ANCHEYTA J, ALVAREZ A, MARROQUÍN G, ALONSO F, CASTILLO A. Effect of different heavy feedstocks on the deactivation of a commercial hydrotreating catalyst[J]. Fuel, 2012, 100(Supplement C):73-79. [2] WEI J. Modeling of hydrodemetallation[J]. Stud Surf Sci Catal, 1991, 68:333-341. doi: 10.1016/S0167-2991(08)62652-X [3] RANA M S, NAVARRO R, LEGLISE J. Competitive effects of nitrogen and sulfur content on activity of hydrotreating CoMo/Al2O3 catalysts:A batch reactor study[J]. Catal Today, 2004, 98(1):67-74. [4] 朱华青, 高志贤, 程昌瑞, 谭长瑜.重油加氢脱氮催化剂的研制——钼镍磷催化剂的表征[J].燃料化学学报, 2000, 28(2):105-110. doi: 10.3969/j.issn.0253-2409.2000.02.003ZHU Hua-qing, GAO Zhi-xian, CHENG Chang-rui, TAN Chang-yu. Study and preparation of HDN catalysis for heavy oil:Characterization of Mo-Ni-P catalysis[J]. J Fuel Chem Technol, 2000, 28(2):105-110. doi: 10.3969/j.issn.0253-2409.2000.02.003 [5] 李广慈, 赵会吉, 赵瑞玉, 刘晨光.不同扩孔方法对催化剂载体氧化铝孔结构的影响[J].石油炼制与化工, 2010, 41(1):49-54. doi: 10.3969/j.issn.1005-2399.2010.01.011LI Guang-ci, ZHAO Hui-ji, ZHAO Rui-yu, LIU Chen-guang. Effects of carious pore-enlarging methods on the pore structure of alumina catalyst support[J]. Pet Process Petrochem, 2010, 41(1):49-54. doi: 10.3969/j.issn.1005-2399.2010.01.011 [6] 程昌瑞, 朱华青, 高志贤, 杜明仙, 翟效珍.重油加氢脱氮催化剂的研制Ⅰ.载体氧化铝的pH摆动法制备[J].石油炼制与化工, 1999, 30(4):41-44. http://www.cnki.com.cn/Article/CJFDTotal-SYLH904.009.htmCHENG Chang-rui, ZHU Hua-qing, GAO Zhi-xian, DU Ming-xian, ZHAI Xiao-zhen. Study and preparation of HDN catalysis for heavy oil I. Preparation of support alumina by ph swing method[J]. Pet Process Petrochem, 1999, 30(4):41-44. http://www.cnki.com.cn/Article/CJFDTotal-SYLH904.009.htm [7] 王鼎聪.纳米自组装合成大孔容介孔氧化铝[J].中国科学(B辑:化学), 2009, 39(5):420-431. http://www.cnki.com.cn/Article/CJFDTotal-JBXK200905006.htmWANG Ding-cong. Mesoporous aluminium oxide support with large pore volume by nanoself-assembly[J]. Sci China Ser B, 2009, 39(5):420-431. http://www.cnki.com.cn/Article/CJFDTotal-JBXK200905006.htm [8] 王鼎聪, 刘纪端.贯穿性框架式渣油脱金属催化剂氧化铝载体的研究[J].石油炼制与化工, 2010, 41(1):31-35. doi: 10.3969/j.issn.1005-2399.2010.01.007WANG Ding-cong, LIU Ji-duan. A research of alumina carrier with penetrating pore structure for asphaltene micelles to diffuse[J]. Pet Process Petrochem, 2010, 41(1):31-35. doi: 10.3969/j.issn.1005-2399.2010.01.007 [9] 张凯, 王鼎聪.第三次纳米自组装制备大孔主客体催化材料[J].中国科学:化学, 2013, 43(11):1548-1556. http://www.cnki.com.cn/Article/CJFDTOTAL-JBXK201311017.htmZHANG Kai, WANG Ding-cong. Preparation of macroporous host-guest catalytic material using third nano self-assembly[J]. Sci China Ser Chem, 2013, 43(11):1548-1556. http://www.cnki.com.cn/Article/CJFDTOTAL-JBXK201311017.htm [10] SADAKANE M, SASAKI K, NAKAMURA H, YAMAMOTO T, NINOMIYAW, UEDA W. Important property of polymer spheres for the preparation of three-dimensionally ordered macroporous (3DOM) metal oxides by the ethylene glycol method:The glass-transition temperature[J]. Langmuir, 2012, 28(51):17766-17770. doi: 10.1021/la303921u [11] VAN DEN REIJEN J E, KEIJZERP H, DE JONGH P E. Pore structure stabilization during the preparation of single phase ordered macroporous α-alumina[J]. Materialia, 2018, 4:423-430. doi: 10.1016/j.mtla.2018.10.016 [12] TAKAHASHI R, ONISHI A, SATOM F. KURAMOTO M. Preparation of bimodal porous alumina using propylene glycol oligomers[J]. J Ceram Soc, 2017, 125(10):742-746 doi: 10.2109/jcersj2.17062 [13] TOKUDOME Y, FUJITA K, NAKANISHI K, MIURA K, HIRAO K. Synthesis of monolithic Al2O3 with well-defined macropores and mesostructured skeletons via the sol-gel process accompanied by phase separation[J]. Chem Mater, 2007, 19(14):3393-3398. doi: 10.1021/cm063051p [14] SUN M, ZHAO T, LI Z, MA Z, WANG J, LI F. Sol-gel synthesis of macro-mesoporous Al2O3-SiO2-TiO2 monoliths via phase separation route[J]. Ceram Int, 2016, 42(14):15926-15932. doi: 10.1016/j.ceramint.2016.07.068 [15] 白秀玲, 马波, 杨卫亚, 凌凤香.三维贯通大孔氧化铝的制备与表征[J].当代化工, 2013, 42(3):253-255. doi: 10.3969/j.issn.1671-0460.2013.03.003BAI Xiu-ling, MA Bo, YANG Wei-ya, LING Feng-xiang. Synthesis and characterization of macroporous Al2O3 with interconnected three-dimensional structure[J]. Contemp Chem Ind, 2013, 42(3):253-255. doi: 10.3969/j.issn.1671-0460.2013.03.003 [16] 吴俊升, 李晓刚, 杜伟, 董超芳.介孔/大孔Al2O3-SiO2复合氧化物的制备与表征[J].催化学报, 2006, 27(9):755-761. doi: 10.3321/j.issn:0253-9837.2006.09.003WU Jun-sheng, LI Xiao-gang, DU Wei, DONG Chao-fang. Preparation and characterization of meso/macro-porous composite oxide Al2O3-SiO2[J]. Chin J Catal, 2006, 27(9):755-761. doi: 10.3321/j.issn:0253-9837.2006.09.003 [17] 杨卫亚, 凌凤香, 张会成, 王少军, 沈智奇.具有三维贯通多级孔道结构大孔氧化铝的制备与表征[J].燃料化学学报, 2018, 46(5):558-563. doi: 10.3969/j.issn.0253-2409.2018.05.007YANG Wei-ya, LING Feng-xiang, ZHANG Hui-cheng, WANG Shao-jun, SHEN Zhi-qi. Synthesis and characterization of hierarchically porous alumina with three-dimensional interconnected pore structure[J]. J Fuel Chem Technol, 2018, 46(5):558-563. doi: 10.3969/j.issn.0253-2409.2018.05.007 [18] ABSI-HALABI M, STANISLAUS A, AL-MUGHNI T, KHAN S, QAMRA A. Hydroprocessing of vacuum residues:Relation between catalyst activity, deactivation and pore size distribution[J]. Fuel, 1995, 74(8):1211-1215. doi: 10.1016/0016-2361(94)00042-P [19] LIU T, JU L, ZHOU Y, WEI Q, DING S, ZHOU W, LUO X, JIANG S, TAO X. Effect of pore size distribution (PSD) of Ni-Mo/Al2O3 catalysts on the Saudi Arabia vacuum residuum hydrodemetallization (HDM)[J]. Catal Today, 2016, 271:179-187. doi: 10.1016/j.cattod.2015.07.045 [20] DAMYANOVA S, GRANGE P, DELMON B. Surface characterization of zirconia-coated alumina and silica carriers[J]. J Catal, 1997, 168(2):421-430. doi: 10.1006/jcat.1997.1671 [21] LOWENTHAL E E, SCHWARZ S, FOLEY H C. Surface chemistry of Rh-Mo/γ-Al2O3:An analysis of surface acidity[J]. J Catal, 1995, 156(1):96-105. doi: 10.1006/jcat.1995.1235 [22] STANISLAUS A, AL-DOLAMA K, ABSI-HALABI M. Preparation of a large pore alumina-based HDM catalyst by hydrothermal treatment and studies on pore enlargement mechanism[J]. J Mol Catal A:Chem, 2002, 181(1):33-39. http://cn.bing.com/academic/profile?id=d1f8f6536b15a20b4a48c8105baaac4d&encoded=0&v=paper_preview&mkt=zh-cn [23] CAI W, YU J, JARONIEC M. Template-free synthesis of hierarchical spindle-like[gamma]-Al2O3materials and their adsorption affinity towards organic and inorganic pollutants in water[J]. J Mate Chem, 2010, 20(22):4587-4594. doi: 10.1039/b924366f [24] HE W, LIU J, CAO Z, LI C, GAO Y. Preparation and characterization of monodisperse zirconia spherical nanometer powder via lamellar liquid crystal template method[J]. Chin J Chem Eng, 2015, 23(10):1721-1727. doi: 10.1016/j.cjche.2015.08.032 [25] 刘冬梅, 马波, 杨卫亚, 凌凤香, 沈智奇, 王少军, 孙万付, 赵小雪.六棱柱状多晶γ-Al2O3的制备、表征及其形成机制研究[J].燃料化学学报, 2013, 41(10):1262-1267. http://manu60.magtech.com.cn/rlhxxb/CN/abstract/abstract18283.shtmlLIU Dong-mei, MA Bo, YANG Wei-ya, LING Feng-xiang, SHEN Zhi-qi, WANG Shao-jun, SUN Wan-fu, ZHAO Xiao-xue. Synthesis, characterization and formation mechanism of hexagonal prism polycrystalline γ-Al2O3[J]. J Fuel Chem Technol, 2013, 41(10):1262-1267. http://manu60.magtech.com.cn/rlhxxb/CN/abstract/abstract18283.shtml -

下载:

下载: