-

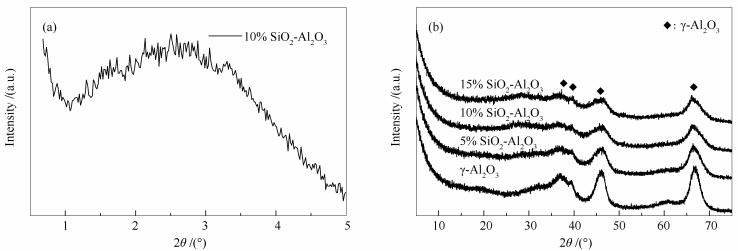

摘要: 以Pluronic P123作结构导向剂,采用Al(NO3)3-NaAlO2双水解法合成氧化铝,在成胶过程中加入正硅酸乙酯,制备硅质量分数分别为5%、10%、15%的SiO2-Al2O3载体,并通过共浸渍法制备出Co-Mo/SiO2-Al2O3润滑油加氢处理催化剂。通过XRD、N2吸附-脱附、Py-FTIR、NH3-TPD、H2-TPR、TEM和XRF等手段对载体及催化剂的性质进行表征。结果表明,硅质量分数为10%的SiO2-Al2O3具有优良的孔结构、较多的中强酸以及部分有序的介孔结构。以此为载体制备的Co-Mo/10% SiO2-Al2O3催化剂中,MoS2颗粒均匀地分散在载体上,具有更多的B酸性位和Ⅱ型CoMoS活性相。以减二线蜡油为原料油的固定床活性评价结果表明,生成油中主要组分为链烷烃与环烷烃;尤其Co-Mo/10% SiO2-Al2O3催化剂具有优良的加氢性能,在15 MPa、380℃、氢油比为1000、空速为0.6 h-1的反应条件下,其HDS和HDN数值均超过99%,产品中S含量小于10 μg/g,N含量小于2 μg/g,可以满足后续异构脱蜡等对原料的要求。

-

关键词:

- SiO2-Al2O3载体 /

- Co-Mo催化剂 /

- 润滑油 /

- 加氢处理

Abstract: SiO2-Al2O3, with a mass content of 5%, 10% and 15%, was synthesized by using a Al(NO3)3-NaAlO2 double hydrolysis method, with surfactant Pluronic P123 as template and Si(OC2H5)4 as Si source. The Co-Mo/SiO2-Al2O3 hydrotreating catalysts for lubricating oil were then prepared by co-impregnation method and characterized by a series of techniques such as XRD, N2 sorption, Py-FTIR, NH3-TPD, H2-TPR, TEM and XRF. The results show that the SiO2-Al2O3 support containing 10% Si is provided with abundant moderate-strong acid sites and partially ordered mesoporous structure; MoS2 particles are uniformly dispersed on the SiO2-Al2O3 surface. Moreover, the Co-Mo/10%SiO2-Al2O3 catalyst exhibits high amount of Bronsted acid sites and type Ⅱ CoMoS active phase. The catalytic performance was evaluated in a high-pressure fixed-bed reactor, with second vacuum side distillate oil as the raw material oil. The results show that the Co-Mo/10%SiO2-Al2O3 catalyst exhibits high activity in hydrotreating and paraffins and cycloalkanes are the main components in product oil. Under 380℃, 15 MPa, a space velocity of 0.6 h-1, and a hydrogen to oil ratio of 1000, the HDS and HDN values over Co-Mo/10%SiO2-Al2O3 exceed 99%. Meanwhile, the contents of S and N in the product are less than 10 and 2 μg/g, respectively, which can meet the requirements on the raw materials for the subsequent isomerization dewaxing process.-

Key words:

- SiO2-Al2O3 support /

- Co-Mo catalyst /

- lubricating oil /

- hydrotreating

-

表 1 不同硅含量载体及催化剂的孔结构性质

Table 1 Textural properties of SiO2-Al2O3 supports with different Si contents

Support ABET /(m2·g-1) Pore volume v/(cm3·g-1) APD /nm γ-Al2O3 262 0.55 8.97 5%SiO2-Al2O3 395 1.03 10.65 10%SiO2-Al2O3 406 1.41 14.41 15%SiO2-Al2O3 372 1.36 15.31 表 2 不同硅含量载体中的酸分布

Table 2 Distribution of acid sites in SiO2-Al2O3 supports with different Si contents

Support Total acidity /% Weak acidity /% Medium strong acidity /% Strong acidity /% γ-Al2O3 100 36 52 12 5%SiO2-Al2O3 82 28 54 18 10%SiO2-Al2O3 65 16 61 23 15%SiO2-Al2O3 75 21 58 21 表 3 不同硅含量催化剂的孔结构性质

Table 3 Textural properties of various catalysts with different Si contents

Catalyst ABET /(m2·g-1) Pore volume v /(cm3·g-1) APD /nm Co-Mo/5%SiO2-Al2O3 343 0.68 7.7 Co-Mo/10%SiO2-Al2O3 363 0.76 8.4 Co-Mo/15%SiO2-Al2O3 316 0.72 9.1 表 4 Co-Mo/10%SiO2-Al2O3催化剂的XRF分析

Table 4 XRF results of Co-Mo/10%SiO2-Al2O3 catalyst

Compound Al2O3 SiO2 MoO3 CoO Composition w/% 62.6 9.8 19.5 8.1 表 5 原料油性质

Table 5 Properties of raw oil

Properties Second vacuum side distillate oil d20 /(g·cm-3) 0.891 Kinematic viscosity /(mm2·s-1) 6.268 Sulphur content /(mg·kg-1) 756 Nitrogen content /(mg·kg-1) 789 Saturate /% 68.20 Aromatics /% 24.43 Colloid and asphaltene /% 7.37 表 6 生成油的组成

Table 6 Composition of product oil over Co-Mo/10%SiO2-Al2O3

Hydrocarbon fractions Content w/% Paraffin 51.2 Cycloalkane 38.2 Mononuclear aromatics 4.1 Double ring aromatics 0.8 Three ring aromatics 0.1 Four ring aromatics 0.1 Aromatics 5.5 Total 100 表 7 原料油和生成油的馏程分布

Table 7 Distillation range of raw oil and product oil over Co-Mo/10%SiO2-Al2O3

Project Distillation range t /℃ raw material oil product oil ASTM D86 - - IBP 354.9 210.8 5% 378.4 229.6 10% 390.7 262.2 20% 404.3 309.4 30% 411.2 343.5 50% 421.4 402.2 70% 426.7 419.3 80% 430.3 434.2 90% 441.7 453.2 FBP 459.5 477.7 -

[1] TAGUCHI A, SCHÜTH F. Ordered mesoporous materials in catalysis[J]. Microporous Mesoporous Mater, 2005, 77(1):1-45. doi: 10.1016/j.micromeso.2004.06.030 [2] SHYAMAL K B, SAMIR K M, UDAY T T. Search for an efficient 4, 6-DMDBT hydrodesulfurization catalyst:A review of recent studies[J]. Energy Fuels, 2004, 18(5):1227-1237. doi: 10.1021/ef030179+ [3] 王延臻, 张金玲, 宋春敏, 段红玲. Co-Mo/meso-Al2O3蜡油加氢处理催化剂的制备[J].石油炼制与化工, 2017, (12):68-73. doi: 10.3969/j.issn.1005-2399.2017.12.014WANG Yan-zhen, ZHANG Jin-ling, SONG Chun-min, DUAN Hong-ling. Preparation of Co-Mo/meso-Al2O3 for vacuum distillate oil hydrotreating[J]. Pet Process Petrochem, 2017, (12):68-73. doi: 10.3969/j.issn.1005-2399.2017.12.014 [4] 岳宝华, 周仁贤, 郑小明. 耐高温高比表面Ce-Zr复合氧化铝的制备及在汽车尾气净化催化剂中的应用研究[C]. 第十三届全国催化学术会议论文集, 2006.YUE Bao-hua, ZHOU Ren-xian, ZHENG Xiao-ming. Preparation and application of Ce-Zr modified alumina with high surface area and high temperature resistance in the automobile emission purification catalyst[C]. 13th Nationwide Academic Conference Proceedings on Catalysis, 2006. [5] 金政伟. 弱酸性体系中非离子表面活性剂导向下硅基介孔材料的合成研究[D]. 北京: 北京化工大学, 2007. http://cdmd.cnki.com.cn/Article/CDMD-10010-1014452123.htmJIN Zheng-wei. Synthesis of silica mesoporous materials by using nonionic surfactant as template under mildly acidity conditions[D]. Beijing: Beijing University of Chemical Technology, 2007. http://cdmd.cnki.com.cn/Article/CDMD-10010-1014452123.htm [6] SUZUKI N, SAKKA Y, YAMAUCHI Y. Simple preparation of silica and alumina with a hierarchical pore system via the dual-templating method[J]. Sci Technol Adv Mater, 2009, 10(2):1-6. https://www.ncbi.nlm.nih.gov/pmc/articles/PMC5090446 [7] LI D, LIN Y S, GULIANTS V V. Synthesis and characterization of ordered meso-macro-porous silica membranes on a porous alumina support[J]. Tsinghua Sci Technol, 2010, 15(4):377-384. doi: 10.1016/S1007-0214(10)70076-6 [8] FU W, ZHANG L, WU D, XIANG M, ZHUO Q, HUANG K, TAO Z, TANG T. Mesoporous zeolite-supported metal sulfide catalysts with high activities in the deep hydrogenation of phenanthrene[J]. J Catal, 2015, 330:423-433. doi: 10.1016/j.jcat.2015.07.026 [9] LI G C, LIU Y Q, TANG Z, LIU C G. Effects of rehydration of alumina on its structural properties, surface acidity, and HDN activity of quinolone[J] Appl Catal A:Gen, 2012, 437/438:79-89. doi: 10.1016/j.apcata.2012.06.017 [10] PARRY E P. An infrared study of pyridine adsorbed on acidic solids. Characterization of surface acidity[J]. J Catal, 1963, 2(5):371-379. doi: 10.1016/0021-9517(63)90102-7 [11] BUSCA G. Spectroscopic characterization of the acid properties of metal oxide catalysts[J]. Catal Today, 1998, 41(1/3):191-206. https://www.sciencedirect.com/science/article/pii/S0920586198000492 [12] GRZECHOWIAK J R, RYNKOWSKI J, WERESZCZAKO-ZIELINSKA I. Catalytic hydrotreatment on alumina-titania supported NiMo sulphides[J]. Catal Today, 2001, 65(2/4):225-231. https://www.sciencedirect.com/science/article/pii/S0920586100005629 [13] ARRIBAS M A, CONCEPCIÓN P, MARTÍNEZ A. The role of metal sites during the coupled hydrogenation and ring opening of tetralin on bifunctional Pt(Ir)/USY catalysts[J]. Appl Catal A:Gen, 2004, 267(1/2):111-119. https://www.sciencedirect.com/science/article/pii/S0926860X04001565 [14] SANTI D, HOLL T, CALEMMA V, WEITKAMP J. High-performance ring-opening catalysts based on iridium-containing zeolite Beta in the hydroconversion of decalin[J]. Appl Catal A:Gen, 2013, 455(2):46-57. https://www.sciencedirect.com/science/article/pii/S0926860X13000471 [15] GALPERIN L B, BRICKER J C, HOLMGREN J R. Effect of support acid-basic properties on activity and selectivity of Pt catalysts in reaction of methylcyclopentane ring opening[J]. Appl Catal A:Gen, 2003, 239(1/2):297-304. https://www.sciencedirect.com/science/article/pii/S0926860X02004167 [16] VALENCIA D, KLIMOVA T. Citric acid loading for MoS2-based catalysts supported on SBA-15. New catalytic materials with high hydrogenolysis ability in hydrodesulfurization[J]. Appl Catal B:Environ, 2013, 129(2):137-145. http://www.doc88.com/p-9813440340424.html [17] EJKA J. Organized mesoporous alumina:Synthesis, structure and potential in catalysis[J]. Appl Catal A:Gen, 2003, 254(2):327-338. doi: 10.1016/S0926-860X(03)00478-2 [18] WANG N, SHEN K, HUANG L, YU X, QIAN W, CHU W. Facile route for synthesizing ordered mesoporous Ni-Ce-Al oxide materials and their catalytic performance for methane dry reforming to hydrogen and syngas[J]. Acs Catal, 2013, 3(3):1638-1651. doi: 10.1021/cs4003113 [19] SONI K, RANA B S, SINHA A K, BHAUMIK A, NANDI M, KUMAR M, DHAR G M. 3-D ordered mesoporous KIT-6 support for effective hydrodesulfurization catalysts[J]. Appl Catal B:Environ, 2009, 90(1):55-63. https://www.sciencedirect.com/science/article/pii/S092633730900071X [20] PARRY E P. An infrared study of pyridine adsorbed on acidic solids. Characterization of surface acidity[J]. J Catal, 1963, 2(5):371-379. doi: 10.1016/0021-9517(63)90102-7 [21] LIU H, LIU C, YIN C, CHAI Y, LI Y, LIU D, LIU B, LI X, WANG Y, LI X. Preparation of highly active unsupported nickel-zinc-molybdenum catalysts for the hydrodesulfurization of dibenzothiophene[J]. Appl Catal B:Environ, 2015, s174-175:264-276. https://www.sciencedirect.com/science/article/pii/S0926337315000600 [22] LÓPEZ C R, LÓPEZ A A. Effect of water extraction on the surface properties of Mo/Al2O3 and NiMo/Al2O3 hydrotreating catalysts[J]. Appl Catal A:Gen, 2000, 202(1):23-28. doi: 10.1016/S0926-860X(00)00449-X [23] OKAMOTO Y, ISHIHARA S, KAWANO M. Preparation of Co-Mo/Al2O3 model sulfide catalysts for hydrodesulfurization and their application to the study of the effects of catalyst preparation[J]. J Catal, 2003, 217(1):12-22. http://www.doc88.com/p-6911574757666.html [24] 杨占林, 姜虹, 彭绍忠, 王继锋, 唐兆吉.制备技术对加氢处理催化剂性能的影响[J].石油化工, 2012, 41(8):885-889. http://www.cnki.com.cn/Article/CJFDTOTAL-SYHG201208005.htmYANG Zhan-lin, JIANG Hong, PENG Shao-zhong, WANG Ji-feng, TANG Zhao-ji. Influence of preparation techniques on the structure and activity of hydrogenation catalysts[J]. Petrochem Technol, 2012, 41(8):885-889. http://www.cnki.com.cn/Article/CJFDTOTAL-SYHG201208005.htm -

下载:

下载: