-

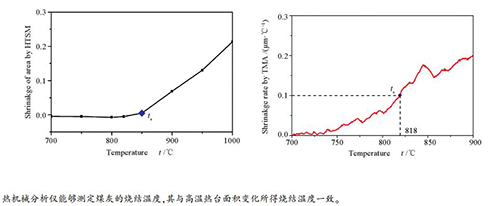

摘要: 采用热机械分析仪、高温热台显微镜、XRD及FactSage软件相结合的方法,研究了五彩湾煤灰的烧结特性及不同添加剂的影响规律。结果表明,沙子(SiO2含量约为80%)和煤矸石(SiO2含量为54%,Al2O3含量为42%)能改变煤灰的烧结特性(烧结温度和烧结速率),但不同添加剂改变的程度不同。添加10%的沙子能使烧结温度提高70 ℃,而0-15%煤矸石不能使烧结温度升高。此外,烧结速率随添加剂增多而减小,烧结区间随添加剂增多而延长。进一步研究表明,添加剂能够改变煤灰初始液相温度、组成、含量、煤灰中硫酸盐的分解温度及初始液相温度从而改变煤灰的烧结特性。Abstract: The effect of different additives on sintering characteristics of Wucaiwan coal ash was studied by TMA combined with XRD, in-situ hot stage microscope and FactSage thermodynamic software. The results show that the additives could improve the sintering problems of coal ash, but the effect of different additives on sintering characteristics is various. For example, the sintering temperature increases by 70 ℃ when 10% of the sand is added, but the sintering temperature does not increase by addition of coal gangue in the range of 0-15%. Further studies show that the variation of sintering characteristics can be attributed to the change of initial liquid phase temperature, compositions, content and decomposition temperature of sulfates in coal ash.

-

Key words:

- additives /

- sintering temperature /

- sintering process /

- initial liquid phase /

- sulfate

-

表 1 五彩湾煤的工业分析和元素分析

Table 1 Proximate and ultimate analyses of Wucaiwan

Sample Proximate analysis wad/% Ultimate analysis wad/% FC M A V C H O N S WCW 60.30 7.00 4.22 28.48 67.11 3.98 27.90 0.63 0.38 ad: air drying basis 表 2 五彩湾煤灰成分分析

Table 2 Ash compositions of Wucaiwan coal ash

Sample Chemical composition w/% SiO2 Al2O3 Fe2O3 CaO MgO SO3 TiO2 K2O Na2O P2O5 WCW 8.73 9.96 6.53 35.55 7.70 22.54 0.23 0.38 4.26 0.18 MGS 54.08 42.82 0.57 0.26 0.29 0.00 1.04 0.31 0.18 0.03 SZ 80.29 9.68 2.18 1.68 0.56 0.17 0.35 2.72 1.98 0.05 MGS: gangue; SZ: sand 表 3 五彩湾煤灰的熔融特征温度

Table 3 Ash fusion temperatures of Wucaiwan coal ash

Sample Temperature t/℃ Ts DT ST HT FT WCW 818 1339 1342 1349 1354 表 4 初始液相温度时煤灰液相组成及含量

Table 4 Contents and chemical compositions of slag at liquid formation temperature

Sample tini /℃ Content

w/%Composition w /% CaO Al2O3 Fe2O3 MgO SiO2 NaAlO2 WCW 1267.79 12.25 39.01 32.33 21.09 5.26 1.61 - 5%MGS 1288.86 34.69 39.84 33.88 18.87 5.13 1.62 - 10%MGS 1295.02 27.931 38.88 32.09 21.45 5.28 1.61 - 15%MGS 1302.86 16.856 36.8 28.1 27.2 5.5 1.6 - 5%SZ 1295.27 33.28 39.7 32.61 20.18 5.18 1.66 - 10%SZ 1304.47 17.99 35.86 26.29 29.81 5.488 1.59 - 15%SZ 1313.64 3.55 44.36 7.09 5.7 5.76 29.39 2.56 -

[1] 杨忠灿, 刘家利, 何红光.新疆准东煤特性研究及其锅炉选型[J].热力发电, 2010, 39(8):38-40. doi: 10.3969/j.issn.1002-3364.2010.08.038YANG Zhong-can, LIU Jia-li, HE Hong-guang. Study on properties of Zhundong coal in Xinjiang region and type-selection for boilers burning this coal sort[J]. Therm Power Gener, 2010, 39(8):38-40. doi: 10.3969/j.issn.1002-3364.2010.08.038 [2] 邱忠, 梁进林.循环流化床锅炉燃烧新疆准东五彩湾煤的对策探讨[J].应用能源技术, 2012, (12) 16-19. doi: 10.3969/j.issn.1009-3230.2012.12.005QIU Zhong, LIANG Jin-lin. Circulating fluidized bed boiler burning Xinjiang Wucaiwan area in Zhundong coal measures[J]. Appl Energy Technol, 2012, (12):16-19. doi: 10.3969/j.issn.1009-3230.2012.12.005 [3] 卢远梅.掺配五彩湾煤对乌鲁木齐主要电厂配烧的影响研究[J].煤质技术, 2011, (1):10-12. doi: 10.3969/j.issn.1007-7677.2011.01.004LU Yuan-mei. Study on the effect of mix-burning with Wucaiwan coal in main power plants in Urumuqi[J]. Coal Qual Technol, 2011, (1):10-12. doi: 10.3969/j.issn.1007-7677.2011.01.004 [4] 董明钢.高钠煤对锅炉受热面结渣、沾污和腐蚀的影响及预防措施[J].热力发电, 2008, 37(9):35-39. doi: 10.3969/j.issn.1002-3364.2008.09.010DONG Ming-gang.Prevention measures and the influence of slagging, fouling and corrosion of high-sodium coal on the heat surfaces of boilers[J]. Therm Power Gener, 2008, 37(9):35-39. doi: 10.3969/j.issn.1002-3364.2008.09.010 [5] CHAO L, YOU C F, ZHANG D K, Composition and sintering characteristics of ashes from co-firing of coal and biomass in a laboratory-scale drop tube furnace[J]. Energy, 2014, 69:562-570. doi: 10.1016/j.energy.2014.03.050 [6] 陈鸿伟, 张志远, 何骏鹏, 梁占伟, 杨新.弱还原性气氛中碱金属盐对煤灰沾污特性的影响[J].动力工程学报, 2017, 37(2):98-104. http://d.old.wanfangdata.com.cn/Periodical/dlgc201702003CHEN Hong-wei, ZHANG Zhi-yuan, HE Jun-peng, LIANG Zhan-wei, YANG-xin. Effects of alkali salts on the fouling properties of coal ash in weak reducing atmosphere[J]. Chin J Power Eng, 2017, 37(2):98-104. http://d.old.wanfangdata.com.cn/Periodical/dlgc201702003 [7] 王勤辉, 揭涛, 李小敏, 洛仲泱, 景妮杰, 岑可法.反应气氛对不同煤灰烧结温度影响的研究[J].燃料化学学报, 2010, 30(1):17-22. doi: 10.3969/j.issn.0253-2409.2010.01.004WANG Qin-hui, JIE Tao, LI Xiao-min, LUO Zhong-yang, JING Ni-jie, CEN Ke-fa. Experiments of the effects of reaction atmosphere on coal ash sintering temperature[J]. J Fuel Chem Technol, 2010, 30(1):17-22. doi: 10.3969/j.issn.0253-2409.2010.01.004 [8] VASSILEV S, VASSILEVA C, BAXTER D, ANDERSEN S. Relationships between chemical and mineral composition of coal and their potential applications as genetic indicators. Part 1. Chemical characteristics[J]. Geol Balc, 2011, 39:21-41. http://publications.jrc.ec.europa.eu/repository/handle/JRC64516 [9] 李君杰, 熊彪, 张泰, 黄晓宏, 卢科, 柳朝晖, 郑楚光.准东煤灰沉积特性的实验研究[J].工程热物理学报, 2017, 38(8):1790-1794. http://d.old.wanfangdata.com.cn/Periodical/hebgydxxb201801012LI Jun-jie, XIONG Biao, ZHANG Tai, HUANG Xiao-hong, LU Ke, LIU Chao-hui, ZHENG Chu-guang. Experimental study on ash deposition of zhundong coal[J]. J Eng Therm, 2017, 38(8):1790-1794. http://d.old.wanfangdata.com.cn/Periodical/hebgydxxb201801012 [10] WANG X B, XU Z X, WEI B, ZHANG L, TAN H Z, YANG T. The ash deposition mechanism in boilers burning Zhundong coal with high contents of sodium and calcium:A study from ash evaporating to condensing[J]. Appl Therm Eng, 2015, 80:150-159. doi: 10.1016/j.applthermaleng.2015.01.051 [11] 沈铭科, 邱坤赞, 黄镇宇, 王智化, 刘建忠.准东煤掺烧高岭土对固钠率及灰熔融特性影响研究[J].燃料化学学报, 2015, 43(9):1044-1051. doi: 10.3969/j.issn.0253-2409.2015.09.004SHEN Ming-ke, QIU Kun-zan, HUANG Zhen-yu, WANG Zhi-hua, LIU Jian-zhong. Influence of kaolin on sodium retention and ash fusion characteristic during combustion of Zhundong coal[J]. J Fuel Chem Technol, 2015, 43(9):1044-1051. doi: 10.3969/j.issn.0253-2409.2015.09.004 [12] 高姗姗, 金晶, 刘敦禹, 王永贞, 姚宇翔, 寇学森.蛭石复合添加剂对准东煤灰特性影响[J].化工进展, 2017, 36(9):3280-3286. http://d.old.wanfangdata.com.cn/Periodical/hgjz201709019GAO Shan-shan, JIN jing, LIU Dun-yu, WANG Yong-zhen, YAO Yu-xiang, KOU Xue-sen. Effect of vermiculite composite additives on the anti-slagging behaviorduring combustion of Zhundong coal[J]. Chem Ind Eng Prog, 2017, 36(9):3280-3286. http://d.old.wanfangdata.com.cn/Periodical/hgjz201709019 [13] 刘大海, 张守玉, 涂圣康, 金涛, 施大钟, 施登宇, 裴育峰.五彩湾煤中钠在燃烧过程中的迁移释放规律[J].化工进展, 2015, 34(3):705-709. http://d.old.wanfangdata.com.cn/Periodical/hgjz2015030021LIU Da-hai, ZHANG Shou-yu, TU Sheng-kang, JIN Tao, SHI Da-zhong, SHI Deng-yu, PEI Yu-feng. Transformation and release of sodium in Wucaiwan coal during combustion[J]. Chem Ind Eng Prog, 2015, 34(3):705-709. http://d.old.wanfangdata.com.cn/Periodical/hgjz2015030021 [14] 涂圣康, 张守玉, 施大钟, 金涛, 杨清宁, 刘大海, 裴育峰.添加剂对高钠煤热解过程中钠析出的影响[J].煤炭转化, 2016, 39:31-34. doi: 10.3969/j.issn.1004-4248.2016.01.007TU Sheng-kang, ZHANG Shou-yu, SHI Da-zhong, JIN Tao, YANG Qing-ning, LIU Da-hai, PEI Yu-feng.Effect of additive on emission of sodium in high sodium coal during pyrolysis[J]. Coal Convers, 2016, 39(1):31-34. doi: 10.3969/j.issn.1004-4248.2016.01.007 [15] LI J B, ZHU M M, ZHANG Z Z, ZHANG D K. A new criterion for determination of coal ash sintering temperature using the pressure-drop technique and the effect of ash mineralogy and geochemistry[J]. Fuel, 2016, 179:71-78. doi: 10.1016/j.fuel.2016.03.078 [16] WALL T F, CREELMAN R A, GUPTA R P, GUPTA S K, COIN C, LOWE A. Coal ash fusion temperatures-New characterization techniques, and implications for slagging and fouling[J]. Prog Energy Combust Sci, 1998, 24:345-353. doi: 10.1016/S0360-1285(98)00010-0 [17] YAN T, KONG L, BAI J, BAI Z Q, LI W. Thermomechanical analysis of coal ash fusion behavior[J]. Chem Eng Sci, 2016, 147:74-82. doi: 10.1016/j.ces.2016.03.016 [18] GUPTA S K, GUPTA R P, BRYANT G W, WALL T F. The effect of potassium on the fusibility of coal ashes with high silica and alumina levels[J]. Fuel, 1998, 77:1195-1201. doi: 10.1016/S0016-2361(98)00016-7 [19] ALOTOOM A Y, ELLIOTT L K, WALL T F, MOGHTADERI B. Measurement of the sintering kinetics of coal ash[J]. Energy & Fuels, 2000, 14:97-109. doi: 10.1021/ef0000126 [20] ALOTOOM A Y, BRYANT G W, ELLIOTT L K, SKRIFVARS B J, HUPA M, WALL T F. Experimental options for determining the temperature for the onset of sintering of coal ash[J]. Energy Fuels, 1999, 14:41-49. doi: 10.1021-ef990196s/ [21] LEE S, JUNG B, LEE N, NAM W, LEE S J, YUN Y. Application of FactSage (R) thermodynamic modeling for predicting the ash transformation with temperatures under partial slagging entrained flow coal gasification condition[J]. Mater Test, 2018, 60:163-172. doi: 10.3139/120.111138 [22] WANG L, SKJEVRAK G, HUSTAD J E, MORTEN G. Sintering characteristics of sewage sludge ashes at elevated temperatures[J]. Fuel Process Technol, 2012, 96:88-97. doi: 10.1016/j.fuproc.2011.12.022 [23] 刘家利, 苏国庆, 张小宏, 杨忠灿, 姚伟.高碱金属煤煤灰沾污特性评价方法[J].热力发电, 2016, 45(1):9-13. doi: 10.3969/j.issn.1002-3364.2016.01.009LIU Jia-li, SU Guo-qing, ZHANG Xiao-hong, YANG Zhong-can, YAO Wei. Evaluation method for ash fouling characteristics of coals with high alkali content[J]. Therm Power Gener, 2016, 45(1):9-13 doi: 10.3969/j.issn.1002-3364.2016.01.009 [24] 王辉, 魏星, 秦雪箭, 王林, 张帅, 吴少华.不同成灰温度下准东煤灰沉积特性实验研究[J].哈尔滨工业大学学报, 2018, 50(1):82-89. http://d.old.wanfangdata.com.cn/Periodical/hebgydxxb201801012WANG Hui, WEI Xing, QIN Xue-Jian, WANG Lin, ZHANG Shuai, WU Shao-hua. Experimental investigation of Zhundong ash deposits characteristics under different ashing temperatures using an online image system[J]. J Harbin Inst Technol, 2018, 50(1):82-89. http://d.old.wanfangdata.com.cn/Periodical/hebgydxxb201801012 [25] KWON O H, MESSING G L. Kinetic analysis of solution-precipitation during liquid-phase sintering of alumina[J]. J Am Ceram Soc, 2010, 73:275-281. doi: 10.1111-j.1151-2916.1990.tb06506.x/ -

下载:

下载: