Study on effect of dispersant on semi-coke water slurry property based on quantum chemistry calculation

-

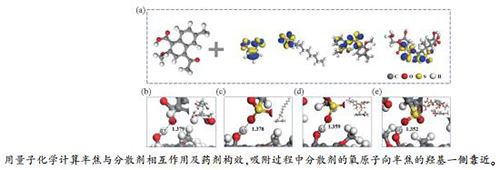

摘要: 为高效利用半焦资源,选择适宜的水焦浆分散剂以提高兰炭制备水焦浆的性能,本研究以陕北半焦及四种不同分散剂(腐植酸钠SH、木质素磺酸钠SLS、十二烷基磺酸钠SDS和一种自制衣康酸型分散剂IPMS)为研究对象,探讨了不同添加剂对水焦浆成浆特性的影响。利用Material Studio(MS)软件计算了分散剂的结构参数及半焦与分散剂间的相互作用能,从量子化学角度对分散剂的作用进行探讨,并与制浆实验结果进行比较。结果表明,加入分散剂可有效降低液体表面张力,增大半焦颗粒表面电负性,从而增强颗粒间静电排斥作用使得浆体更加稳定。相同制备条件下,分散剂IPMS制备水焦浆时效果较优,在剪切速率为100 s-1时,其表观黏度为625 mP·s,7 d析水率仅为2.38%且无硬沉淀。通过计算机模拟得出吸附过程中分散剂的氧原子向半焦的羟基一侧靠近,产生电荷转移,四种分散剂活性大小顺序为IMPS > SH > SLS > SDS,IMPS与半焦相互作用的吸附作用较强与实验结果一致。证明了采用量子化学计算结合实验数据可以对水焦浆分散剂的性能进行评价,为浆体燃料制备技术及新型药剂的设计开发提供了理论基础。Abstract: In order to utilize semi-coke resources efficiently and select the suitable dispersant to improve the performance of slurry prepared by semi-coke, the effects of different dispersants (sodium humate, sodium lignosulfonate, sodium dodecyl sulfonate and a self-made itaconic acid dispersant IPMS) on the pulping property of semi-coke slurry were studied. The structure parameters of dispersant and the interaction energy between semi-coke and dispersants were calculated by the software-Material Studio (MS) and compared with experimental value. The results show that the addition of dispersants can effectively reduce the surface tension of liquid and increase the electronegativity of semi-coke particles, enhancing the electrostatic repulsion between particles and making the slurry more stable. The self-made itaconic acid dispersant IPMS has a better effect on the property of semi-coke water slurry under the same preparation conditions. The apparent viscosity is 625 mP·s when the shear rate is 100 s-1, the water-liberating rate in 7 d of slurry is only 2.38% and there is no hard precipitation. The adsorption simulation indicates that the oxygen atom of the dispersant approaches to the hydroxyl side of the semi-coke and makes charge transfer, and the order of activity of four dispersants is IMPS > SH > SLS > SDS. The interaction between IMPS and the semi-coke leads to a strong adsorption, which is consistent with the experimental results. It is proven that the performance of dispersants can be evaluated by quantum chemical calculation combined with experimental data, providing a theoretical basis for the preparation technology of slurry fuel as well as the design and development of new reagents.

-

Key words:

- semi-coke water slurry /

- dispersant /

- molecular structure /

- quantum chemistry

-

表 1 半焦的工业分析和元素分析

Proximate analysis w/% Ultimate analysis wad/% Mad Aad Vdaf FCad C H O* N 3.24 13.30 13.74 69.72 70.67 1.96 8.60 0.964 *: by difference 表 2 不同分散剂的前线轨道能量

Table 2 Frontier orbital energy of different dispersants

Dispersant E/eV |ΔELUMO-HOMO| HOMO LUMO SH -3.461 -1.455 2.006 SLS -4.412 -1.123 3.289 SDS -3.772 -1.412 2.360 IPMS -2.549 -1.933 0.616 表 3 半焦-不同水焦浆分散剂间的吸附能

Table 3 Adsorption energy between semi-coke and different dispersants

Adsorption site SH SLS SDS IPMS Eads/(kJ·mol-1) -65.87 -81.18 -98.18 -131.27 表 4 半焦与分散剂吸附前后的Mulliken电荷分布(以半焦中H原子为例)

Table 4 Mulliken charge populations of atoms before and after dispersant adsorbed on semi-coke

Adsorption site Atom Bond length d/nm Mullinken charge of H/e before after semi-coke+ SH H(C-H73…O14) 0.1378 0.283 0.315 semi-coke+ SLS H(C-H88…O15) 0.1359 0.283 0.334 semi-coke+ SDS H(C-H53…O5) 0.1379 0.283 0.323 semi-coke+ IPMS H(C-H92…O31) 0.1352 0.283 0.339 -

[1] LIU S Q, ZHANG Y J, TUO K Y, WANG L P, CHEN G. Structure, electrical conductivity, and dielectric properties of semi-coke derived from microwave-pyrolyzed low-rank coal[J]. Fuel Process Technol, 2018, 178:139-147. doi: 10.1016/j.fuproc.2018.05.028 [2] LI Q, LI X H, JIANG J K, DUAN L, GE S, ZHANG Q, DENG J G, WANG S X, HAO J M. Semi-coke briquettes:towards reducing emissions of primary PM 2.5, particulate carbon, and carbon monoxide from household coal combustion in China[J]. Sci Rep-UK, 2016, 6:19306. doi: 10.1038/srep19306 [3] 李慧, 李刚, 林涛海, 胡天宝.焦粉与低阶煤混配制备水煤焦浆的成浆性研究[J].煤化工, 2018, 46(5):16-19. http://d.old.wanfangdata.com.cn/Periodical/mhg201805004LI Hui, LI Gang, LIN Tao-hai, HU Tian-bao. Slurryability study on mixed preparation of coal-coke water slurry from coke powder and low rank coal[J]. Coal Chem Ind, 2018, 46(5):16-19. http://d.old.wanfangdata.com.cn/Periodical/mhg201805004 [4] 王思同, 杨志远, 赵敏捷, 李智华.神府兰炭粉改性制浆的实验研究[J].西安科技大学学报, 2016, 36(5):680-684. http://d.old.wanfangdata.com.cn/Periodical/xakyxyxb201605012WANG Si-tong, YANG Zhi-yuan, ZHAO Min-jie, LI Zhi-hua. Preparation and mechanism of Shenfu semi-coke modification for the water semi-coke slurry[J]. J Xian Uni Sci Technol, 2016, 36(5):680-684. http://d.old.wanfangdata.com.cn/Periodical/xakyxyxb201605012 [5] 吕向阳.高浓度低阶煤水煤浆添加剂的筛选及应用[J].洁净煤技术, 2018, 24(4):54-59. http://d.old.wanfangdata.com.cn/Periodical/jjmjs201804010LV Xiang-yang. Selection and application of additive for high concentration low rank coal water slurry[J]. Clean Coal Technol, 2018, 24(4):54-59. http://d.old.wanfangdata.com.cn/Periodical/jjmjs201804010 [6] 杨东杰, 郭闻源, 李旭昭, 王玥, 邱学青.不同相对分子质量对接枝磺化木质素水煤浆分散剂吸附分散性能的影响[J].燃料化学学报, 2013, 41(1):20-25. doi: 10.3969/j.issn.0253-2409.2013.01.004YANG Dong-jie, GUO Wen-yuan, LI Xu-zhao, WANG Yue, QIU Xue-qing. Effects of molecular weight of grafted sulfonated lignin on its dispersion and adsorption properties as a dispersant for coal water slurries[J]. J Fuel Chem Technol, 2013, 41(1):20-25. doi: 10.3969/j.issn.0253-2409.2013.01.004 [7] SAHOO H, DAS B, RATHE S S. Density functional calculations of amines on the (101) face of quartz[J]. Miner Eng, 2014, 69:57-64. doi: 10.1016/j.mineng.2014.07.007 [8] 卢廷亮.烃类捕收剂性能的量子化学计算与试验研究[D].太原: 太原理工大学, 2015. http://cdmd.cnki.com.cn/Article/CDMD-10112-1015607108.htmLU Ting-liang. Quantum chemistry calculations and experimental research of the performance of hydrocarbon flotation reagents[D]. Taiyuan: Taiyuan University of Technology, 2015. http://cdmd.cnki.com.cn/Article/CDMD-10112-1015607108.htm [9] CHEN J, MIN F F, LIU L Y, LIU C F, LU F Q. Experimental investigation and DFT calculation of different amine/ammonium salts adsorption on kaolinite[J]. Appl Surf Sci, 2017, 419:241-251. doi: 10.1016/j.apsusc.2017.04.213 [10] YANG Z Y, MENG Z Y, LI Z H, WANG S T. Synthesis and application of itaconic acid water-coke slurry dispersant[J]. Mater Sci Forum, 2017, 896:167-174. doi: 10.4028/www.scientific.net/MSF.896.167 [11] 吴君宏.褐煤水热提质改善水煤浆的成浆性、流变性和稳定性的实验研究[J].燃料化学学报, 2019, 47(3):271-278. http://d.old.wanfangdata.com.cn/Periodical/rlhxxb201903003WU Jun-hong. Hydrothermal dewatering of lignite to improve the slurry-ability, rheology, and stability of coal-water slurry[J]. J Fuel Chem Technol, 2019, 47(3):271-278. http://d.old.wanfangdata.com.cn/Periodical/rlhxxb201903003 [12] 李科褡, 谢燕, 曹阳, 郭妤, 陈前林, 敖先权.无烟煤掺混白酒酒糟制备生物质水煤浆[J].燃料化学学报, 2016, 44(4):408-414. doi: 10.3969/j.issn.0253-2409.2016.04.004LI Ke-da, XIE Yan, CAO Yang, GUO Yu, CHEN Qian-lin, AO Xian-quan. Preparation of biomass coal water slurry through blending distillers' grains with anthracite[J]. J Fuel Chem Technol, 2016, 44(4):408-414. doi: 10.3969/j.issn.0253-2409.2016.04.004 [13] 于晓慧.胜利褐煤热解产物结构分析及典型半焦分子模型构建[D].徐州: 中国矿业大学, 2016. http://cdmd.cnki.com.cn/Article/CDMD-10290-1016910168.htmYU Xiao-hui. Analysis of Shengli lignite pyrolysis products and construction of typical char's molecular structure model[D]. Xuzhou: China University of Mining and Technology, 2016. http://cdmd.cnki.com.cn/Article/CDMD-10290-1016910168.htm [14] GRIMME S. Semiempirical GGA-type density functional constructed with a long-range dispersion correction[J]. J Comput Chem, 2006, 27(15):1787-1799. doi: 10.1002/jcc.20495 [15] DAS D, DASH U, MEHER J, MISRA P K. Improving stability of concentrated coal-water slurry using mixture of a natural and synthetic surfactants[J]. Fuel Process Technol, 2013, 113:41-51. doi: 10.1016/j.fuproc.2013.02.021 [16] ZHANG K, JIN L E, CAO Q. Evaluation of modified used engine oil acting as a dispersant for concentrated coal-water slurry[J]. Fuel, 2016, 175:202-209. doi: 10.1016/j.fuel.2016.02.026 [17] 李和平, 张晓光, 吴佳芮, 王雪梅, 胡奇林, 刘万毅.水煤浆添加剂的特性参数测定与筛选[J].煤炭转化, 2017, 40(4):48-56. doi: 10.3969/j.issn.1004-4248.2017.04.008LI He-ping, ZHANG Xiao-guang, WU Jia-rui, WANG Xue-mei, HU Qi-lin, LIU Wan-yi. Characteristic parameters test and selection of coal water slurry additives[J]. Coal Convers, 2017, 40(4):48-56. doi: 10.3969/j.issn.1004-4248.2017.04.008 [18] WANG C Y, ZHAO H, DAI Z H, LI W F, LIU H F. Influence of alkaline additive on viscosity of coal water slurry[J]. Fuel, 2019, 235:639-646. doi: 10.1016/j.fuel.2018.08.060 [19] WANG J Q, LIU J F, WANG S N, CHENG J. Slurrying property and mechanism of coal-coal gasification wastewater-slurry[J]. Energy Fuels, 2018, 32(4):4833-4840. doi: 10.1021/acs.energyfuels.8b00107 [20] 张剑锋, 胡岳华, 徐兢, 王淀佐.苯氧乙酸类浮选抑制剂性能的量子化学计算[J].中国有色金属学报, 2004, 14(8):1437-1441. doi: 10.3321/j.issn:1004-0609.2004.08.032ZHANG Jian-feng, HU Yue-hua, XU Jing, WANG Dian-zuo. Quantum chemical calculation on properties of phenoxy acetic acids depressants[J]. Chin J Nonferrous Met, 2004, 14(8):1437-1441. doi: 10.3321/j.issn:1004-0609.2004.08.032 [21] 周灵初, 张一敏.几种常用捕收剂与红柱石作用机理的量子化学研究[J].武汉科技大学学报, 2010, 33(6):632-635. doi: 10.3969/j.issn.1674-3644.2010.06.016ZHOU Ling-chu, ZHANG Yi-min. A quantum chemistry analysis of the interaction mechanism of andalusite and several common collectors[J]. J Wuhan Univ Sci Technol, 2010, 33(6):632-635. doi: 10.3969/j.issn.1674-3644.2010.06.016 [22] 陈军.高泥化煤泥水中微细颗粒疏水聚团特性及机理研究[D].安徽: 安徽理工大学, 2017. http://cdmd.cnki.com.cn/Article/CDMD-10361-1017171822.htmCHEN Jun. Characteristics and mechanism research on hydrophobic aggregation of fine particles in high muddied coal slurry water[D]. Huainan: Anhui University of Science and technology, 2017. http://cdmd.cnki.com.cn/Article/CDMD-10361-1017171822.htm -

下载:

下载: