Performance research of lanthanum-loaded dolomite catalyst for pine catalytic gasification

-

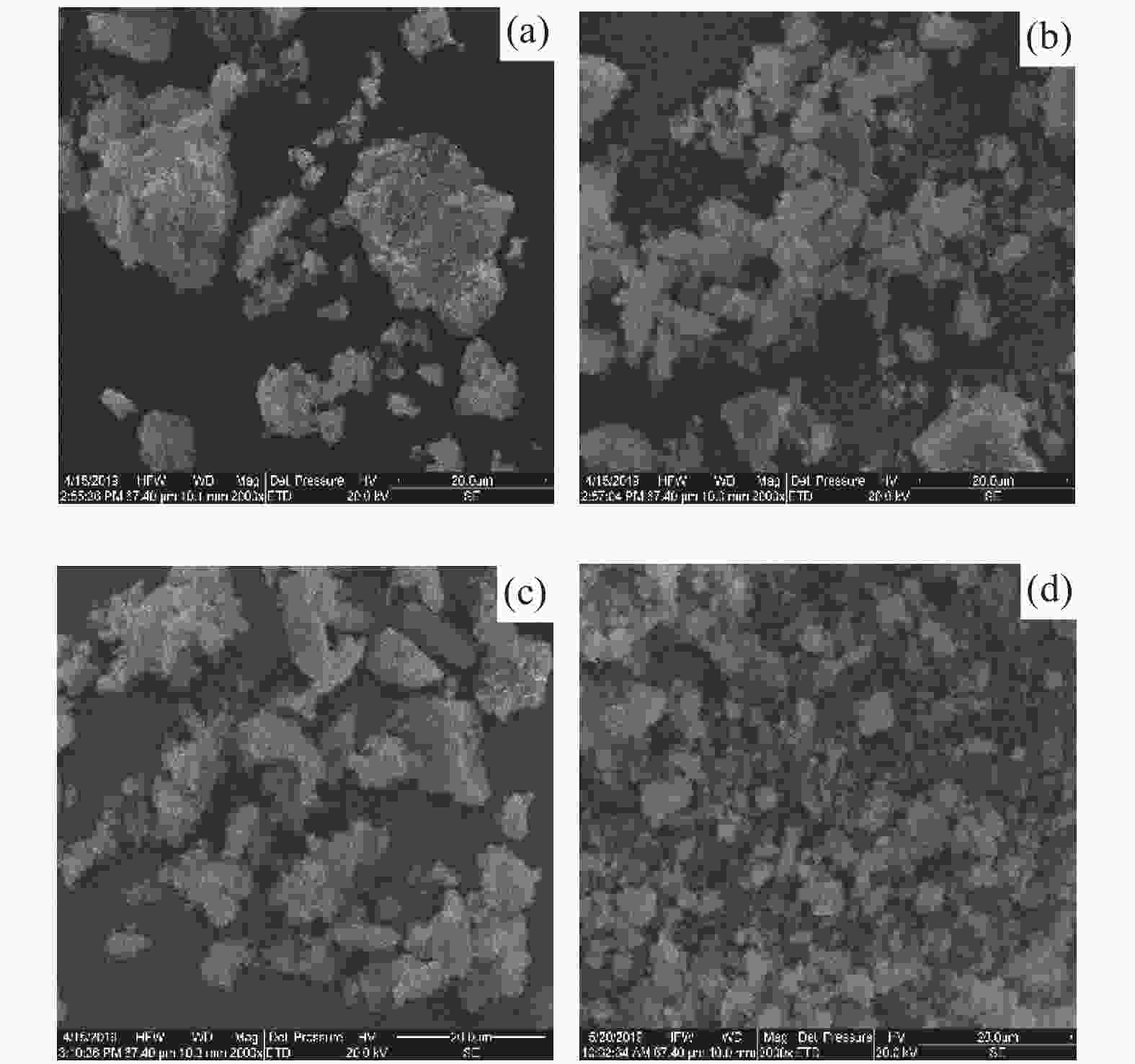

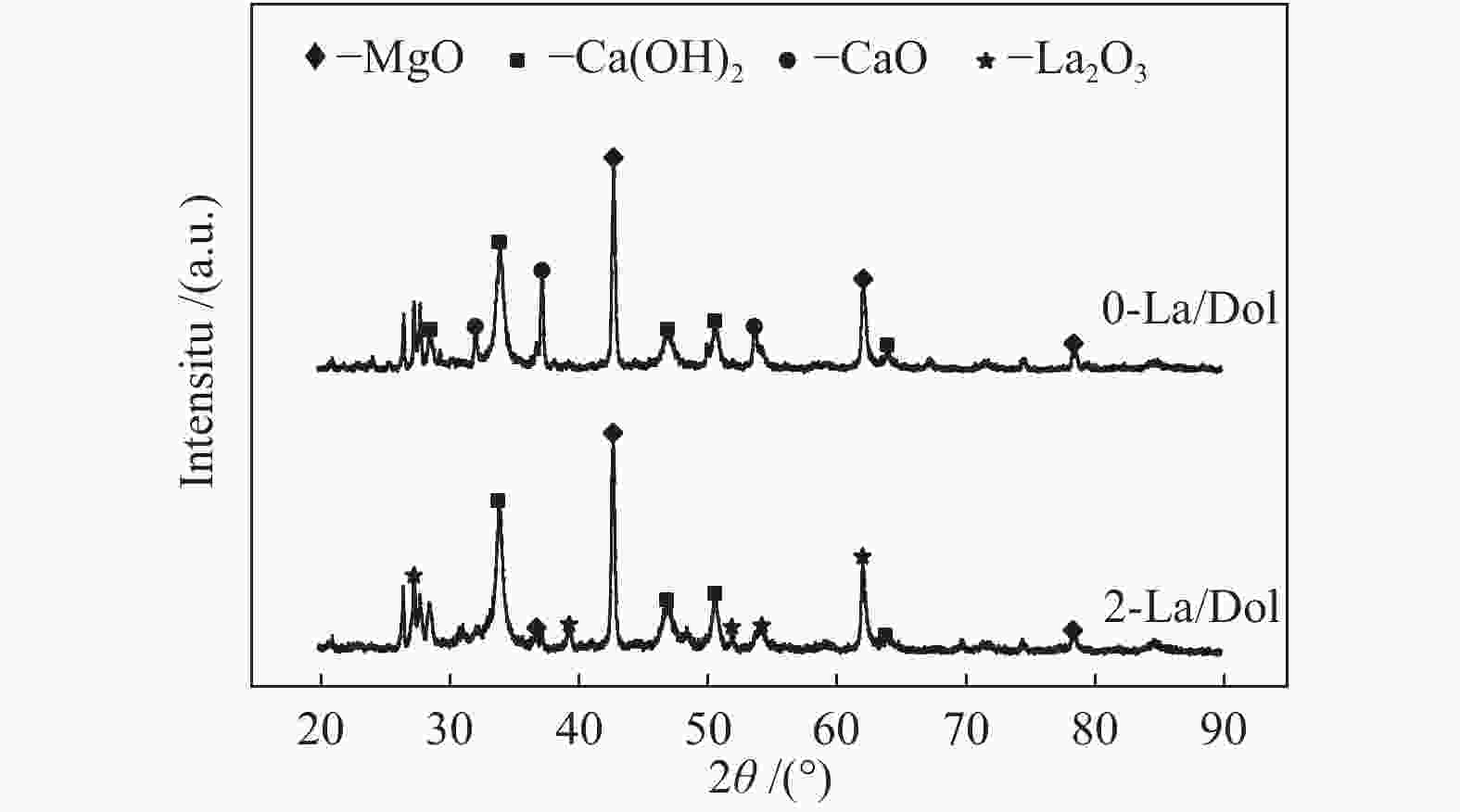

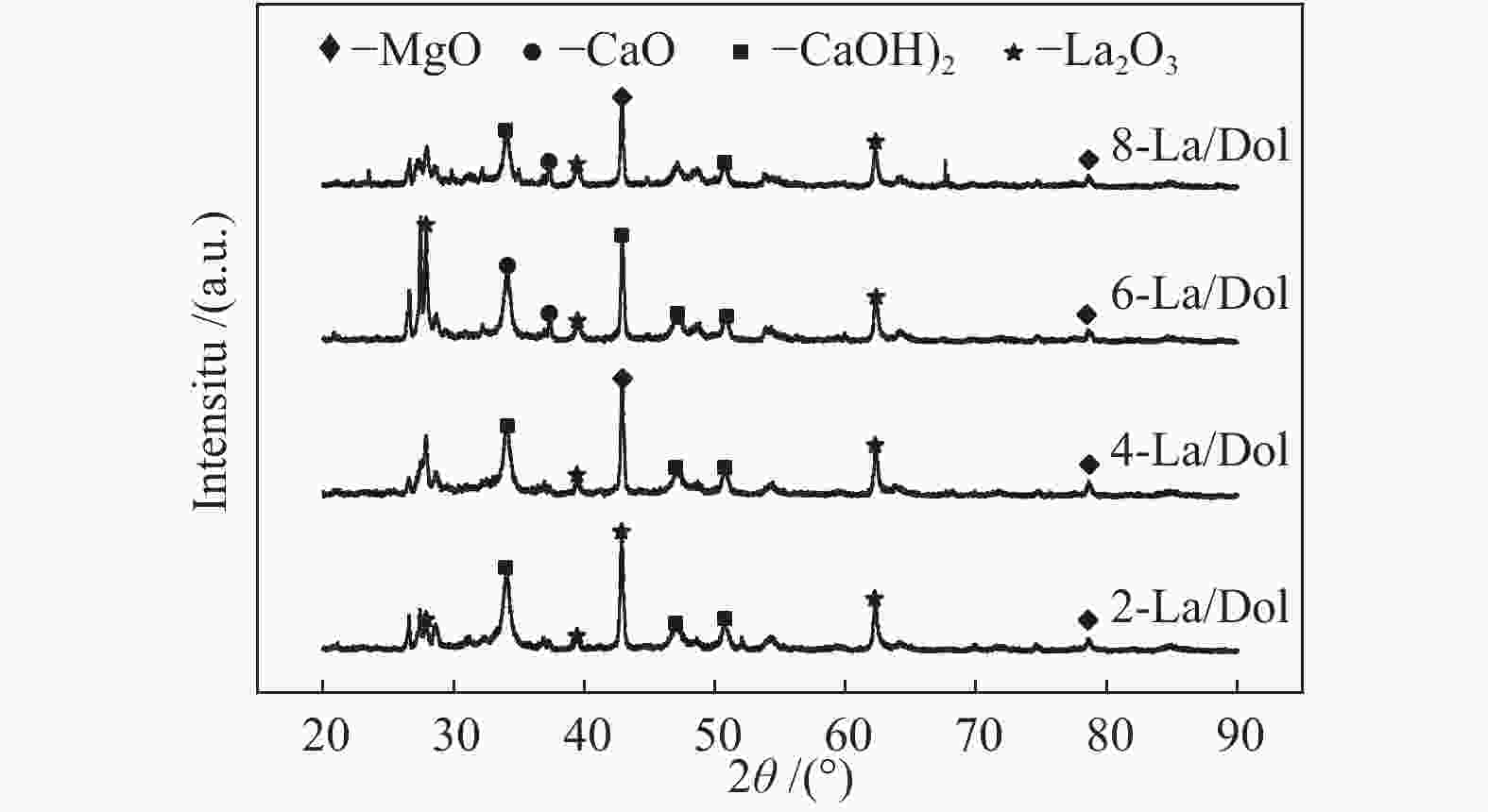

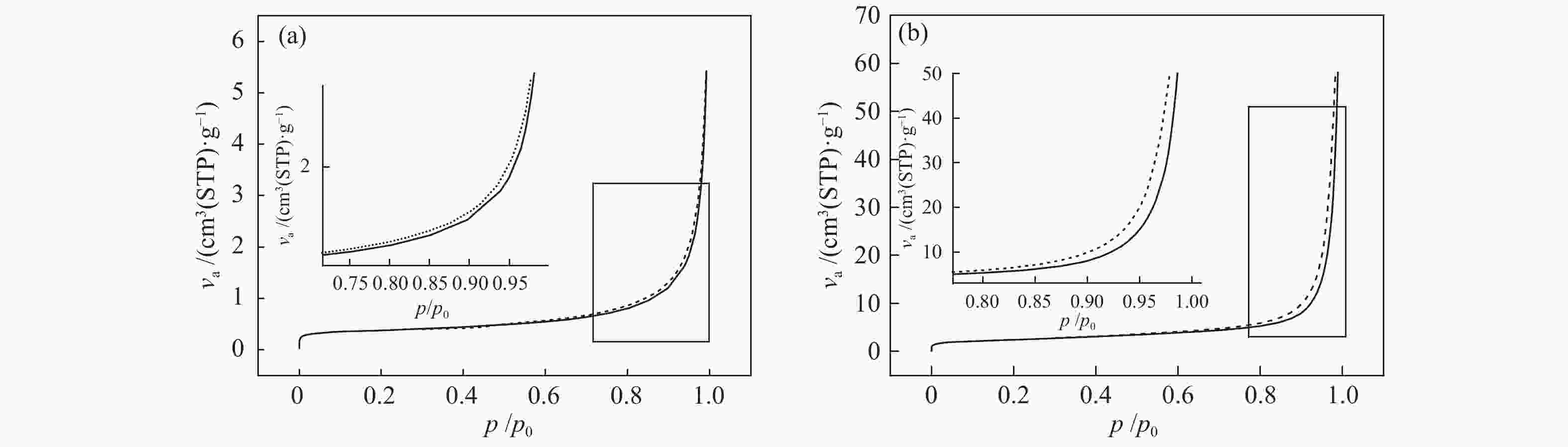

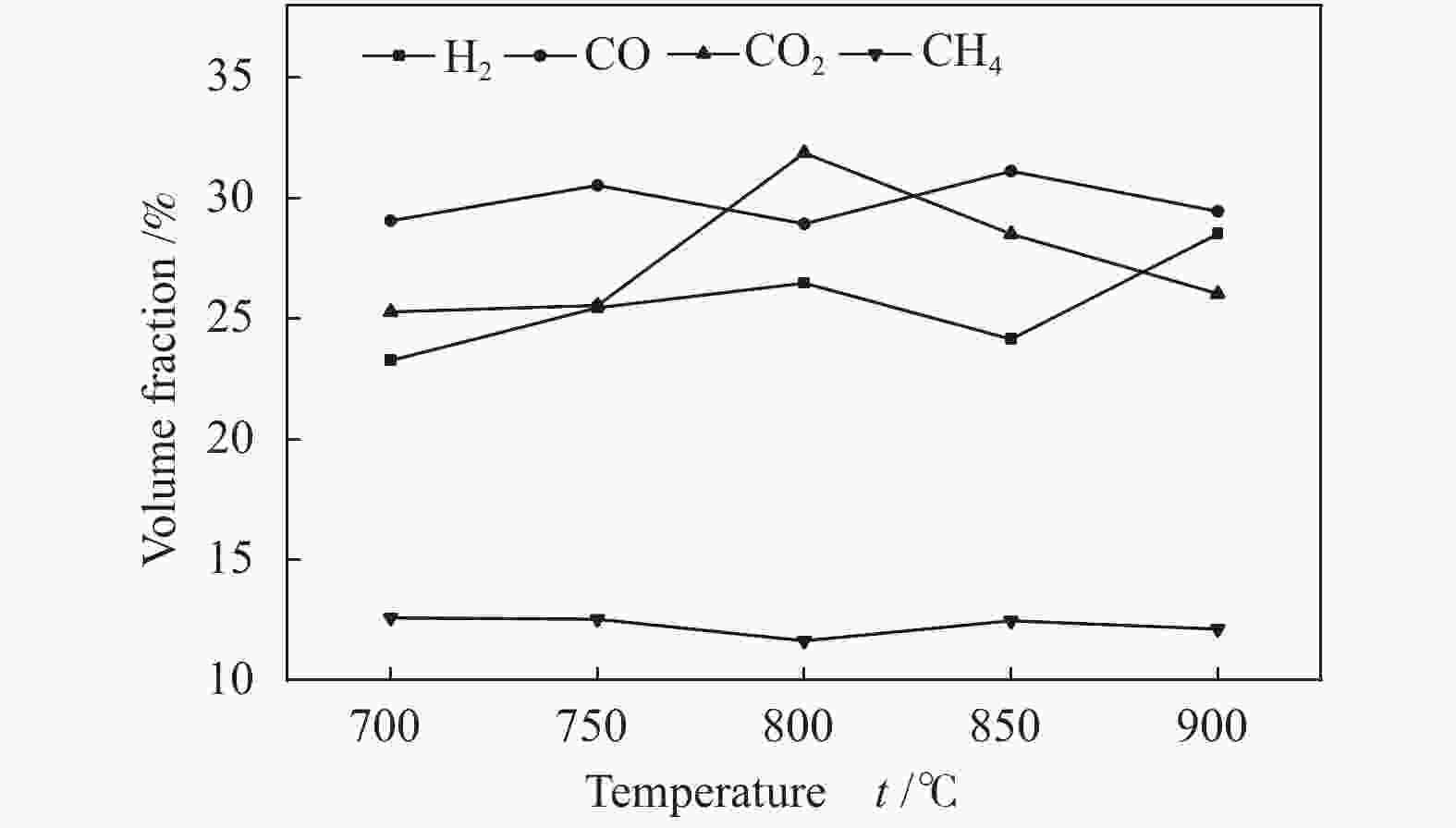

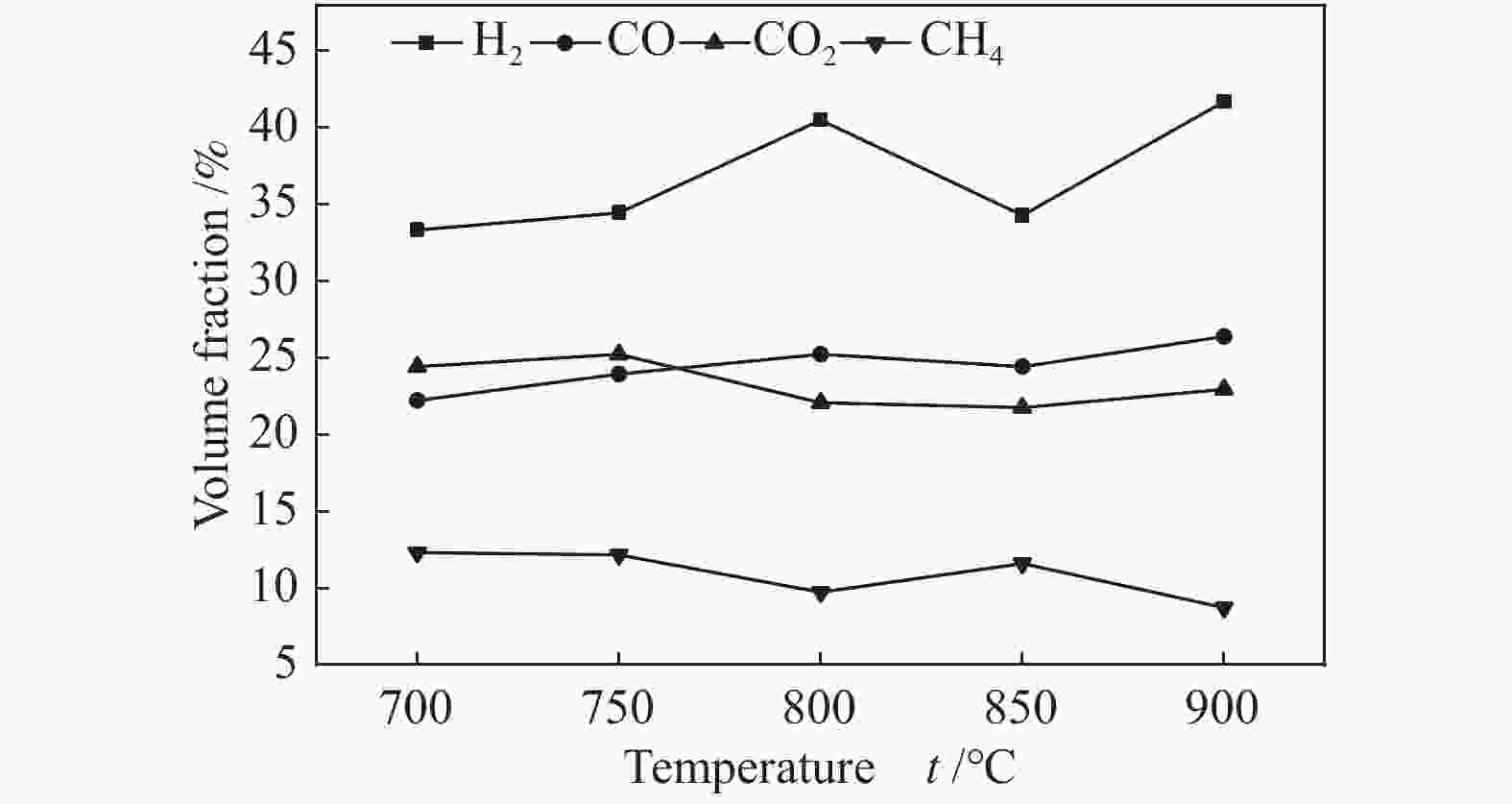

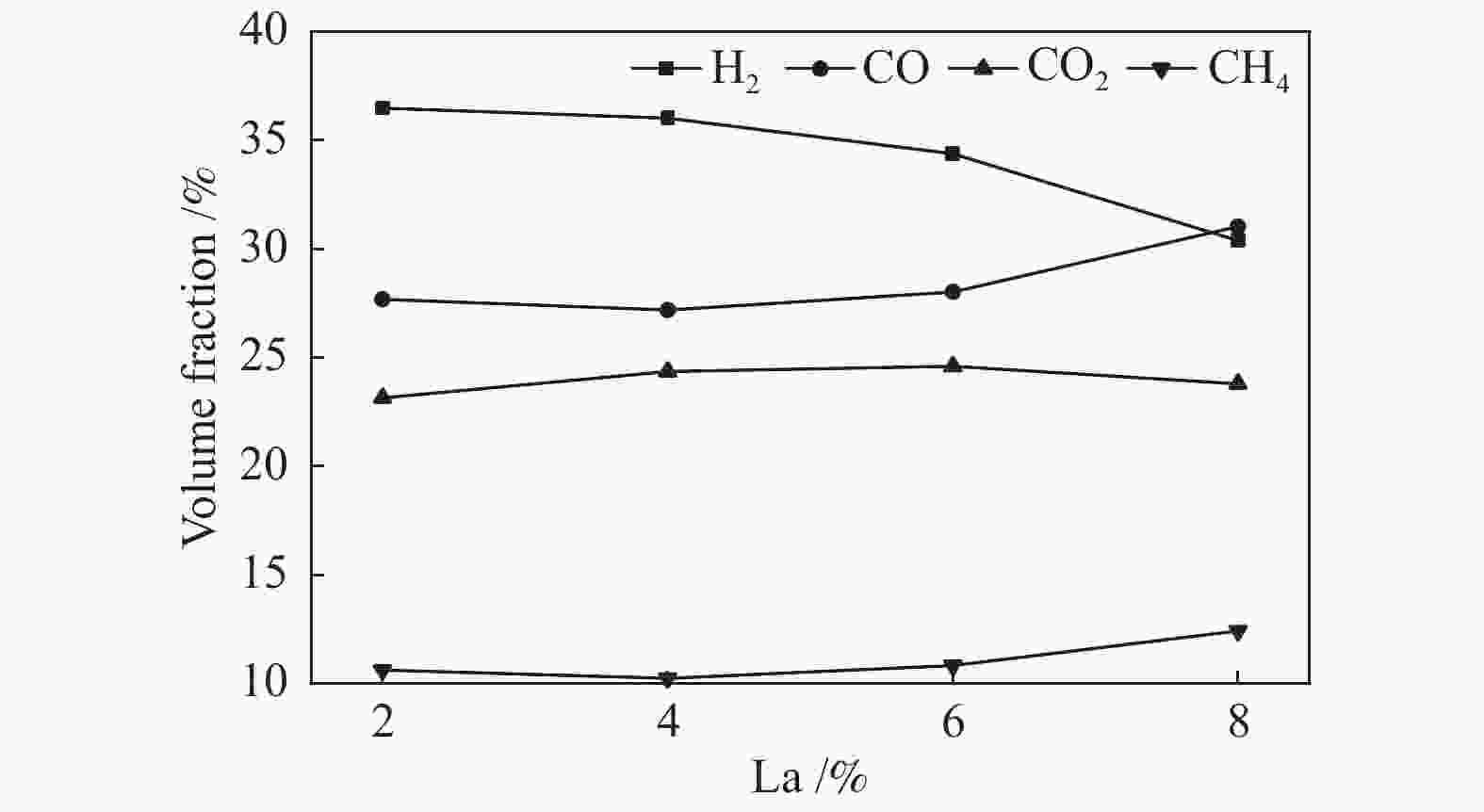

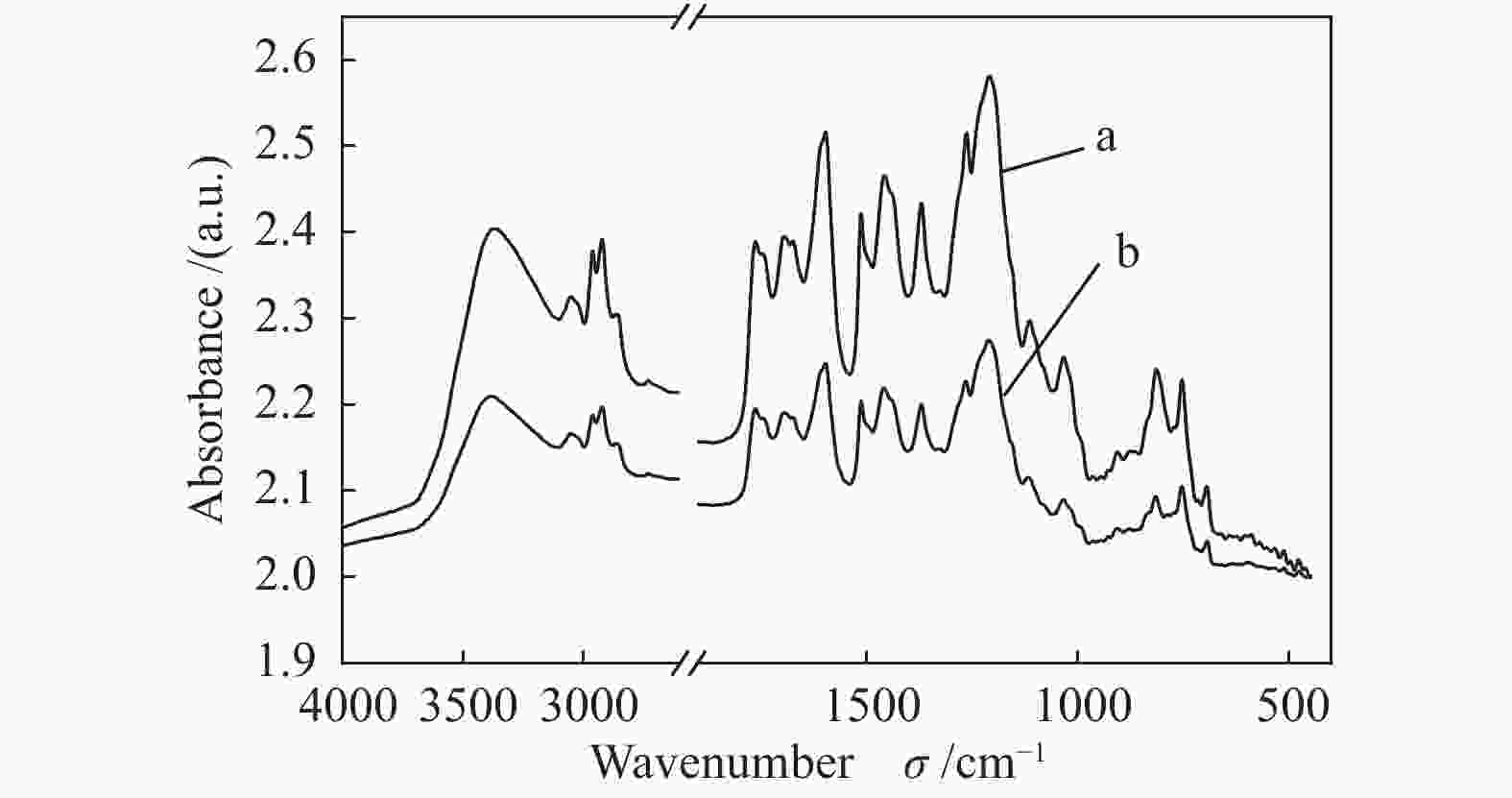

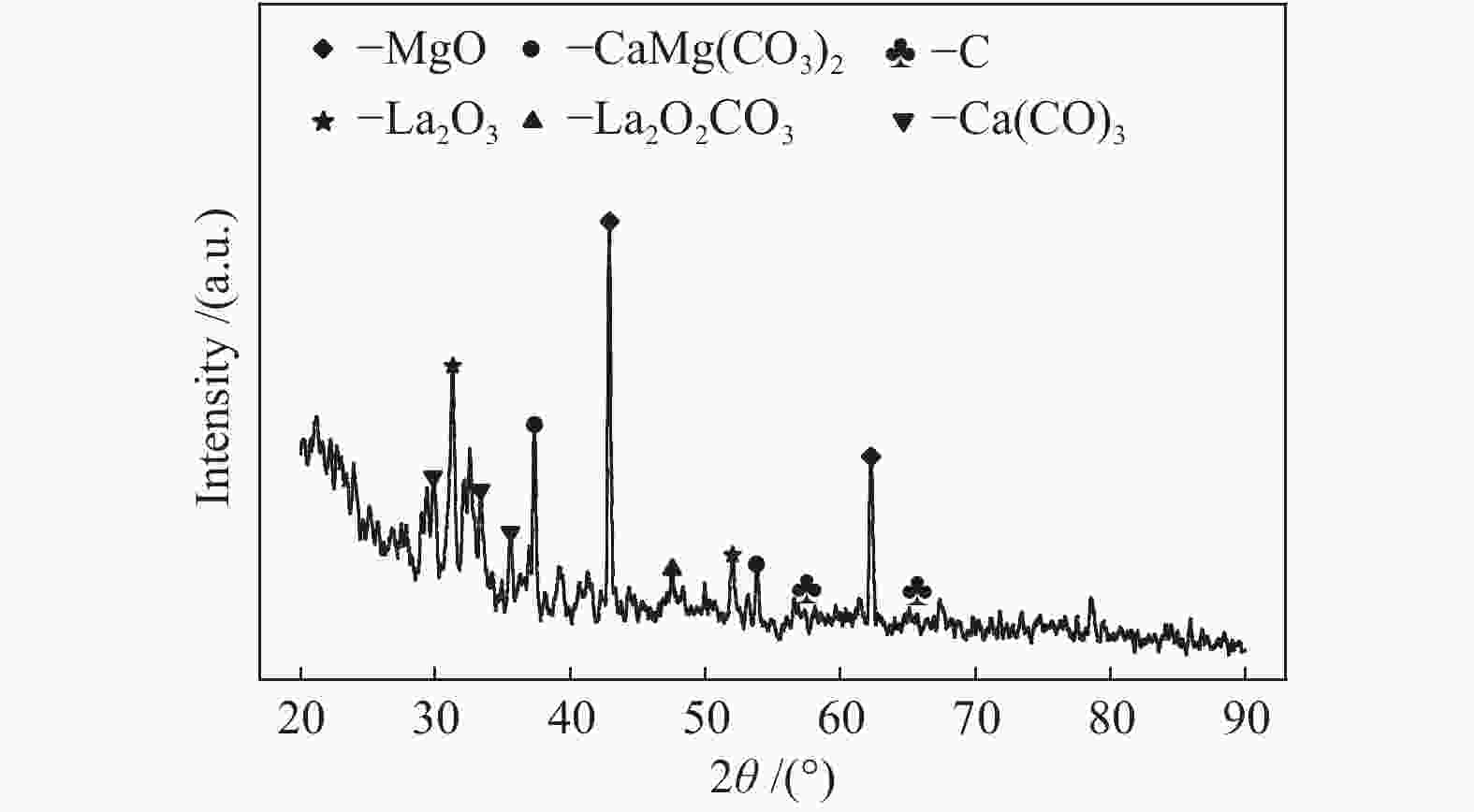

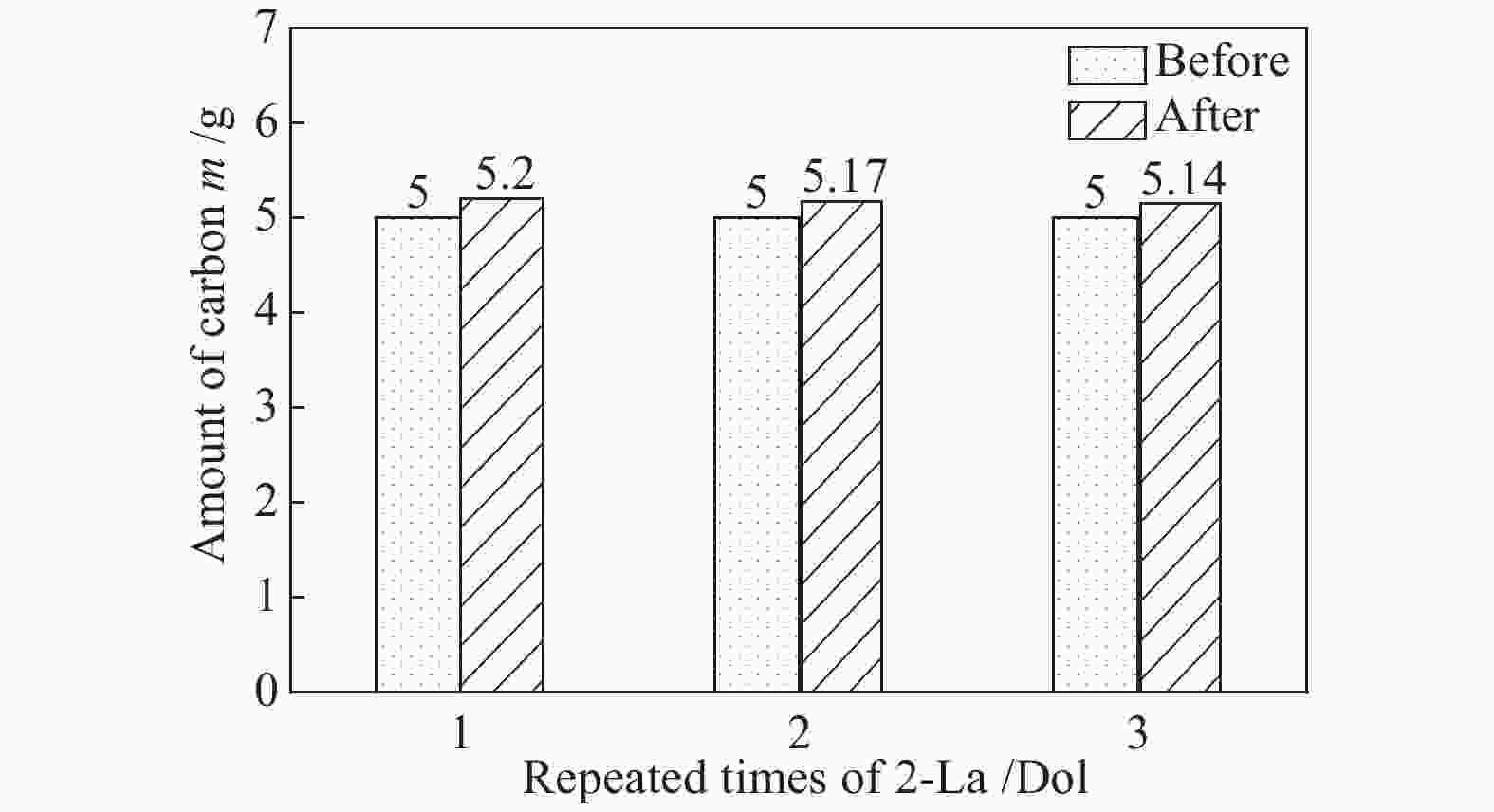

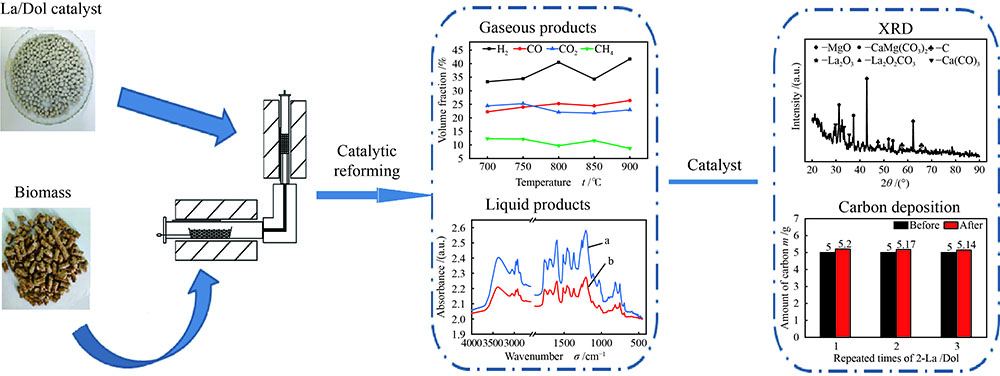

摘要: 为增强白云石的催化效果,以La(NO3)3为助剂,采用浸渍法对白云石进行改性研制La/Dol催化剂,通过BET、SEM、XRD对其进行了表征。以松木燃料棒为生物质原料,La/Dol为重整催化剂,采用自制的两段式生物质气化重整试验炉对比分析了不同气化温度、不同载La量催化剂对松木屑催化气化结果的影响。结果表明,少量的La(2%)可明显促进水煤气反应的正向进行,改善催化重整效果。2-La/Dol在催化剂蒸汽流量为10 g/min,重整温度为750 ℃ 的工况下,随着气化温度的升高,产H2量显著增加,H2体积分数的最高值从28.51%(0-La/Dol)增加到41.72%(2-La/Dol)。催化剂内的La2O3促进了焦油的二次裂解,使得液相产物焦油含量明显减少,官能团数目减少,分布在白云石表面的La2O3占据了活性位点,使得碳丝不宜集聚,抑制了积炭的生成,同时存在于催化剂中的碳酸盐(La2O2CO3)亦与表面的积炭发生反应,减缓催化剂积炭问题,提高了催化剂活性和使用寿命。Abstract: To enhance the catalytic effect of dolomite, La/Dol catalyst was prepared by impregnation modification of dolomite with La (NO3)3 as additive. The catalyst was characterized by BET, SEM and XRD. With pine rods as raw materials and La/Dol as reforming catalysts, the effects of gasification temperature and La amount of catalysts on the catalytic gasification of pine were compared and analyzed in a self-made two-stage biomass gasification reforming experimental furnace. The results show that a small amount of La (2%) can obviously promote the forward progress of water gas reaction and perfect the catalytic reforming effect. Under the working condition of steam flow rate of 10 g/min, 2-La/Dol catalyst and reforming temperature of 750℃, with the increase of gasification temperature, the amount of H2 increases significantly, and the highest volume fraction of H2 increases from 28.51% (0-La/Dol) to 41.72% (2-La/Dol). La2O3 in the catalyst promotes the secondary cracking of tar. As a result, the tar content of liquid phase product is obviously reduced, and the number of functional groups is also reduced. La2O3 on dolomite surface occupies active sites, so carbon filaments are not suitable for accumulation and carbon deposition is inhibited. Carbonate (La2O2CO3) in the catalyst can react with carbon to slow down the carbon deposition on the surface and improve the activity and service life of the catalyst.

-

Key words:

- biomass /

- La/dolomite catalyst /

- catalystic gasification /

- steam gasification

-

图 1 实验系统装置示意图

Figure 1 Schematic diagram of the experimental system

1: nitrogen bottle; 2: flow meter; 3: water storage tank; 4: peristaltic water pump; 5: steam generator; 6: gasification furnace; 7: crucible; 8: thermocouple; 9: temperature controller; 10: insulation cotton; 11: bracket; 12: catalytic furnace; 13: catalyst; 14: tar absorption system; 15: drying device; 16: air bag; 17: flame

表 1 松木棒元素分析及工业分析

Table 1 Element analysis and industrial analysis of pine rod particles

Elemental analysis w/% Industrial analysis w/% Cad Had Oad Nad Sad FCd Vd Ad 50.54 7.08 41.11 0.15 0.57 17.16 82.29 0.55 表 2 催化剂的孔结构

Table 2 Pore structure properties of catalysts

Sample Surface area A/(m2·g−1) Mean pore diameter d/nm Total pore volume v/(cm3·g−1)(× 10−2) Natural dolomite 1.4 22.4 0.764 Calcined dolomite 8.6 45.9 9.83 2-La/Dol 4.5 17.3 1.95 4-La/Dol 4.8 17.4 2.11 6-La/Dol 4.9 20.4 2.50 8-La/Dol 4.0 16.2 1.62 -

[1] TIAN Y, ZHOU X, LIN S H, JI X Y, BAI J S, XU M. Syngas production from air-steam gasification of biomass with natural catalysts[J]. Sci Total Environ,2018,645(15):518−523. [2] RANGEL M D C, QUERINO P S, BORGES S M S, MARCHETTI S G, RAMON A P. Hydrogen purification over lanthanum-doped iron oxides by WGSR[J]. Catal Today,2017,296:262−271. doi: 10.1016/j.cattod.2017.05.058 [3] 毕冬梅, 张凯真, 易维明, 柳善建, 李泊铮. 白云石基多孔陶瓷负载Al2O3催化生物质热解试验[J]. 农业机械学报,2019,50(10):315−322. doi: 10.6041/j.issn.1000-1298.2019.10.036BI Dong-mei, ZHANG Kai-zhen, YI Wei-ming, LIU Shan-jian, LI Po-zheng. Experiment on Al2O3 catalyzed biomass pyrolysis of dolomite-based porous ceramics[J]. Trans Chin Soc Agric Mach,2019,50(10):315−322. doi: 10.6041/j.issn.1000-1298.2019.10.036 [4] 张波. 钙基添加剂强化生物质热解气化产氢特性及作用机制研究[D]. 重庆: 重庆大学, 2016.Zhang Bo. Study on the characteristics and mechanism of hydrogen production from biomass pyrolysis and gasification enhanced by calcium-based additives[D]. Chongqing: Chongqing University, 2016. [5] 牛永红, 韩枫涛, 张雪峰, 陈义胜, 王丽, 许嘉. 膨润土/褐铁矿改性白云石催化剂改善松木蒸汽富氢气化性能[J]. 农业工程学报,2017,(7):220−226.NIU Yong-hong, HAN Feng-tao, ZHANG Xue-feng, CHEN Yi-sheng, WANG Li, XU Jia. Performance improvement of steam gasification of pine for hydrogen-rich gas with dolomite catalyst modified by bentonite/limonite[J]. Trans Chin Soc Agric Eng,2017,(7):220−226. [6] 孙宁. 木屑水蒸气催化气化制取富氢燃气研究[D]. 北京: 中国林业科学研究院, 2017.SUN Ning. Study on the catalytic vaporization of wood chips with steam to produce hydrogen-rich gas[D]. Beijing: Chinese Academy of Forestry, 2017. [7] LU H L, YANG X Z, GAO G J, WANG J, HAN Ch H, LIANG X Y, LI Ch F, LI Y Y, ZHANG W D, CHEN X T. Metal (Fe, Co, Ce or La) doped nickel catalyst supported on ZrO2 modified mesoporous clays for CO and CO2 methanation[J]. Fuel,2016,183:335−344. doi: 10.1016/j.fuel.2016.06.084 [8] MUSSO M, VEIGA S, ESTEFAN N, BUSSI J. Catalytic assessment of Fe-La-Zr trimetallic mixed oxides in the Fischer-Tropsch synthesis using bio-syngas[J]. Biomass Bioenergy,2019,127(AUG.):105278.1−105278.7. [9] POUR A N, SHAHRI S M K, BOZORGZADEH H R, ZAMANI Y, TAVASOLI A, MARVAST M A. Effect of Mg, La and Ca promoters on the structure and catalytic behavior of iron-based catalysts in Fischer–Tropsch synthesis[J]. Appl Catal A: Gen,2008,348(2):201−208. doi: 10.1016/j.apcata.2008.06.045 [10] VAN DER BERG F R, CRAJE M W J, KOOYMAN P J, VAN DER KRAAN A M, GEUS J W. Synthesis of highly dispersed zirconia-supported iron-based catalysts for Fischer-Tropsch synthesis[J]. Appl Catal A: Gen,2002,235(1):217−224. [11] LUCRÉDIO A F, ASSAF J M, ASSAF E M. Reforming of a model sulfur-free biogas on Ni catalysts supported on Mg(Al)O derived from hydrotalcite precursors: Effect of La and Rh addition[J]. Biomass Bioenergy,2014,60:8−17. doi: 10.1016/j.biombioe.2013.11.006 [12] LIU F, ZHAO L, WANG H, BAI X, LIU Y. Study on the preparation of Ni-La-Ce oxide catalyst for steam reforming of ethanol[J]. Int J Hydrog Energy,2014,39(20):10454−10466. doi: 10.1016/j.ijhydene.2014.05.036 [13] 张波, 张力, 杨仲卿, 闫云飞, 冉景煜, 蒲舸, 何江, 秦昌雷. NiO/CaO添加剂下生物质水蒸气气化特性[J]. 工程热物理学报,2016,37(9):1961−1968.ZHANG Bo, ZHANG Li, YANG Zhong-qing, YAN Yun-Fei, RAN Jing-Yu, PU Ge, HE Jiang, QIN Chang-Lei. Influence of NiO/CaO Additive on Biomass Steam Gasification[J]. J Eng Thermophys,2016,37(9):1961−1968. [14] BAHADI M B., GOO B C, PHAM T L M., SIANG T J, DANH H T, AINIRAZALI N, DAI V N. Hydrogen-rich syngas production from ethanol dry reforming on La-doped Ni/Al2O3 catalysts: effect of promoter loading[J]. Proc Eng,2016,148:654−661. doi: 10.1016/j.proeng.2016.06.531 [15] 林少华, 周婷婷, 李佳. 凹凸棒土颗粒吸附剂制备优化及对铅、铜吸附研究[J]. 科学技术与工程,2016,16(20):301−305. doi: 10.3969/j.issn.1671-1815.2016.20.055LIN Shao-hua, ZHOU Ting-ting, LI Jia. Preparation optimization of granular attapulgite adsorbent and its adsorption characteristics for Pb2+ and Cu2+ removal[J]. Sci Technol Eng,2016,16(20):301−305. doi: 10.3969/j.issn.1671-1815.2016.20.055 [16] 张丽奇. 基于新型复合催化剂的生物质催化热解试验研究[D]. 包头: 内蒙古科技大学, 2019.ZHANG Li-qi. Experimental study on biomass catalytic pyrolysis based on novel composite catalyst[D]. Baotou: Inner Mongolia University of Science and Technology, 2019. [17] 牛永红, 田一鸣. Ni-Zn/玄武岩催化剂生物质催化气化试验[J/OL]. 农业机械学报, 2019, 50(6): 331-337.NIU Yong-hong, TIAN Yi-ming. experimental catalytic gasification of Ni-Zn/ basalt catalysts[J/OL]. Trans Chin Soc Agric Mach, 2019, 50(6): 331-337. [18] 甄开吉. 催化作用基础[M]. 3版. 北京. 科学出版社, 2005: 166.ZHEN Kai-ji. Basis of Catalysis[M]. 3rd ed. Beijing. Science Press, 2005: 166. [19] RACHED J A, CESARIO M R., ESTEPHANE J, TIDAHY H L, GENNEQUIN C, SAMER A S, ANTOINE A A, EDMOND A. Effects of cerium and lanthanum on Ni-based catalysts for CO2, reforming of toluene[J]. J Environ Chem Eng,2018,6(4):4743−4754. doi: 10.1016/j.jece.2018.06.054 [20] 翁诗甫. 傅里叶变换红外光谱分析. [M]. 2版. 化学工业出版社, 2010: 256.WENG Shi-fu. Fourier Transform Infrared Spectroscopy Analysis. [M]. 2nd Ed. Chemical Industry Press, 2010: 256 [21] 张玉黎, 肖睿, 何光莹. Fe/La/SBA-15对生物质气化影响研究[J]. 工程热物理学报,2013,34(1):173−176.ZHANG Yu-li, XIAO Rui, HE Guang-ying. Study on the influence of Fe/La/SBA-15 on biomass gasification[J]. J Eng Thermophys,2013,34(1):173−176. [22] 李小华, 王嘉骏, 樊永胜, 刘莎, 蔡忆昔. Fe、Co、Cu改性HZSM-5催化热解制备生物油实验[J]. 农业机械学报,2017,48(2):305−313. doi: 10.6041/j.issn.1000-1298.2017.02.041LI Xiao-hua, WANG Jia-jun, FAN Yong-sheng, LIU Sha, CAI Yi-xi. Experiment of preparing bio-oil by catalytic pyrolysis of Fe, Co, Cu modified HZSM-5[J]. Trans Chin Soc Agric Mach,2017,48(2):305−313. doi: 10.6041/j.issn.1000-1298.2017.02.041 -

下载:

下载: