Performance of Cu-Mn-Zn/ZrO2 catalysts for methanol synthesis from CO2 hydrogenation: The effect of Zn content

-

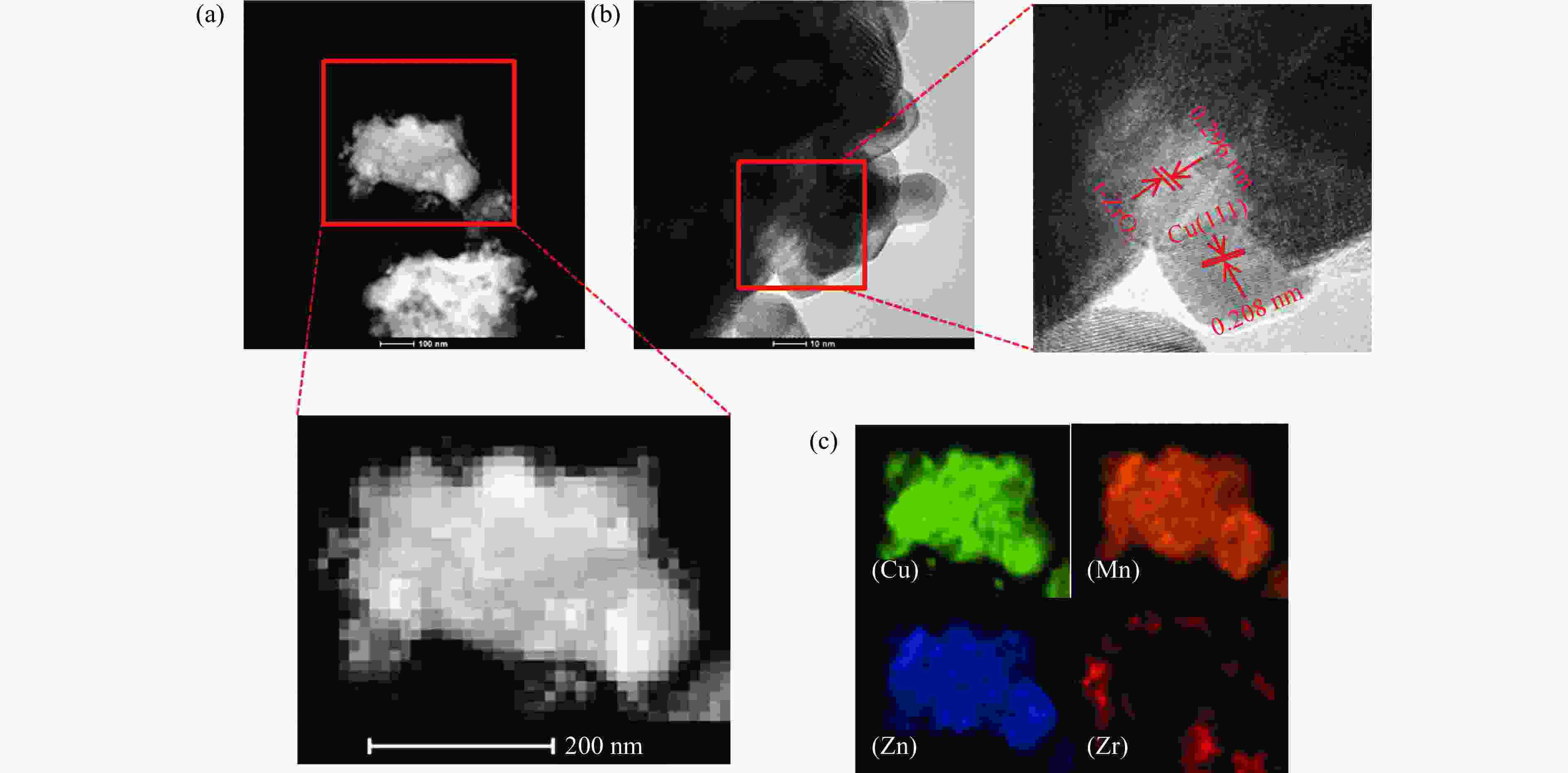

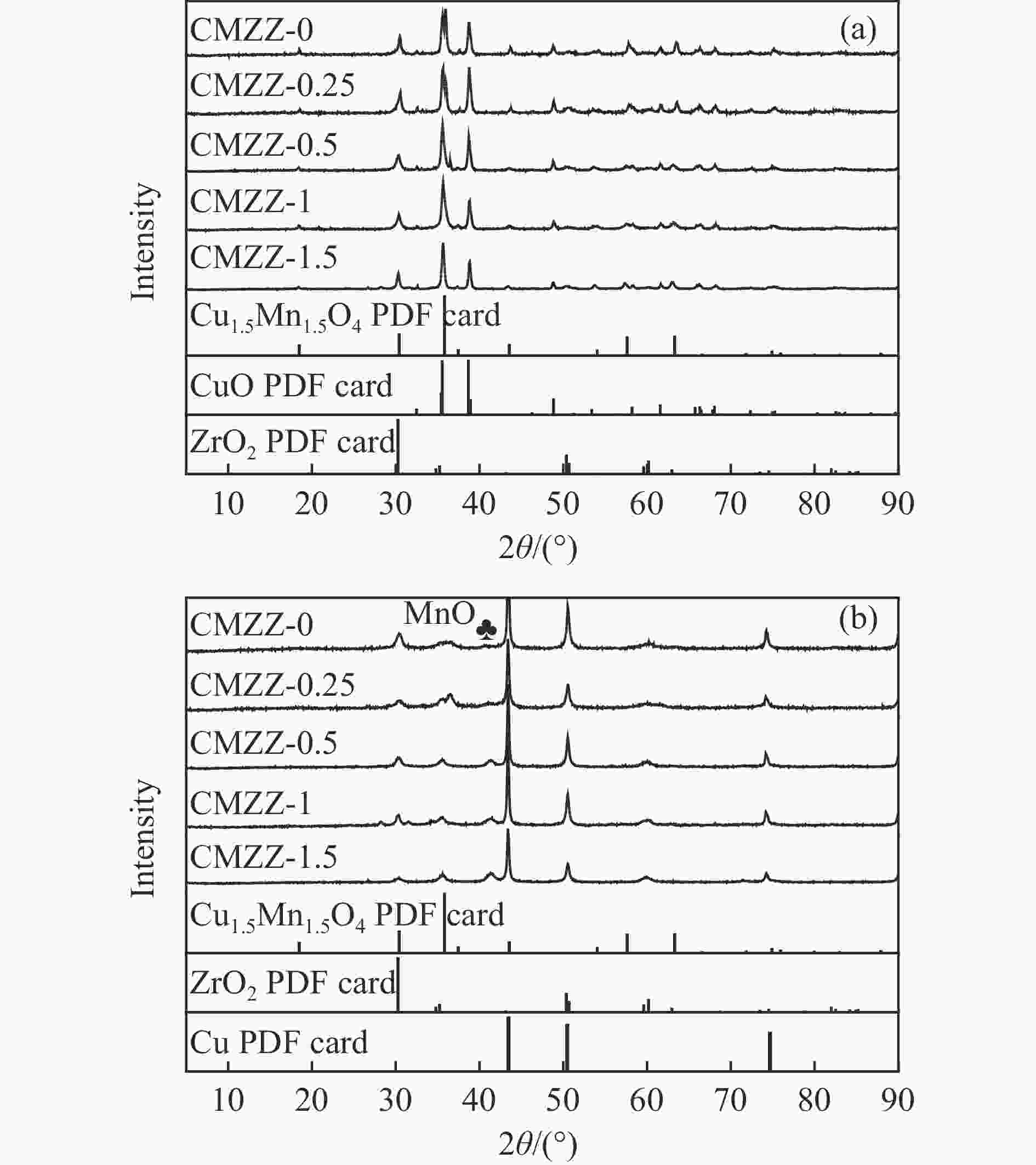

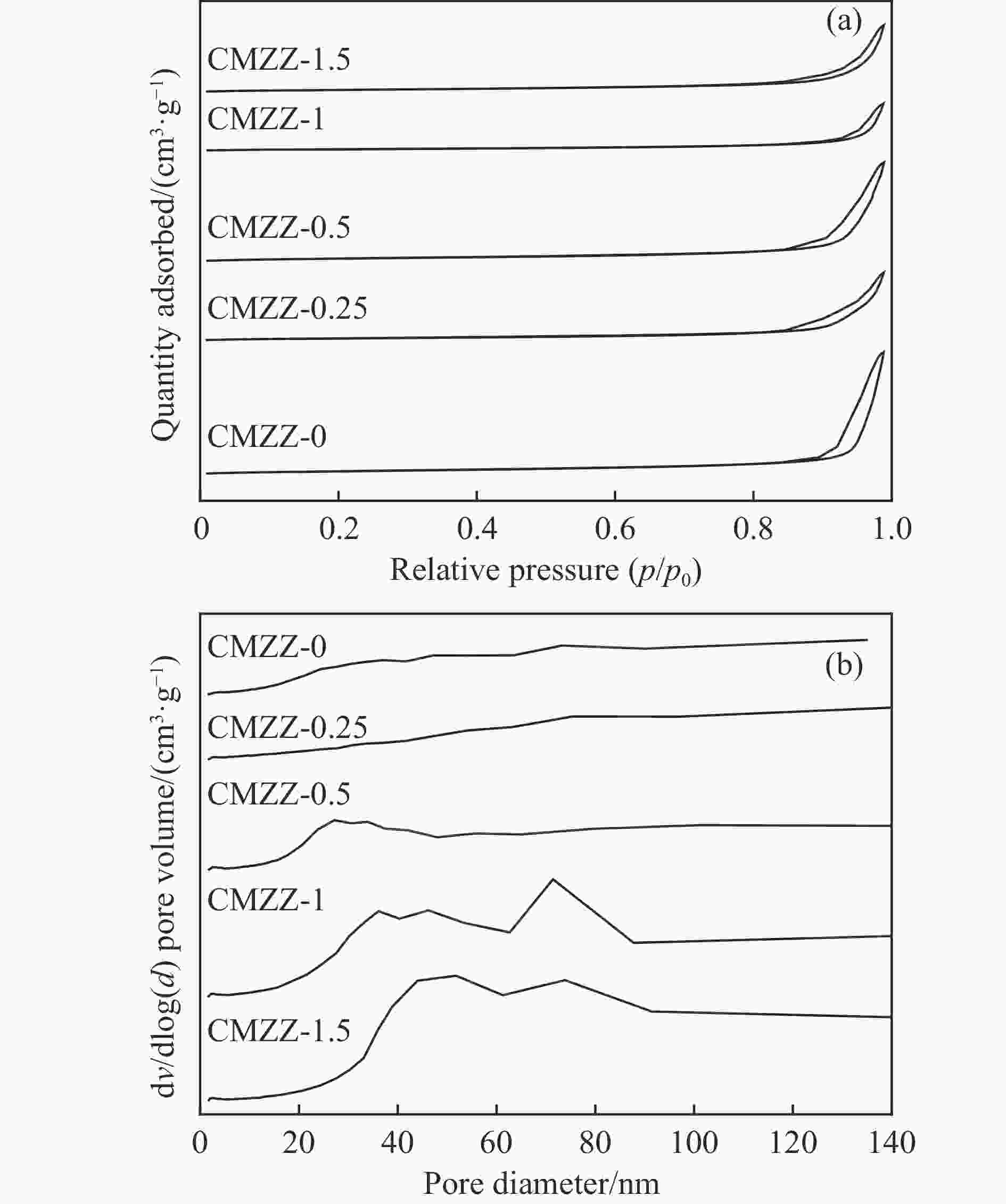

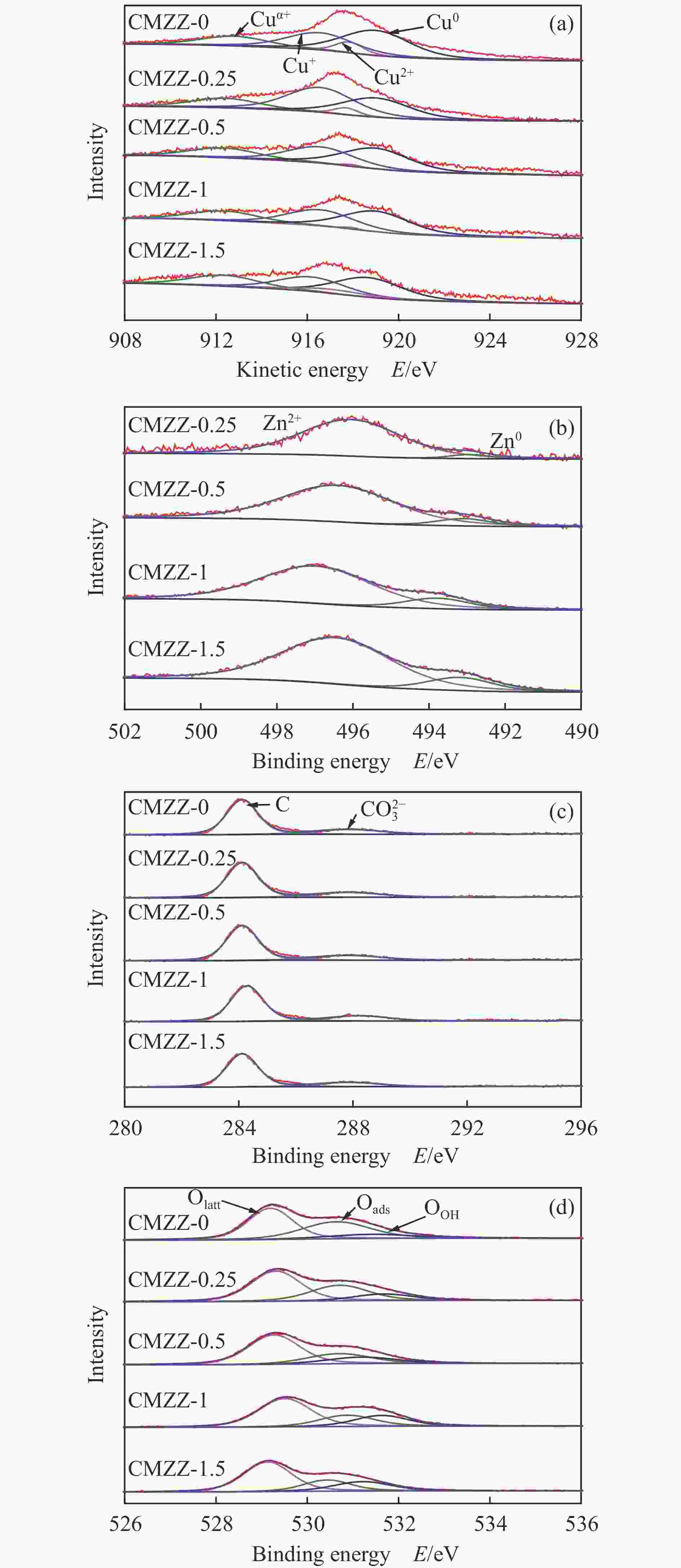

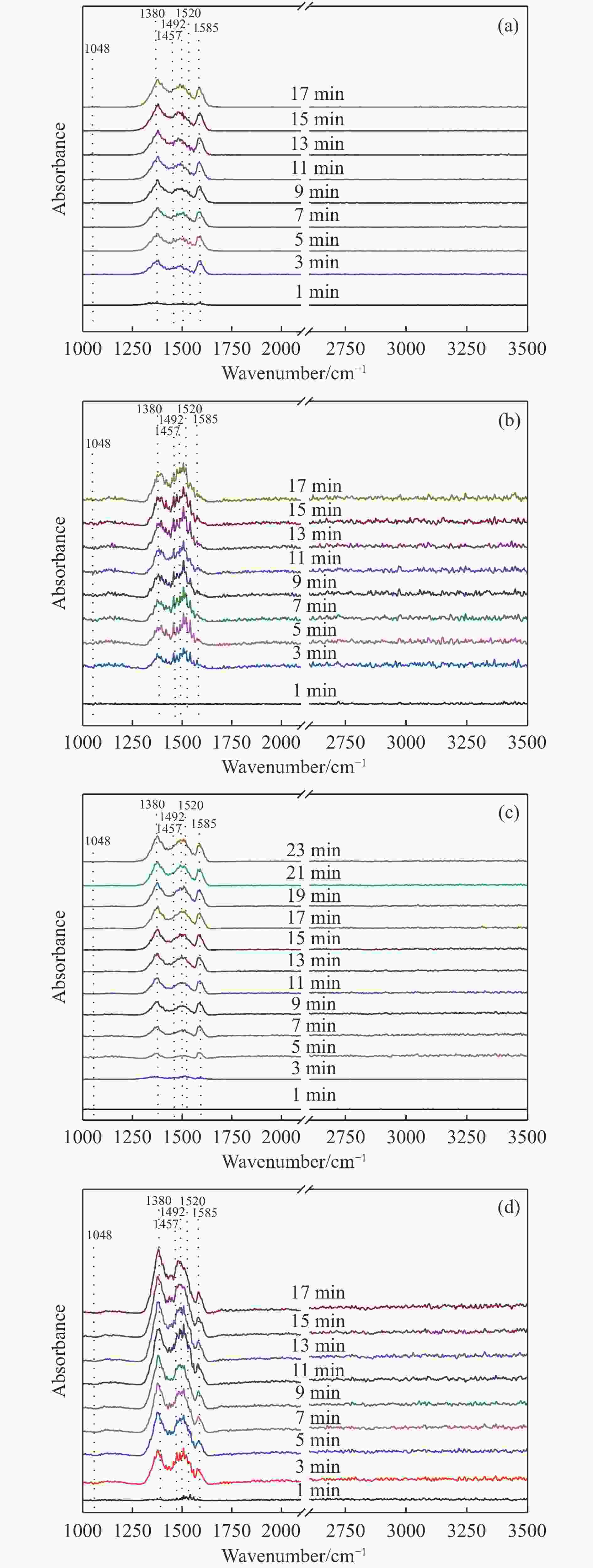

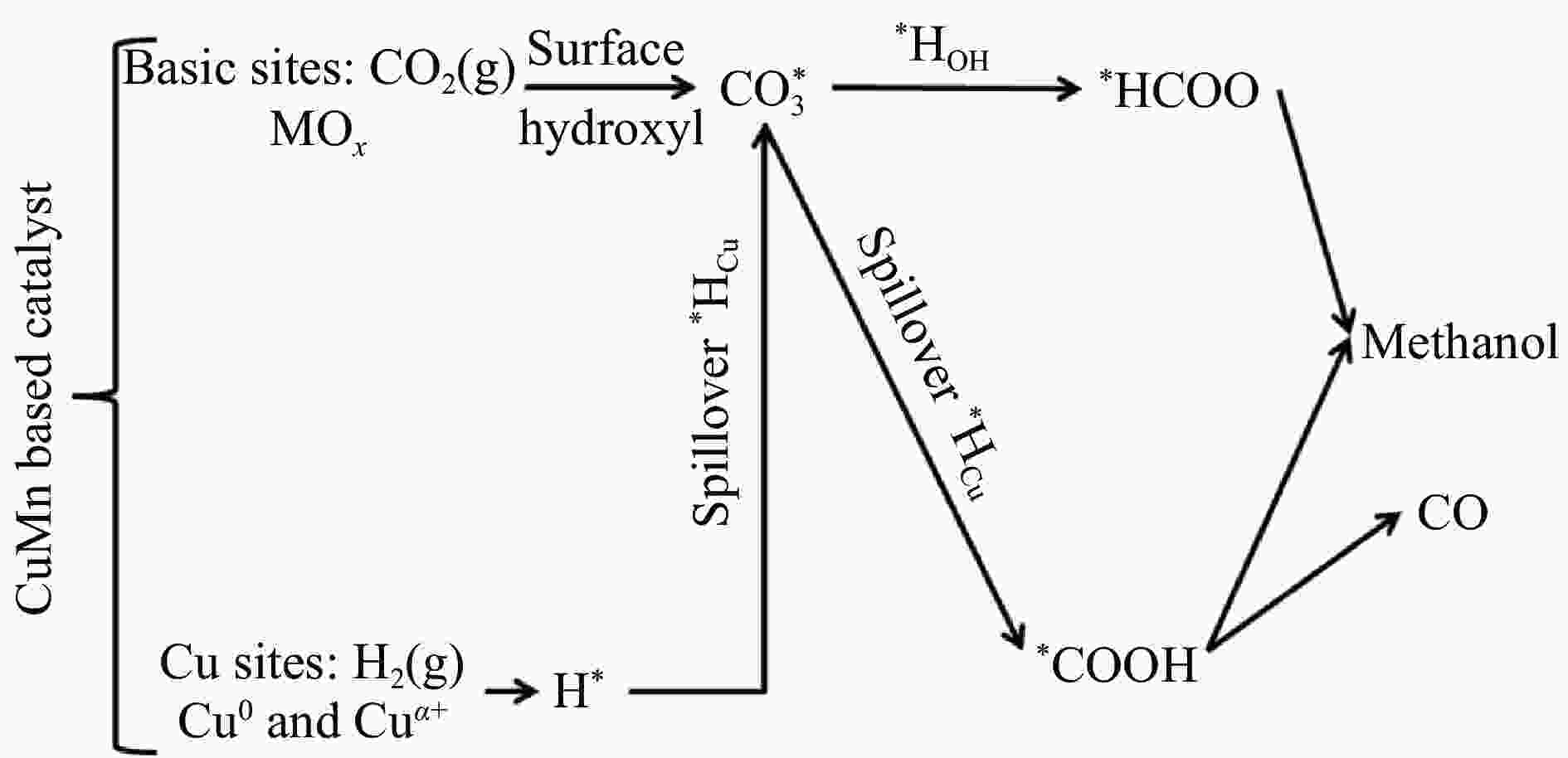

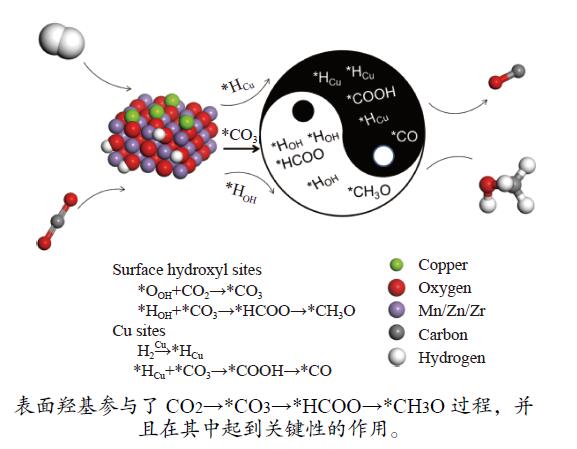

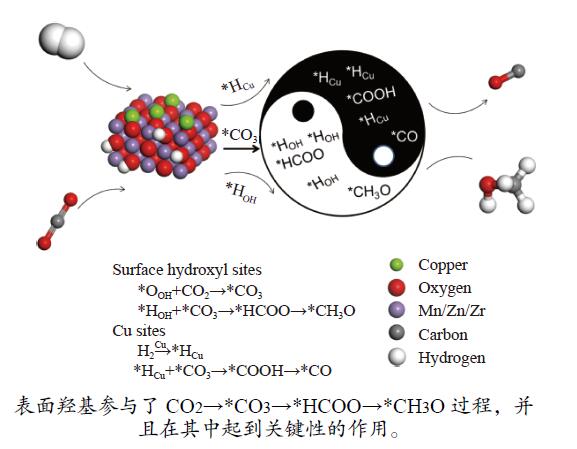

摘要: 通过溶胶-凝胶方法制备了一系列不同Zn含量的Cu-Mn-Zn/ZrO2催化剂,并通过XRD、BET、TPR、N2O吸附、XPS、TPD和 in-situ DRIFTS进行了表征。结果表明,随着Zn含量增加,催化剂上CO2加氢反应的活性增加。在所有样品中,Cu3MnZn0.5Zr0.5(CMZZ-0.5)在250 ℃和5 MPa条件下具有最高的CO2转化率(6.5%)和甲醇选择性(73.7%)。表征结果表明,Zn进入Cu1.5Mn1.5O4尖晶石结构,形成ZnOx,导致催化剂表面羟基含量的增加,同时增加了Cu0和Cuα+的含量,改善了H2和CO2的活化能力。此外,通过原位漫反射红外光谱研究了 CO2转化为甲醇的途径。Abstract: A series of Cu-Mn-Zn/ZrO2 catalysts with different Zn contents were prepared by sol-gel method and characterized by XRD, BET, TPR, N2O-adsorption, XPS, TPD and in-situ DRIFTS. It was found that by increasing a certain amount of Zn, the catalytic activity for CO2 hydrogenation increased. Among all samples, Cu3MnZn0.5Zr0.5 (CMZZ-0.5) possessed the best CO2 conversion (6.5%) and methanol selectivity (73.7%) at 250 °C and 5 MPa. Characterization results showed that Zn entered the Cu1.5Mn1.5O4 spinel structure, forming ZnOx and thus more surface OH groups. This increased the content of Cu0 and Cuα+, which improved the activation of H2 and CO2. The pathway of CO2 to methanol was also clarified through in-situ DRIFTS.

-

Key words:

- CO2 hydrogenation /

- methanol /

- copper-based catalyst /

- surface hydroxyl

-

Table 1 Texture parameters of the CMZZ-X catalysts

Catalyst ABET*

/(m2·g−1)Pore volume*

/(cm3·g−1)Pore size*/nm DCu**

/%ACu**

/(m2·g−1)dCu**

/nmCMZZ-0 10.6 0.085 32.7 5.5 3.7 18.3 CMZZ-0.25 9.9 0.048 24.8 7.9 5.4 12.6 CMZZ-0.5 8.1 0.069 28.6 10.4 7.0 9.6 CMZZ-1 7.7 0.033 26.7 7.8 5.3 12.8 CMZZ-1.5 5.1 0.047 27.2 6.3 4.3 15.9 *: The data were obtained by N2 adsorption-desorption experiment; **: The data were calculated by N2O adsorption-desorption experiment. Table 2 Bulk/surface elemental percentages (% molar ratio) of the CMZZ-X catalysts

Catalyst Cu Mn Zn Zr bulk* surface** bulk surface bulk surface bulk surface CMZZ-0 77.9 45.3 18.6 35.8 0.1 1.9 3.4 17.0 CMZZ-0.25 68.7 31.9 25.2 48.9 3.5 6.4 2.6 12.8 CMZZ-0.5 73.6 33.9 14.6 32.1 9.5 12.6 2.3 21.4 CMZZ-1 63.5 33.3 18.9 38.3 13.3 16.7 4.3 11.7 CMZZ-1.5 63.0 26.4 14.6 28.3 18.1 20.8 4.3 24.5 *: calculated from ICP; **: calculated from XPS. Table 3 The relative surface concentration of Cu of the catalysts

Catalyst Molar ratio/% Cu0/Cu Cuα+/Cu Cu+/Cu Cu2+/Cu CMZZ-0 34.5 16.8 34.2 14.5 CMZZ-0.25 38.2 20.3 32.3 9.2 CMZZ-0.5 40.8 22.3 28.0 8.9 CMZZ-1 40.1 22.7 28.3 8.9 CMZZ-1.5 38.8 21.3 29.5 10.4 Table 4 The relative surface concentration of Zn of the catalysts

Catalyst Molar ratio/% Zn0/Zn Zn2+/Zn CMZZ-0 − − CMZZ-0.25 9.1 90.9 CMZZ-0.5 16.7 83.3 CMZZ-1 19.9 80.1 CMZZ-1.5 20.9 79.1 Table 5 Relative surface concentration of C of the catalysts

Catalyst Molar ratio/% ${\rm{CO}}_3^{2-} $/(${\rm{CO}}_3^{2-} $+C) C/(${\rm{CO}}_3^{2-} $+C) CMZZ-0 12.3 87.7 CMZZ-0.25 11.9 88.1 CMZZ-0.5 12.3 87.7 CMZZ-1 12.1 87.9 CMZZ-1.5 12.4 87.6 Table 6 Relative surface concentration of O of the catalysts

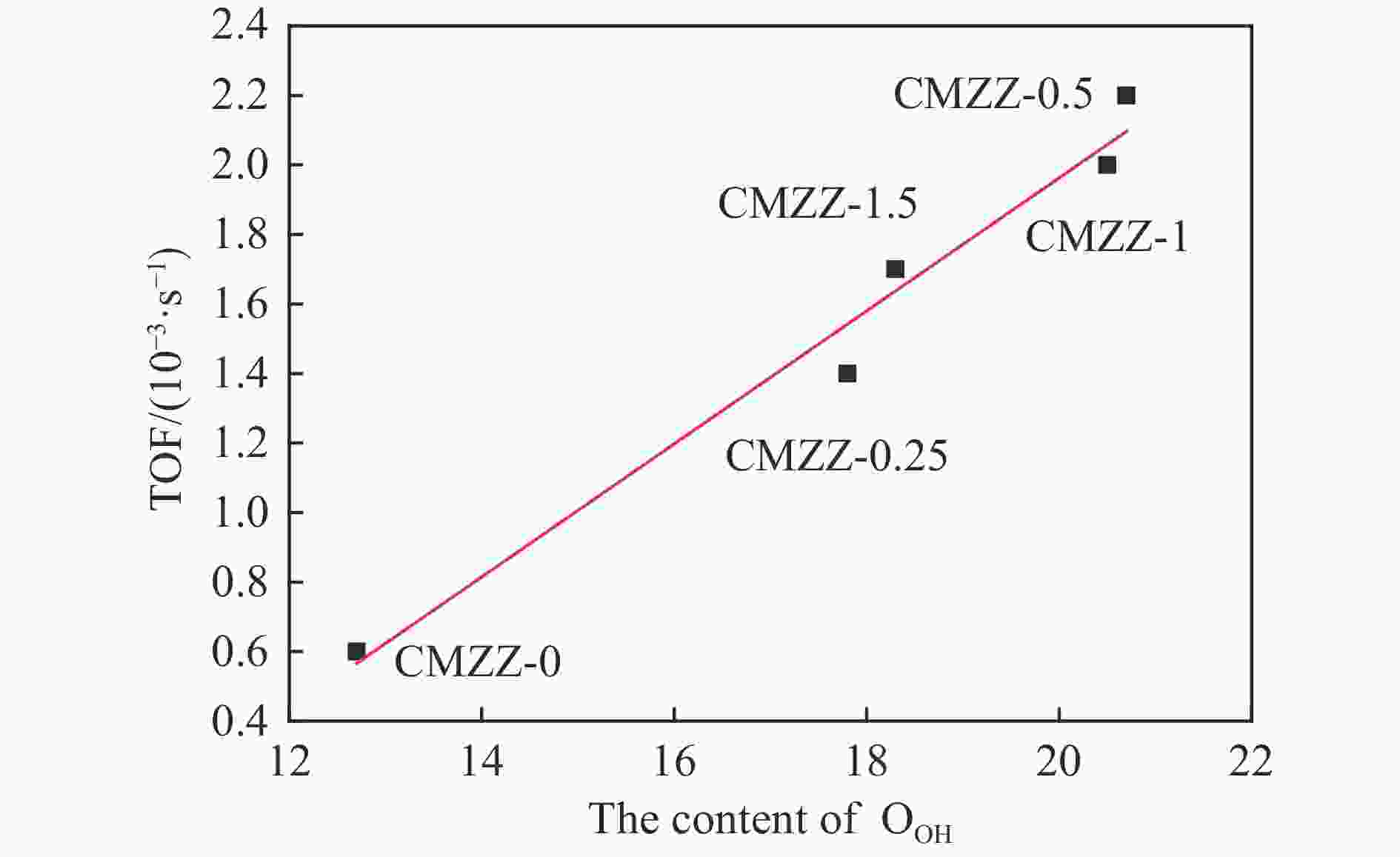

Catalyst Molar ratio/% Olatt/O Oads/O OOH/O CMZZ-0 57.8 29.5 12.7 CMZZ-0.25 57.8 24.4 17.8 CMZZ-0.5 56.7 22.6 20.7 CMZZ-1 56.8 22.7 20.5 CMZZ-1.5 59.2 22.5 18.3 Table 7 Center of reduction peaks with corresponding contributions derived from H2-TPR profiles of CMZZ-X catalysts

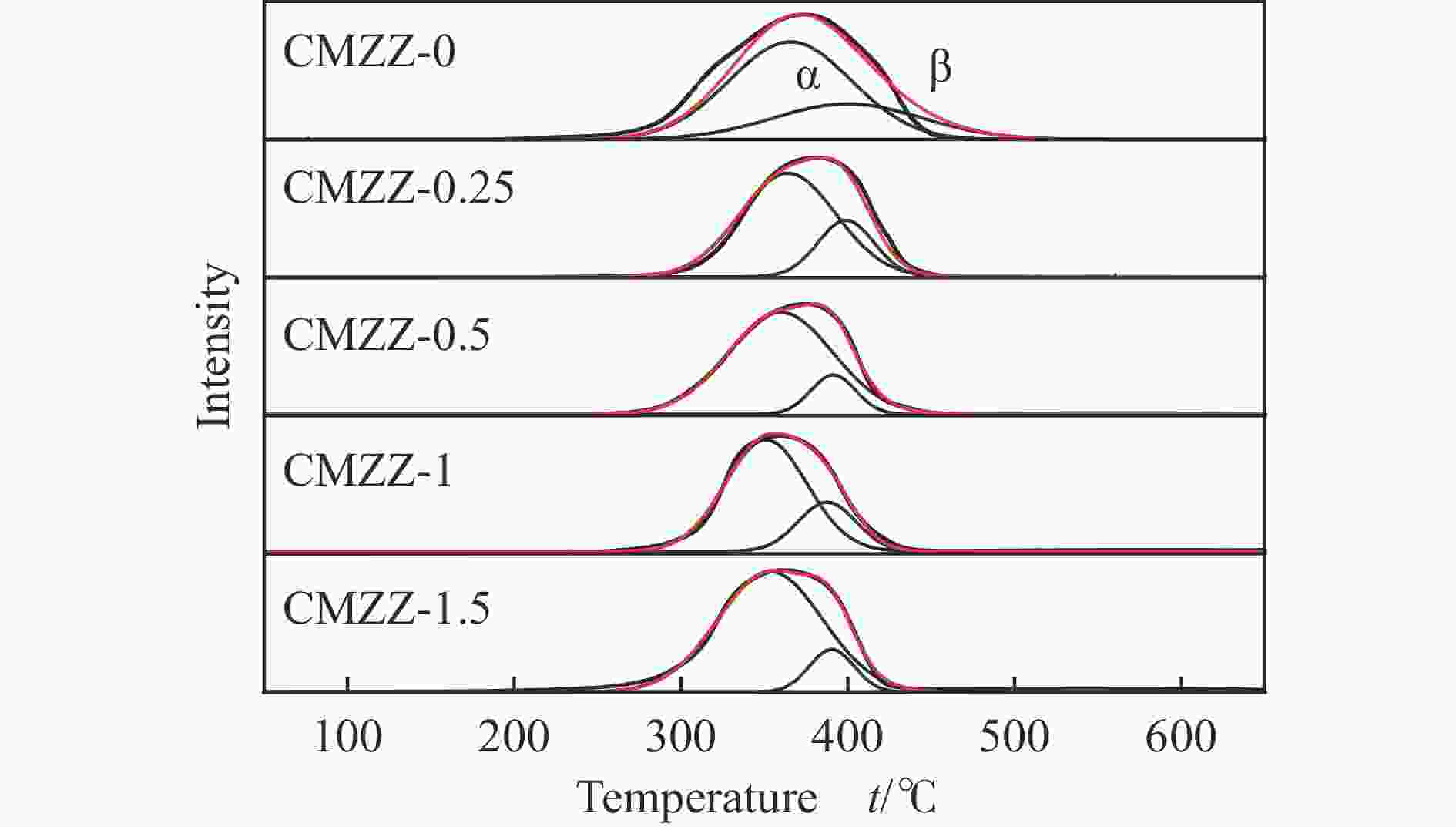

Catalyst Location of reduction peaks/°C (proportion of each peak/%) α β CMZZ-0 365.5(69.3) 400.0(30.7) CMZZ-0.25 364.0(75.9) 391.3(24.1) CMZZ-0.5 359.7(85.8) 391.3(14.2) CMZZ-1 351.0(76.4) 387.6(23.6) CMZZ-1.5 353.3(86.8) 390.3(13.2) Table 8 Basic sites distribution of the CMZZ-X catalysts

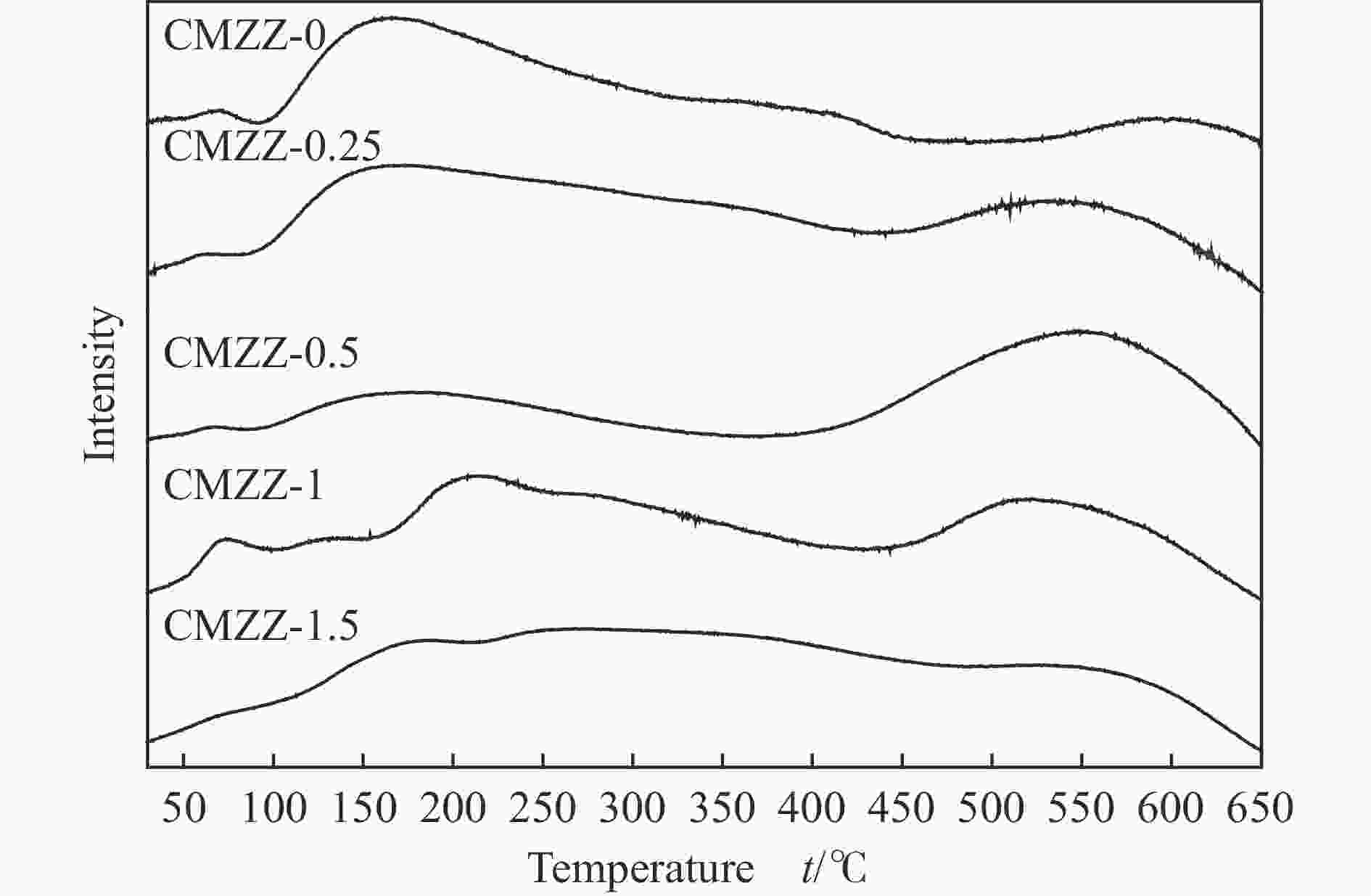

Catalyst The ratio of basic sites/% Number of total basic sites

/(μmol·g−1)α β γ CMZZ-0 70.9 21.1 8.0 240.7 CMZZ-0.25 53.6 17.5 28.9 228.5 CMZZ-0.5 25.7 12.3 62.0 239.1 CMZZ-1 22.9 57.2 19.9 237.8 CMZZ-1.5 20.5 62.2 17.3 248.9 Table 9 Catalytic performance of the catalysts

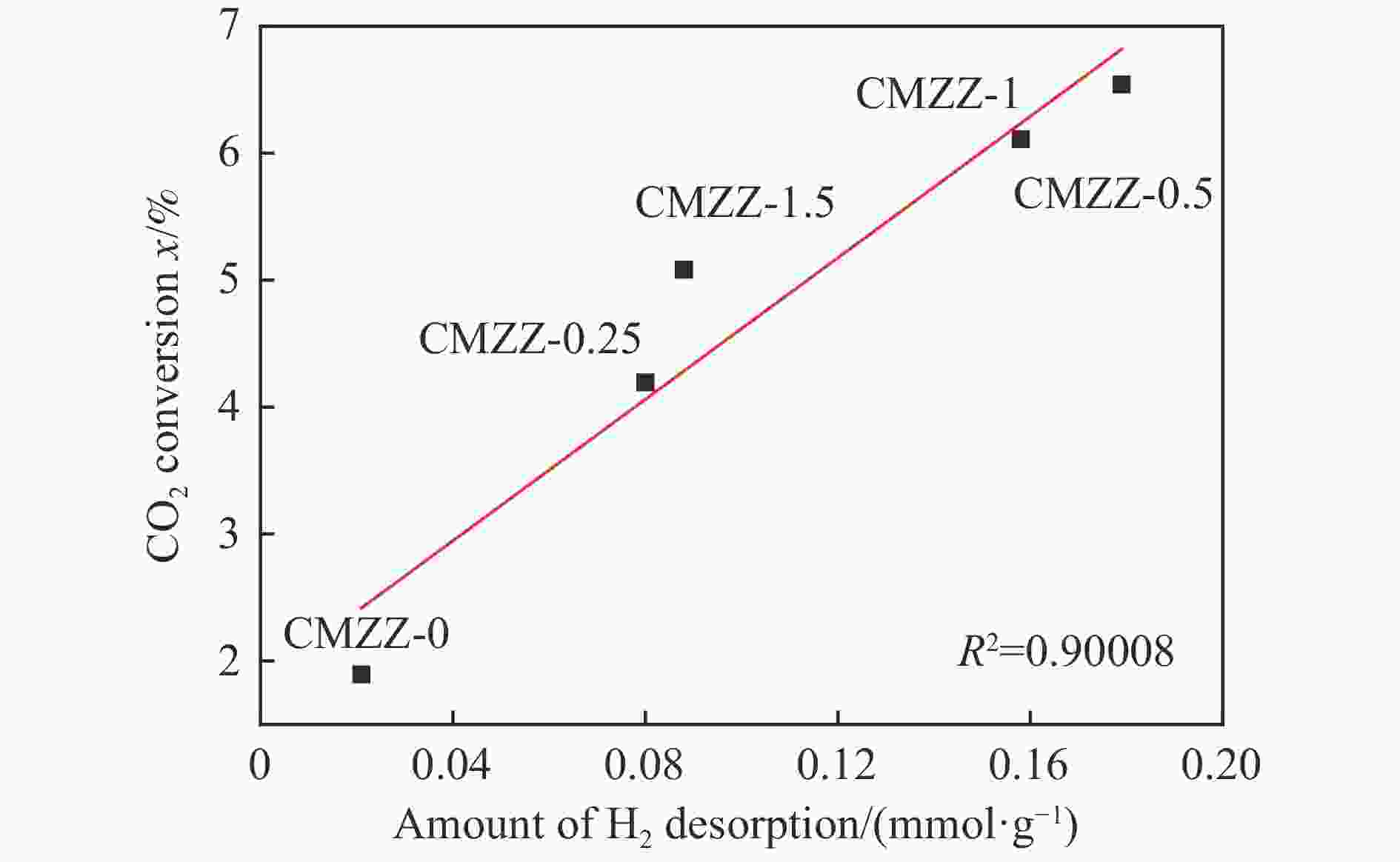

Catalyst CO2 conv.

/%CH3OH sele.

/%STY

/(mg·mL·h−1)TOF

/(10−3s−1)CMZZ-0 1.9 54.5 11.5 0.6 CMZZ-0.25 4.2 68.5 35.5 1.4 CMZZ-0.5 6.5 73.7 63.6 2.2 CMZZ-1 6.1 67.4 49.8 2.0 CMZZ-1.5 5.1 62.9 41.1 1.7 Reaction conditions: 250 °C, 5 MPa, H2/CO2=3∶1, 4000 mL/(mL·h). -

[1] ATSBHA T A, YOON T, SEONGHO P, et al. A review on the catalytic conversion of CO2 using H2 for synthesis of CO, methanol and hydrocarbons[J]. J CO2 Util,2021,44:101413. doi: 10.1016/j.jcou.2020.101413 [2] SUN J, LIU F, SALAHUDDIN U, et al. Optimization and understanding of ZnO nanoarray supported Cu-ZnO-Al2O3 catalyst for enhanced CO2-methanol conversion at low temperature and pressure[J]. Chem Eng J,2023,455:140559. doi: 10.1016/j.cej.2022.140559 [3] MARCOS F C F, ALVIM R S, LIN L, et al. The role of copper crystallization and segregation toward enhanced methanol synthesis via CO2 hydrogenation over CuZrO2 catalysts: A combined experimental and computational study[J]. Chem Eng J,2023,452:139519. doi: 10.1016/j.cej.2022.139519 [4] GUO T, GUO Q, LI S, et al. Effect of surface basicity over the supported Cu-ZnO catalysts on hydrogenation of CO2 to methanol[J]. J Catal,2022,407:312−321. doi: 10.1016/j.jcat.2022.01.035 [5] MALIK A S, ZAMAN S F, AL-ZAHRANI A A, et al. Selective hydrogenation of CO2 to CH3OH and in-depth DRIFT analysis for PdZn/ZrO2 and CaPdZn/ZrO2 catalysts[J]. Catal Today,2020,357:573−582. doi: 10.1016/j.cattod.2019.05.040 [6] PARK K, HAKEEM D A, CHA J S. Synthesis and structural properties of thermoelectric Ca3_xAgxCo4O9+delta powders[J]. Dalton Trans,2016,45(16):6990−6997. doi: 10.1039/C5DT04959H [7] DUMA Z G, MOMA J, LANGMI H W, et al. Towards high CO2 conversions using Cu/Zn catalysts supported on aluminum fumarate metal-organic framework for methanol synthesis[J]. Catalysts,2022,12(10):1104. doi: 10.3390/catal12101104 [8] HAN X, LI M, CHANG X, et al. Hollow structured Cu@ZrO2 derived from Zr-MOF for selective hydrogenation of CO2 to methanol[J]. J Energy Chem,2022,71:277−287. doi: 10.1016/j.jechem.2022.03.034 [9] SINGH R, PANDEY V, PANT K K. Promotional role of oxygen vacancy defects and Cu-Ce interfacial sites on the activity of Cu/CeO2 catalyst for CO2 hydrogenation to methanol[J]. ChemCatChem,2022,14(24):e202201053. doi: 10.1002/cctc.202201053 [10] XU Y, GAO Z, PENG L, et al. A highly efficient Cu/ZnOx/ZrO2 catalyst for selective CO2 hydrogenation to methanol[J]. J Catal,2022,414:236−244. doi: 10.1016/j.jcat.2022.09.011 [11] MURTHY P S, LIANG W, JIANG Y, et al. Cu-Based nanocatalysts for CO2 hydrogenation to methanol[J]. Energy Fuels,2021,35(10):8558−8584. [12] WANG Y, WANG G, VAN DER WAL L I, et al. Visualizing element migration over bifunctional metal-zeolite Catalysts and its impact on catalysis[J]. Angew Chem Int Ed,2021,60:17735−17743. doi: 10.1002/anie.202107264 [13] LI J W, DOU L G, GAO Y, et al. Revealing the active sites of the structured Ni-based catalysts for one-step CO2/CH4 conversion into oxygenates by plasma-catalysis[J]. J CO2 Util,2021,52:101675. doi: 10.1016/j.jcou.2021.101675 [14] NEZAM I, ZHOU W, GUSMAO G S, et al. Direct aromatization of CO2 via combined CO2 hydrogenation and zeolite-based acid catalysis[J]. J CO2 Util,2021,45:101405. doi: 10.1016/j.jcou.2020.101405 [15] HADDED A, MASSOUDI J, DHAHRI E, et al. Structural, optical and dielectric properties of Cu1.5Mn1.5O4 spinel nanoparticles[J]. RSC Adv,2020,10(69):42542−42556. doi: 10.1039/D0RA08405K [16] LI F, ZHANG R K, LI Q M, et al. Preparation of ultrafine Cu1.5Mn1.5O4 spinel nanoparticles and its application in p-nitrophenol reduction[J]. Res Chem Intermed,2017,43(11):6505−6519. doi: 10.1007/s11164-017-3001-9 [17] WANG J J, TIAN P, LI K X, et al. The excellent performance of nest-like oxygen-deficient Cu1.5Mn1.5O4 applied in activated carbon air-cathode microbial fuel cell[J]. Bioresour Technol,2016,222:107−113. doi: 10.1016/j.biortech.2016.09.126 [18] NAKAMURA J, NAKAMURA I, UCHIJIMA T, et al. A surface science investigation of methanol synthesis over a Zn-deposited polycrystalline Cu surface[J]. J Catal,1996,160(1):65−75. doi: 10.1006/jcat.1996.0124 [19] FUJITANI T, NAKAMURA I, UCHIJIMA T, et al. The kinetics and mechanism of methanol synthesis by hydrogenation of CO2 over a Zn-deposited Cu(111) surface[J]. Surf Sci,1997,383(2):285−298. [20] HU J, LI Y Y, ZHEN Y P, et al. In situ FTIR and ex situ XPS/HS-LEIS study of supported Cu/Al2O3 and Cu/ZnO catalysts for CO2 hydrogenation[J]. Chin J Catal,2021,42(3):367−375. doi: 10.1016/S1872-2067(20)63672-5 [21] WANG S W, YANG J H, WANG S Q, et al. Effect of Cu and Zn on the performance of Cu-Mn-Zn/ZrO2 catalysts for CO2 hydrogenation to methanol[J]. Fuel Process Technol,2023,247:107789. doi: 10.1016/j.fuproc.2023.107789 [22] WITOON T, CHALORNGTHAM J, DUMRONGBUNDITKUL P, et al. CO2 hydrogenation to methanol over Cu/ZrO2 catalysts: Effects of zirconia phases[J]. Chem Eng J,2016,293:327−336. doi: 10.1016/j.cej.2016.02.069 [23] L'HOSPITAL V, ANGELO L, ZIMMERMANN Y, et al. Influence of the Zn/Zr ratio in the support of a copper-based catalyst for the synthesis of methanol from CO2[J]. Catal Today,2021,369:95−104. doi: 10.1016/j.cattod.2020.05.018 [24] ZHAN H J, LI F, XIN C L, et al. Performance of the La-Mn-Zn-Cu-O based perovskite precursors for methanol synthesis from CO2 hydrogenation[J]. Catal Lett,2015,145(5):1177−1185. doi: 10.1007/s10562-015-1513-8 [25] DONG X S, LI F, ZHAO N, et al. CO2 hydrogenation to methanol over Cu/ZnO/ZrO2 catalysts prepared by precipitation-reduction method[J]. Appl Catal B: Environ,2016,191:8−17. doi: 10.1016/j.apcatb.2016.03.014 [26] ZHAN H J, LI F, GAO P, et al. Methanol synthesis from CO2 hydrogenation over La-M-Cu-Zn-O (M=Y, Ce, Mg, Zr) catalysts derived from perovskite-type precursors[J]. J Power Sources,2014,251:113−21. doi: 10.1016/j.jpowsour.2013.11.037 [27] ARENA F, ITALIANO G, BARBERA K, et al. Basic evidences for methanol-synthesis catalyst design[J]. Catal Today,2009,143(1):80−85. [28] AN B, ZHANG J Z, CHENG K, et al. Confinement of ultrasmall Cu/ZnOx nanoparticles in metal-organic frameworks for selective methanol synthesis from catalytic hydrogenation of CO2[J]. J Am Chem Soc,2017,139(10):3834−3840. doi: 10.1021/jacs.7b00058 [29] DHAGE P, SAMOKHVALOV A, REPALA D, et al. Regenerable Fe-Mn-ZnO/SiO2 sorbents for room temperature removal of H2S from fuel reformates: performance, active sites, operando studies[J]. Phys Chem Chem Phys,2011,13(6):2179−2187. doi: 10.1039/C0CP01355B [30] ALABSI M H, CHEN X, WANG X, et al. Highly dispersed Pd nanoparticles supported on dendritic mesoporous CeZrZnOx for efficient CO2 hydrogenation to methanol[J]. J Catal,2022,413:751−761. doi: 10.1016/j.jcat.2022.07.029 [31] XIE Y, CHEN J, WU X, et al. Frustrated Lewis pairs boosting low-temperature CO2 methanation performance over Ni/CeO2 nanocatalysts[J]. ACS Catal,2022,12(17):10587−10602. doi: 10.1021/acscatal.2c02535 [32] WANG S Q, YANG J H, WANG S W, et al. Effect of preparation method on the performance of Cu-Mn-(La)-Zr catalysts for CO2 hydrogenation to methanol[J]. ChemCatChem,2022,14(23):e202200957. doi: 10.1002/cctc.202200957 [33] LIU X, LUO J, WANG H, et al. In situ spectroscopic characterization and theoretical calculations identify partially reduced ZnO1−x/Cu interfaces for methanol synthesis from CO2[J]. Angew Chem Int Ed Eng,2022,61(23):e202202330. doi: 10.1002/anie.202202330 [34] CHEN S Y, ZHANG J F, SONG F E, et al. Induced high selectivity methanol formation during CO2 hydrogenation over a CuBr2-modified CuZnZr catalyst[J]. J Catal,2020,389:47−59. doi: 10.1016/j.jcat.2020.05.023 [35] CHEN K, YU J, LIU B, et al. Simple strategy synthesizing stable CuZnO/SiO2 methanol synthesis catalyst[J]. J Catal,2019,372:163−173. doi: 10.1016/j.jcat.2019.02.035 [36] RODRIGUEZ J A, LIU P, STACCHIOLA D J, et al. Hydrogenation of CO2 to methanol: Importance of metal-oxide and metal-carbide interfaces in the activation of CO2[J]. ACS Catal,2015,5(11):6696−6706. doi: 10.1021/acscatal.5b01755 [37] WANG W W, QU Z P, SONG L X, et al. An investigation of Zr/Ce ratio influencing the catalytic performance of CuO/Ce1−xZrx O2 catalyst for CO2 hydrogenation to CH3OH[J]. J Energy Chem,2020,47:18−28. doi: 10.1016/j.jechem.2019.11.021 [38] ZHU C Z, WEI X Q, LI W Q, et al. Crystal-plane effects of CeO2{110} and CeO2{100} on photocatalytic CO2 reduction: Synergistic interactions of oxygen defects and hydroxyl groups[J]. ACS Sustainable Chem Eng,2020,8(38):14397−14406. [39] DOSTAGIR N H M, RATTANAWAN R, GAO M, et al. Co single atoms in ZrO2 with Inherent oxygen vacancies for selective hydrogenation of CO2 to CO[J]. ACS Catal,2021,11(15):9450−9461. doi: 10.1021/acscatal.1c02041 [40] GAO P, ZHANG L N, LI S G, et al. Novel heterogeneous catalysts for CO2 hydrogenation to liquid fuels[J]. ACS Cent Sci,2020,6(10):1657−1670. doi: 10.1021/acscentsci.0c00976 [41] GAO P, LI S G, BU X N, et al. Direct conversion of CO2 into liquid fuels with high selectivity over a bifunctional catalyst[J]. Nat Chem,2017,9(10):1019−1024. doi: 10.1038/nchem.2794 [42] GAO P, LI F, ZHAN H J, et al. Influence of Zr on the performance of Cu/Zn/Al/Zr catalysts via hydrotalcite-like precursors for CO2 hydrogenation to methanol[J]. J Catal,2013,298:51−60. doi: 10.1016/j.jcat.2012.10.030 -

下载:

下载: